All-weather variable-working-condition compensating type high-low-temperature environment simulating test chamber

A technology of environmental simulation test and changing working conditions, applied in laboratory appliances, heating or cooling equipment, shells or chambers, etc., can solve problems such as high investment cost, complex control system, damage, etc., to achieve stable working performance and control. The effect of high precision and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

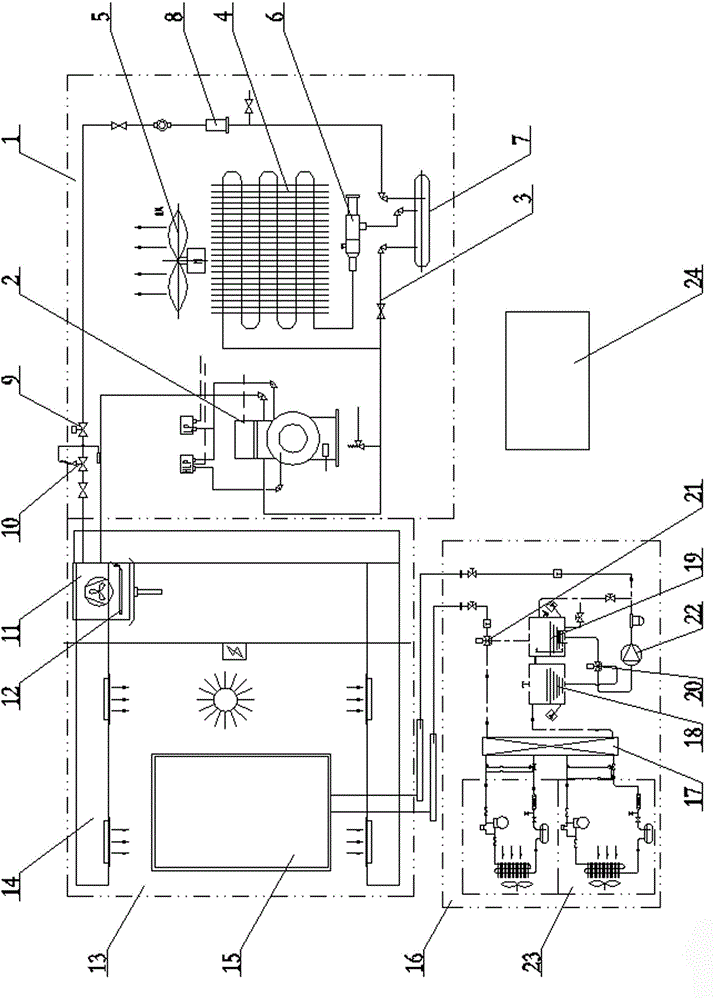

[0017] Further description will be made below in conjunction with the accompanying drawings.

[0018] figure 1 As shown, an all-weather variable working condition compensation type high and low temperature environmental simulation test box includes an environmental climate simulation cabin 13, an air-cooled refrigeration device 1, a liquid cooling source device 16, and a console 24. The inner wall of the environmental climate simulation box 13 is provided with a flow equalizer The air supply device 14, the equipment under test 15 are arranged in the environmental climate simulation box 13, and the environmental climate simulation box is provided with a call button, and the air-cooled refrigeration device 1 includes a compressor 2, a balance pipe 3, an air-cooled condenser 4, and a cooling fan 5. Condensing pressure regulating valve 6, liquid reservoir 7, dry filter 8, solenoid valve 9, expansion valve 10 and air cooler 11, the exhaust port of compressor 2 is connected to liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com