3D printed dental cast processing technology

A 3D printing and processing technology, which is applied in the fields of dentistry, dental prosthesis, medical science, etc., can solve the problems of long printing time of solid models, many photosensitive resin raw materials, and affecting processing efficiency, etc., so as to save photosensitive resin raw materials, The effect of saving transportation costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

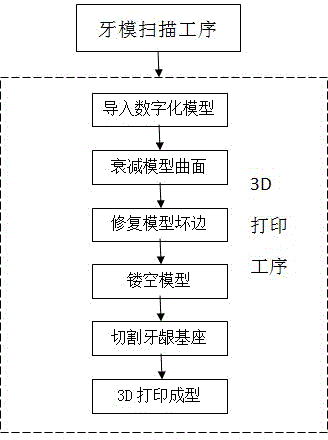

[0020] Below in conjunction with specific embodiment the present invention is described in further detail, please refer to figure 1 .

[0021] In the field of orthodontic correction of dento-jaw deformity, the dento-jaw model used in the pressure film forming process of the invisible aligner can adopt the processing technology of the present invention.

[0022] Including dental model scanning process and 3D printing process.

[0023] Dental model scanning process. The pretreated dental model is scanned by scanning equipment, and the scanning method can be semi-automatic scanning or manual scanning.

[0024] 3D printing process. Obtain the three-dimensional digital model of the scanned dental model on the computer client, and then use the following steps to perform pre-printing processing and printing.

[0025] 1) Import digital model: "import" the 3D data of the dental model to be designed into Magics reverse engineering software, and store it in STL file format;

[0026]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com