UV (Ultraviolent) deglossing paint and preparation method thereof

A matting paint and resin technology, applied in the field of coatings, can solve the problems of prone to blooming and uneven gloss of UV matting paint, and achieve the effects of hard hardness, no blooming in matting powder distribution, and uniform matting powder distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

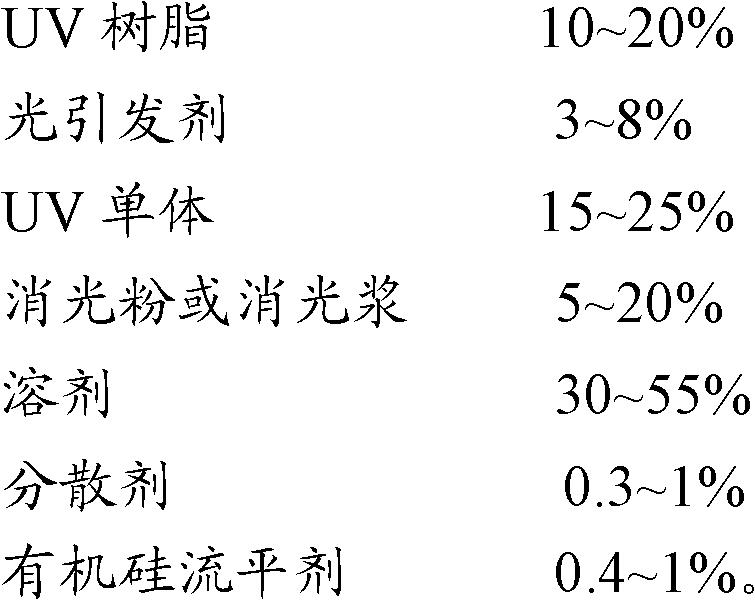

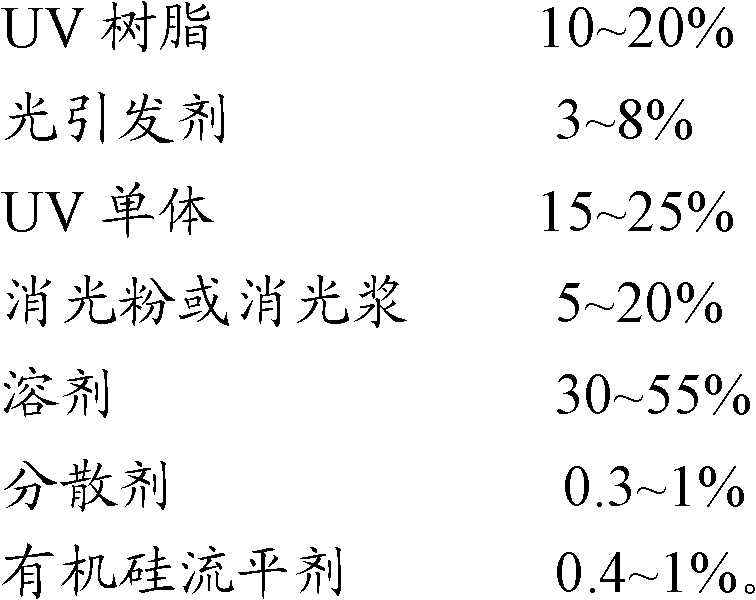

Method used

Image

Examples

Embodiment 1

[0020] 0.6kg of dispersant (BYK161), 5kg of photoinitiator (Changzhou Huati 1173), 0.4kg of silicone leveling agent (BYK333), 53kg of ethyl acetate, xylene, methyl isobutyl ketone, Add diisobutyl ketone mixed solvent (mass ratio 2:1:1.5:0.2) into the container, disperse evenly with a high-speed disperser, add 6 kg of matting powder (OK520) during high-speed dispersion, and disperse evenly until the fineness is less than 25 μm. Add 15kg epoxy acrylate (Changxing, Taiwan) and 20kg EOTMPTA (Changxing, Taiwan), and disperse evenly at a high speed to obtain a matte coating.

[0021] The paint is sprayed on the black ABS substrate, the test gloss is less than 2 (60° gloss meter), and the paint film is uniform in color by visual inspection, and there is no Bernard vortex.

[0022] After the paint is sprayed on the glass sheet and UV cured, the glossiness is less than 2 (60° gloss meter), and the glass sheet is visually inspected, and there is no uneven gloss, and the paint film is sm...

Embodiment 2

[0024] 0.5kg of dispersant (BYK111), 5kg of photoinitiator (Changzhou Huati 184), 0.5kg of silicone leveling agent (BYK333), 51kg of ethyl acetate, xylene, methyl isobutyl ketone, Diisobutyl ketone mixed solvent (mass ratio: 2:1:1.5:0.2) is added to the container, and dispersed evenly with a high-speed disperser. During high-speed dispersion, 8kg of matting powder (OK607) is added to disperse evenly until the fineness is less than 25 μm. Finally, add 17kg epoxy acrylate (Changxing, Taiwan) and 18kg EOTMPTA (Changxing, Taiwan), and disperse evenly at a high speed to obtain a matte coating.

[0025] The paint is sprayed on the black ABS substrate, the test gloss is less than 1 (60° gloss meter), and the paint film is uniform in color and without Bernard vortex.

[0026] After the paint is sprayed on the glass sheet and UV cured, the glossiness is less than 2 (60° gloss meter), and the glass sheet is visually inspected, and there is no uneven gloss, and the paint film is smooth. ...

Embodiment 3

[0028] Mix 0.6kg of dispersant (BYK161), 5kg of photoinitiator (Changzhou Huati 184), 0.5kg of leveling agent (BYK333), 52.9kg of ethyl acetate, xylene, methyl isobutyl ketone, di Add mixed solvent of isobutyl ketone (mass ratio 2:0.5:2:0.5) into the container, and disperse evenly with a high-speed disperser. Add 6kg of matting powder (OK520) during high-speed dispersion, and disperse evenly until the fineness is less than 25 μm. Add 10kg of epoxy acrylate (Taiwan Changxing), 25kg of Taiwan Changxing EOTMPTA and TMPTA (mass ratio 1:1), and disperse evenly at a high speed to obtain a matte coating.

[0029] The paint is sprayed on the black ABS substrate, the test gloss is less than 1 (60° gloss meter), and the paint film is uniform in color and without Bernard vortex.

[0030] After the paint is sprayed on the glass sheet and UV cured, the glossiness is less than 2 (60° gloss meter), and the glass sheet is visually inspected, and there is no uneven gloss, and the paint film is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com