Manufacture method of individual orthodontic appliance for tongue

A manufacturing method and appliance technology, applied in brackets and other directions, can solve the problems of the appliance base plate being far away from the tooth surface, inaccurate control of orthodontic force, difficult clinical operation, etc. Short, good anchorage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

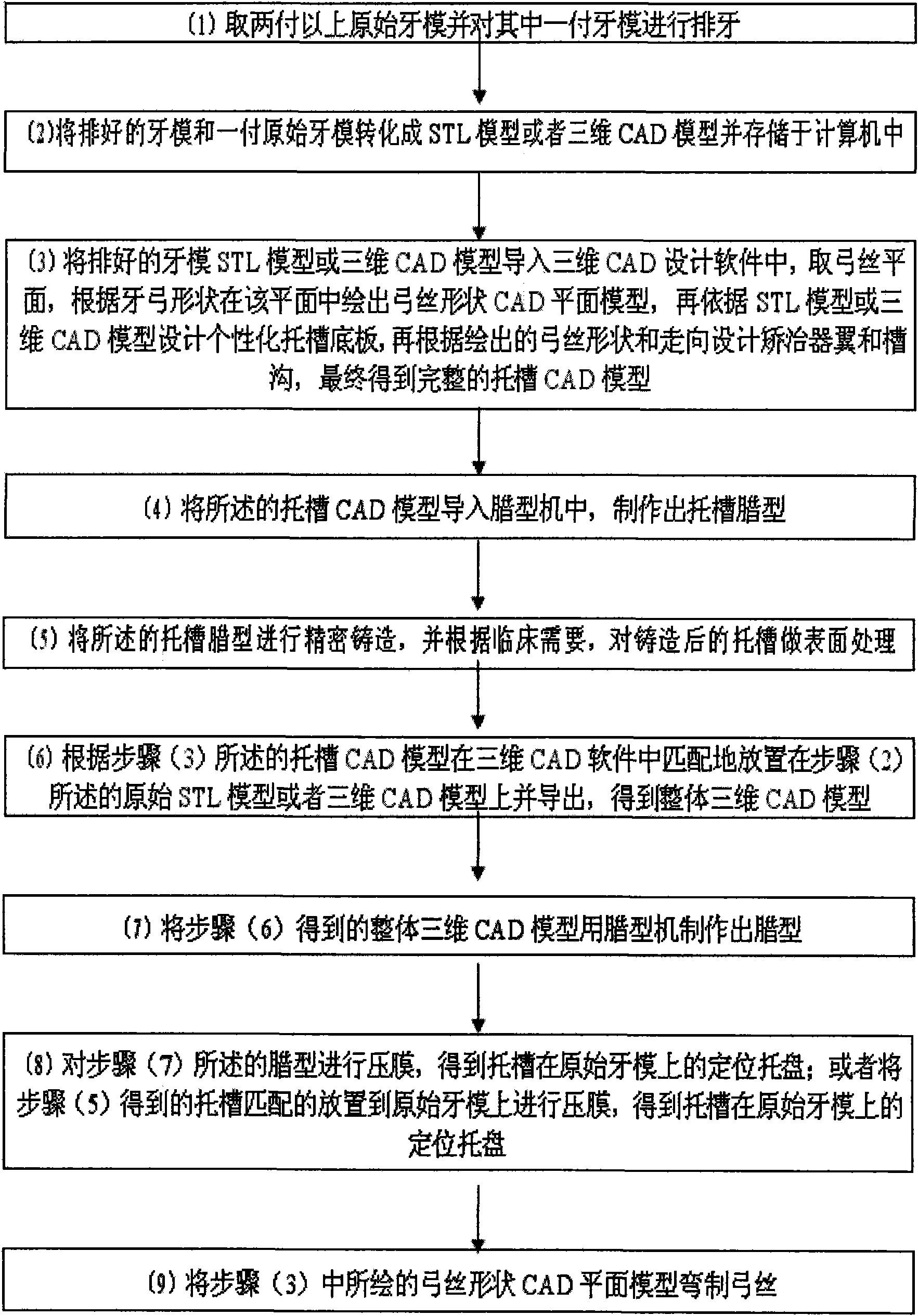

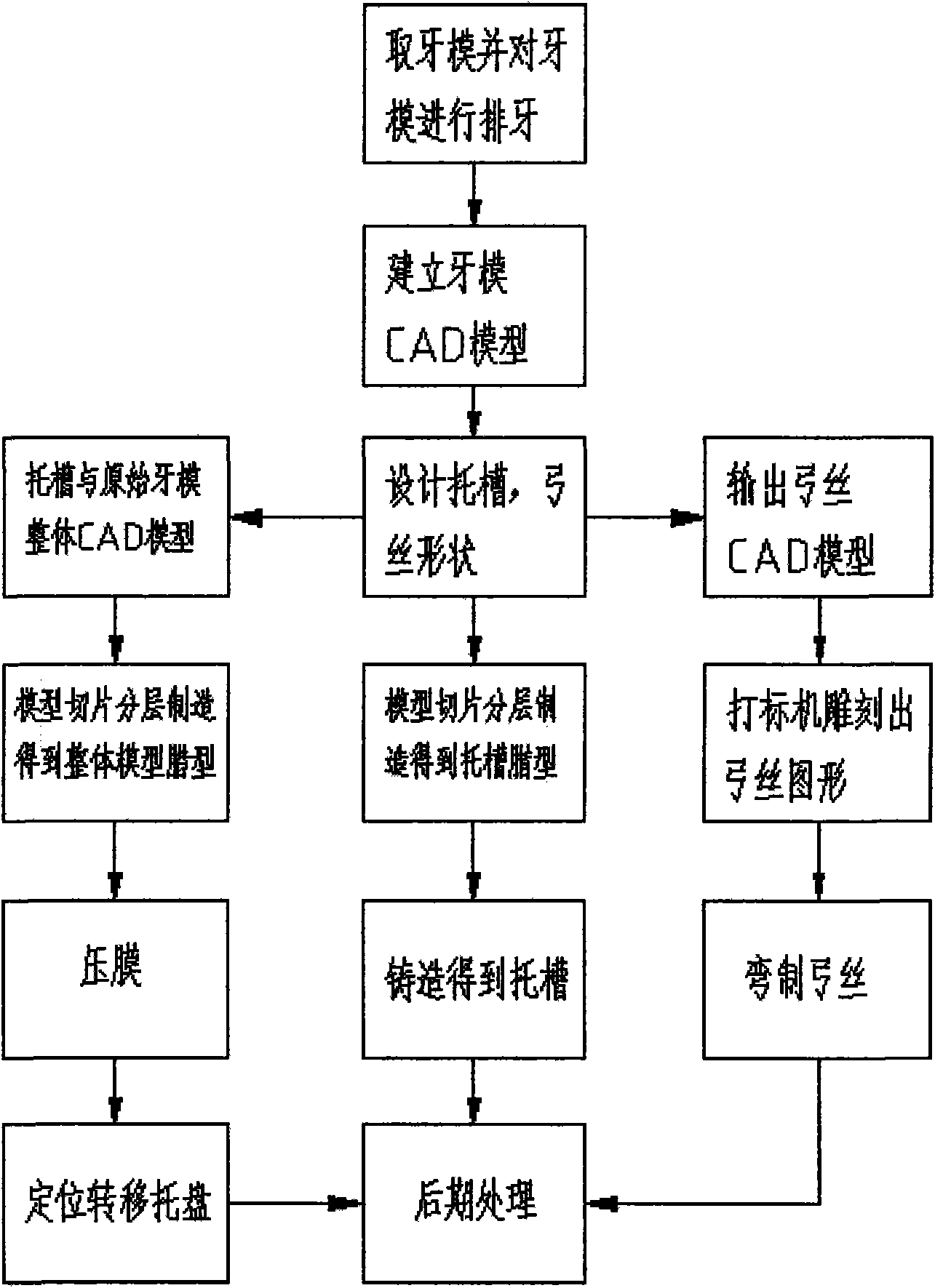

[0035] refer to figure 1 , the manufacturing method of personalized lingual orthodontic appliance, it is characterized in that comprising the following steps:

[0036] (1) Take more than two sets of original dental models and arrange the teeth on one of the sets of dental models;

[0037] (2) convert the arranged dental model and a pair of original dental models into an STL model or a three-dimensional CAD model and store them in the computer;

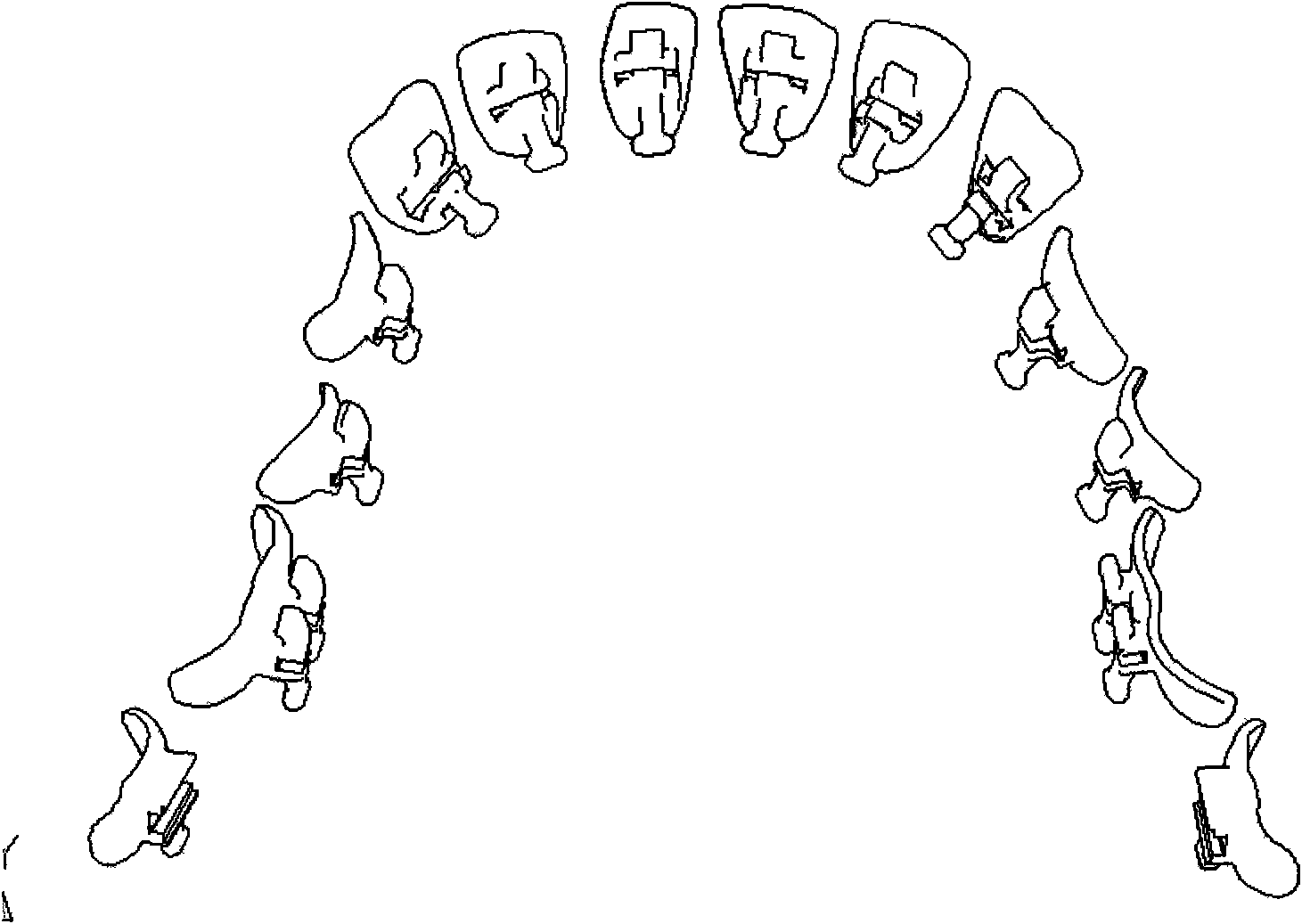

[0038] (3) Import the STL model or 3D CAD model of the arranged dental model into the 3D CAD design software, take the plane of the arch wire, draw the CAD plane model of the arch wire shape on the plane according to the shape of the dental arch, and then draw the CAD plane model of the arch wire according to the STL model or 3D CAD model to design a personalized bracket base plate, and then design the appliance wings and grooves according to the drawn arch wire shape and direction, and finally obtain a complete bracket CAD model;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com