Method for manufacturing multi-scale structure aluminum/stannum-based bearing alloy

A technology of tin-based bearing alloy and manufacturing method, which is applied in the field of manufacturing multi-scale structure aluminum-tin-based bearing alloy, can solve problems such as sintering of Al-Sn alloy powder, achieve improved friction and wear performance, overcome limitations, and enhance mutual coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

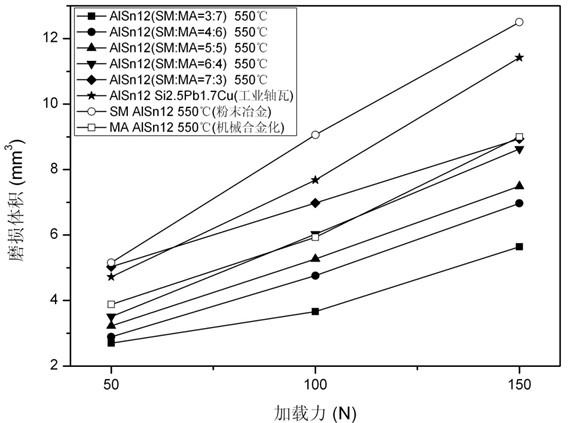

[0033] The above-mentioned MA powder and SM powder are prepared according to the mass ratio of 70wt%MA+30wt%SM, and then uniformly mixed to obtain a secondary mixed powder;

[0034] The above-mentioned secondary mixed powder is cold-pressed and formed into blocks by uniaxial pressing, and the pressing pressure is 300KN;

[0035] Vacuum 8×10- 3 Pa, and then heated to 100°C with argon gas and kept for 0.5 hours, then raised to 550°C and kept for 1 hour, then cooled with the furnace.

[0036] Example 2

[0037] The 88wt%Al and 12wt%Sn powders with a purity of 99.9% and a particle size of 200 mesh were ball milled under the protection of argon, the ball mill speed was 250rpm, the ball milling time was 40h, and the ball-to-material ratio was 15:1 to obtain Al-Sn alloy powder Body (MA powder);

Embodiment 2

[0039] The above MA powder and SM powder are uniformly mixed at a mass ratio of 60wt%MA+40wt%SM to obtain a secondary mixed powder;

[0040] The above-mentioned secondary mixed powder is cold-pressed and formed into blocks by uniaxial pressing, and the pressing pressure is 300KN;

[0041] Vacuum 8×10- 2 Pa, and then heated to 100°C with argon gas and kept for 0.5 hours, then raised to 550°C and kept for 1 hour, then cooled with the furnace.

[0042] Example 3

[0043] The 88wt%Al and 12wt%Sn powders with a purity of 99.9% and a particle size of 200 mesh were ball milled under the protection of argon, the ball mill speed was 250rpm, the ball milling time was 40h, and the ball-to-material ratio was 15:1 to obtain Al-Sn alloy powder Body (MA powder);

Embodiment 3

[0045] The above-mentioned MA powder and SM powder are prepared according to the mass ratio of 50%MA+50%SM, and then uniformly mixed to obtain a secondary mixed powder;

[0046] The above-mentioned secondary mixed powder is cold-pressed and formed into blocks by uniaxial pressing, and the pressing pressure is 300KN;

[0047] Vacuum 6×10- 2 Pa, and then heated to 100°C with argon gas and kept for 0.5 hours, then raised to 550°C and kept for 1 hour, then cooled with the furnace.

[0048] Example 4

[0049] The 88wt%Al and 12wt%Sn powders with a purity of 99.9% and a particle size of 200 mesh were ball milled under the protection of argon, the ball mill speed was 250rpm, the ball milling time was 40h, and the ball-to-material ratio was 15:1 to obtain Al-Sn alloy powder Body (MA powder);

PUM

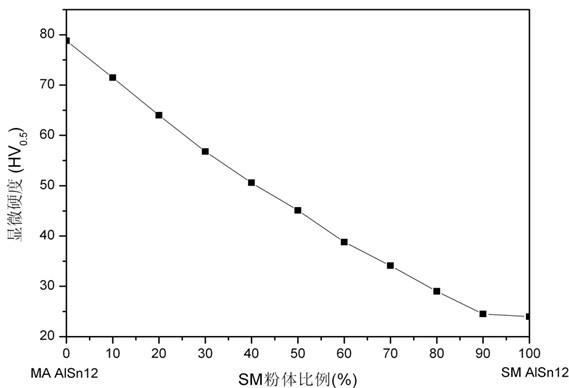

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com