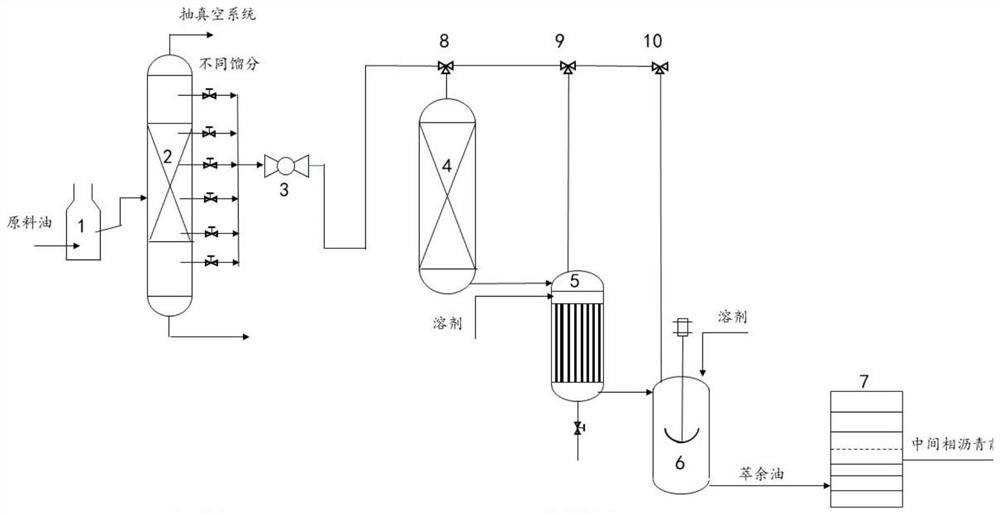

Continuous preparation method of oil-based raw material for mesophase pitch production

A mesophase asphalt and raw material technology, applied in the processing of tar pitch/petroleum pitch/natural pitch by chemical method, processing of tar pitch/petroleum pitch/natural pitch by selective extraction, processing of tar pitch/petroleum pitch/natural pitch, etc. , can solve problems such as difficulty in obtaining refined feedstock oil, complex composition of aromatic-rich distillate oil, and high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C. Take 350g of rich-aromatic distillate oil and place it in an ultrasonic generator and adjust the power to 600W. Conditions for 60min. Then, the treated distillate oil was hot filtered at 130°C using a 20nm filter medium, followed by ion exchange at 100°C, using n-heptane, toluene, and toluene-ethanol mixed solvent (1:1) as solvents in sequence. Phase, adjust the colloid and asphaltene content of the mixed components. The filtered distillate was subjected to solvent extraction, and in a 500mL three-neck flask, furfural was used as the solvent, and the ratio of component to solvent was 1:4, and refluxed for 2h. Obtain refined raw material, get 200g refined raw material oil and place in autoclave, and add 1.5gAlCl 3 The particles are used as a catalyst, and reacted at 300°C and 0.1MPa for 30 mi...

Embodiment 2

[0032]Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C. Take 350g of rich-aromatic distillate oil and place it in an ultrasonic generator and adjust the power to 800W. Conditions for 70min. Then, the treated distillate oil was hot filtered at 130°C using a 50nm filter medium, followed by ion exchange at 110°C, using n-heptane, toluene, toluene-ethanol mixed solvent (1:1) solvent as the flow Phase, adjust the colloid and asphaltene content of the mixed components. The distillate oil after hot filtration is subjected to solvent extraction, in a 500mL three-necked flask, N-methylpyrrolidone is used as a solvent, the ratio of component to solvent is 1:4, and the refined raw material is obtained by reflux for 2.5h, and 200g of the refined raw material oil is taken Place in a high pressure reactor and add 2g of AlCl 3 The particles are used as a catalys...

Embodiment 3

[0035] Under the condition of absolute pressure of 5KPa, 3000g of catalytic oil slurry was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C. Take 350g of rich-aromatic distillate oil and place it in an ultrasonic generator and adjust the power to 700W. Conditions for 90min. Then, the treated distillate oil was hot filtered at 140°C using a 30nm filter medium, followed by ion exchange at 130°C, using n-heptane, toluene, toluene-ethanol mixed solvent (1:1) solvent as the flow Phase, adjust the colloid and asphaltene content of the mixed components. The hot filtered distillate oil is subjected to solvent extraction, and in a 500mL three-necked flask, a mixture of N-methylpyrrolidone and N,N-dimethylformamide (mixing ratio 2:1) is used as the solvent, and the ratio of component to solvent = 1:4, reflux for 3 hours to obtain refined raw materials, take 200g of refined raw material oil and place it in a high-pressure reactor, and add 3g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com