Preparation method of carbon-ceramic friction material

A technology of friction materials and carbon ceramics, which is applied in the direction of friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve problems that cannot meet the working conditions of amphibious aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a carbon-ceramic friction material, comprising the following steps:

[0036] A) Using propylene as the carbon source and nitrogen as the dilution gas, the C / C preform is densified by chemical vapor deposition, and then subjected to graphitization heat treatment to obtain the C / C matrix;

[0037] B) immersing the C / C matrix in the impregnation solution, impregnating it under vacuum conditions, and then performing heat curing, high temperature carbonization treatment and graphitization treatment in sequence to obtain the C / C porous matrix;

[0038] C) processing several grooves on the friction surface of the C / C porous matrix;

[0039] D) performing siliconization on the processed C / C porous substrate obtained in step C) by embedding infiltration process to obtain a siliconized substrate;

[0040] E) immersing the siliconized substrate into the coating solution to impregnate the coating, and then raise the temperature to perf...

Embodiment 1

[0076] Step 1 Preparation of C / C preform

[0077] The carbon content of the untwisted PAN carbon fiber should not be less than 92%. The prefabricated body adopts a layer of PAN carbon fiber non-weft cloth and a layer of carbon fiber thin mesh tires alternately laid, that is, 1.X+1.Y method of continuous needle punching, and the non-weft cloth is 0° / 90° / 270 ° Angle layup. The interlayer density is 15±1 layer / cm; the acupuncture row distance and spacing are ≤2mm; the acupuncture density is controlled at 20-25 needles / cm 2 within range. Ratio of long fiber without weft cloth to thin mesh tire: long fiber without weft cloth 75±2%, thin mesh tire 25±2%. Preform bulk density: 0.60±0.02g / cm 3 .

[0078] Step 2 Preparation of C / C matrix

[0079] Perform CVD densification on the preform in step 1, using propylene gas as the carbon source and nitrogen as the dilution gas. During CVD, control the furnace pressure to 1.0KPa and temperature to 980°C; the volume ratio of propylene gas...

Embodiment 2

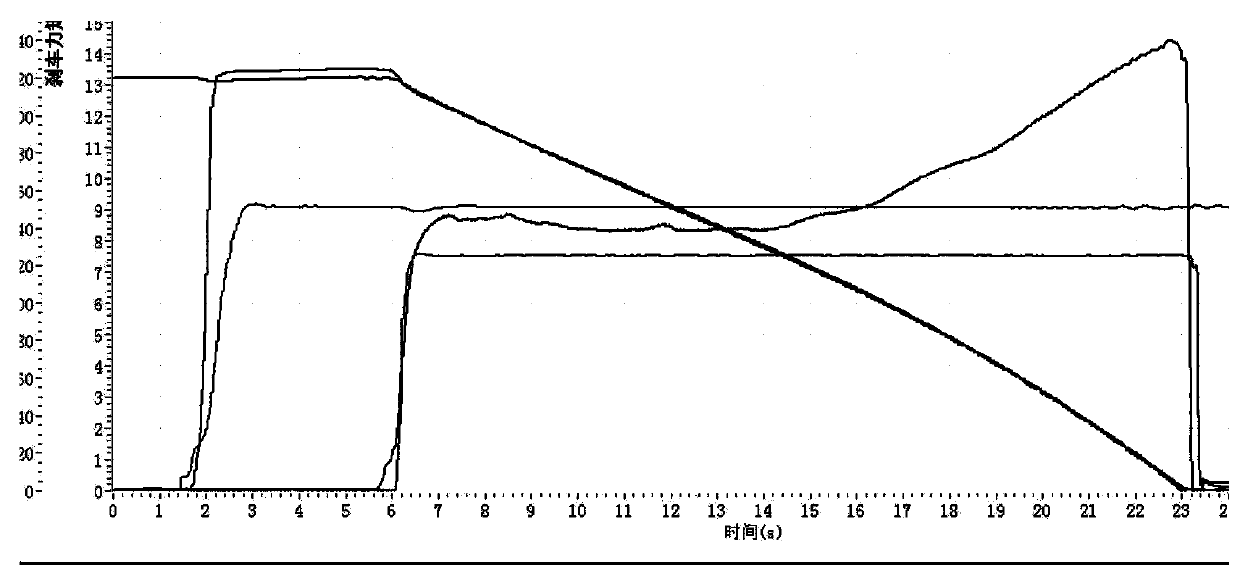

[0096] The C / SiC brake disc was prepared according to the method in Example 1, except that in this example, three grooves were made for each brake disc of the brake pair.

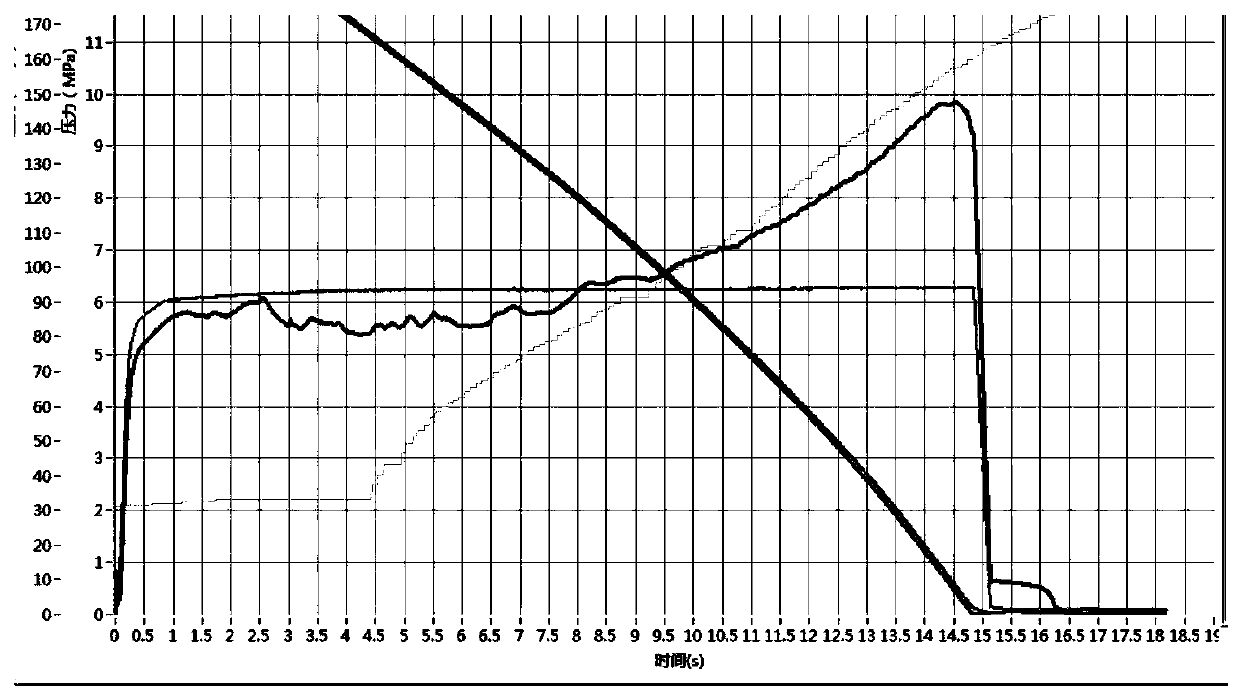

[0097] The braking curve with 3 grooves in this embodiment is not significantly different from the braking curve with 6 grooves in Embodiment 1, and the wet braking performance does not attenuate or attenuates less than 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com