False tooth veneering manufacturing method and system, computer equipment and readable storage medium

A manufacturing method and technology of dentures, applied in the field of dental restoration, can solve the problems of low precision, low efficiency of denture veneers, long design time, etc., and achieve the effect of improving efficiency and precision, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

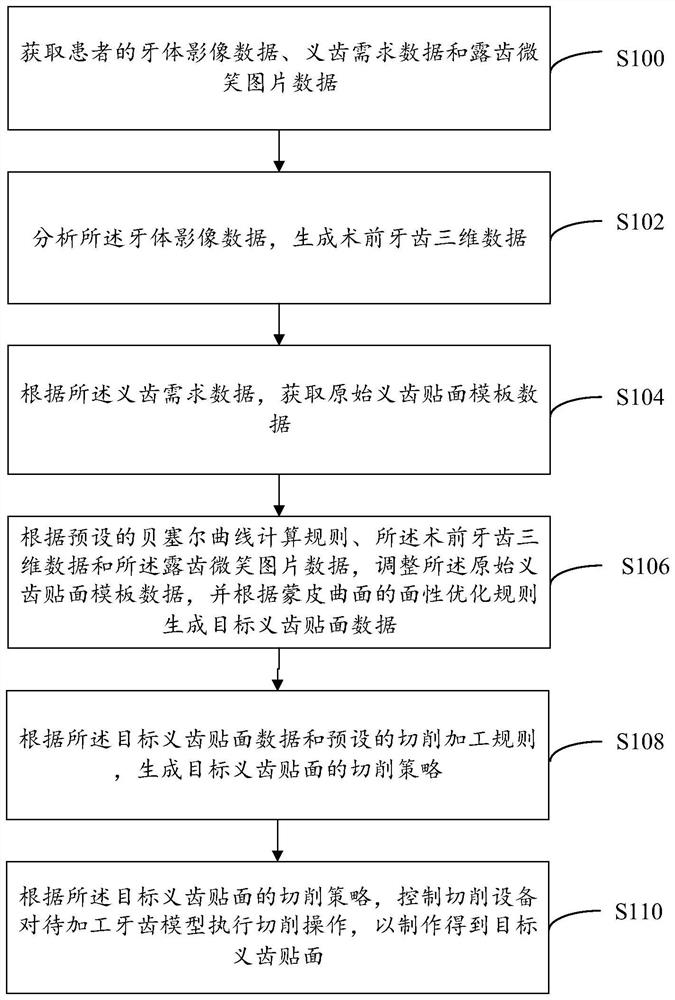

[0061] see figure 1 , shows a flow chart of the steps of the method for making a denture veneer according to an embodiment of the present invention. It can be understood that the flowchart in this method embodiment is not used to limit the sequence of execution steps. The following is an exemplary description taking computer equipment as the execution subject, as follows:

[0062] Such as figure 1 As shown, the method for making a denture veneer may include step S100 to step S110, wherein:

[0063] In step S100, the patient's dental image data, denture demand data and toothy smile picture data are acquired.

[0064] In this embodiment, a CBCT device is used to acquire CBCT data information of the patient's oral cavity, that is, the predicate image data. Among them, the CBCT (Cone beam CT) device is a cone beam CT device, which is a cone beam projection computerized reconstruction tomography device.

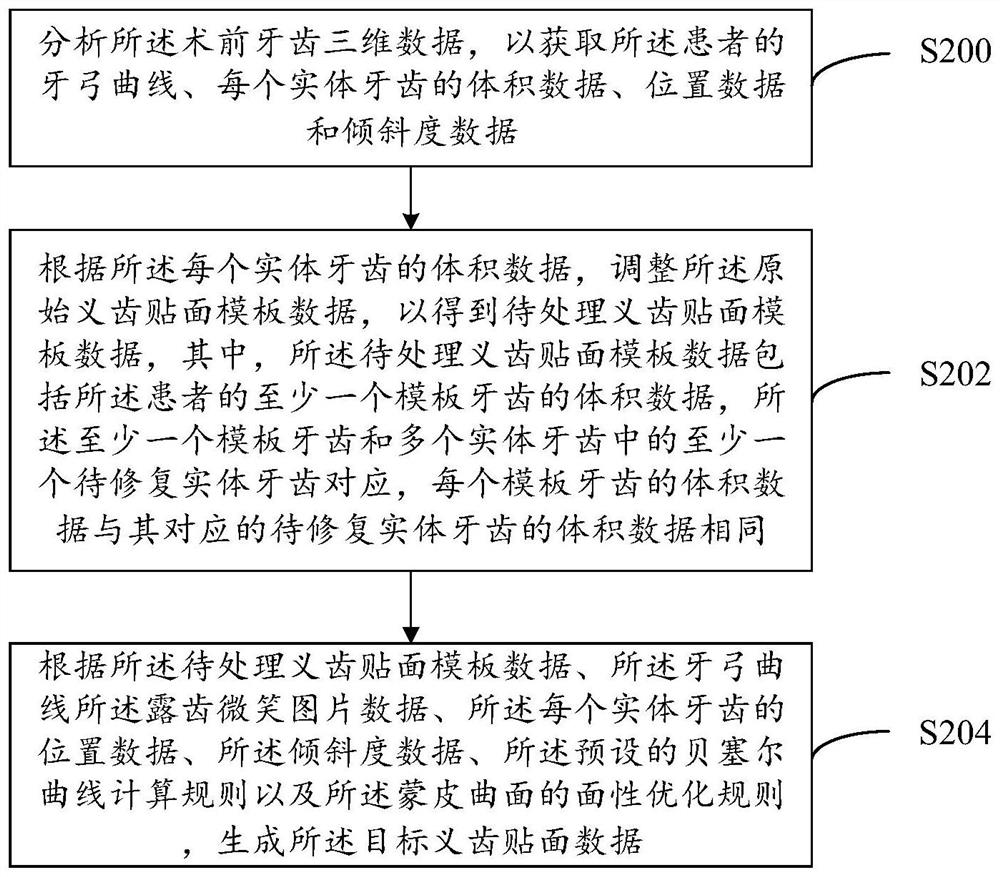

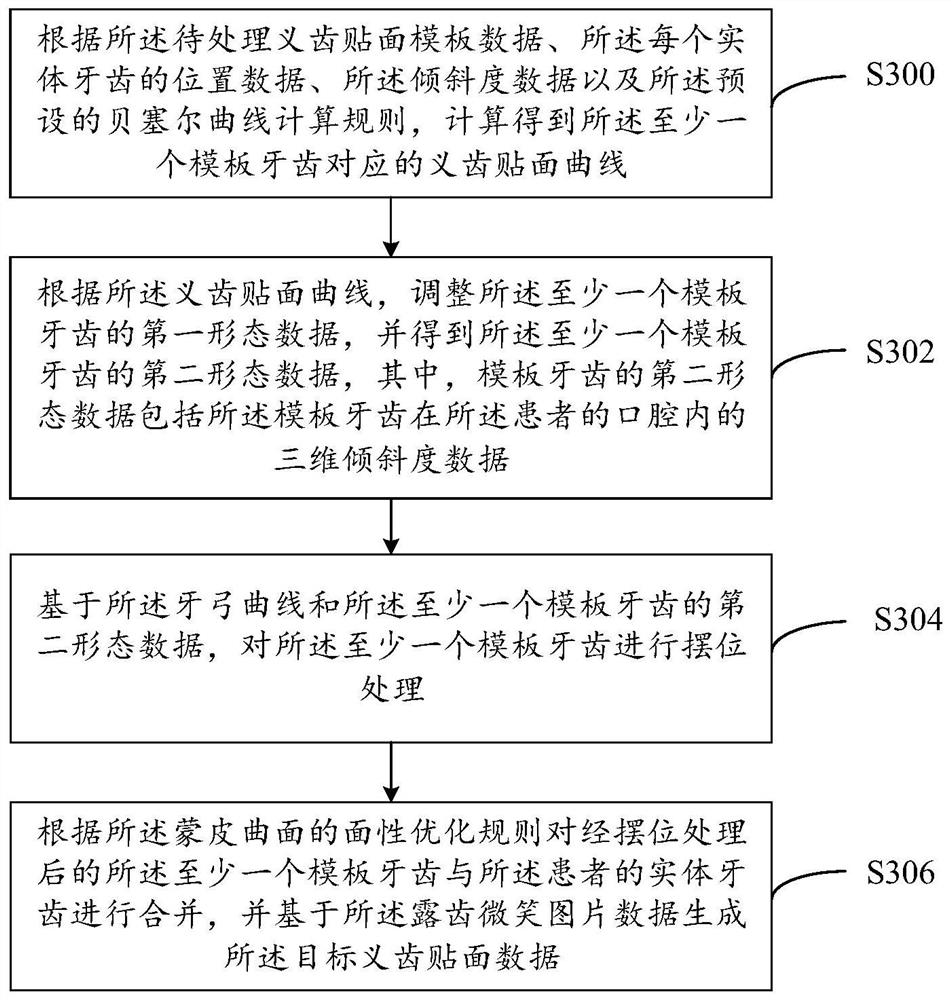

[0065] Step S102, analyzing the tooth image data to generate pre-operati...

Embodiment 2

[0104] read on Figure 7 , shows a schematic diagram of the program modules of the denture veneer production system 70 according to the embodiment of the present invention. In this embodiment, the denture veneer manufacturing system 70 may include or be divided into one or more program modules, and one or more program modules are stored in an embedded memory chip and executed by one or more processors , to complete the present invention, and can realize the above-mentioned denture veneer manufacturing method. The program module referred to in the embodiment of the present invention refers to a series of computer program instruction segments capable of completing specific functions, which is more suitable for describing the execution process of the denture veneer manufacturing system 70 in the storage medium than the program itself. The following description will specifically introduce the functions of each program module of the present embodiment:

[0105] The system include...

Embodiment 3

[0119] Figure 8 A schematic diagram of a hardware architecture of a computer device 10000 suitable for implementing a denture veneer manufacturing method according to Embodiment 3 of the present invention is schematically shown. In this embodiment, the computer device 10000 is a device capable of automatically performing score calculation and / or information processing according to preset or stored instructions. For example, it can be a smartphone, a tablet computer, a laptop computer, a desktop computer, a rack server, a blade server, a tower server or a rack server (including a stand-alone server, or a server cluster composed of multiple servers), a gateway Wait. Such as Figure 8 As shown, the computer device 10000 at least includes but is not limited to: a memory 10010 , a processor 10020 , and a network interface 10030 that can communicate with each other through a system bus. in:

[0120] The memory 10010 includes at least one type of computer-readable storage medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com