Low-dielectric LTCC green tape as well as preparation method and use thereof

A green ceramic tape and low dielectric technology, which is applied in the field of low dielectric LTCC green ceramic tape and its preparation, can solve the problem of non-crystallization of glass, and achieve the effects of reducing glass content, reducing dielectric loss and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention also discloses a method for preparing a low dielectric LTCC green ceramic belt, which includes the following steps:

[0046] Preparation of ceramic materials: according to the chemical composition of ceramic materials Zn 2-x SiO 4-x Weigh ZnO and SiO 2 As the initial powder, Zn 2-x SiO 4-x Ceramic material;

[0047] Preparation of glass material: weigh CaCO according to the ratio 3 , SiO 2 、H 3 BO 3 、Al 2 o 3 ,P 2 o 5 、Na 2 CO 3 , Li 2 CO 3 After mixing, melt and quench to obtain broken glass, then ball mill and dry to obtain glass material;

[0048] Preparation of green porcelain tape slurry: mix the Zn 2-x SiO 4-x The ceramic material and the glass material, sintering aids, solvents, plasticizers, dispersants, and binders are mixed by ball milling and defoamed to make cast slurry;

[0049] Casting of raw porcelain tape: cast the casting slurry to make a low dielectric LTCC green tape.

[0050] Preferably, in the preparation process of...

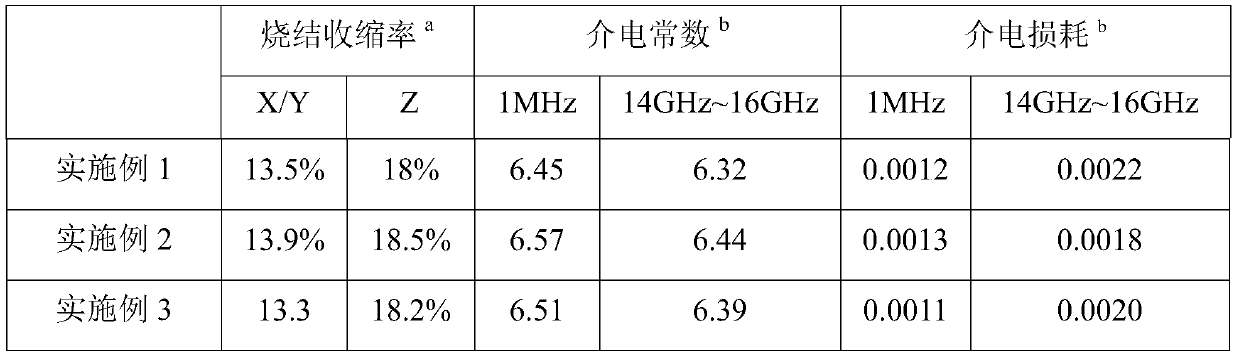

Embodiment 1

[0056] a. Preparation of ceramic materials: Weigh 71.4wt% ZnO and 28.6wt% SiO according to the mass ratio 2 As the initial powder, the initial powder was milled with alcohol as the ball milling medium, dried with agate balls for 6 hours, and calcined at 1150°C for 4 hours. The calcined powder was refined by ball milling to obtain Zn 1.91 SiO 3.91 Ceramic material.

[0057] b. Preparation of glass material: weigh 43.6wt% CaCO 3 , 15.2wt%H 3 BO 3 , 34.3% SiO 2 , 2.2wt% Al 2 o 3 , 2.7wt%P 2 o 5 , 0.8 wt% Na 2 CO 3 , 1.2wt% Li 2 CO 3 Mix well, put it in a platinum crucible for melting at 1400°C, pour the molten glass directly into deionized water and quench it to obtain fluffy cullet with a milky white appearance, ball mill the cullet to a particle size of D50:1 ~1.5μm, dried to make glass-ceramics.

[0058] c, the preparation of raw porcelain tape: weigh 42wt% glass-ceramics, 58wt% Zn 1.91 SiO 3.91 Ceramic material, 1.5wt% CuO, 1.5wt% V 2 o 5 In the roller mill...

Embodiment 2

[0063] a. Preparation of ceramic materials: weigh 69.7wt% ZnO, 30.3wt% SiO 2 As the initial powder, the initial powder was milled with alcohol as the ball milling medium, dried with agate balls for 6 hours, and calcined at 1150°C for 4 hours. The calcined powder was refined by ball milling to obtain Zn 1.79 SiO 3.79 Ceramic material.

[0064] b. Preparation of glass material: weigh 43.1wt% CaCO 3 , 18.2wt%H 3 BO 3 , 31.8% SiO 2 , 2.2wt%Al 2 o 3 , 2.7wt%P 2 o 5 , 0.8 wt% Na 2 CO 3 , 1.2wt% Li 2 CO 3 Mix evenly, melt in a platinum crucible at 1400°C, pour the molten glass directly into deionized water and quench to obtain milky white fluffy cullet, and ball mill the cullet until the particle size is D50: 1~ 1.5μm, dried to obtain glass-ceramics.

[0065] c, the preparation of raw porcelain tape: weigh 45wt% glass-ceramics, 52wt% Zn 1.79 SiO 3.79 Ceramic material, 1.2wt% CuO, 1.8wt% V 2 o 5In the roller mill for 12 hours, the powder is mixed evenly to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com