Aqueous nano zirconia particle paint and method for preparing paint film thereof

A technology of nano-zirconia and particles, applied in the direction of coating, etc., can solve the problems of mismatched surface properties, poor transparency, and low ZrO2 content, and achieve the effects of good environmental protection, good transparency, and outstanding mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

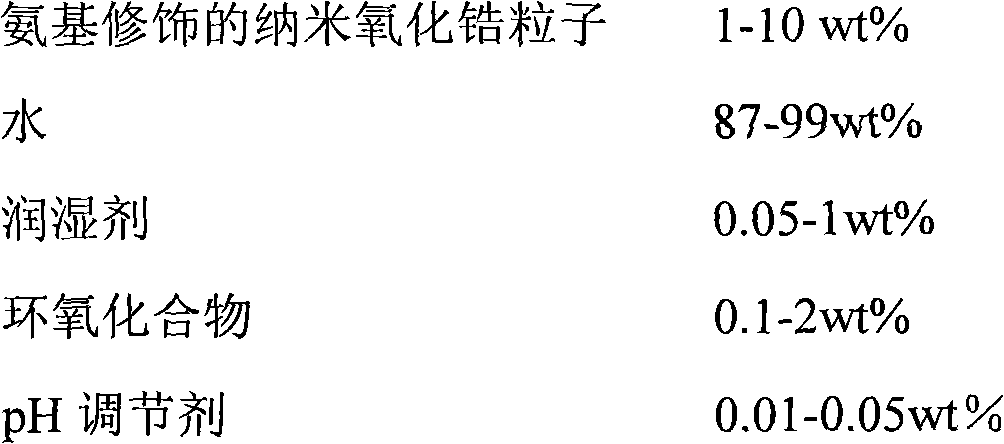

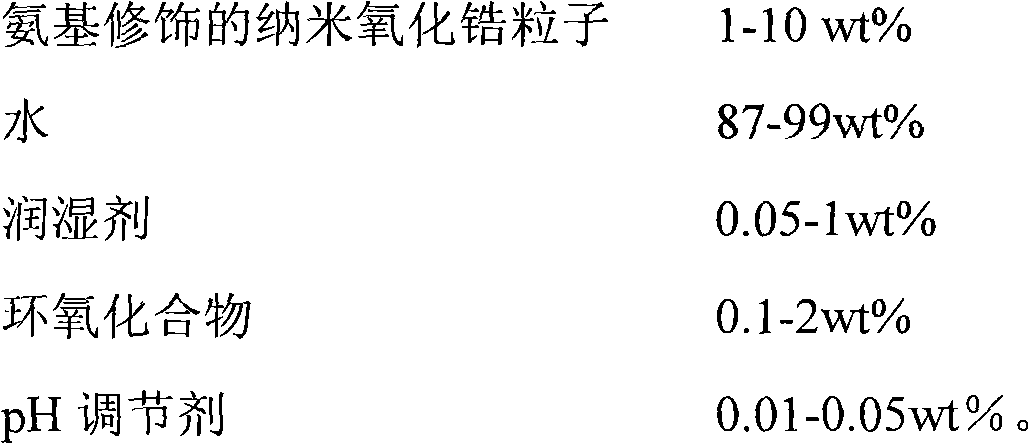

Method used

Image

Examples

Embodiment 1

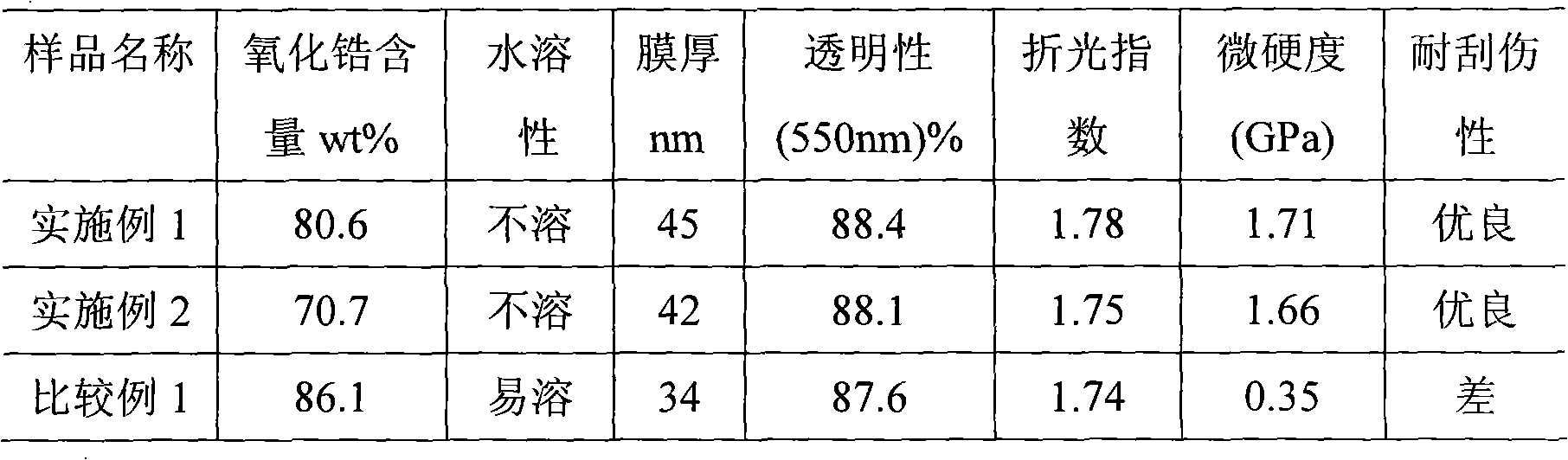

[0025] 0.1g nanometer ZrO 2 Particles, 0.03g of γ-aminopropyltriethoxysilane, and 10g of tetrahydrofuran are added to the reactor, ultrasonicated for 5-50 minutes, and reacted at 50-80°C for 12-24 hours to obtain a cloudy solution. The turbid liquid is washed, centrifuged, and separated, then transferred to an aqueous solution with a pH value of 13.5, and a transparent dispersion can be obtained after ultrasonication for 5-30 minutes. Nano ZrO 2 The amount of organic amino groups grafted on the particle surface is 125mg / g-ZrO 2, further add 1,4-butanediol diglycidyl ether 11.5mg, wetting agent FOS-110 aqueous solution (concentration is 5wt%) 0.1g, obtain aqueous nanometer ZrO 2 coating. Apply the above coating on the polycarbonate substrate by dip coating, the dip coating rate is 50mm / min, dry at room temperature for 0.5-2.0 hours and then heat at 120°C for 1 hour to obtain cross-linked and cured nano-ZrO 2 granular film. The coating properties are shown in Table 1.

Embodiment 2

[0027] 0.1g nanometer ZrO 2 Particles, 0.04g of N-β-aminoethyl-γ-aminopropyltriethoxysilane, and 10g of tetrahydrofuran are added to the reactor, ultrasonicated for 5-50 minutes, and reacted at 50-80°C for 12-24 hours to obtain a cloudy solution. After washing, centrifuging and separating the turbid solution, transfer it to a strong alkaline aqueous solution with a pH value of 13.5, and obtain a transparent dispersion after ultrasonication for 5-30 minutes. Nano ZrO 2 The amount of organic amino groups grafted on the particle surface is 162mg / g-ZrO 2 , further add 1,6-hexanediol diglycidyl ether 25.2mg, add wetting agent FOS-110 aqueous solution (concentration is 5wt%) 0.1g, obtain aqueous nanometer ZrO 2 coating. Apply the above coating on the polycarbonate substrate by dip coating, the dip coating rate is 100mm / min, dry at room temperature for 0.5-2.0 hours, and then heat at 110°C for 2 hours to obtain nano-ZrO 2 granular film. The coating properties are shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com