Circuit board special-shaped device plug-in device and path memory control method thereof

A plug-in device and circuit board technology, which is applied in the fields of printed circuit manufacturing, electrical components, electrical components, etc., can solve the problems of low work efficiency, inability to automate, and lack of versatility, so as to improve plug-in efficiency and improve operation reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

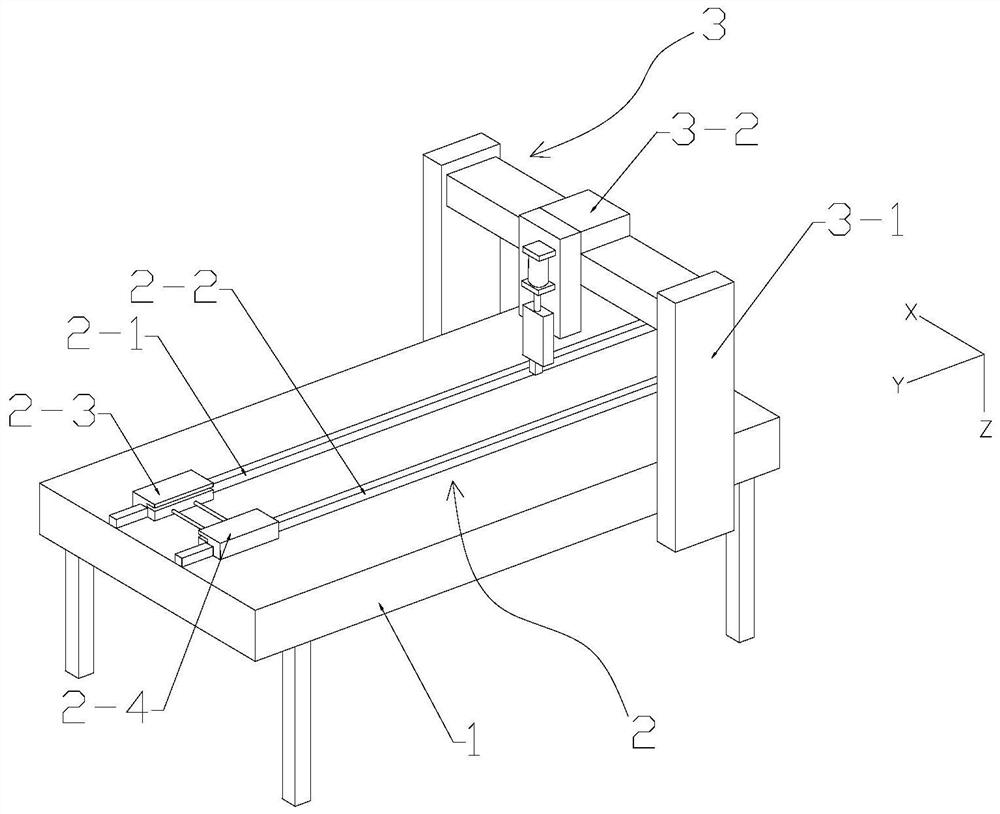

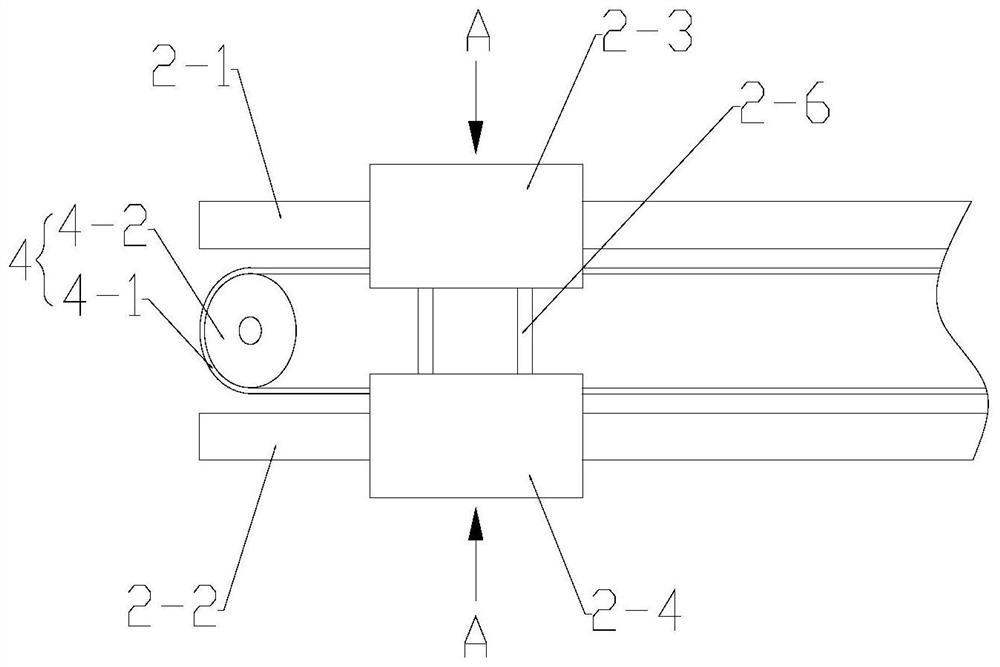

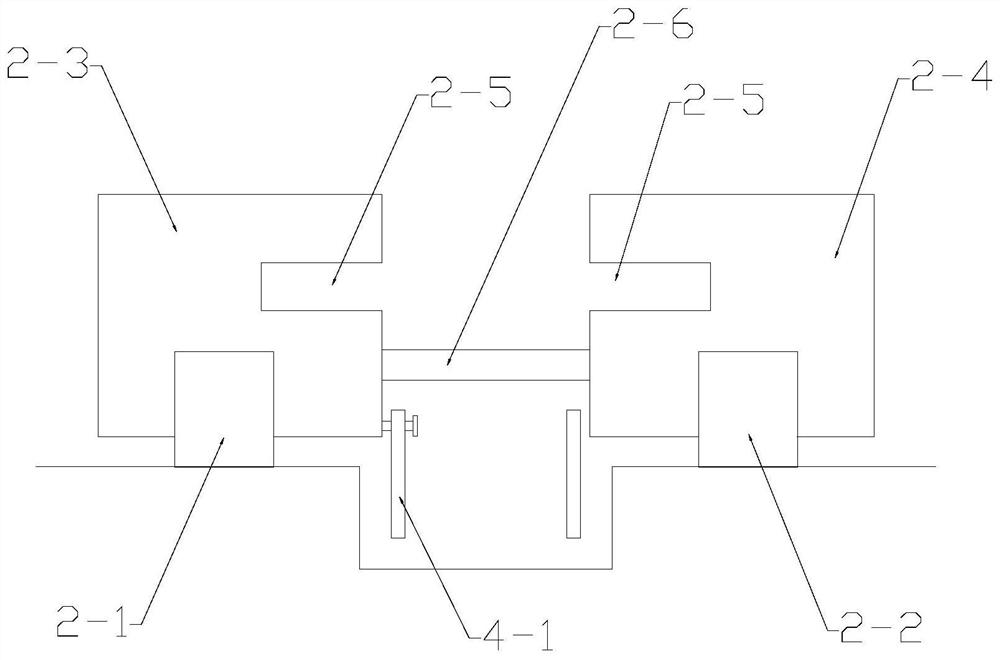

[0027] Such as figure 1 As shown, the present invention is a circuit board special-shaped device plug-in device, including a frame 1, a circuit board conveying mechanism 2 and a terminal insertion mechanism 3 arranged on the frame 1, characterized in that the circuit board conveying The mechanism 2 includes a first guide rail 2-1, a second guide rail 2-2 arranged in parallel along the Y-axis direction, a first slider 2-3 movably connected to the first guide rail 2-1, and a first slider 2-3 movably connected to the first guide rail 2-1. The second slider 2-4 on the second guide rail 2-2, wherein the first slider 2-3 and the second slider 2-4 are driven by the power device 4 along the first guide rail 2 -1 slides with the second guide rail 2-2, and the inner middle part of the first slider 2-3 and the second slider 2-4 is provided with an accommodating cavity 2-5 for accommodating a circuit board;

[0028] The terminal insertion mechanism 3 includes a gantry 3-1 and an insertio...

Embodiment 2

[0039] The structure of a plug-in device for special-shaped circuit boards provided in this embodiment is basically the same as in Embodiment 1, the difference is that: Figure 6 As shown, the number of its terminal insertion mechanism is 3, which can respectively carry out different path memory for the insertion head assembly on it, and can realize the continuous insertion of different types of special-shaped devices on the same production line, greatly improving the insertion efficiency. In other embodiments, multiple terminal insertion mechanisms may also be provided according to production requirements, which is not limited to this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com