High-performance single-clack dual-seal pneumatic adjusting valve for nuclear power

A pneumatic regulating valve, a high-performance technology, applied in the direction of shaft sealing, valve lift, valve details, etc., can solve the problems of unsuitable nuclear power unit opening or closing control, large damage, large opening and closing torque of the regulating valve, etc., to achieve operating torque Small size, long service life, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

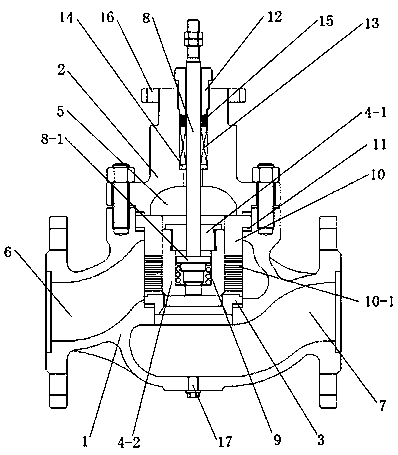

[0015] Such as Figure 1-2 As shown, a high-performance single-plate double-sealed pneumatic regulating valve for nuclear power includes a valve body 1, a valve cover 2, a valve seat 3, and a valve clack assembly 4. The valve cover 2 is installed on the valve body 1 to form a valve cavity 5. Both ends of the valve body 1 are respectively provided with an inlet 6 and an outlet 7. The inlet 6 communicates with the upper part of the valve cavity 5, the outlet 7 communicates with the bottom of the valve cavity 5, and the valve seat 3 is horizontally arranged in the valve cavity 5 and is detachable from the valve body 1. Connected, located at the junction of the outlet 7 and the valve cavity 5. The valve disc assembly 4 is arranged on the valve seat 3, and the valve core shaft 8 drives it to move up and down in the valve cavity 5 to open or close the valve; the disc assembly 4 includes The disc 4-1 is opposite to the valve seat 3, the disc 4-1 is opposite to the valve seat 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com