Medicinal implant and preparation method thereof

An implant and medical technology, which is applied in the field of medical coating materials and its preparation, can solve the problems of high price, complicated process, and low production efficiency, and achieve the effects of low cost, simple preparation process, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

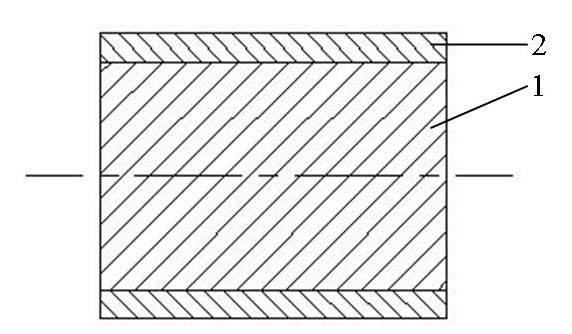

[0024] figure 1 It is a structural schematic diagram of Embodiment 1 of the medical implant of the present invention. From figure 1 It can be seen from the figure that in the structure of the medical implant of the present invention, the implant 1 is made of 1Cr18Ni9Ti stainless steel base material, and the implant 1 and the tantalum coating 2 are closely combined. The shape of the implant 1 in the figure should be adapted to the shape of the human bone at the implant site. In this embodiment, the structure of the implant 1 is represented by a cylinder, and the shape of the tantalum coating 2 is also consistent with the shape of the implant 1. same.

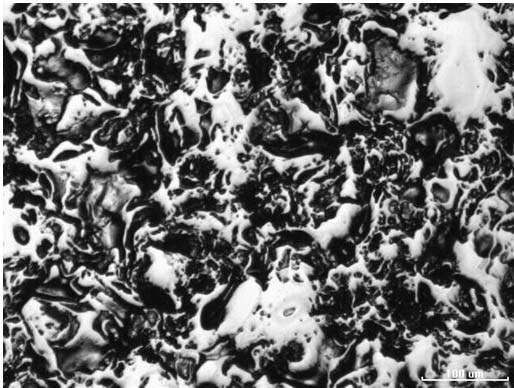

[0025] figure 2 It is a cross-sectional metallographic photograph of the tantalum coating in Example 1 of the medical implant of the present invention, in which the black parts in the figure are pores, and the white parts are the tantalum coating. Use alumina (white corundum) with a particle size of 1165 mm to sandblast the ...

Embodiment 2

[0032] Using the same tantalum powder raw material, sand blasting treatment and spraying process parameters as in Example 1, a tantalum coating with a porosity volume percentage of 48% can also be obtained on the titanium substrate, and the thickness of the tantalum coating can reach 0.1-2.0 mm. The tensile bonding strength and roughness test results of the coating are shown in Table 2.

[0033] Table 2 Coating performance test results*

[0034]

[0035] *Measurement conditions for tensile bond strength and roughness are the same as those in Table 1

[0036] **The coating did not break within the test limits of the universal testing machine.

Embodiment 3

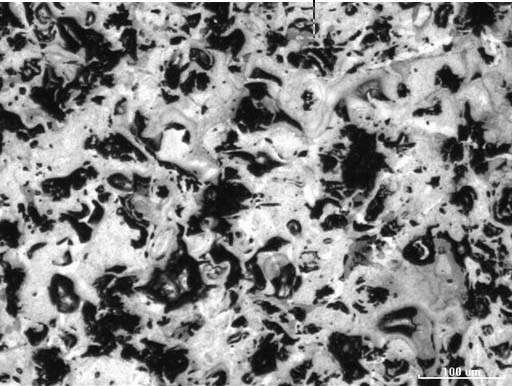

[0038] image 3 It is a cross-sectional metallographic photograph of the tantalum coating in Example 3 of the medical implant of the present invention, the black parts in the figure are pores, and the white parts are tantalum coatings. Using the same sandblasting pretreatment and tantalum powder raw materials as in Example 3, with argon as the main gas and hydrogen as the auxiliary gas, the atmospheric plasma spraying process parameters are adopted: plasma arc voltage 50 V, current 720 A, powder feeding rate 45 g / min, the spraying distance is 150 mm, and a tantalum coating with a porosity volume percentage of 32% can be obtained; through the same multiple intermittent spraying, the thickness of the tantalum coating can also reach 0.1-2.0 mm, and the tensile strength of the coating can be combined See Table 3 for test results for strength and roughness.

[0039] Table 3 Coating performance test results*

[0040]

[0041]*Measurement conditions for tensile bond strength an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com