Organic silicon heat conduction bonding agent adopting high-power light emitting diode (LED) for illumination and preparation method thereof

A technology of LED lighting and heat-conducting adhesives, applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of extrusion performance and elasticity decline, production difficulty increase, etc., to achieve excellent elasticity, relative Good capacitance, eliminate the effect of storage instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

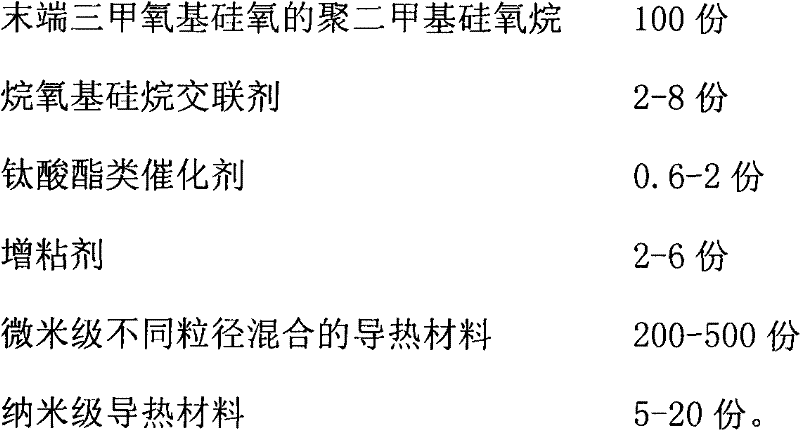

Method used

Image

Examples

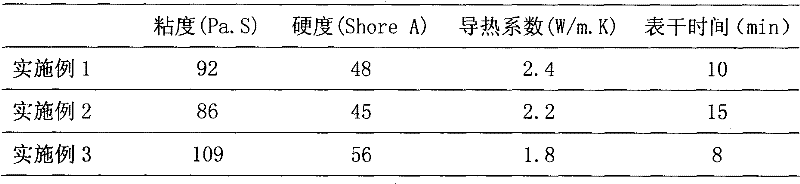

Embodiment 1

[0030] In terms of parts by weight, 100 parts of aluminum nitride with an average particle size of 40 nanometers and 4 parts of hexamethyldisilazane were stirred and reacted in a high-speed disperser at a temperature of 110°C for 3 hours, and used as a nano-thermal conductive material after hydrophobic treatment .

[0031] Take 100 parts of polydimethylsiloxane with a viscosity of 1Pa.S terminal trimethoxysiloxane at 25°C, 200 parts of spherical alumina with an average particle diameter of 10 microns, and 100 parts of spherical alumina with an average particle diameter of 1 micron, Add 15 parts of hydrophobically treated 40nm aluminum nitride into a high-speed dispersion mixer, stir and dehydrate in vacuum at 120°C for 2 hours, then add 5 parts of methyltrimethoxysilane, 0.5 parts of tetra-n-butyl titanate, bis (Ethyl acetoacetate) diisobutyl titanate 0.5 parts, γ-aminopropyltriethoxysilane 2 parts, 1,3,5-tris(trimethoxysilylpropyl) polyisocyanate 2 parts, vacuum stirring for ...

Embodiment 2

[0033] In terms of parts by weight, 100 parts of aluminum nitride with an average particle size of 40 nanometers and 2 parts of hexamethyldisilazane were stirred and reacted in a high-speed dispersion mixer at a temperature of 100°C for 5 hours, and used as a nano-thermal conductive material after hydrophobic treatment .

[0034] Take 100 parts of polydimethylsiloxane with a viscosity of 10 Pa.S terminal trimethoxysiloxane at 25°C, 130 parts of aluminum nitride with an average particle size of 30 microns, and 70 parts of aluminum nitride with an average particle size of 5 microns, Add 20 parts of hydrophobically treated 40nm aluminum nitride into a high-speed dispersion mixer, stir and dehydrate under vacuum for 3 hours at 110°C, and then add 2 parts of vinyltrimethoxysilane, 0.3 parts of tetraisopropoxytitanium, bis (Ethyl acetoacetate) diisobutyl titanate 0.3 part, γ-glycidyl etheroxypropyl trimethoxysilane 1 part, 1,3,5-tris(trimethoxysilylpropyl) polyisocyanate 1 part, Af...

Embodiment 3

[0036] In terms of parts by weight, 100 parts of aluminum nitride with an average particle size of 40 nanometers and 6 parts of hexamethyldisilazane were stirred and reacted in a high-speed disperser at a temperature of 120°C for 2 hours, and used as a nano-thermal conductive material after hydrophobic treatment .

[0037] Take 100 parts of polydimethylsiloxane with a viscosity of 0.5Pa.S terminal trimethoxysiloxane at 25°C, 340 parts of zinc oxide with an average particle size of 20 microns, 160 parts of aluminum oxide with an average particle size of 2 microns, hydrophobic Add 5 parts of the treated 40nm aluminum nitride into a high-speed dispersing mixer, stir and dehydrate under vacuum for 1 hour at 130°C, and then add 5 parts of phenyltrimethoxysilane, 3 parts of methyltrimethoxysilane, tetraiso 2 parts of titanium propoxide and 6 parts of γ-aminopropyltriethoxysilane were vacuum stirred for 60 minutes and then discharged into a sealed single-component package. The produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com