Large-angle stable miniaturized frequency selective surface

A technology of frequency selective surface and large angle, applied in antennas, electrical components, etc., can solve the problems of poor stability at large angles and insufficient miniaturization, and achieve the effects of improving stability, improving stability at large angles, and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

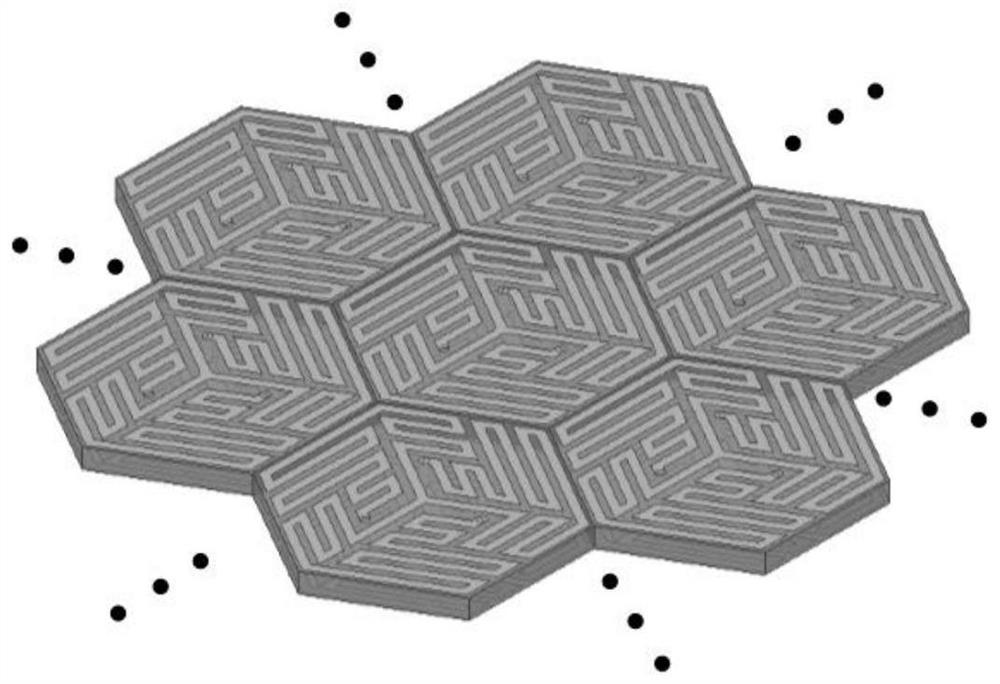

[0022] refer to figure 1 , a large-angle stable miniaturized frequency selective surface, including S×T resonant units periodically arranged, where S=40, T=40, combined into a honeycomb-like structure.

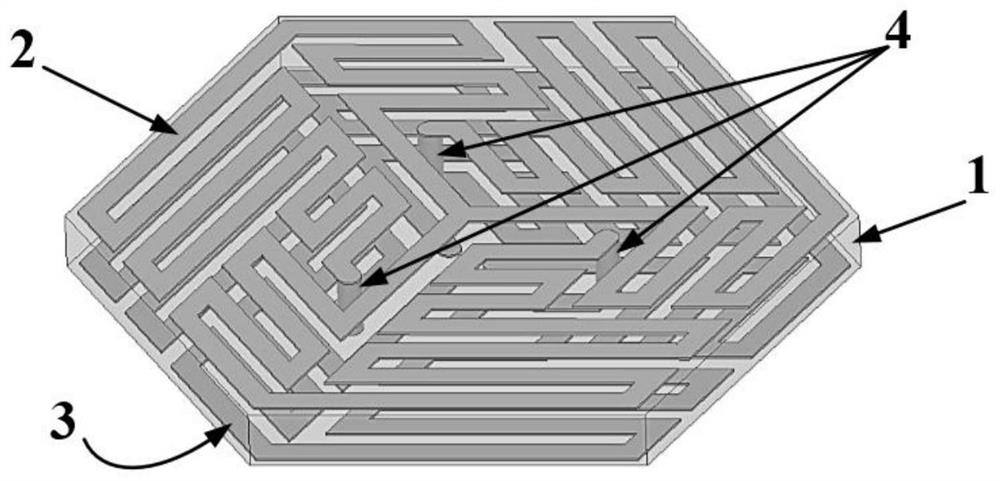

[0023] refer to figure 2 The frequency selective surface unit structure consists of a dielectric plate 1 with a regular hexagonal cross-sectional shape, an upper surface metal layer 2 printed on the upper surface of the dielectric plate 1, a lower surface metal layer 3 printed on the lower surface of the dielectric plate 1, and The metal via group 4 vertically penetrating through the dielectric board 1 is formed.

[0024] The side length of the dielectric plate 1 is 3.2 mm, the thickness is 0.5 mm, the relative dielectric constant is 2.2, and the loss tangent is 0.0009.

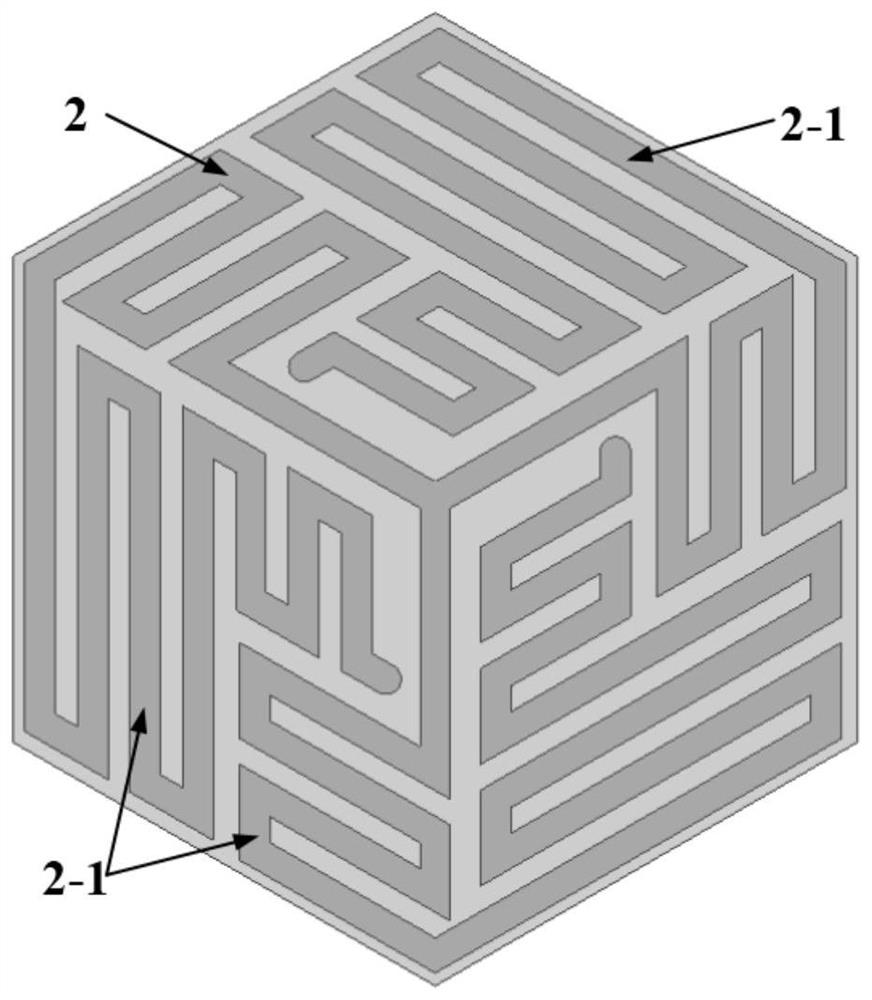

[0025] refer to image 3 and Figure 4 , the upper surface metal layer 2 and the lower surface metal layer 3 are respectively composed of three rotationally symmetrical first metal strip lines 2-1 and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com