Leadless, cadmium-free and strontium-free glass and manufacture process thereof

A technology of colored glaze and annealing temperature, applied in the field of colored glaze composition and preparation technology, can solve the problems of difficult supply of raw materials, high price, etc., and achieve the effects of cost reduction, pollution prevention and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation process of lead-free, cadmium-free and strontium-free transparent glass

[0048](1) Ingredients: According to the chemical composition of raw materials, calculate the amount of raw materials required for each oxide according to the chemical composition of glass, then use the weight of quartz sand as 100kg to obtain the weight of other raw materials, weigh various raw materials and mix them evenly; Weigh and mix the above-mentioned various raw materials, among which the amount of decolorizer and colorant is relatively small, and must be accurately weighed with a 1 / 1000 precision balance, mixed with quartz sand to form a 1 / 100 and 1 / 500 mixture, and then mixed with other raw materials , to ensure that the decolorizer and colorant can be mixed evenly with other raw materials without stratification and uneven mixing;

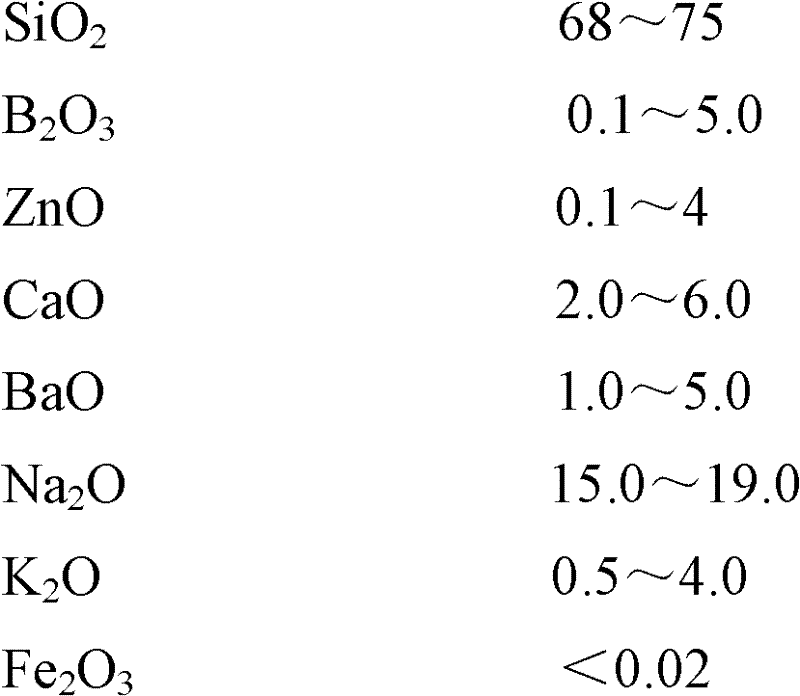

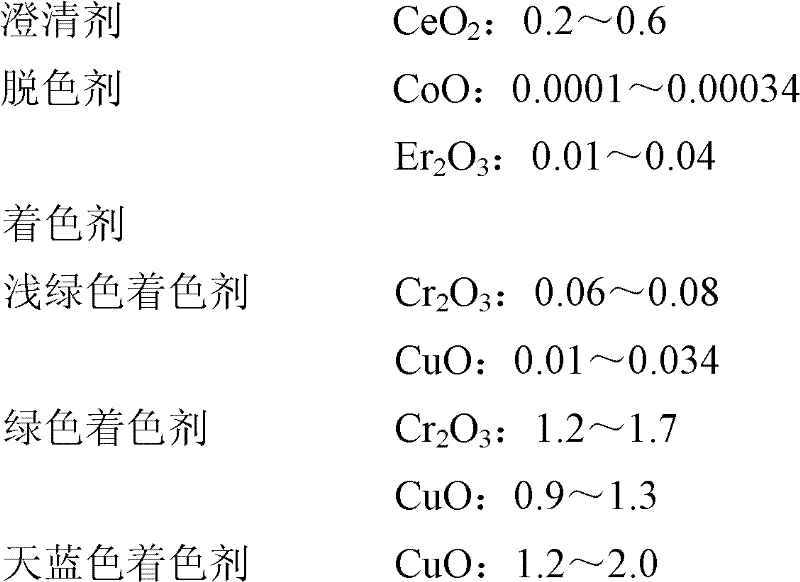

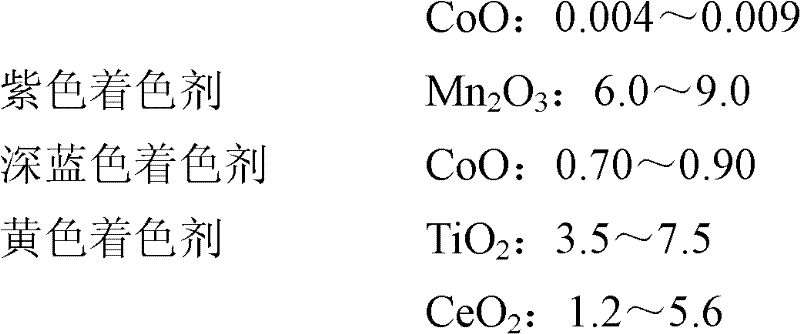

[0049] The parts by weight of the glass chemical composition are shown in Table 1, and the raw material formula is shown in Table 2:

[0050...

Embodiment 2

[0067] (1) Manufacturing process of lead-free, cadmium-free and strontium-free transparent colored glass

[0068] (1) Ingredients: According to the chemical composition of raw materials, calculate the amount of raw materials required for each oxide according to the chemical composition of glass, then use the weight of quartz sand as 100kg to obtain the weight of other raw materials, weigh various raw materials and mix them evenly;

[0069] The parts by weight of glass blue transparent glass chemical composition are shown in Table 3, and the raw material formula is shown in Table 4:

[0070] Table 3. Parts by weight of the chemical composition of blue transparent glass

[0071]

[0072] Note: in the above table, C is the chemical composition, and W' is the weight part.

[0073] Table 4. Raw material formula of blue transparent glass

[0074]

[0075]

[0076] Note: In the above table, M is raw material, W is weight (unit: kg).

[0077] (2) Melting: melting the raw m...

Embodiment 3

[0087] Manufacturing process of lead-free, cadmium-free and strontium-free colored glass flowers

[0088] (1) Ingredients: According to the chemical composition of raw materials, calculate the amount of raw materials required for each oxide according to the chemical composition of glass, then use the weight of quartz sand as 100kg to obtain the weight of other raw materials, weigh various raw materials and mix them evenly;

[0089] The parts by weight of the colored and transparent colored glaze chemical components are shown in Table 5, and the raw material formula is shown in Table 6:

[0090] Table 5. Parts by weight of the chemical composition of colored transparent glaze

[0091]

[0092] Note: in the above table, C is the chemical composition, and W' is the weight part.

[0093] Table 6. Colored transparent glass raw material formula

[0094]

[0095] Note: In the above table, M is raw material, W is weight (unit: kg).

[0096] (2) Melting: melting the raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com