Benchmark integration processing method and multi-directional locating block thereof

A technology that integrates processing and positioning blocks, and is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., to reduce labor intensity, reduce economic costs, and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

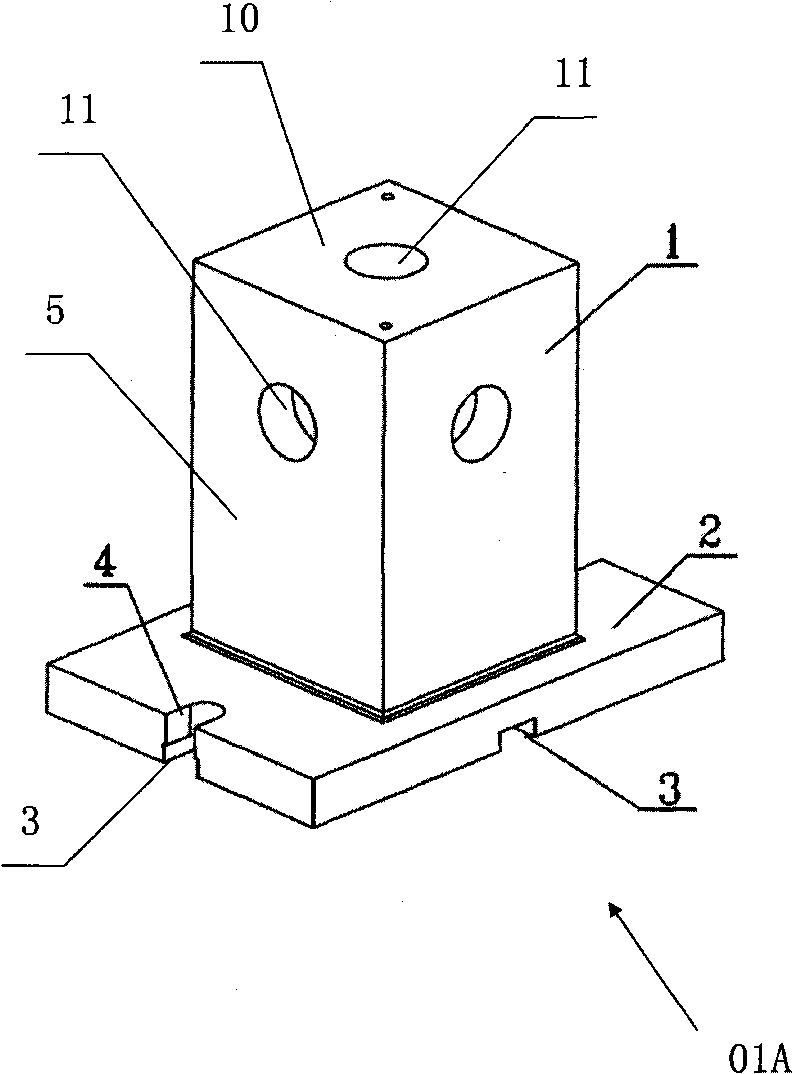

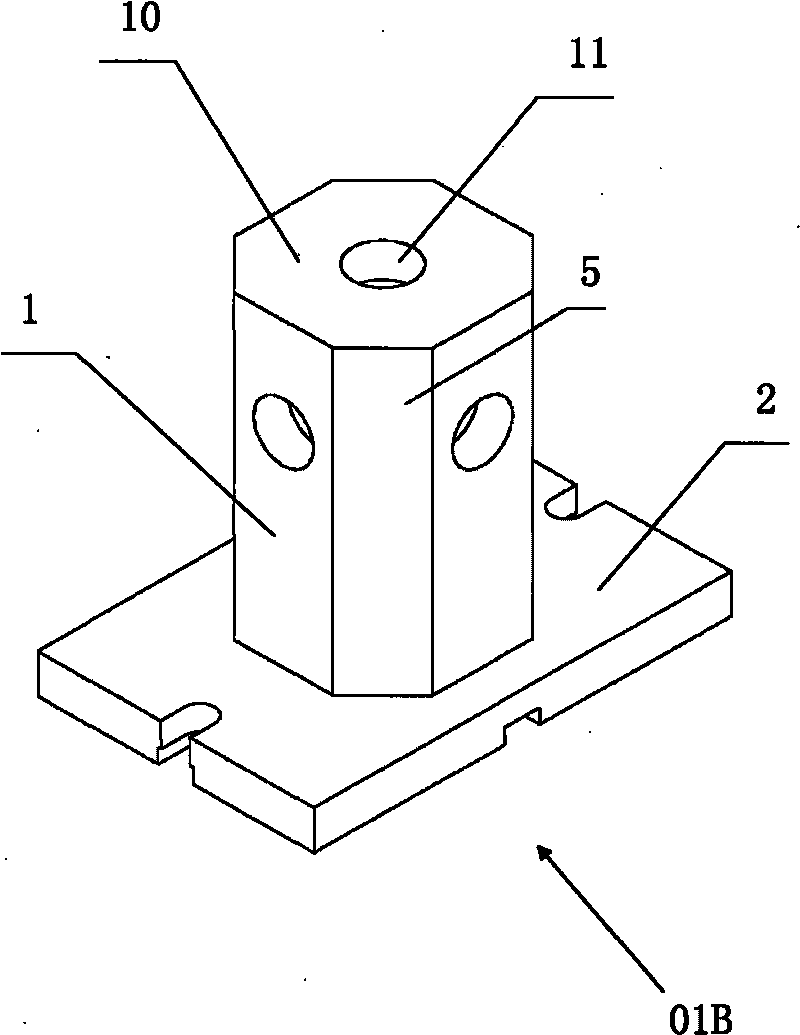

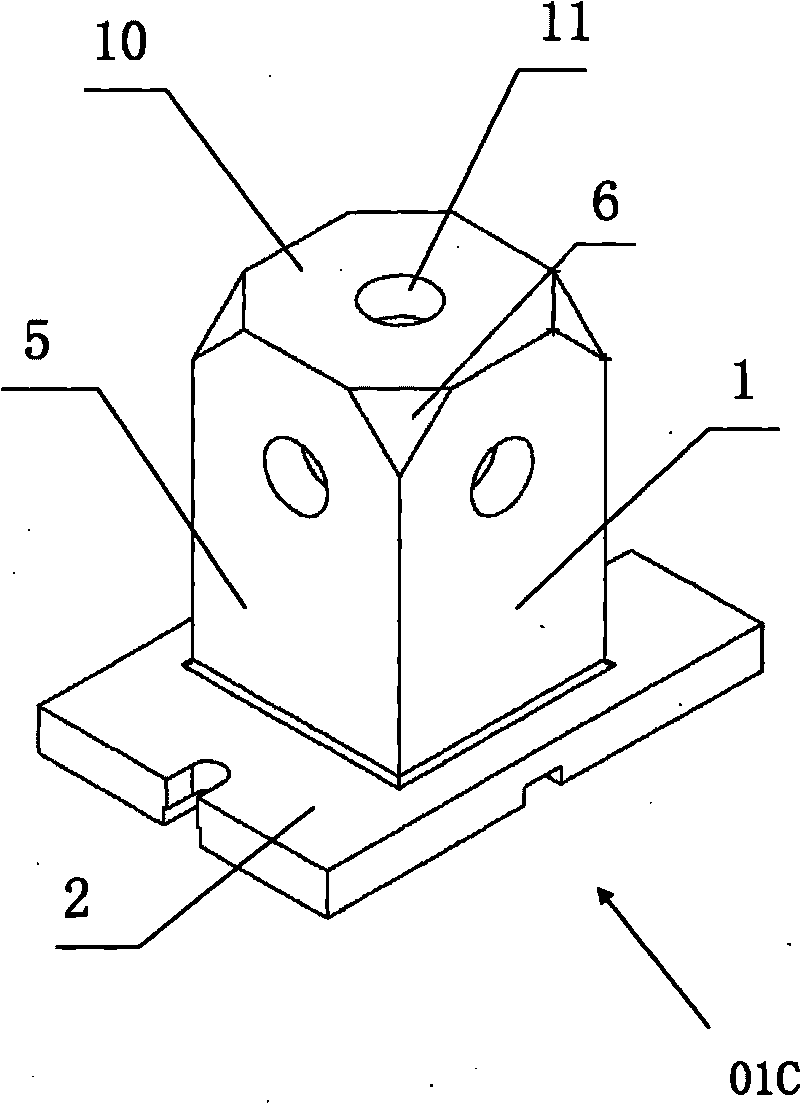

[0037] The benchmark integrated processing method described in the present invention is used for processing large workpieces on a large CNC gantry milling machine. In this method, a multi-directional positioning block with several positioning elements is fixed on the workbench of the large NC gantry milling machine, and Use this multi-directional positioning block as the reference origin to establish a processing space coordinate system, and integrate the references of each direction in the coordinate system into the multi-directional positioning block, so as to serve as a unified reference for the zero point position of the tool calibration in each processing step, and at the same time Also take the center point of the positioning element on the multi-directional positioning block as the starting point and the end point of the numerical control subroutine for programming and controlling each working step, so that the processing of each working step starts from the multi-directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com