Hot press molding system and method of shell dental instrument scale production

A technology of hot-press forming and dental model, which is applied in the field of hot-press forming system, can solve the problems of heavy manual operation workload, high labor intensity, high price, etc. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below by embodiment the present invention will be further described, and its purpose is only to understand research content of the present invention better but not limit protection scope of the present invention.

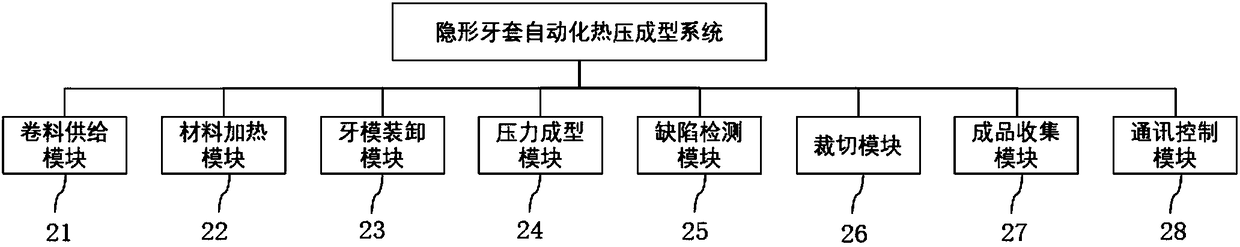

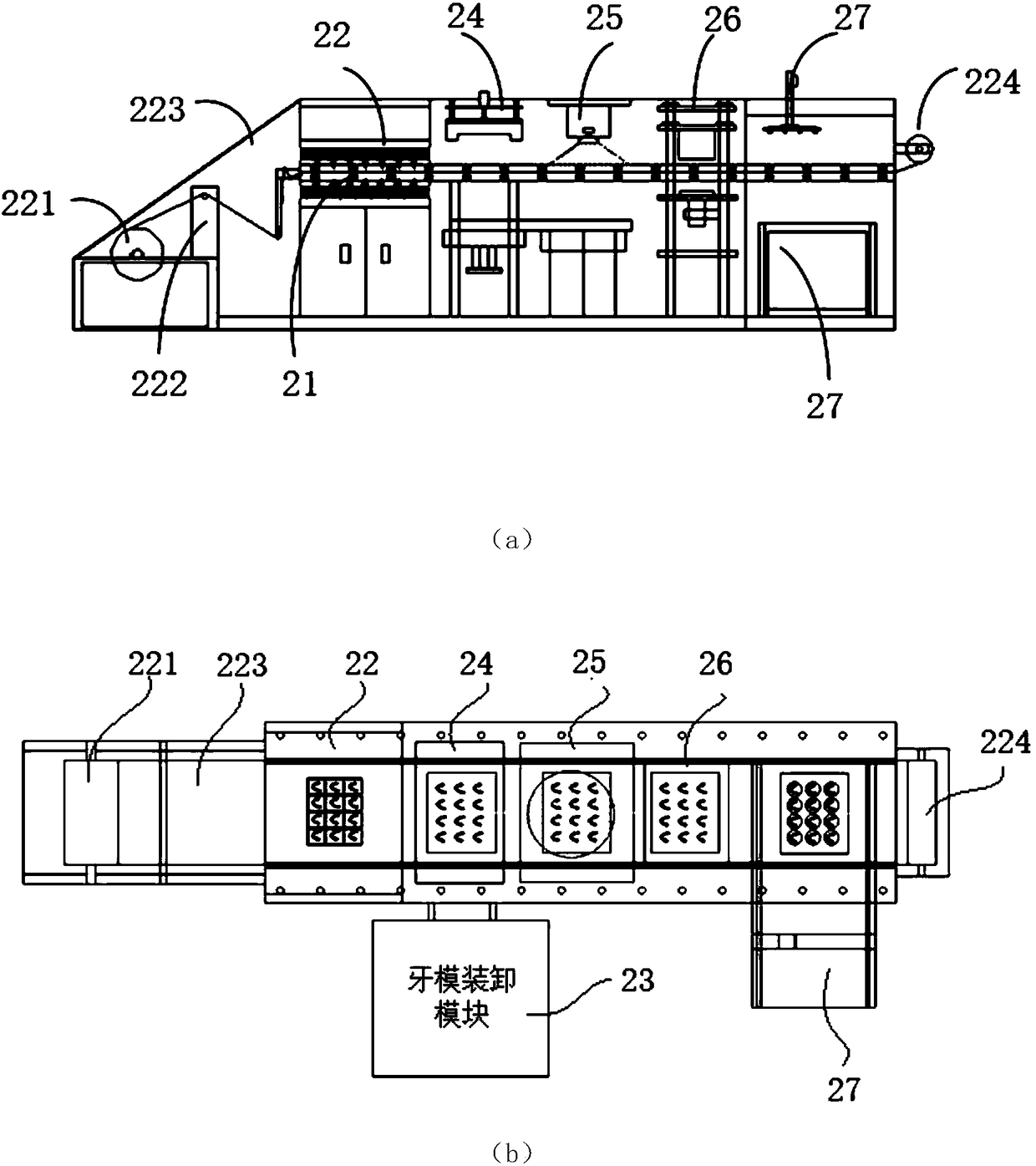

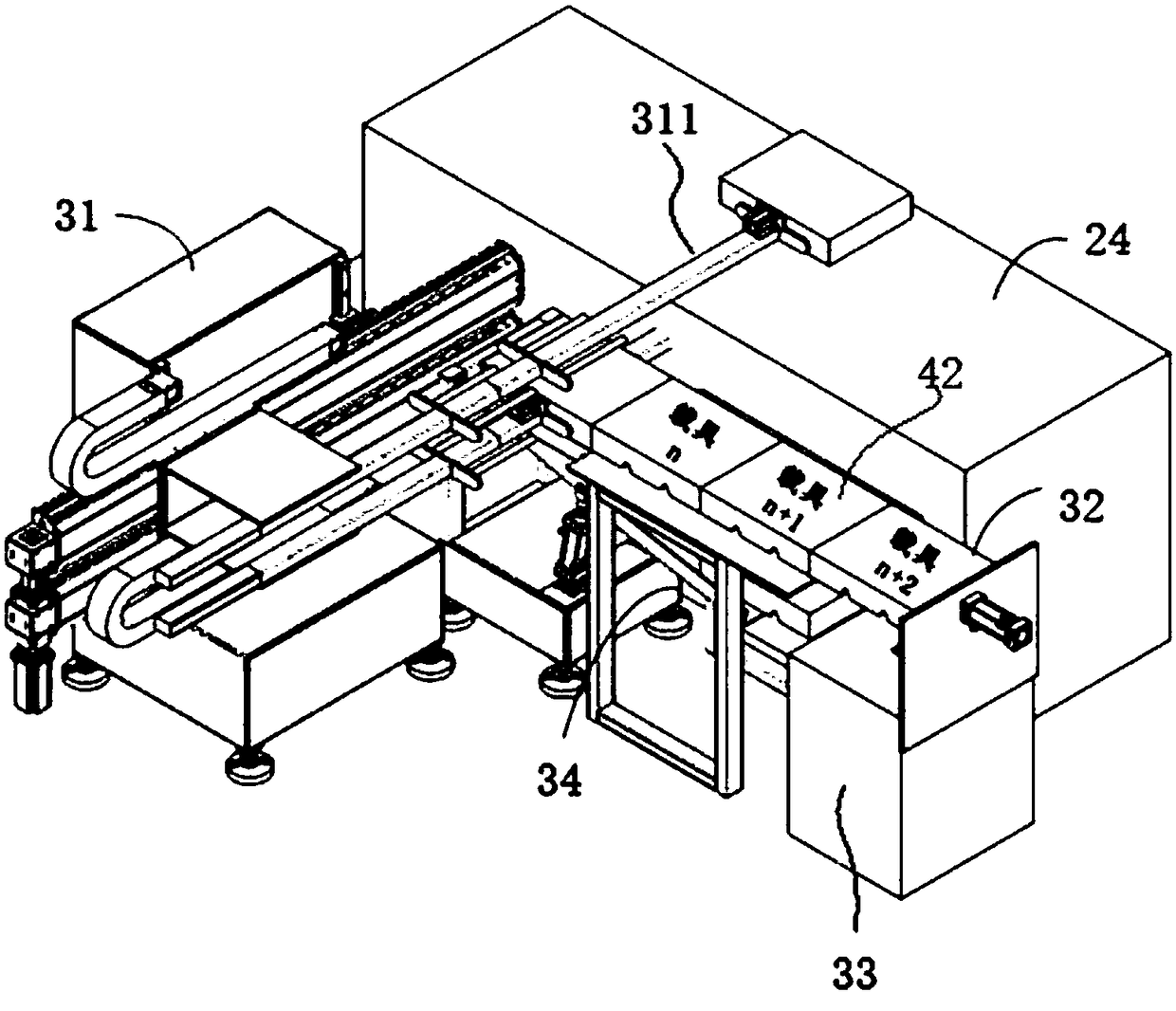

[0034] The thermocompression molding system for the mass production of shell-shaped dental instruments of the present invention will be described below with reference to the accompanying drawings. The shell-shaped dental instruments referred to in the present invention include but are not limited to invisible aligners, invisible retainers, cosmetic braces, sports protective braces, and other functional braces made of thermoplastic polymer materials. In the specific embodiment, invisible braces are taken as an example. The invention is suitable for the automatic continuous hot-pressing forming process of the invisible braces whose raw materials are in the form of coils, and can produce the invisible braces in multi-mode batches on a large scale. The forming p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com