Dehydrator

A dehydrator and dehydration technology, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of low dehydration efficiency, change of discharge pressure, decrease of operation rate, etc., and achieve simple structure and operation method. and simplicity, increase the pushing capacity and extrusion, and improve the effect of the operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the dehydrator according to the present invention will be described in detail with reference to the accompanying drawings.

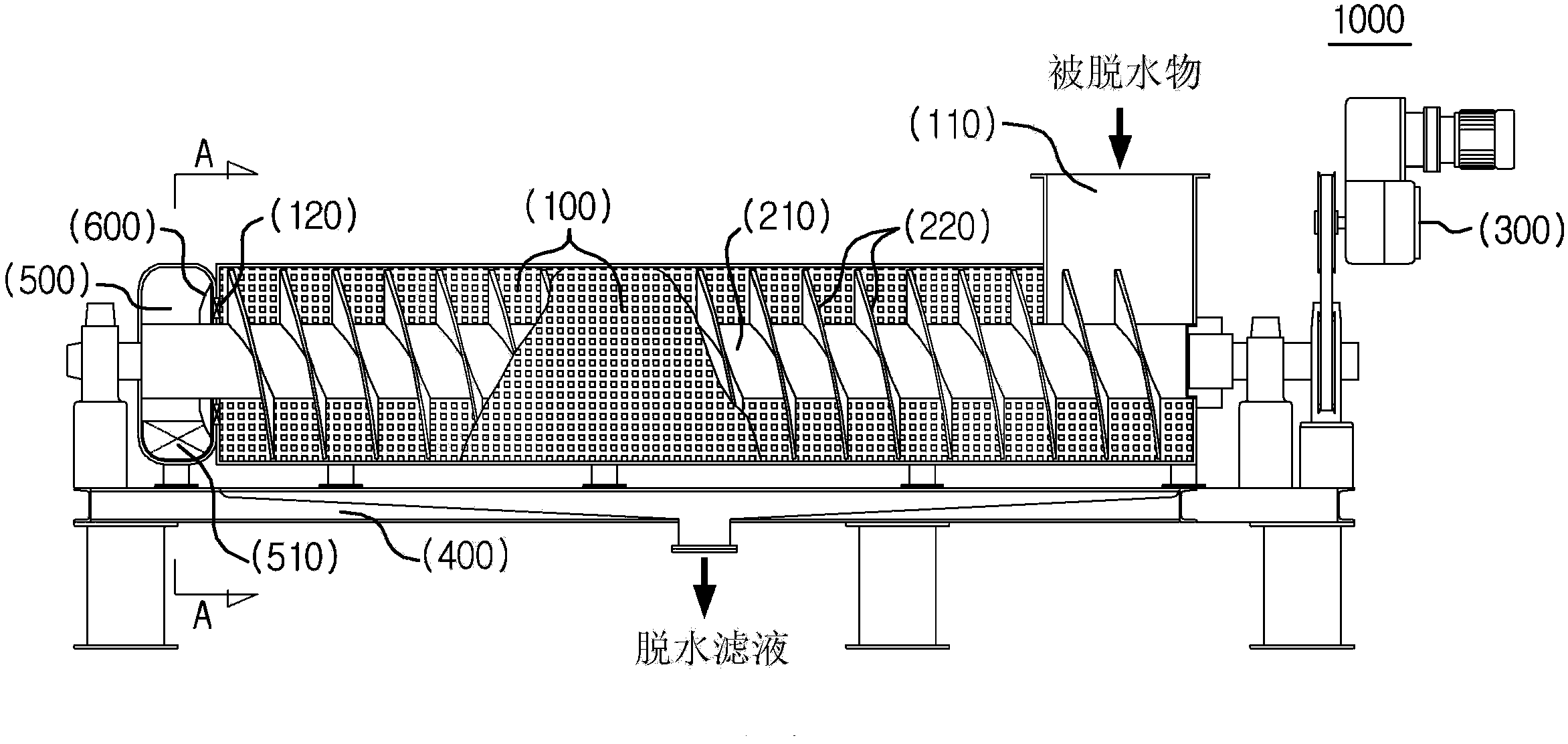

[0049] figure 1 is a front sectional view of a dehydrator according to the present invention.

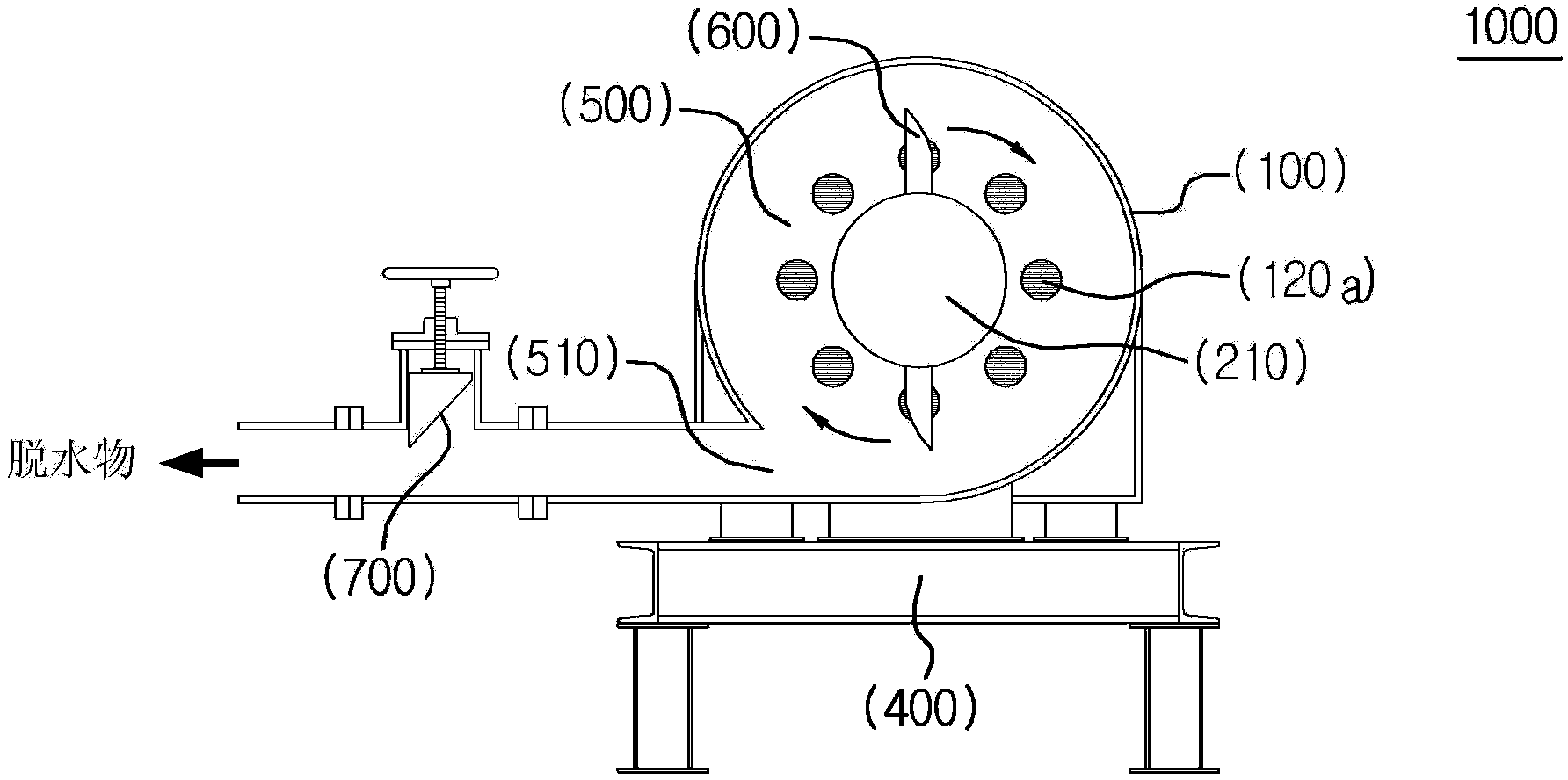

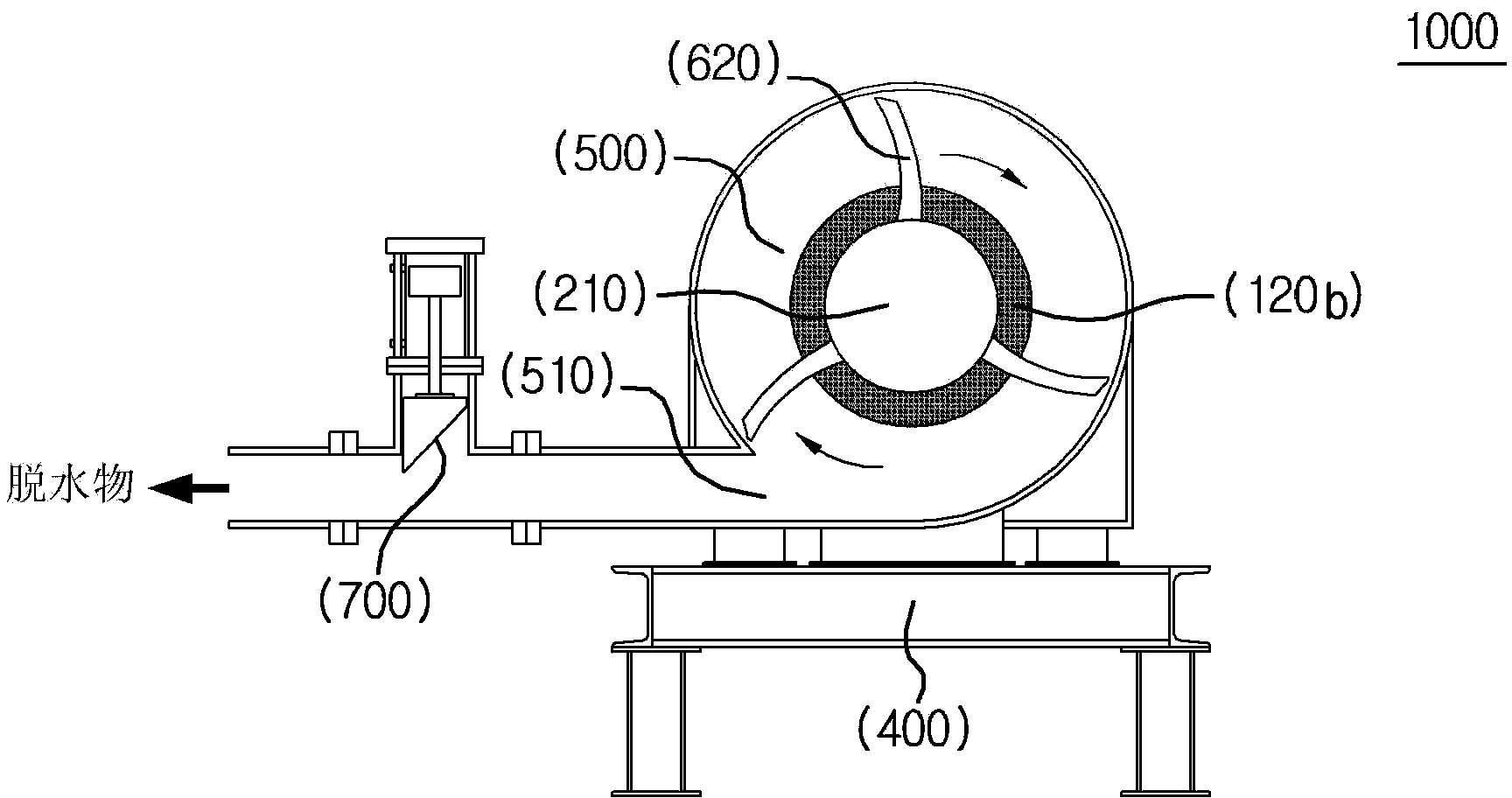

[0050] The dehydrator according to the basic concept of the present invention includes: a cylindrical screen 100 formed with a plurality of fine holes; a screw consisting of a rotating shaft 210 and a helical rotating blade 220; a driving part 300 which makes the The screw rotates; the input port 110 is arranged on one side of the sieve, and the dehydrated matter is put into the inside of the sieve; the discharge port 120 is arranged on the other side of the sieve, and the dehydrated matter is discharged to the outside of the sieve The pressurization chamber 500, which communicates with the discharge port, stores the discharged dehydrated matter inside and pressurizes; the discharge port 510, which is formed in the pressurized chamber, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com