Outer-layer variable heat dissipation structure of transformer

A heat dissipation structure and transformer technology, applied in the field of transformer equipment, can solve the problems of limited heat dissipation effect, decomposition of transformer oil, and inability to dissipate heat to the outside in time, and achieve the effect of improving heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

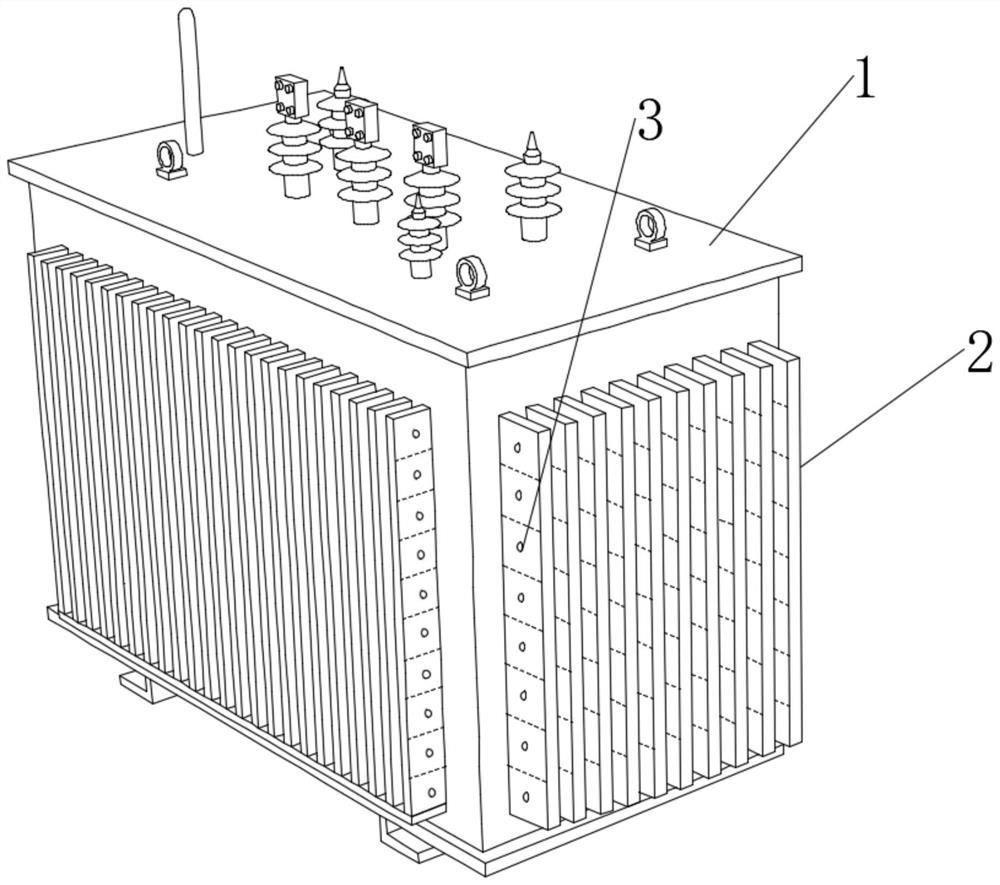

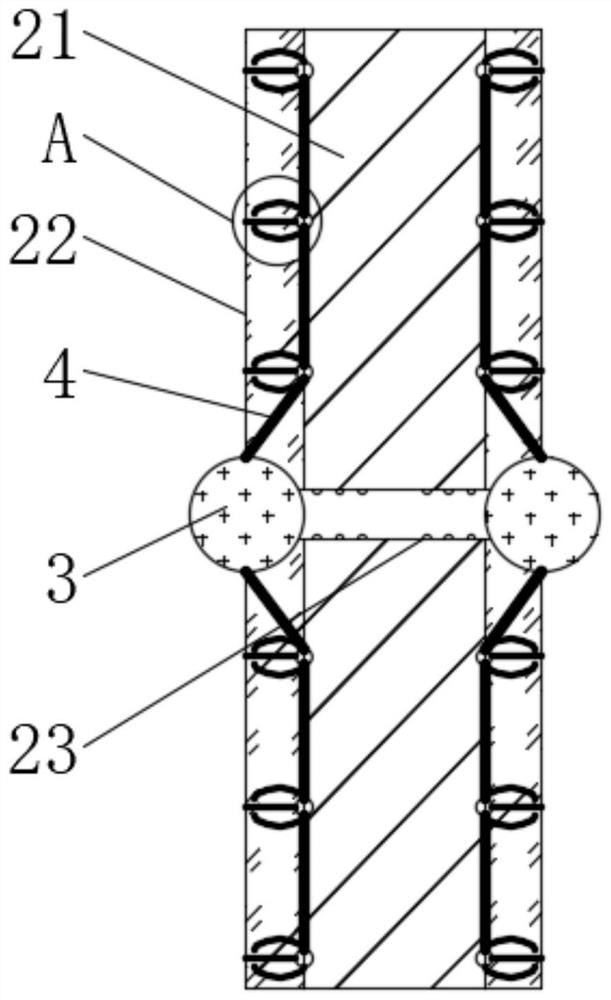

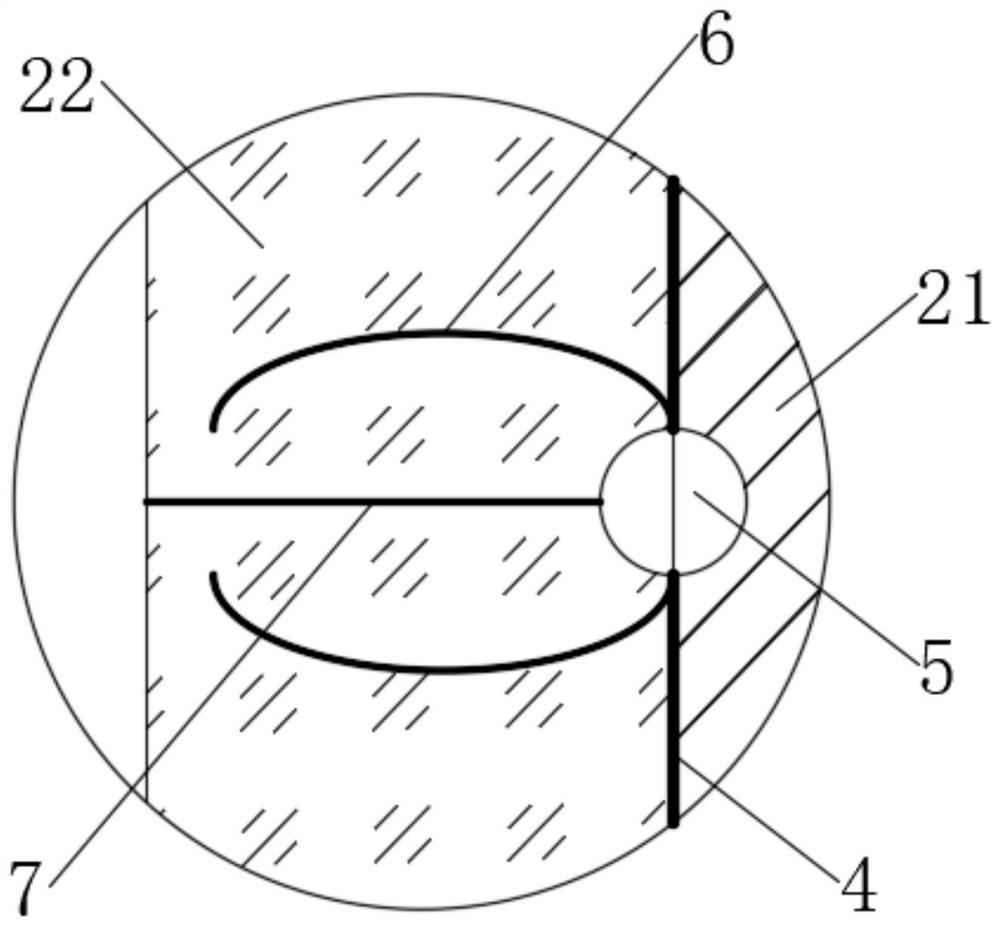

[0043] see Figure 1-2 , a variable heat dissipation structure for the outer layer of a transformer, including a transformer body 1, a plurality of evenly distributed variable heat sinks 2 connected to the outer end of the transformer body 1, the variable heat sink 2 includes a plurality of variable heat dissipation units, and the variable heat dissipation The unit includes a heat dissipation substrate 21 and two shape transformation heat layers 22, the shape transformation heat layer 22 is covered on the two side walls of the heat dissipation substrate 21, and the heat dissipation substrate 21 is connected with the transformer body 1, and the center of the shape transformation heat layer 22 A water-based ball 3 is inlaid and connected, and a thermal extension trigger cylinder 23 is inlaid and connected to the center of the heat dissipation substrate 21, and both ends of the thermal extension trigger cylinder 23 are respectively connected with the water-based balls 3 on both si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com