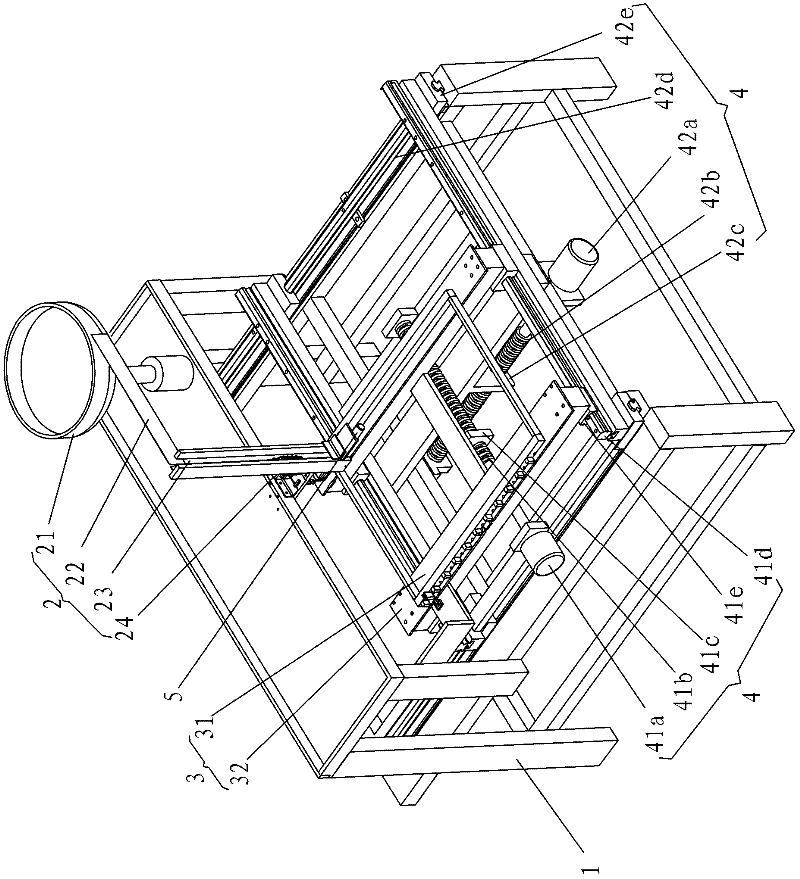

Automatic hanging machine of pullers

A slider and automatic technology, which is applied in the stacking, transportation and packaging of objects, can solve the problems of low efficiency and affecting the production efficiency of sliders, so as to improve the insertion efficiency and facilitate the layout of feeding devices and insertion devices , Improve the effect of inserting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

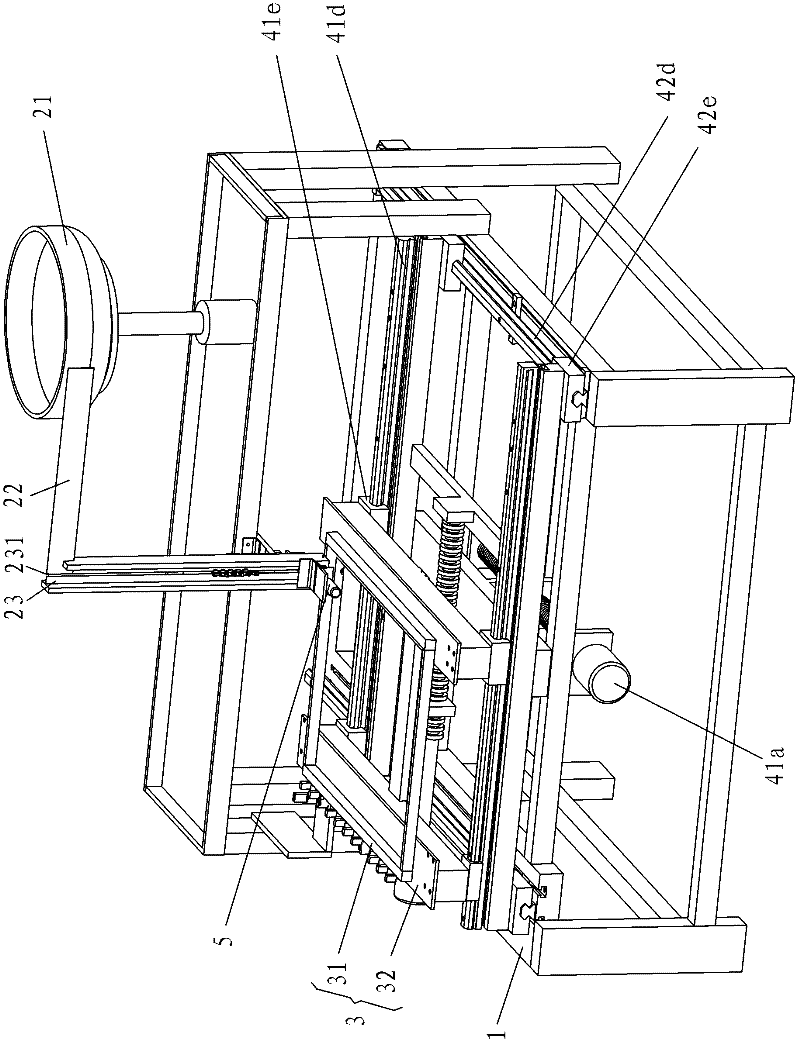

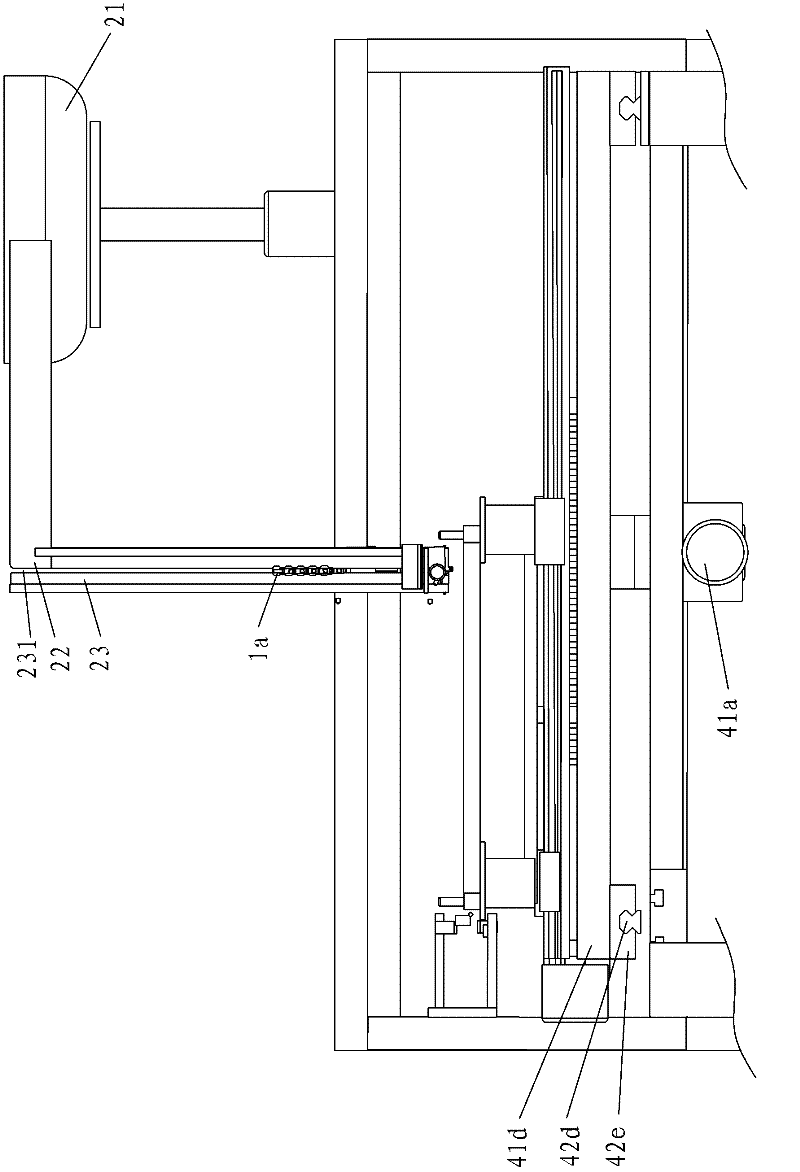

[0041] 1. The control system includes a correspondingly connected control circuit, a number of sensors and a number of sensor rods and other detectors; when the control circuit receives signals such as the presence or absence of the slider 1a and whether the slider 1a is in place measured by these detectors, the control system respectively Control the first cylinder 241a, the second cylinder 242a, the transverse motor 41a, the longitudinal motor 42a, the blade cylinder 512, the lift cylinder 521, and the longitudinal cylinder 523 to make corresponding actions; It can also send out alarm signals; the control system can also set the parameters of each driving part through the man-machine interface, or perform on-site and real-time operations;

[0042] 2. In the feeding device 2, the plate thickness at the opening 231 at the bottom of the vertical slide plate 23 can be slightly thickened, and the slider 1a slides here and stays at this insertion position, waiting for the insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com