UV curing resin, preparation method thereof and coating prepared therefrom

A technology of curing resin and curing coating, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficult control and unstable system, achieve high elasticity, increase internal crosslinking density, and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

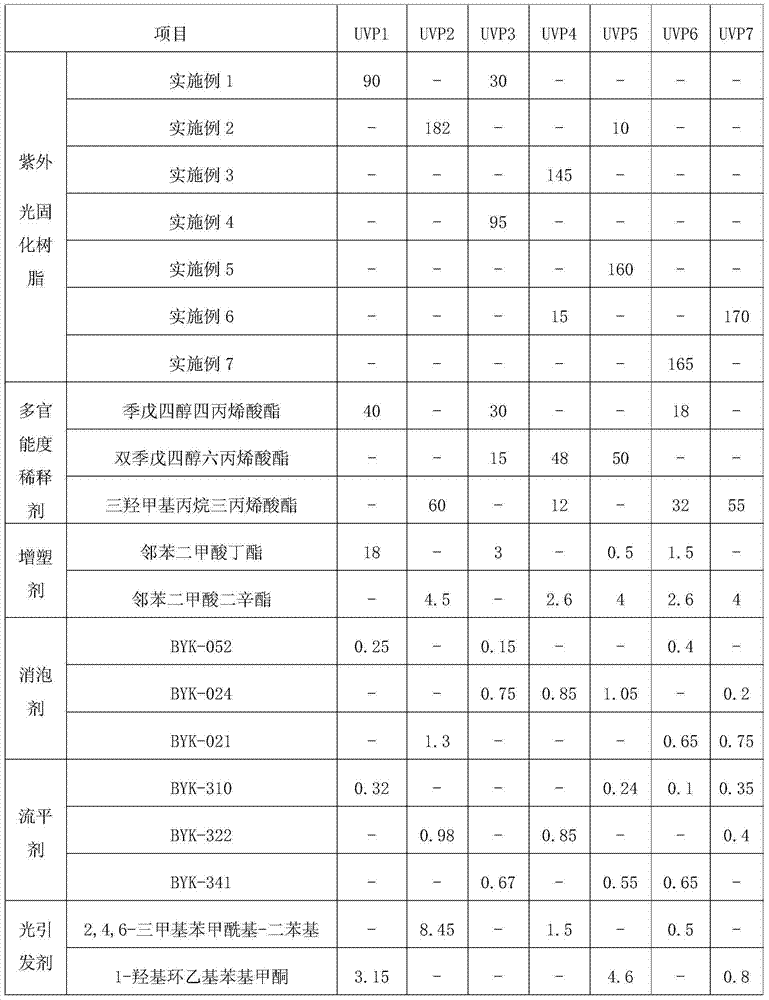

Examples

Embodiment 1

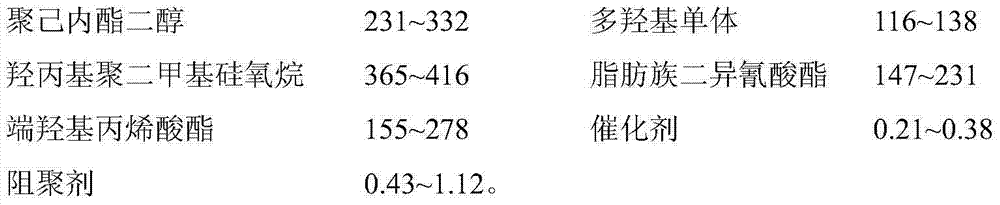

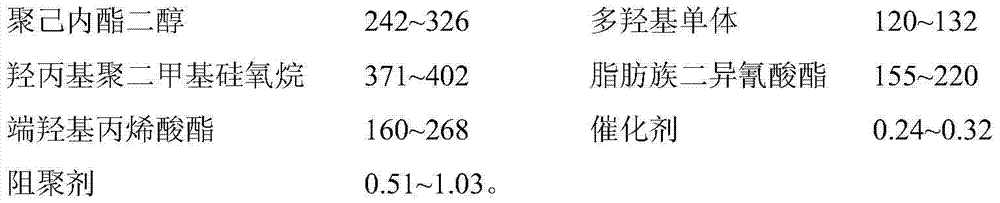

[0044] A UV curable resin. The raw materials include the following components in weight ratio: 231 grams of polycaprolactone diol with a molecular weight of 1500 Daltons, 116 grams of pentaerythritol, 147 grams of hexamethylene diisocyanate, and a molecular weight of 3500 Dalton's hydroxypropyl polydimethylsiloxane 365 grams, pentaerythritol triacrylate 173 grams, dibutyltin dilaurate 0.21 grams, and p-hydroxyanisole 0.43 grams.

[0045] The specific preparation steps are as follows:

[0046] The first step: the polycaprolactone diol and pentaerythritol are respectively dewatered at 110°C and 0.098MPa pressure for 1 hour;

[0047] Step 2: Put polycaprolactone diol and pentaerythritol into the reactor, control the temperature in the reactor at 70°C, add hexamethylene diisocyanate dropwise at a rate of 8 mL / min, and continue the reaction after the addition is complete 2 hours to obtain the first intermediate;

[0048] The third step: increase the temperature in the reactor to 75°C, add...

Embodiment 2

[0052] A UV-curable resin, based on the weight ratio, the raw materials include the following components: 332 grams of polycaprolactone diol with a molecular weight of 5000 Daltons, 138 grams of dipentaerythritol, 231 grams of isophorone diisocyanate, and a molecular weight of 416 grams of 6500 Dalton hydroxypropyl polydimethylsiloxane, 237 grams of dipentaerythritol pentaacrylate, 0.38 grams of stannous octoate, and 1.12 grams of hydroquinone.

[0053] The specific preparation steps are as follows:

[0054] The first step: the polycaprolactone diol and dipentaerythritol are respectively dewatered at 130°C and 0.098MPa pressure for 3 hours;

[0055] The second step: Put polycaprolactone diol and dipentaerythritol into the reactor, control the temperature in the reactor at 80°C, drip isophorone diisocyanate at a rate of 15 mL / min, and continue after the addition is complete React for 4.5 hours to obtain the first intermediate;

[0056] The third step: Raise the temperature in the reac...

Embodiment 3

[0060] A UV-curable resin, based on weight ratio, the raw materials include the following components: 256 grams of polycaprolactone diol with a molecular weight of 2000 Daltons, 128 grams of pentaerythritol, 4,4'-dicyclohexylmethane diisocyanate 163 Grams, 380 grams of hydroxypropyl polydimethylsiloxane with a molecular weight of 4000 Daltons, 248 grams of dipentaerythritol pentaacrylate, 0.26 grams of stannous octoate, and 0.65 grams of hydroquinone.

[0061] The specific preparation steps are as follows:

[0062] The first step: the polycaprolactone diol and pentaerythritol are respectively at 120°C and 0.098MPa pressure, and the water is removed under reduced pressure for 2 hours;

[0063] Step 2: Put polycaprolactone diol and pentaerythritol into the reactor, control the temperature in the reactor at 75°C, and add 4,4'-dicyclohexylmethane diisocyanate dropwise at a rate of 13mL / min. After the addition, the reaction is continued for 3 hours to obtain the first intermediate;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com