A kind of continuous preparation method of oil-based raw material for mesophase pitch production

A technology for mesophase pitch and raw material, which is applied in the field of continuous preparation of oil-based raw materials, can solve the problems of complex composition of aromatic-rich distillate oil, high impurity content, difficulty in obtaining refined raw material oil, etc., and achieves low content of heteroatoms and solid impurities, The effect of single structure composition and low softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

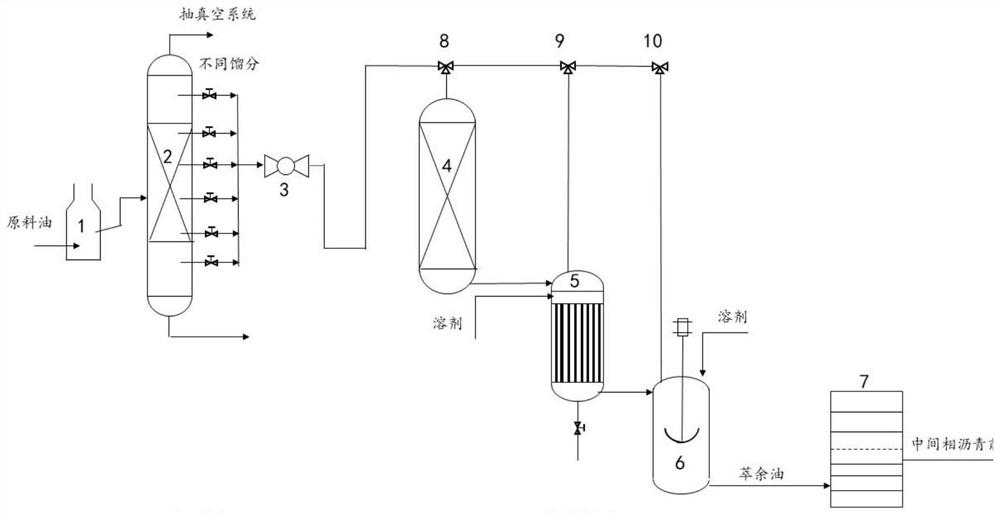

Image

Examples

Embodiment 1

[0029] Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C. Take 350g of rich-aromatic distillate oil and place it in an ultrasonic generator and adjust the power to 600W. Conditions for 60min. Then, the treated distillate oil was hot filtered at 130°C using a 20nm filter medium, followed by ion exchange at 100°C, using n-heptane, toluene, and toluene-ethanol mixed solvent (1:1) as solvents in sequence. Phase, adjust the colloid and asphaltene content of the mixed components. The filtered distillate was subjected to solvent extraction, and in a 500mL three-neck flask, furfural was used as the solvent, and the ratio of component to solvent was 1:4, and refluxed for 2h. Obtain refined raw material, get 200g refined raw material oil and place in autoclave, and add 1.5gAlCl 3 The particles are used as a catalyst, and reacted at 300°C and 0.1MPa for 30 mi...

Embodiment 2

[0032]Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C. Take 350g of rich-aromatic distillate oil and place it in an ultrasonic generator and adjust the power to 800W. Conditions for 70min. Then, the treated distillate oil was hot filtered at 130°C using a 50nm filter medium, followed by ion exchange at 110°C, using n-heptane, toluene, toluene-ethanol mixed solvent (1:1) solvent as the flow Phase, adjust the colloid and asphaltene content of the mixed components. The distillate oil after hot filtration is subjected to solvent extraction, in a 500mL three-necked flask, N-methylpyrrolidone is used as a solvent, the ratio of component to solvent is 1:4, and the refined raw material is obtained by reflux for 2.5h, and 200g of the refined raw material oil is taken Place in a high pressure reactor and add 2g of AlCl 3 The particles are used as a catalys...

Embodiment 3

[0035] Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C. Take 350g of rich-aromatic distillate oil and place it in an ultrasonic generator and adjust the power to 700W. Conditions for 90min. Then, the treated distillate oil was hot filtered at 140°C using a 30nm filter medium, followed by ion exchange at 130°C, using n-heptane, toluene, toluene-ethanol mixed solvent (1:1) solvent as the flow Phase, adjust the colloid and asphaltene content of the mixed components. The hot filtered distillate oil is subjected to solvent extraction, and in a 500mL three-necked flask, a mixture of N-methylpyrrolidone and N,N-dimethylformamide (mixing ratio 2:1) is used as the solvent, and the ratio of component to solvent = 1:4, reflux for 3 hours to obtain refined raw materials, take 200g of refined raw material oil and place it in a high-pressure reactor, and add 3g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com