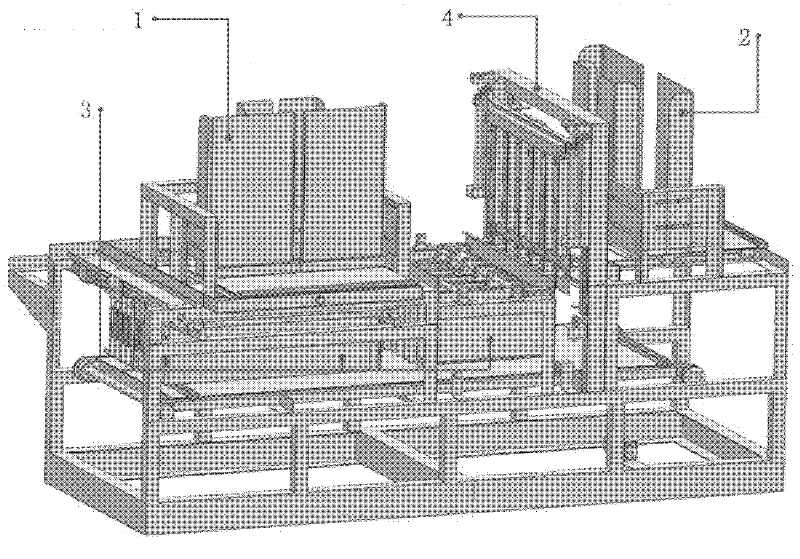

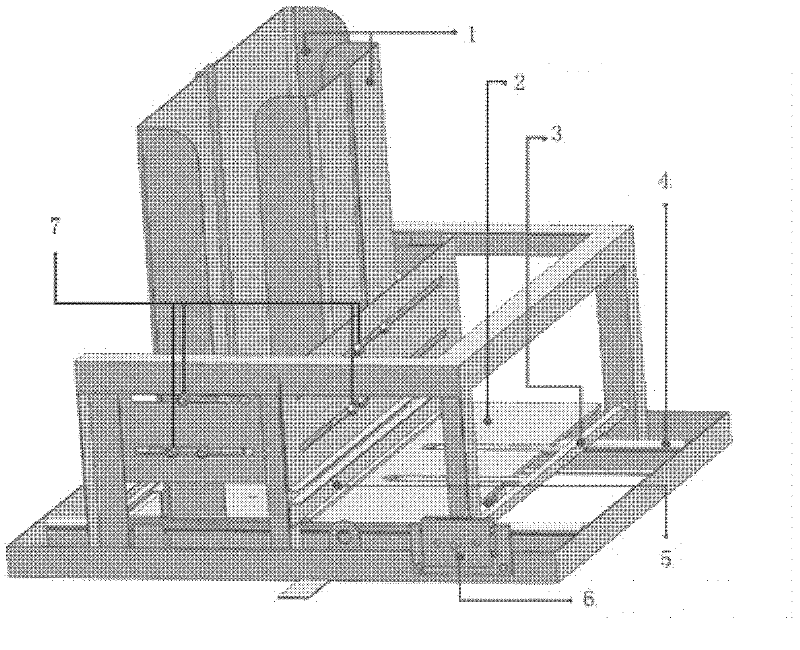

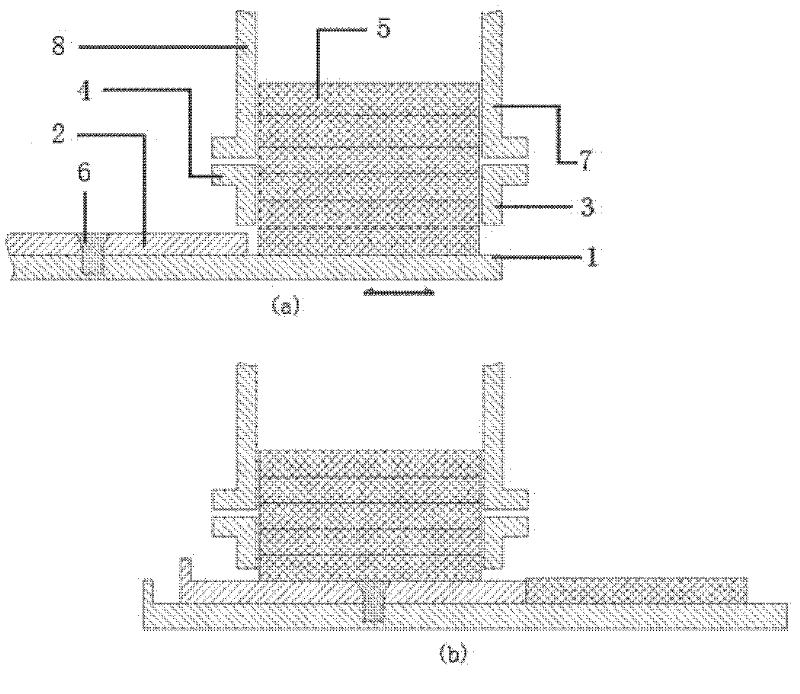

Automatic insertion machine of carton clapboard

A plugging machine and partition technology, applied in the field of carton partition automatic plugging machine, to achieve the effect of improving plugging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The accompanying drawings of this specification have clearly listed the overall structure of the machine and the structural details of each part. The description part also gives a detailed description of the working process of the machine and the working principle of each part. When making the machine according to this scheme, the size design should also be done according to the size of the packaging carton to be plugged. Although this design allows the machine to have room for adjustment, it can adapt to the plugging requirements of different blades. However, the maximum size of the blade should be determined, that is, the maximum length, width and maximum number of blade sockets allowed by the machine, and the corresponding minimum size before the final design and production.

[0029] The control system of the machine makes the machine a whole with coordinated actions of all parts. Among them, there is an overall sequence relationship. For example, the push rod feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com