Method for preparing spinnable petroleum mesophase pitch

A mesophase pitch and petroleum technology, applied in the field of high-performance pitch-based carbon fiber spinning raw material preparation, can solve the problems of high risk, high cost, and high requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

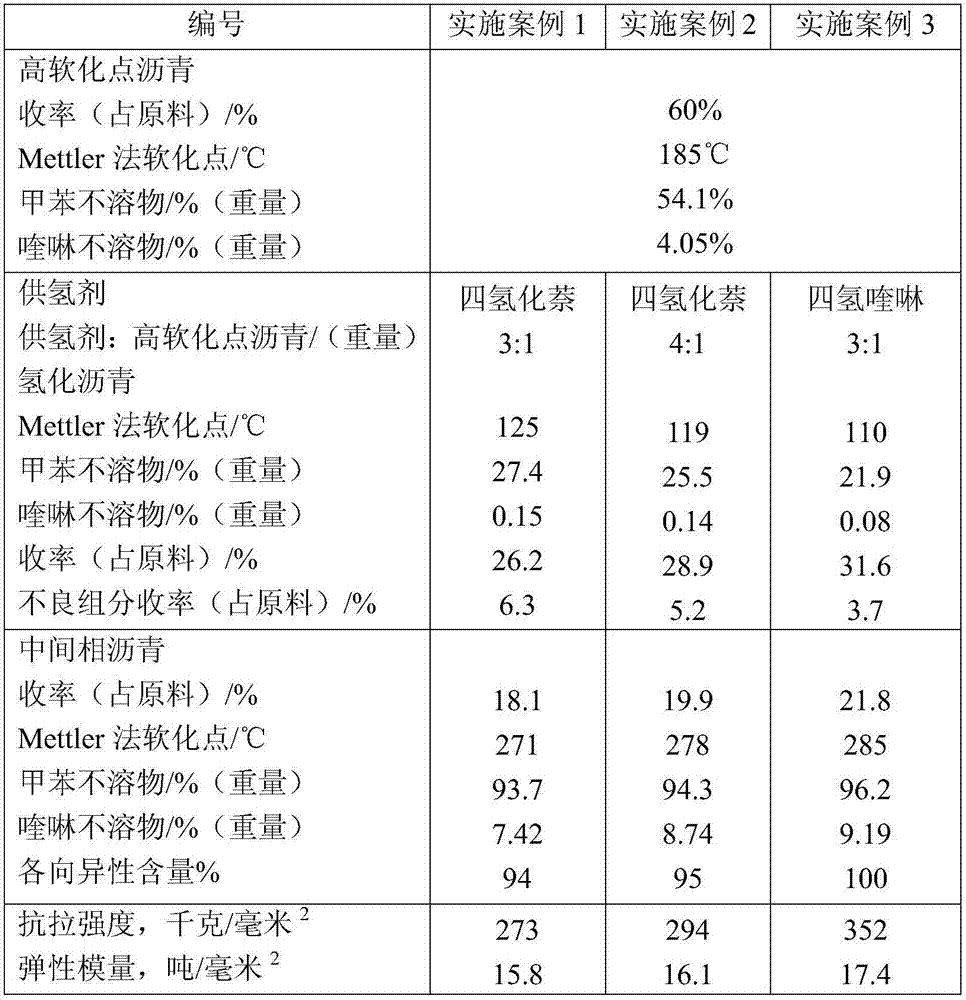

[0018] Petroleum-based medium-temperature asphalt with the properties shown in Table 1 was used as raw material, and heat-treated in an autoclave at a temperature of 410°C, a pressure of 1 MPa, and a residence time of 5 hours. After the reaction, the reaction product was distilled under reduced pressure at 330° C. and 2000 Pa (absolute pressure) to obtain pitch with a high softening point. The yield and properties of the pitch are shown in Table 2.

[0019] In an autoclave, dissolve one part by weight of high softening point asphalt and three parts by weight tetralin, and carry out hydrogenation treatment at a temperature of 430 ° C, a pressure of 5 MPa, and a time of 120 minutes, and then let it settle for 1 hour to remove After the undesired components, the hydrogenated product was flashed at 400°C under normal pressure to obtain hydrogenated pitch. The yield and properties of the hydrogenated pitch are shown in Table 2.

[0020] The hydrogenated pitch undergoes thermal poly...

Embodiment 2

[0023] The first step is the same as in Example 1.

[0024] In an autoclave, one part by weight of high softening point pitch was dissolved in four parts by weight of tetralin. The reaction conditions were the same as the second step in Example 1. The yield and properties of the hydrogenated pitch obtained are shown in Table 2.

[0025] The conditions of the third step in the implementation case 1 are the same, and the properties and yield of the obtained mesophase pitch are shown in Table 2.

[0026] The obtained mesophase spinning pitch was spun at 348°C with spinning equipment, and carbonized to make carbon fibers. The properties are shown in Table 2.

Embodiment 3

[0028] The first step is the same as in Example 1.

[0029] In an autoclave, one part by weight of high softening point pitch was dissolved in three parts by weight of tetrahydroquinoline. The reaction conditions were the same as the second step in Example 1. The yield and properties of the hydrogenated pitch obtained are shown in Table 2.

[0030] The conditions of the third step in the implementation case 1 are the same, and the properties and yield of the obtained mesophase pitch are shown in Table 2.

[0031] The obtained mesophase spinning pitch was spun at 355°C with spinning equipment, and carbonized to make carbon fibers. The properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com