High-safety power supply apparatus

A power supply device and safety technology, which is applied in the direction of coupling devices, components of connecting devices, circuits, etc., can solve problems such as potential safety hazards, poor circuit contact, and low safety, so as to prevent accidental electric shock accidents and improve plug-in efficiency , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

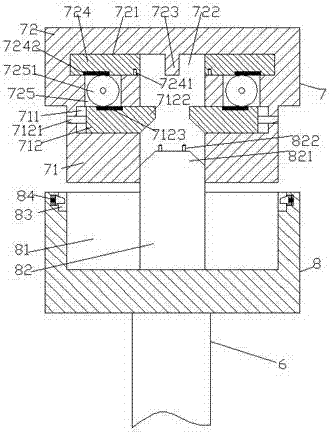

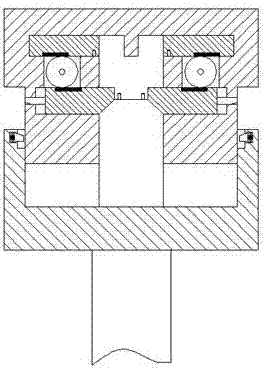

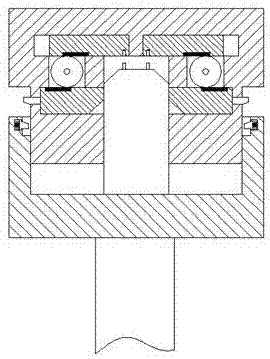

[0020] Such as Figure 1-Figure 5 As shown, a high-safety power supply device of the present invention includes a fixed socket 7 composed of a power supply part 72 and a joint part 71 and a plug 8 with a wire 6 at the bottom, and the wire 6 is connected to the electrical equipment. The inner center of the power supply part 72 is provided with a slot 722 extended downwards, the bottom of the slot 722 is set through the joint part 71, and the inner top wall of the slot 722 is provided with a baffle 723, the baffle The power supply part 72 on the left and right sides of the plate 723 is provided with a first chute 721, the bottom of the first chute 721 is provided with a cavity 725, and the joint part 71 at the bottom of the cavity 725 is provided with a The second chute 711, the first chute 721 is provided with a first sliding block 724, the inner side of the bottom of the first sliding block 724 is provided with a spring hole 7241, and the outer side of the spring hole 7241 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com