Resistance heating thermal desorption device for repairing contaminated soil and underground water

A resistance heating and polluted soil technology, applied in the restoration of polluted soil, etc., can solve the problem of high construction cost, achieve the effect of precise optimization of heating, reduce energy consumption, and keep the circuit smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that the drawings are not necessarily drawn to scale.

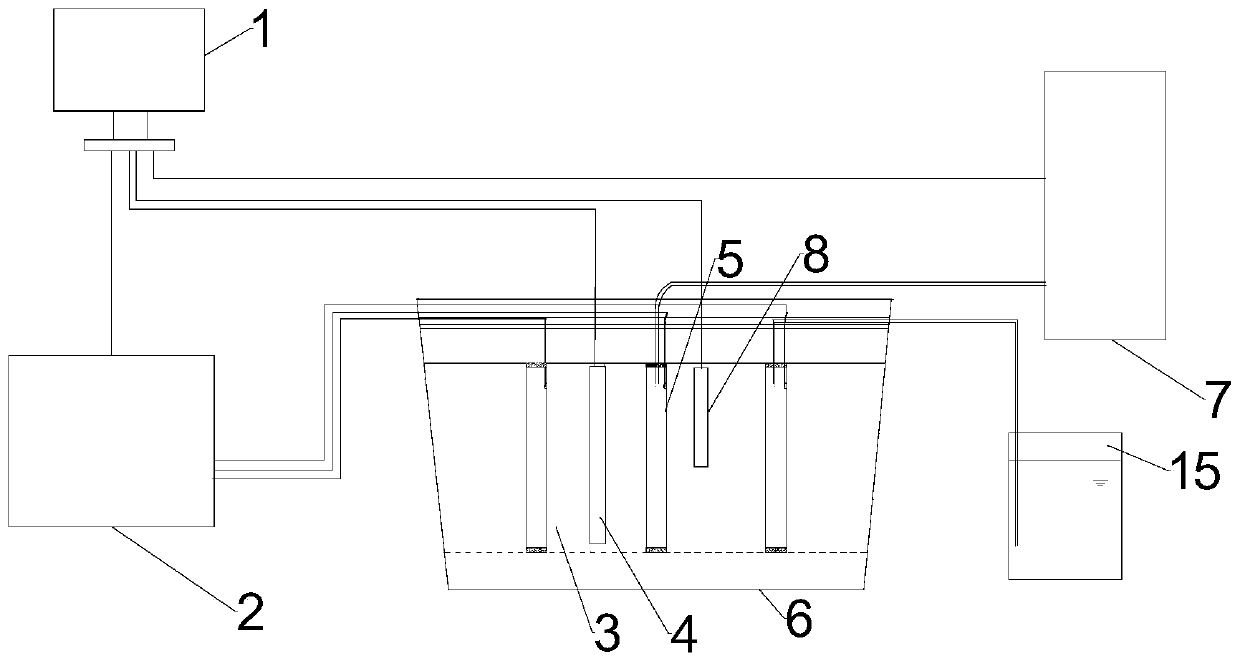

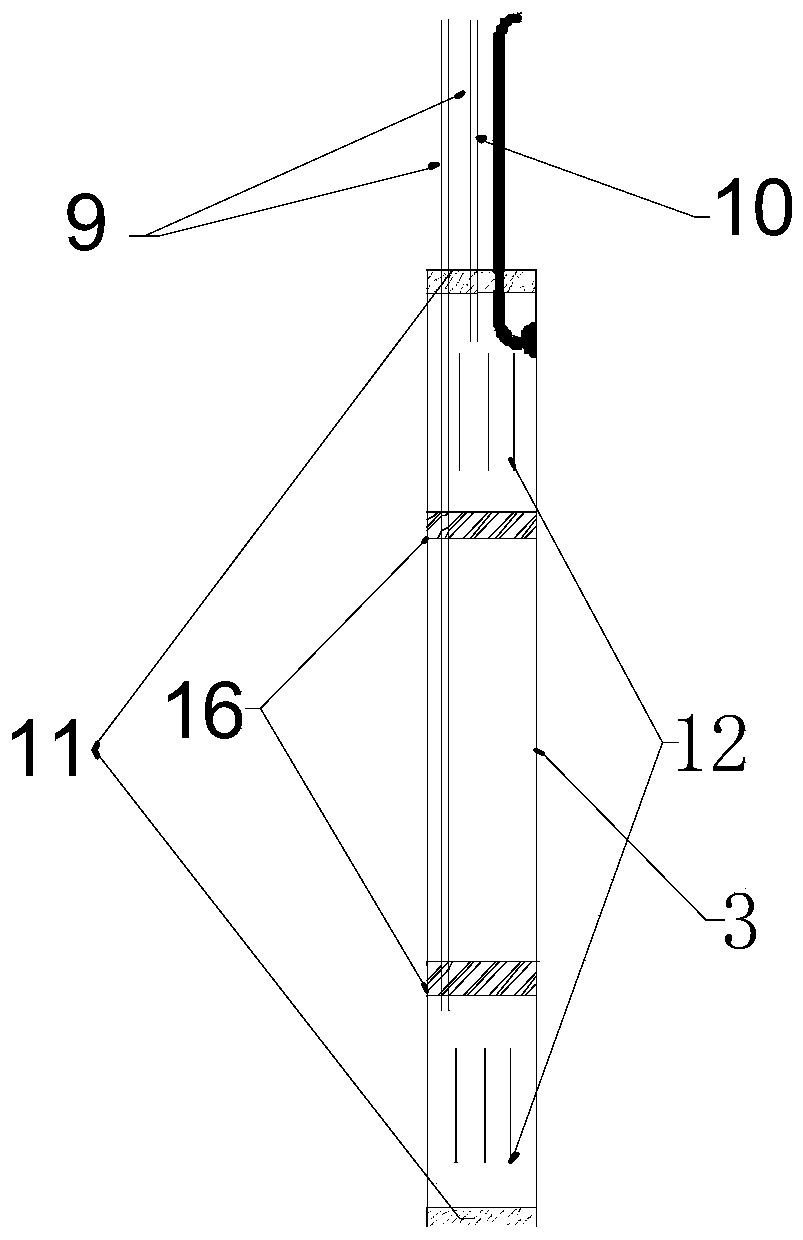

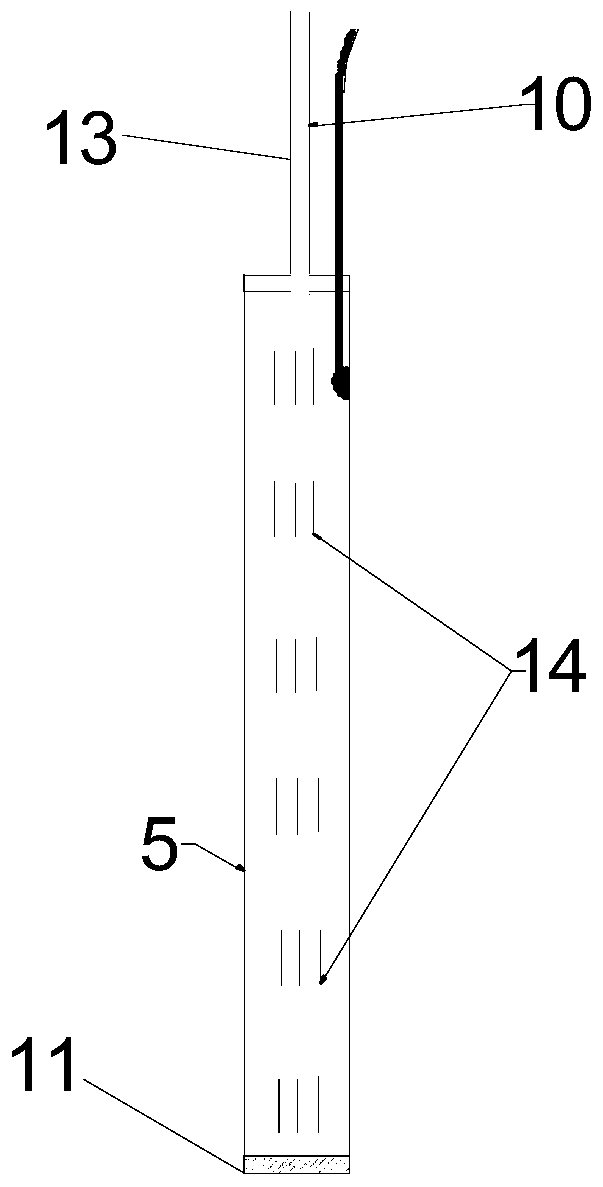

[0030] Such as figure 1 , Figure 4 As shown, the present invention provides a resistance heating thermal desorption device for remediating polluted soil and groundwater, mainly in which a plurality of fire wires arranged in an equilateral triangle are arranged in the remediation site (including the container 6 filled with polluted soil) Electrode 3, the three live wire electrodes 3 arranged in an equilateral triangle are respectively connected to one phase of the three-phase four-wire alternating current, and a neutral electrode 5 is arranged at the center of each equilateral triangle, and the neutral elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com