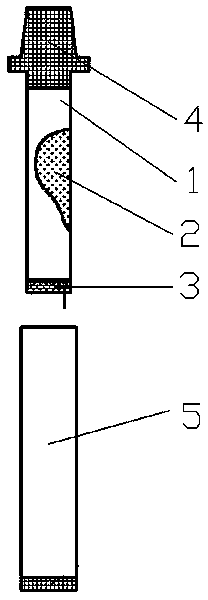

Electroless welding rod

A technology without electrode and flux, applied in welding equipment, welding medium, welding equipment and other directions, can solve the problems of high risk, complex welding flux composition, serious welding spatter, etc., to increase welding heat and improve welding slag removal. resistance, avoid the effect of slipping off the casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Drug tube size: diameter 12mm, length 130mm; welding flux formula: by mass percentage, CuO powder 58.0%, Al powder 18.0%, Si-Ca alloy powder 6.7%, CaF 2 Powder 5.8%, B powder 1.0%, Fe powder 9.5%, Mn powder 1.0%. Base material to be welded: Two Q235 steel plates of 70mm×30mm×3mm are butt welded on a flat plate; process parameters: welding inclination angle 80°, welding rod flame length about 6mm, welding speed 9mm / s; welding effect: weld shape is good, reaching single Double-sided forming effect of surface welding.

Embodiment 2

[0033] Drug tube size: diameter 12mm, length 140mm; welding flux formula: by mass percentage, CuO powder 62.0%, Al powder 15.5%, Si-Ca alloy powder 6.0%, CaF 2 Powder 6.3%, B powder 0.7%, Fe powder 9.0%, Mn powder 0.5%; base material to be welded: two Q235 steel plates of 70mm×30mm×5mm for flat butt welding; process parameters: welding inclination angle 80°, electrode flame length About 6mm, welding speed 8mm / s; Welding effect: The welding seam is well formed, achieving the effect of single-sided welding and double-sided forming.

Embodiment 3

[0035] Drug tube size: diameter 12.5mm, length 150mm; welding flux formula: by mass percentage, CuO powder 66.0%, Al powder 17.0%, Si-Ca alloy powder 5.0%, CaF 2 Powder 5.5%, B powder 0.8%, Fe powder 5.2%, Mn powder 0.5%; base material to be welded: two 70mm×30mm×3mm stainless steel plates for flat butt welding; process parameters: welding inclination angle 80°, electrode flame length About 6mm, welding speed 7mm / s; Welding effect: The welding seam is well formed, achieving the effect of single-sided welding and double-sided forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com