Plastic concrete small component automatic production line

An automated production line and plastic concrete technology, applied in chemical instruments and methods, object stacking, supply devices, etc., can solve problems such as low production efficiency, lack of good solutions, and inability to meet short-term and large-scale purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

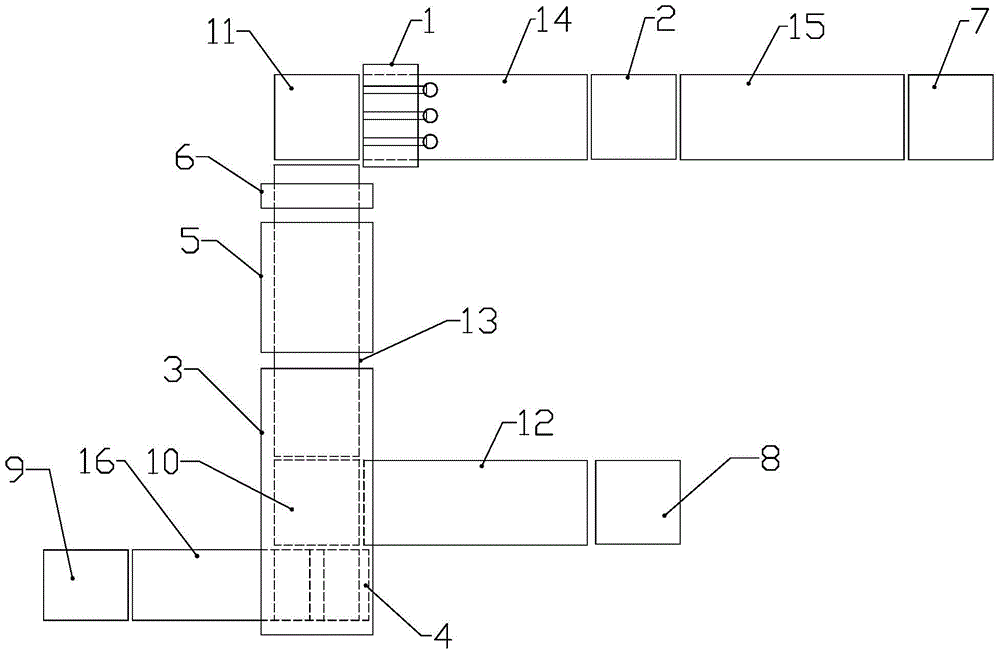

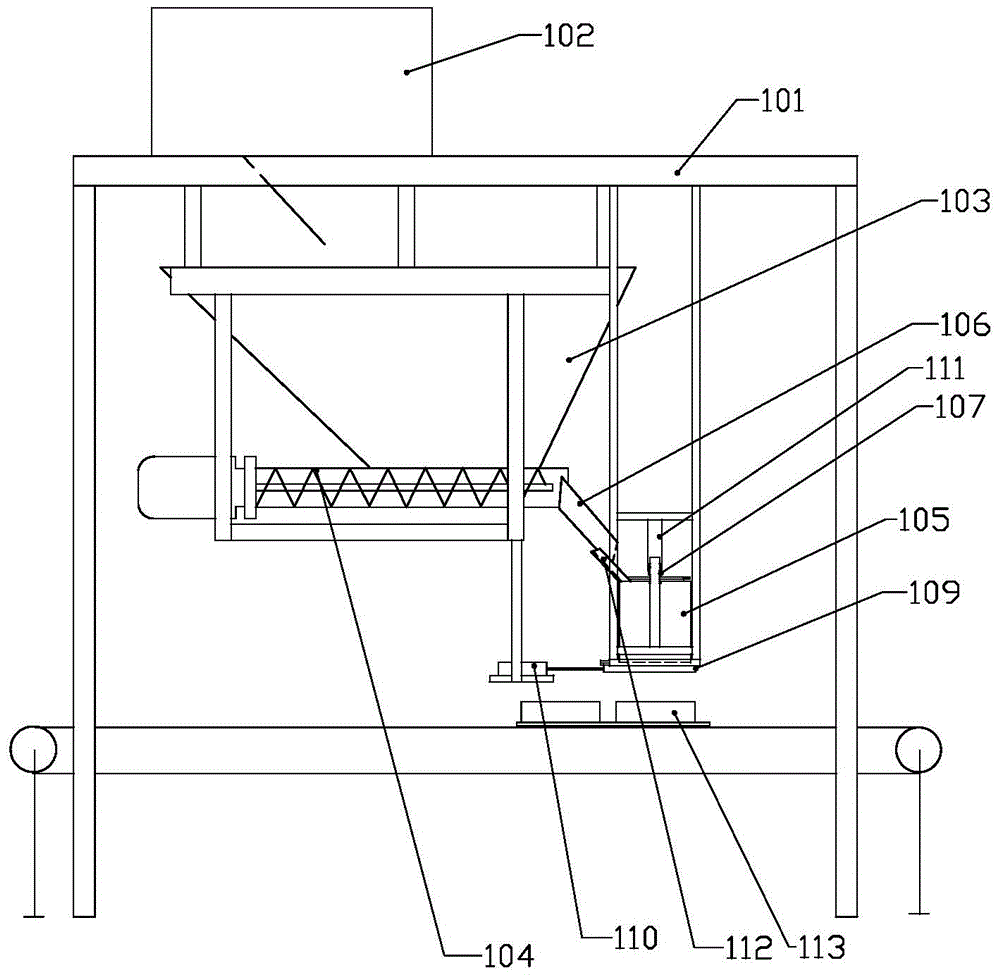

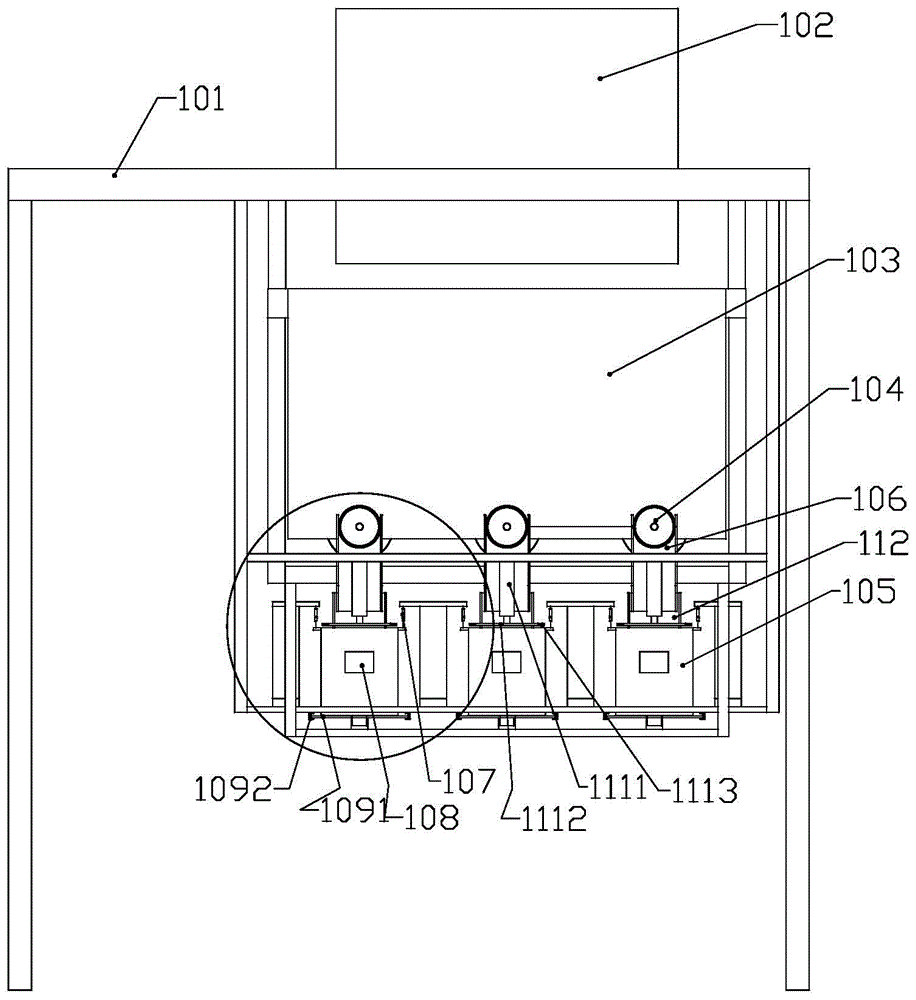

[0082] Refer to the attached figure 1 to attach Figure 25 The automatic production line for small plastic concrete components of the present invention will be described in detail below.

[0083] Such as figure 1 Shown: the automatic production line of small plastic concrete components of the present invention, its structure includes a metering pouring machine 1, a vibrating table 2, a mechanical gripper handling machine 3, a turning demoulding machine 4, a mold cleaning machine 5, a color pouring machine 6, and a stacking machine Machine, turning platform and conveyer; Described stacker comprises the first stacker 7, the second stacker 8 and the 3rd stacker 9, and described turning platform comprises the first turning platform 10 and the second The turning platform 11, the conveyor includes the first conveyor 12, the second conveyor 13, the third conveyor 14, the fourth conveyor 15 and the fifth conveyor 16; the first turning platform 10 and the second turning platform 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com