Low viscosity and high thermal conductivity organosilicon gel and preparation method thereof

A technology with high thermal conductivity and low viscosity, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of increased cost of thermally conductive gel materials, inability to realize automatic dispensing, difficulty in filling tiny gaps, etc., and achieve aging stability Good, low oil absorption value, the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

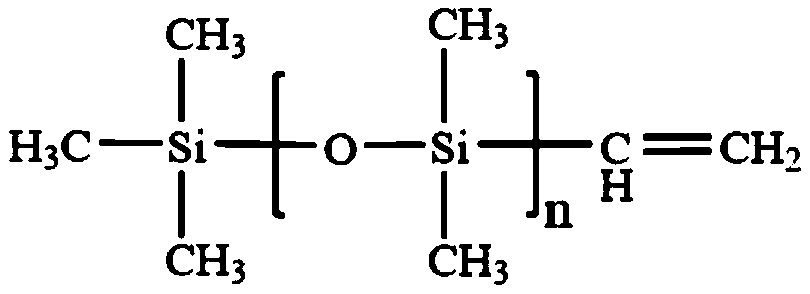

[0025] A low-viscosity, high-thermal-conduction silicone gel, the low-viscosity, high-thermal-conduction silicone gel consists of components A and B, wherein component A includes the following components in parts by mass: 100 parts of vinyl silicone oil, 5 parts of polyvinyl silicone oil, 5 parts of alkyl modified silicone oil, 5 parts of reactive diluent, 500 parts of high thermal conductivity composite inorganic filler, 1 part of catalyst and 2 parts of pigment, component B includes the following components in parts by mass: 100 parts of vinyl silicone oil, 5 parts of polyvinyl silicone oil, 5 parts of alkyl modified silicone oil, 5 parts of reactive diluent, 500 parts of high thermal conductivity compound inorganic filler, 1 part of hydrogen-containing silicone oil, 0.5 parts of inhibitor, 0.5 parts of extender adhesive. The vinyl silicone oil is vinyl-terminated polydimethylsiloxane, the mass content of vinyl is between 0.2%, and the viscosity is 30mPa·s. The polyvinyl si...

Embodiment 2

[0031]A low-viscosity, high-thermal-conduction silicone gel, the low-viscosity, high-thermal-conduction silicone gel consists of components A and B, wherein component A includes the following components in parts by mass: 100 parts of vinyl silicone oil, 20 parts of polyvinyl silicone oil, 20 parts of alkyl modified silicone oil, 25 parts of reactive diluent, 2500 parts of high thermal conductivity composite inorganic filler, 10 parts of catalyst and 10 parts of pigment, component B includes the following components by mass parts: 100 parts of vinyl silicone oil, 20 parts of polyvinyl silicone oil, 20 parts of alkyl modified silicone oil, 25 parts of reactive diluent, 2500 parts of high thermal conductivity compound inorganic filler, 20 parts of hydrogen-containing silicone oil, 10 parts of inhibitor, 10 parts of extender adhesive. The vinyl silicone oil is vinyl-terminated polydimethylsiloxane, polydimethyl-methylvinylsiloxane and polymethylphenyl-methylvinylsiloxane, and the ...

Embodiment 3

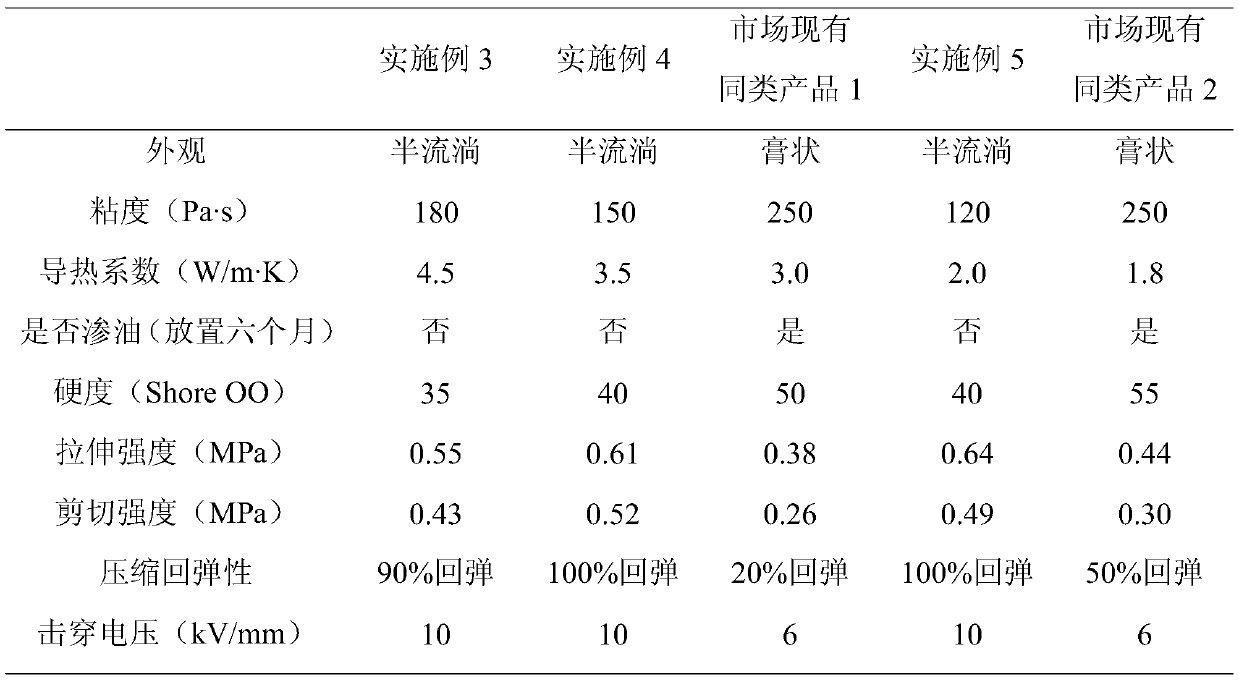

[0037] A low-viscosity, high-thermal-conductivity silicone gel, said low-viscosity, high-thermal-conduction silicone gel is composed of A component and B component, wherein A component includes: 70g of vinyl-terminated polydiethylene glycol with a viscosity of 50mPa·s Methylsiloxane, 30g viscosity is 250mPa·s vinyl-terminated polydimethyl-methylvinylsiloxane, 5g viscosity is 500mPa·s polyvinyl silicone oil, the polyvinyl silicone oil is methyl-terminated Terminal, side chain containing vinyl polysiloxane, 20g alkyl modified silicone oil, described alkyl modified silicone oil is long carbon chain alkyl grafted polydimethylsiloxane, 20g active diluent, described active The diluent is single-end vinyl polysiloxane, 2300g of high thermal conductivity composite inorganic filler treated with long-chain alkyl silane, the oil absorption value is 4%, which contains 1900g of spherical alumina (wherein the particle size is 100μm, accounting for 5%, 70μm accounts for 10%, 30μm accounts fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com