Timing automatic ball-throwing apparatus and method

A pitching device and automatic technology, applied in chemical instruments and methods, cleaning methods and tools, earthwork drilling and mining, etc., can solve problems such as difficult automatic control, achieve significant economic benefits, solve manual operations, and reduce human resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

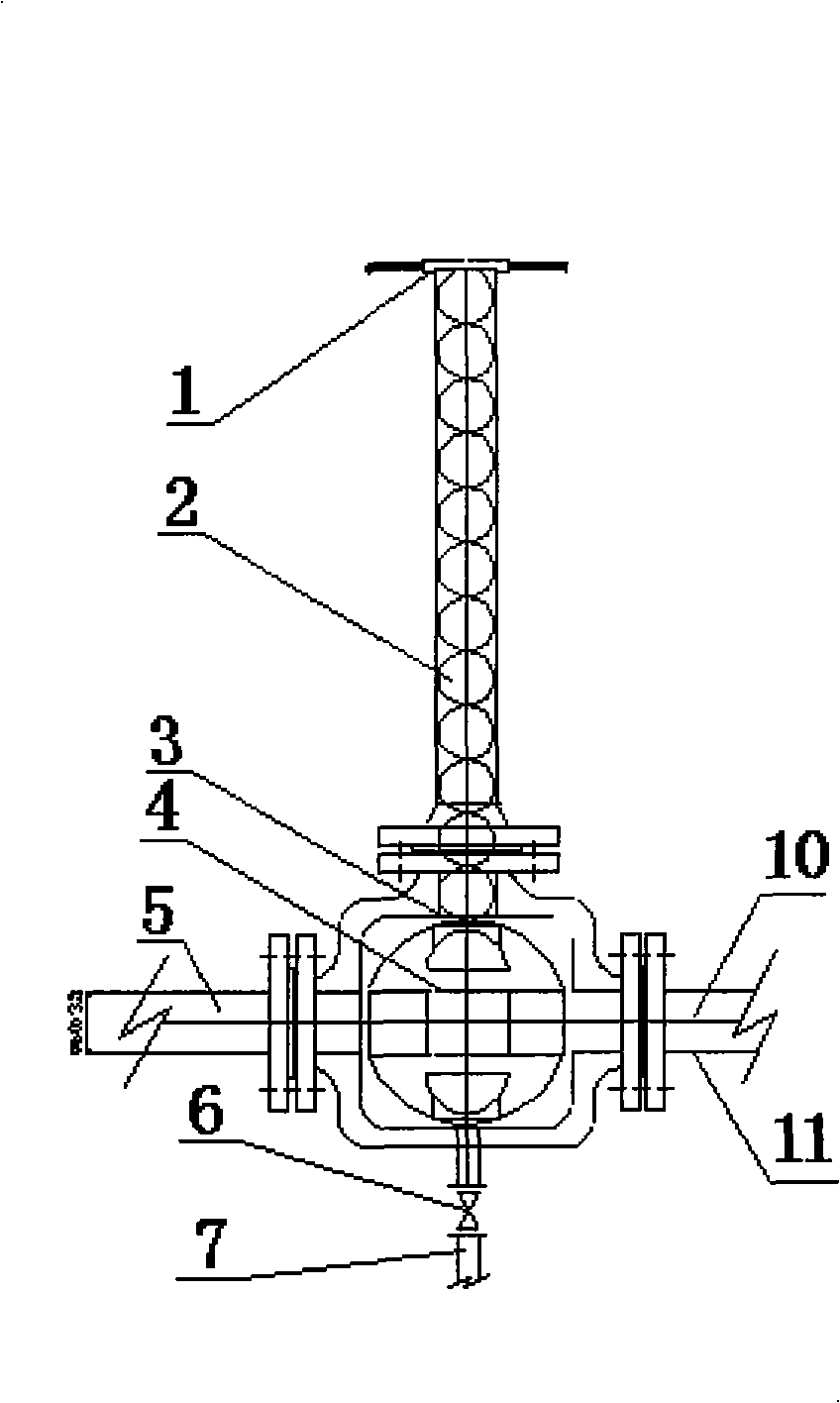

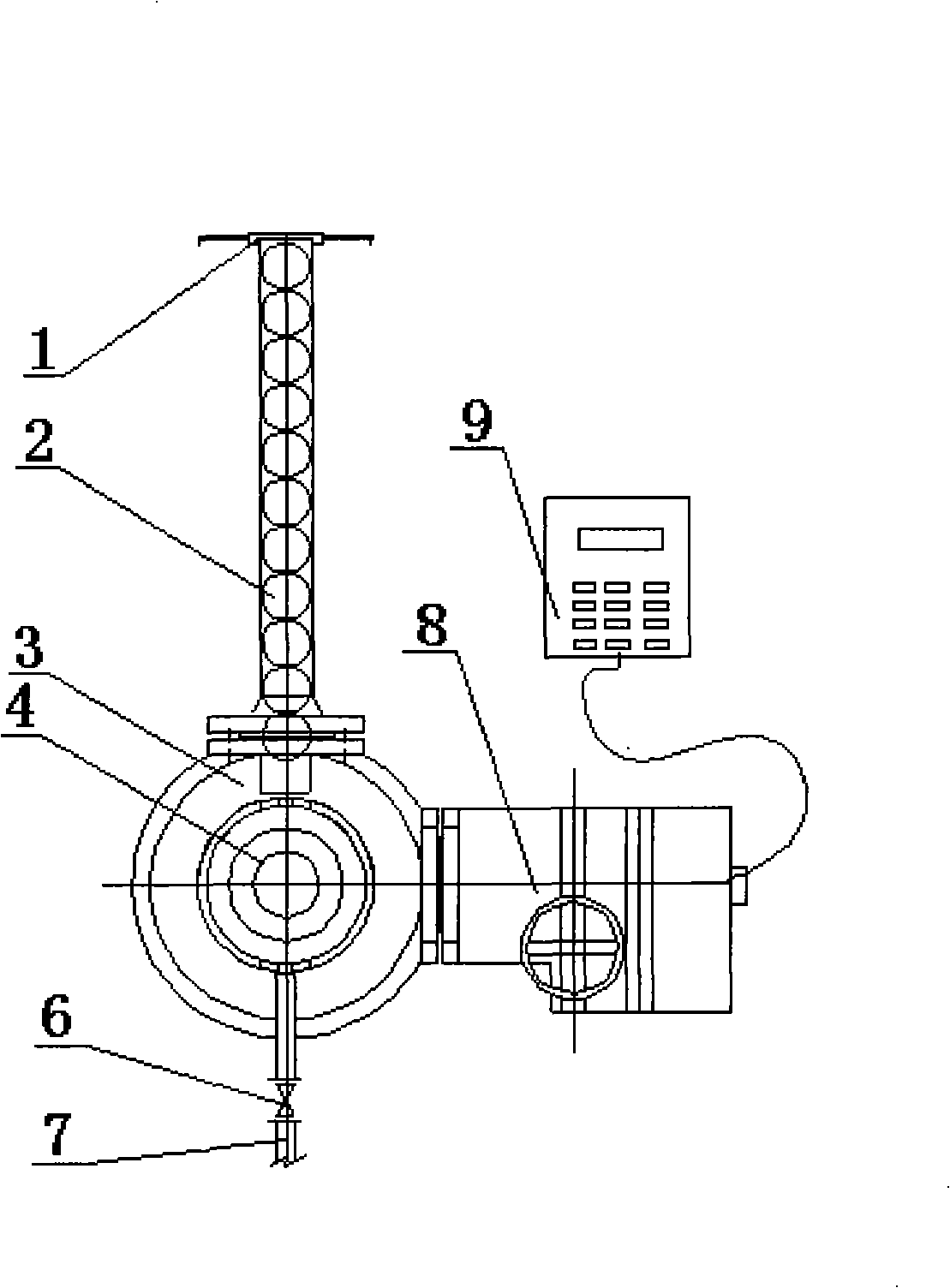

[0023] Such as figure 1 , figure 2 As shown, it includes a ball loading cylinder 1, a control valve 3 and a control unit 9. The ball loading cylinder 1 is vertically connected to the upper port of the control valve 3 through a flange. The upper end of the ball loading cylinder 1 is the inlet of the wax removal ball 2, and the lower end is The outlet of the wax ball 2 and the outlet of the wax removal ball 2 are connected to the control valve port of the connecting pipeline 11. The control valve 3 is a ball valve, and the ball valve 3 is connected between the crude oil input pipeline 5 and the crude oil output pipeline 10. The core 4 rotates 90 degrees, and the wax removal ball 2 of the ball tube 1 will remove the wax in the direction of the crude oil output pipeline 10. The ball valve spool 4 opens a circular hole in the direction of 90 degrees of the original flow direction, and the cross-sectional area of the hole is not less than 1 / 2 the cross-sectional area of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com