Fabricated building damping structure

A prefabricated, shock-absorbing mechanism technology, applied in building components, buildings, protective buildings/shelters, etc., can solve the problems of not meeting the needs of modern use, single shock-absorbing mechanism, limited shock-absorbing effect, etc. Strong practicability, good shock absorption effect, ensuring the effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

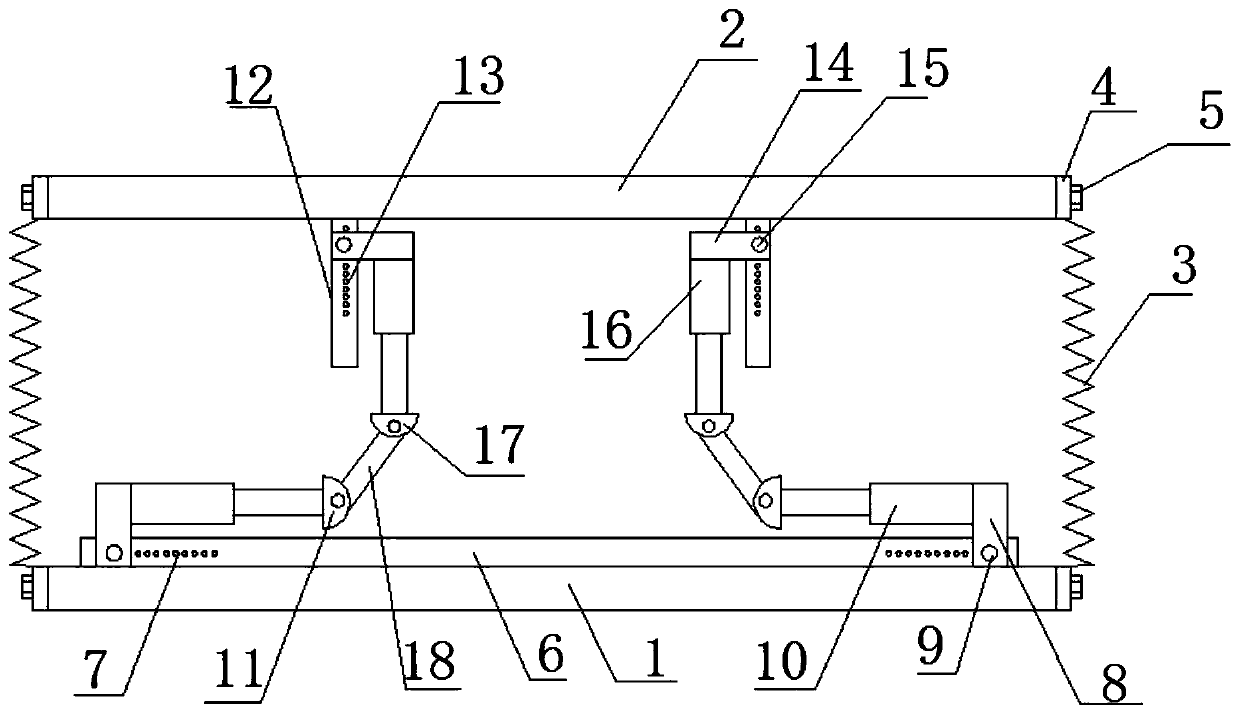

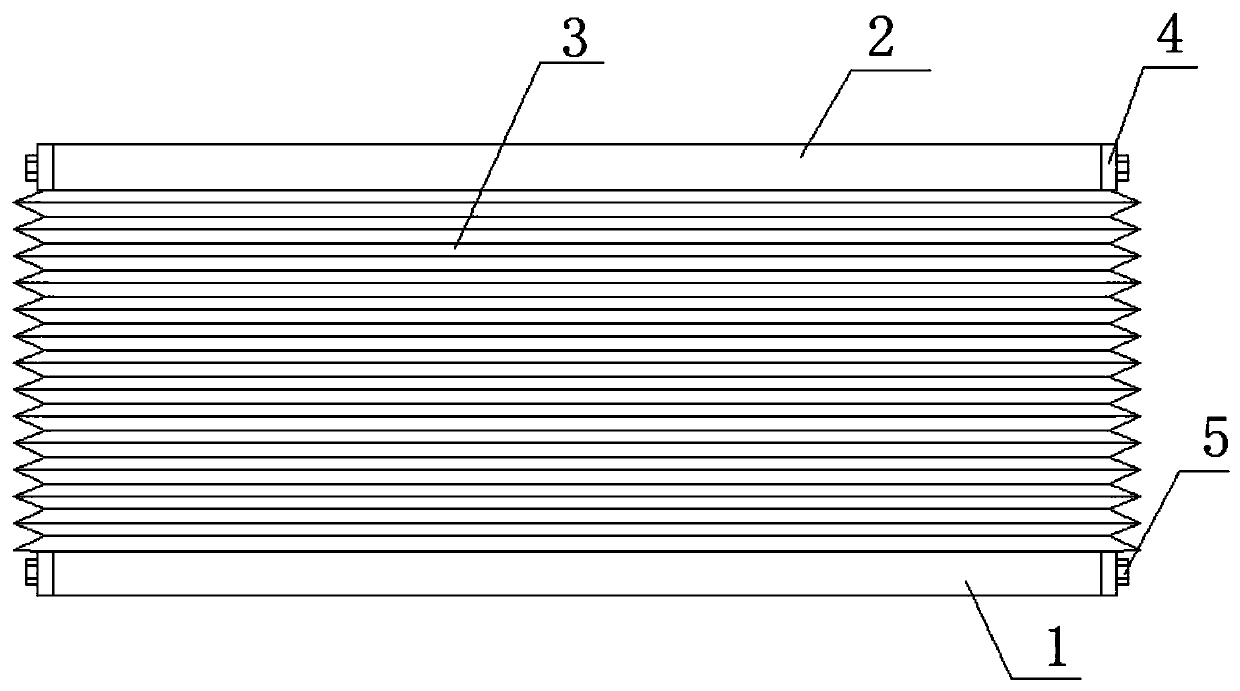

[0023] see Figure 1-3 , in an embodiment of the present invention, a prefabricated building shock absorbing structure includes a base 1, a support base 2 and a protective cover 3, the support base 2 is arranged above the base 1, and the upper and lower ends of the protective cover 3 are respectively Connected with the base 1 and the support base 2, the upper and lower ends of the protective cover 3 are provided with mounting bases 4, the mounting base 4 is connected with the base 1 and the support base 2 through mounting bolts 5, the upper part of the base 1 A first adjusting rod 6 is arranged on the side, and a plurality of first adjusting holes 7 are provided symmetrically on the first adjusting rod 6, and a first adjusting plate 8 is arranged symmetrically on the first adjusting rod 7. The adjustment plate 8 is connected with the first adjustment rod 6 through the cooperation of the first adjustment bolt 9 and the first adjustment hole 7, and the first adjustment plate 8 i...

Embodiment 2

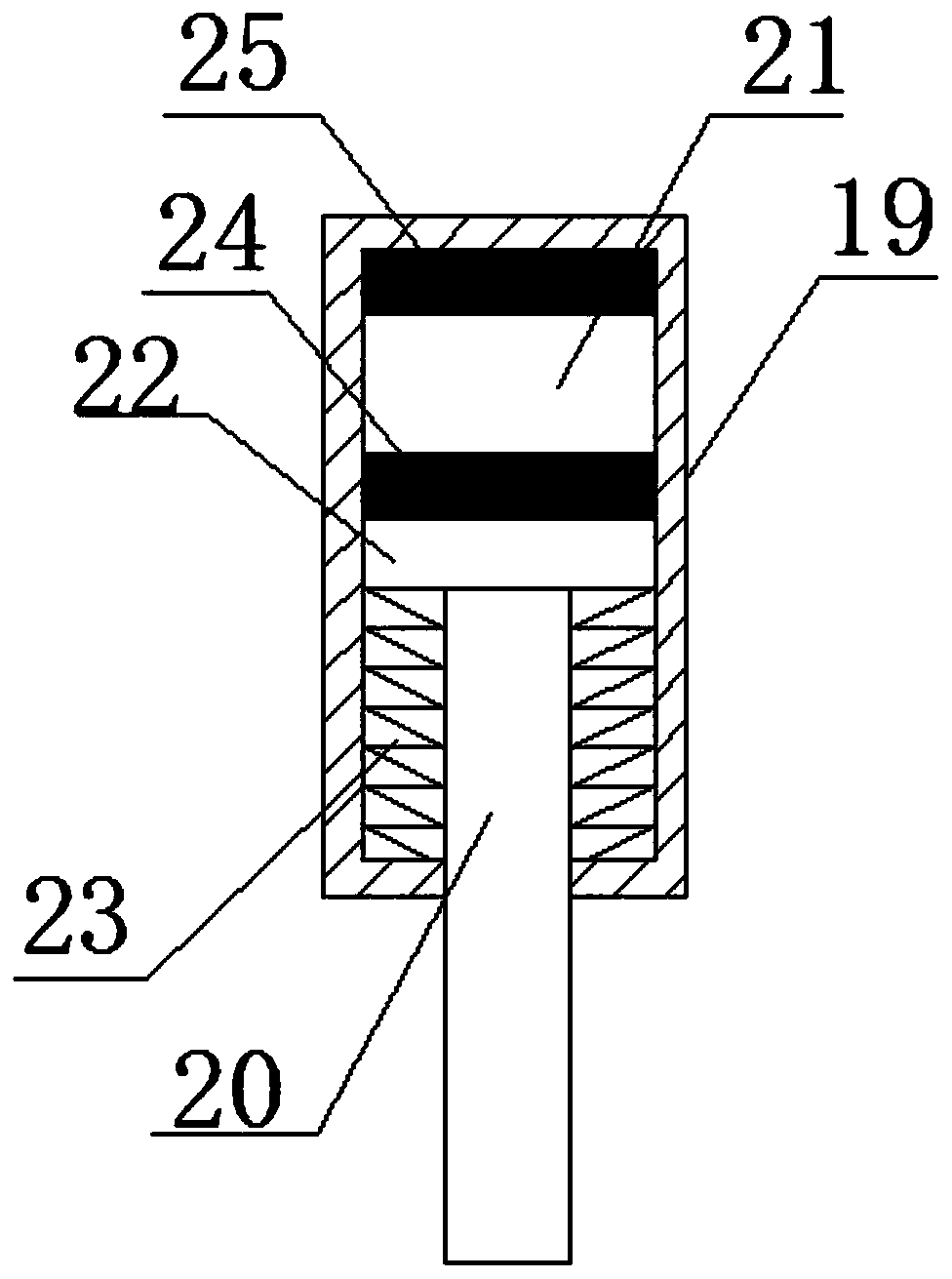

[0027] Both the first shock absorbing mechanism 10 and the second shock absorbing mechanism 16 include a support column 19 and a telescopic column 20, the inside of the support column 20 is provided with a shock absorber chamber 21, and the inside of the shock absorber chamber 21 is provided with a shock absorber. Shock plate 22, the telescopic column 19 stretches into the shock absorbing cavity 21 and is connected with the shock absorbing plate 22, and the lower side of the shock absorbing plate 22 is provided with some shock absorbing springs 23, and the other end of the shock absorbing spring 23 is connected with the shock absorbing plate 22. Cavity 21 is connected, and the upper side of damping plate 22 is provided with lower magnet plate 24, and the inner upper end of shock absorbing cavity 21 is provided with upper magnet plate 25, and the magnetic poles of the opposite surface of described lower magnet plate 24 and upper magnet plate 25 are identical. The arrangement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com