Fully-automatic flexible assembly line

An assembly line, fully automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of engineering economic loss, long downtime of assembly line, low assembly efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, and the aforementioned and other objects, features, aspects and advantages of the present invention will become more apparent, so that those skilled in the art can implement them with reference to the description.

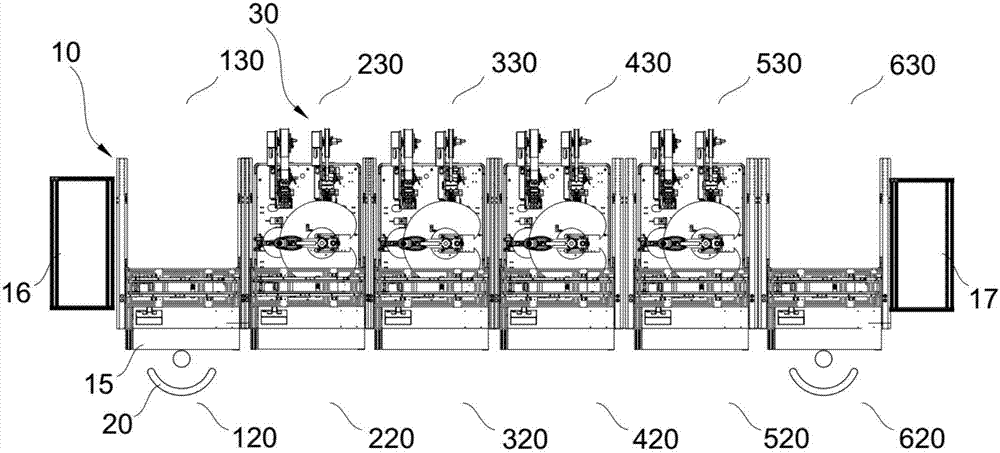

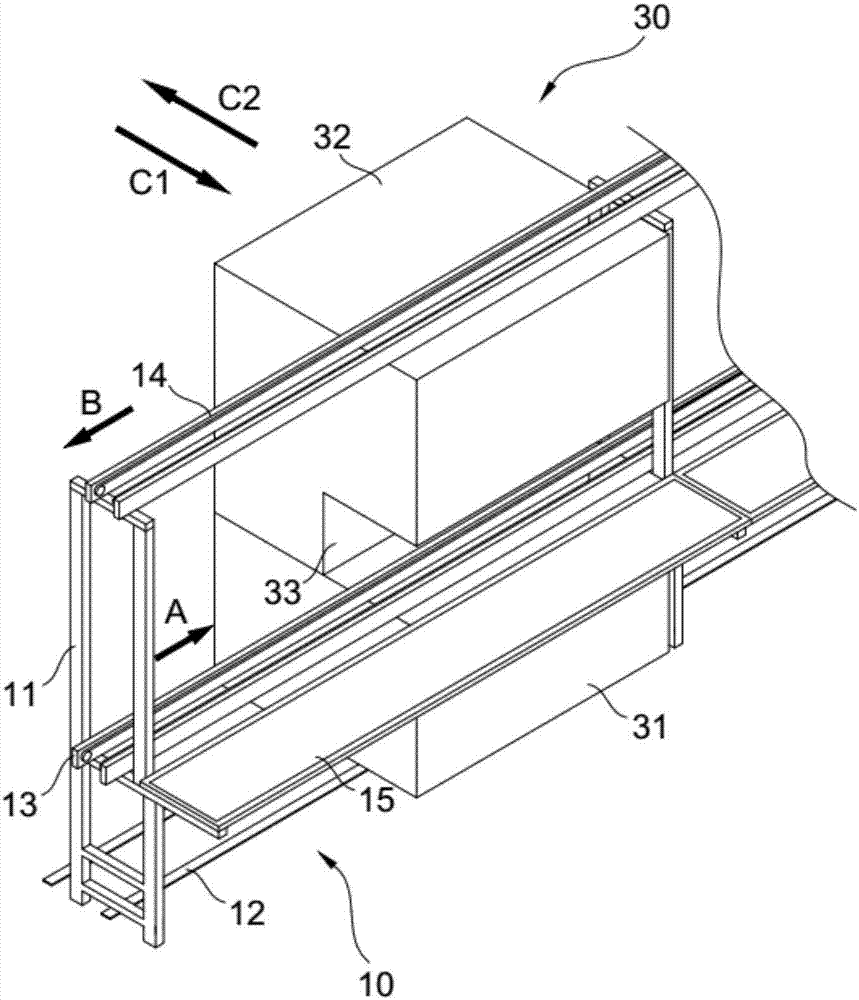

[0038] refer to figure 1 , the fully automatic flexible assembly line includes: control system;

[0039] pipeline assembly 10; and

[0040] A number of machine stations and artificial stations respectively located on both sides of the assembly line assembly 10,

[0041] Among them, the machine station and the artificial station are set in one-to-one correspondence, and each machine station is provided with an assembly machine 30 with different functions according to different assembly procedures, and the assembly line assembly 10 and several assembly machines 30 are all compatible with all The above control system is electrically connected, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com