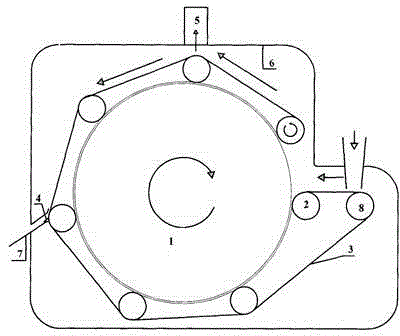

Rotary drum type film squeezing sludge dryer

A sludge drying and drum-type technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of complex drying process and equipment, high drying thermal efficiency, and small processing capacity of a single machine, so as to shorten the drying time, Uniform moisture content and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0014] The dewatered sludge is slowly fed along with the movement of the conveying mesh belt 3. When in contact with the rotating heating surface 1, the rotating heating surface 1 rotates clockwise, and the pressure roller 2 rotates counterclockwise, and the sludge is squeezed between them, so that The sludge feed maintains a certain thickness, so that the drying efficiency will not be low due to too thin material, and the drying effect will not be affected by too thick cloth. When the sludge rotates along the rotating heating surface 1 and the conveying mesh belt 3 to the pressure roller 2 with the largest opening angle (the pressure roller 2 marked with the rotation arrow), the sludge in the contact part of the sludge and the rotating heating surface 1 has been heated and dried. , forming a layer of sludge drying film, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com