High-power thick rod fuel element simulation device

A fuel element and simulation device technology, applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems that simulation components are not suitable for pool reactor fuel element simulation devices, so as to alleviate flow instability, volume increase, prevent burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

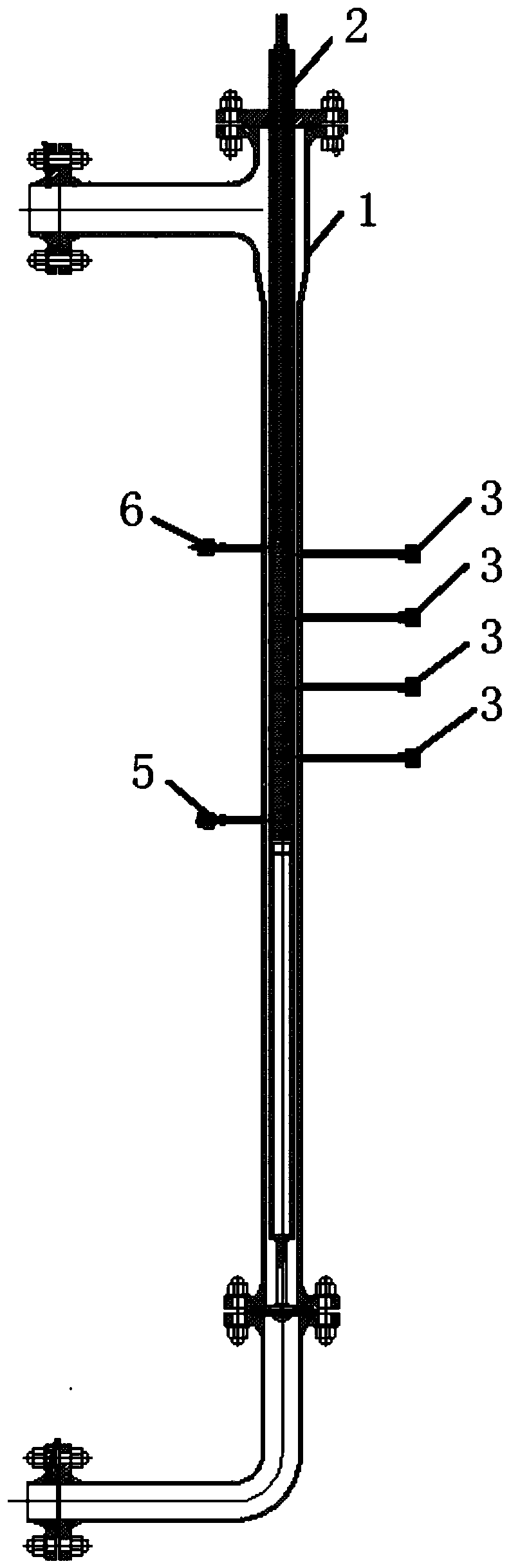

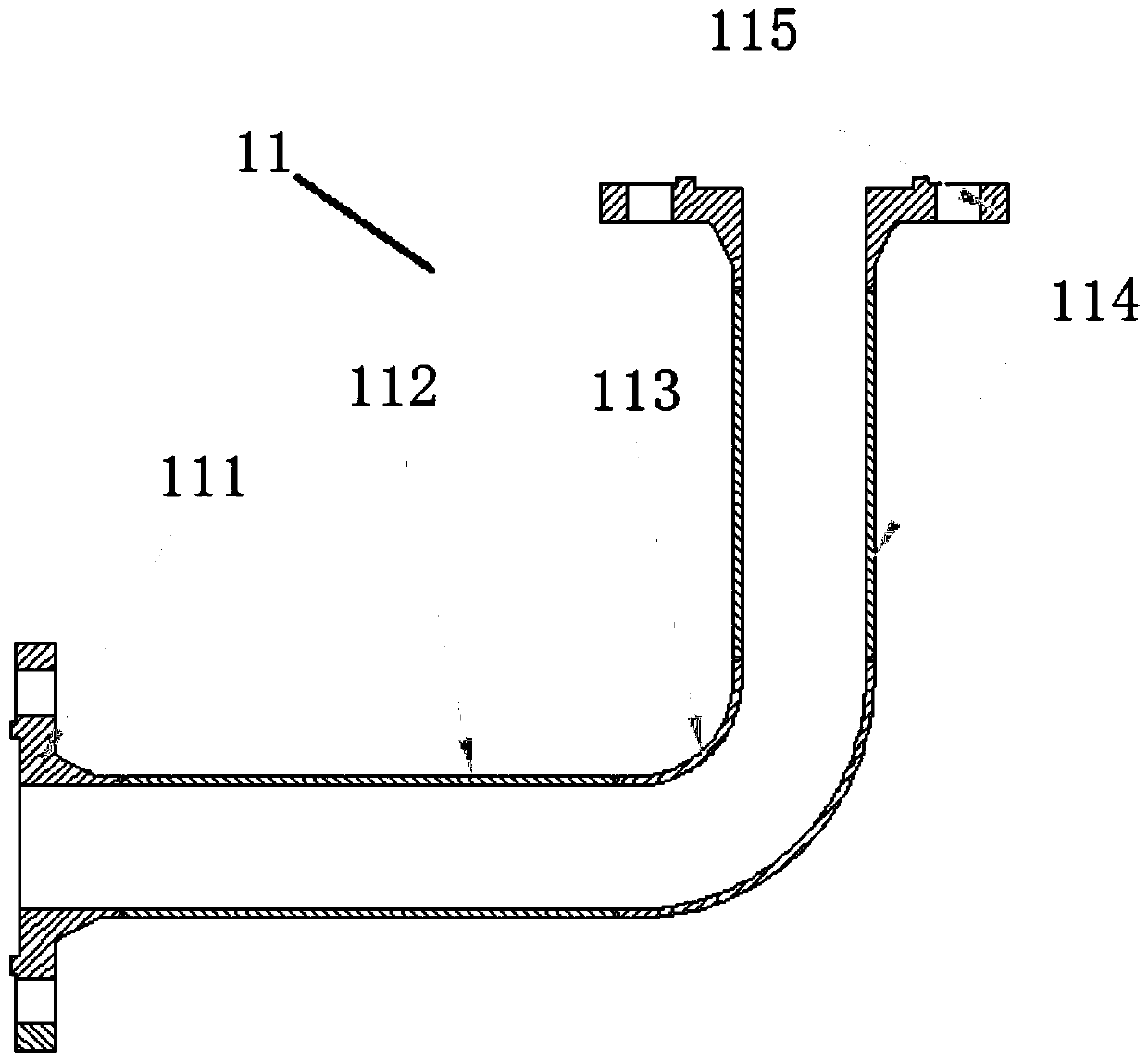

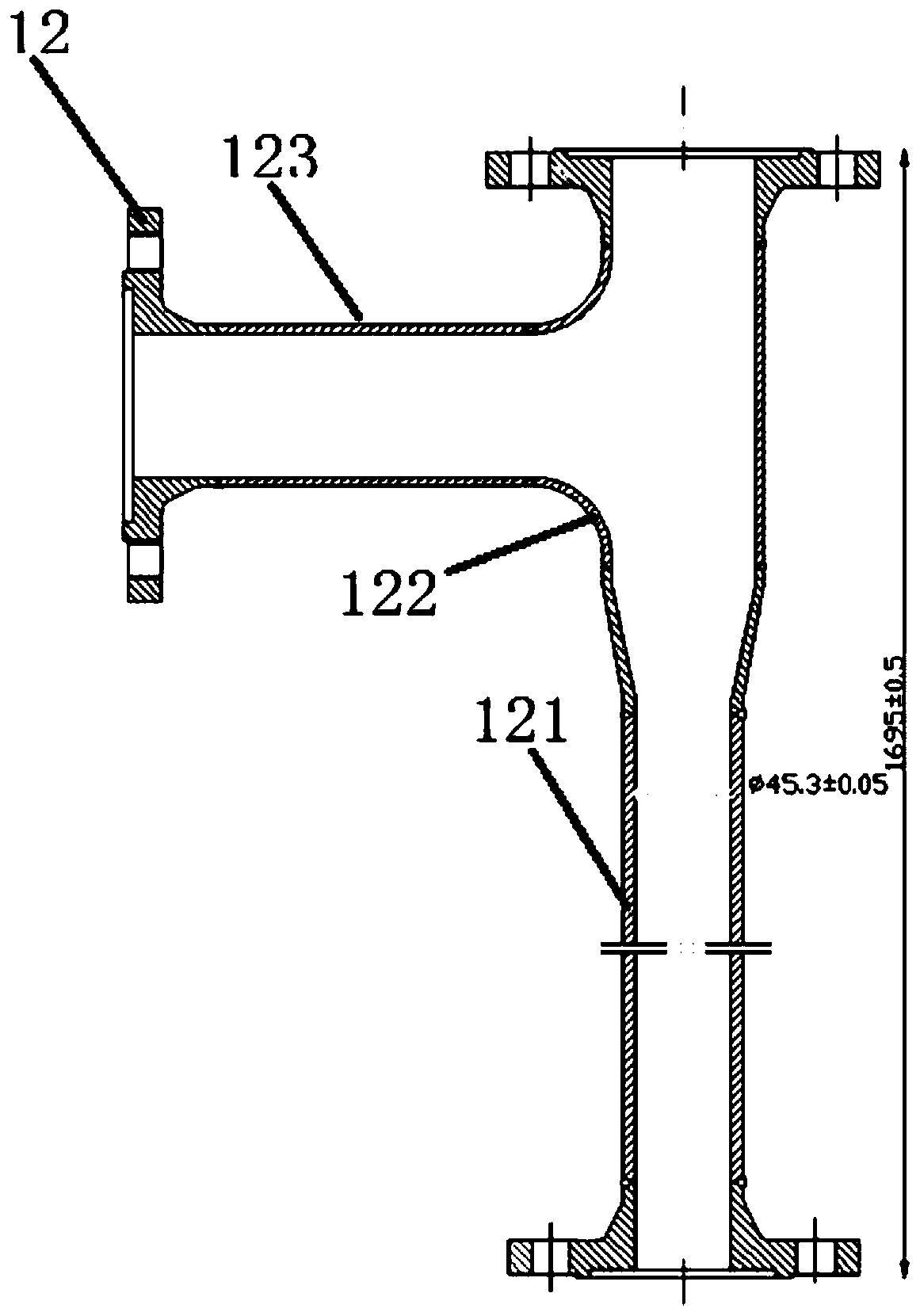

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0042] The core heat source is to generate energy through the fission of nuclear fuel. Usually, the critical heat flux experiment uses electric heating to simulate the heating of the fuel element, and the size of the heating part of the simulated element should be consistent with the size of the heating part of the pool reactor fuel element.

[0043] The experimental working conditions must be consistent with the operating conditions of the pool reactor, that is, to meet the requirements of natural circulation, and the core inlet pressure is 0.16MPa. In order to meet the requirements of the critical heat flux experiment, the power of the simulation device must reach a predetermined value, and the size and characteristics of the selected simulation components must be determined according to the power requirements.

[0044] In the critical heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Effective length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com