Organic silicone thixotropic agent and thixotropy addition type liquid silicone rubber

A thixotropic agent and silicone technology, applied in the field of silicone thixotropic agent and thixotropic addition type liquid silicone rubber, can solve the problems of limited improvement effect, high cost, complicated mixing process, etc., and achieve thixotropy and extrusion performance. Good, simple preparation method, promoting the effect of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

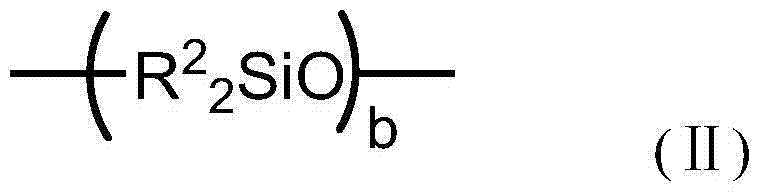

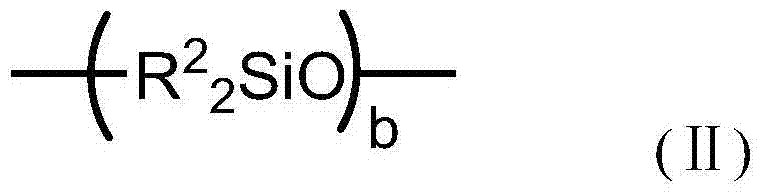

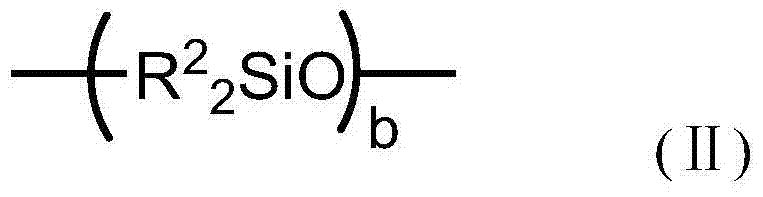

[0083] It should be pointed out that the modified polysiloxane and the modified cyclosiloxane in the organosilicon thixotropic agent of the present invention can be prepared according to existing methods, or can be purchased. Wherein, the preferred preparation method of modified polysiloxane comprises the following steps:

[0084] Hydrogen-containing silicone oil and modified reactants containing terminal alkenyl groups are reacted in an inert gas environment and an organic solvent at 85-95°C with a platinum catalyst for 6-12 hours. After the reaction is completed, the modified product is obtained by distillation under reduced pressure. polysiloxane.

[0085] In the above preparation methods, the synthesis of hydrogen-containing silicone oil can be carried out with reference to existing methods to adjust the molecular structure of modified polysiloxane, such as viscosity, phenyl content, etc.; group, ether group, hydroxyl group, amine group or ester group, and compounds with ...

Embodiment 1

[0097] Preparation of modified cyclosiloxane Ⅰ:

[0098] In the four-neck flask, dry N 2 , join D 4 H (24.00g, 0.10mol, hydrogen content is 1.6125%), petroleum ether (100.00g) and Pt / IPA (0.15g, 60μg / g), stir and heat up to 85°C, drop allyl shrinkage with a constant pressure funnel Glyceryl ether (AGE) (57.08g, 0.50mol), after the dropwise addition, was reacted at 85°C for 6h, and after the reaction was completed, it was distilled under reduced pressure to obtain the modified cyclosiloxane I.

[0099] The hydrogen content of modified cyclosiloxane I was measured to be 0.1568%, and the modified group containing epoxy group ( The content is 0.53mol / 100g.

Embodiment 2

[0101] Preparation of modified cyclosiloxane II:

[0102] In the four-neck flask, dry N 2 , join D 4 H (24.00g, 0.10mol, hydrogen content is 1.6125%), hydroquinone monomethyl ether (0.09g, 0.00072mol), (petroleum ether (100.00g) and Pt / IPA (0.16g, 60μg / g), Stir and heat up to 85°C, add butyl acrylate (64.08g, 0.5mol) dropwise with a constant pressure funnel. After the dropwise addition, react at 85°C for 10h. After the reaction, distill under reduced pressure to obtain modified cyclosiloxane II.

[0103] The hydrogen content of modified cyclosiloxane II was measured to be 0.2486%, and the modified group containing ester group ( The content is 0.45mol / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com