Acidic and transparent silicone weather-resistant sealant for construction

A construction and sealant technology, applied in the direction of adhesives, adhesive additives, dyed low-molecular-weight organic compounds, etc. The problem of harsh glue environment, etc., can achieve the effect of broadening the wavelength of absorbed light, reducing the influence of external humidity and temperature, and improving the conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

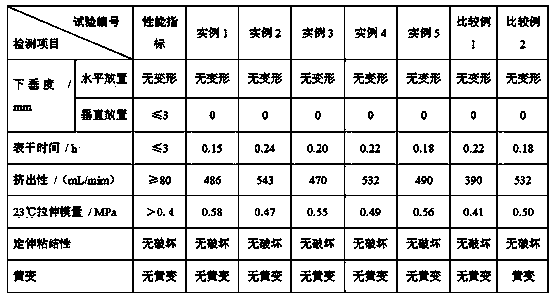

Examples

example 1

[0022] Hydroxyl-terminated polydimethylsiloxane 80000 mPa·s: 25 parts

[0023] Hydroxyl-terminated polydimethylsiloxane 200000 mPa·s: 25 parts

[0024] Methyl-terminated polydimethylsiloxane 500 mPa·s: 20 parts

[0025] Modified fumed silica 150 m 2 / g: 10 parts

[0026] Methyltriacetoxysilane: 5 parts

[0027] Dibutyltin diacetate: 0.05 parts

[0028] 2,3-dihydroxy-4-n-decyloxybenzophenone: 0.04 parts

[0029] Tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite: 0.01 parts

[0030] The preparation method of the modified fumed silica is as follows: (1) firstly carry out a coupling modification treatment on the surface of fumed silica with vinyl tris (β-methoxyethoxy) silane; (2 ) The primary modified silica and vinyl silicone oil are subjected to secondary coating and grafting modification under peroxide conditions.

[0031] The above-mentioned acidic transparent silicone weather-resistant sealant for construction is prepared by the following steps: (1) adding hydroxyl-ter...

example 2

[0033] Hydroxyl-terminated polydimethylsiloxane 10000 mPa·s: 50 parts

[0034] Hydroxyl-terminated polydimethylsiloxane 1000000 mPa·s: 100 parts

[0035] Methyl-terminated polydimethylsiloxane 1000 mPa s: 140 parts

[0036] Modified fumed silica 400 m 2 / g: 60 parts

[0037] Methyltriacetoxysilane: 25 parts

[0038] Ethyltriacetoxysilane: 10 parts

[0039] Propyltriacetoxysilane: 5 parts

[0040] Dibutyltin dilaurate: 0.5 parts

[0041] 2,3-dihydroxy-4-n-decyloxybenzophenone: 0.1 parts

[0042] Tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite: 0.4 parts

[0043] The above raw materials were uniformly mixed according to the method of Example 1 to prepare an acidic transparent silicone weather-resistant sealant.

example 3

[0045] Hydroxyl-terminated polydimethylsiloxane 10000 mPa·s: 10 parts

[0046] Hydroxyl-terminated polydimethylsiloxane 400000 mPa·s: 90 parts

[0047] Methyl-terminated polydimethylsiloxane 100 mPa·s: 50 parts

[0048] Modified fumed silica 200 m 2 / g: 25 servings

[0049] Ethyltriacetoxysilane: 15 parts

[0050] Dibutyltin dilaurate: 0.1 part

[0051] Dioctyltin dilaurate: 0.1 parts

[0052] 2,3-dihydroxy-4-n-decyloxybenzophenone: 0.1 parts

[0053] Tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite: 0.1 parts

[0054]The above raw materials were uniformly mixed according to the method of Example 1 to prepare an acidic transparent silicone weather-resistant sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com