Impeller assembly machine

A technology for assembly machines and impellers, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as inability to quickly turn the blade, poor adjustability of the rolling riveting mechanism, and unreasonable design of the rotor structure, and achieve the goal of turning the blade Stable pace, improved work efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

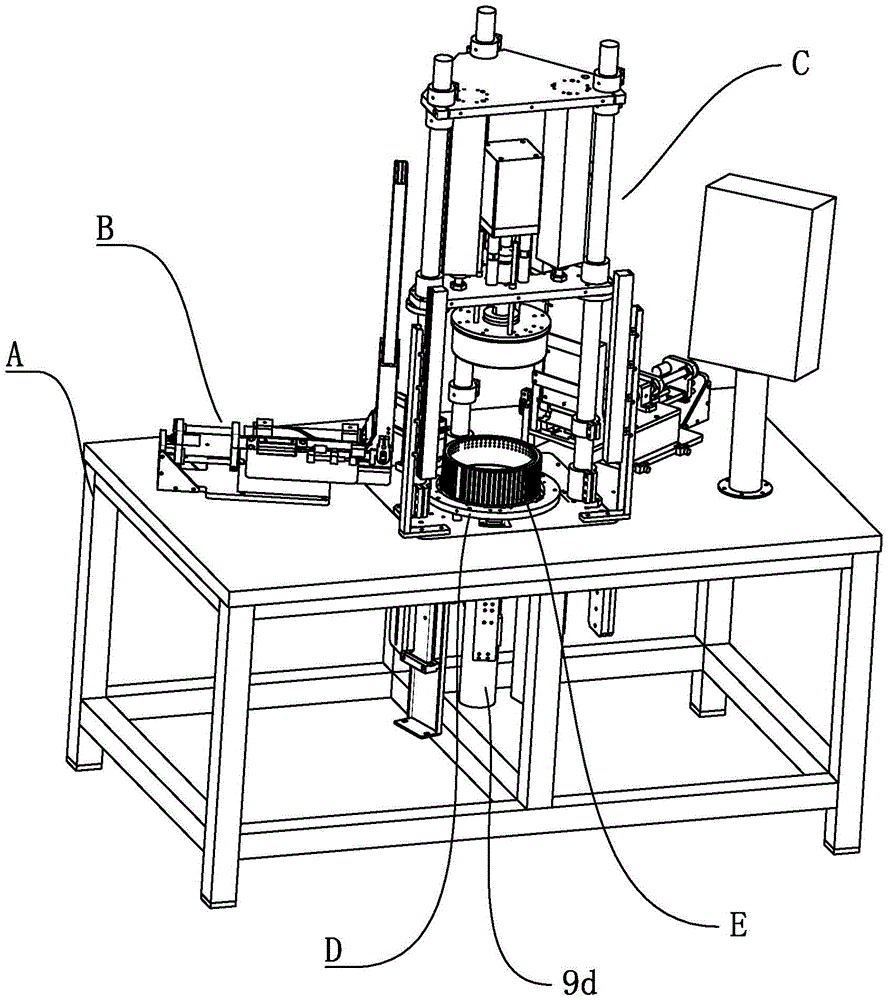

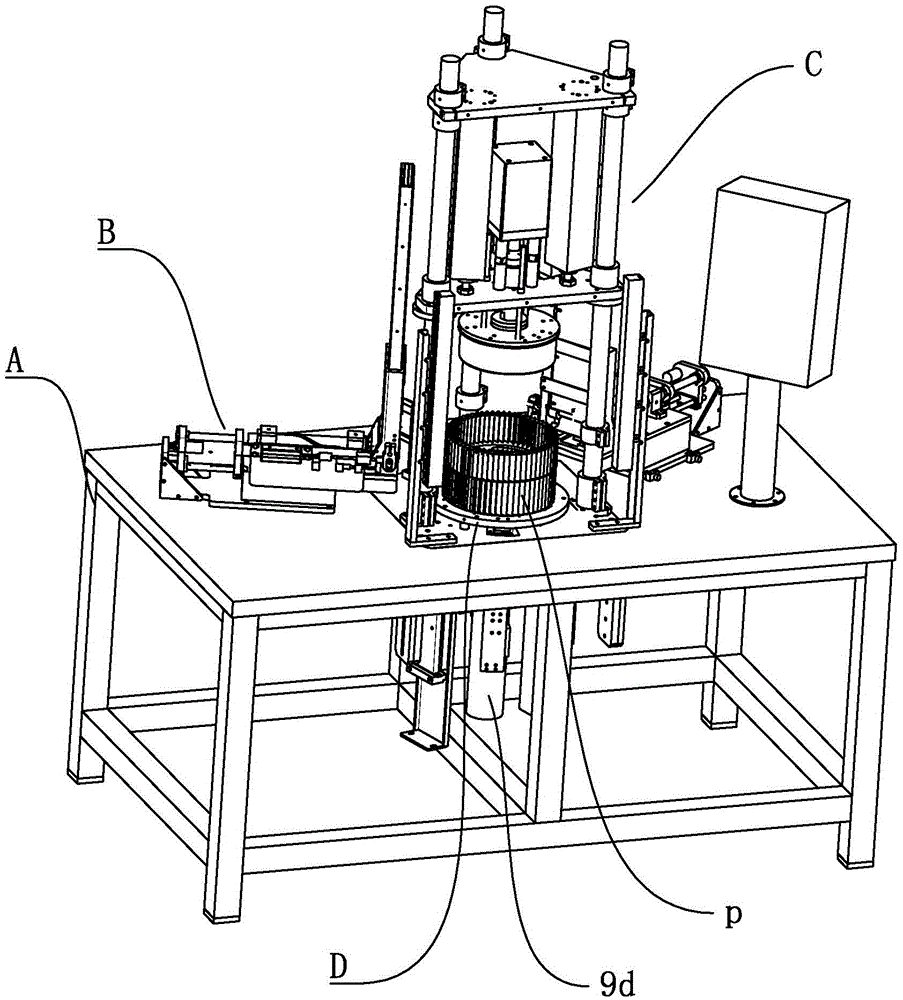

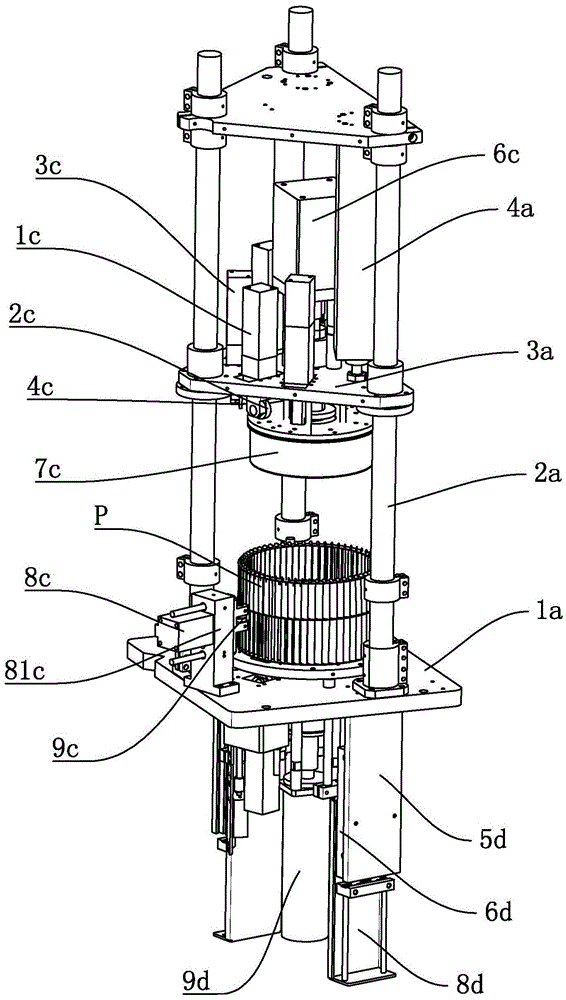

[0048] The overall schematic diagram of embodiment is referring to appendix figure 1 , mainly includes the frame A, the mold E mounted on the base plate 1a of the frame A, the motor 9d for driving the mold E to rotate, the positioning mechanism D for positioning the lower gland 2p of the impeller P, and the positioning mechanism D for positioning the blade 1p is fed into the slot of the mold E by the pushing mechanism B and the rolling riveting mechanism C which rivets the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com