Method for coating asbestos-graphite seal coating on surface of titanium alloy parts

A technology of sealing coating and titanium alloy, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve problems such as low bonding strength and affecting product delivery cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The surface of an aero-engine titanium alloy gas seal ring is sealed with hand-coated graphite coating. The drawing requires the coating thickness to be 1.1mm, and the bonding strength of the asbestos-graphite sealing coating is required to be above 1MPa, which is well bonded to the surface of the titanium alloy.

[0052] Implementation process

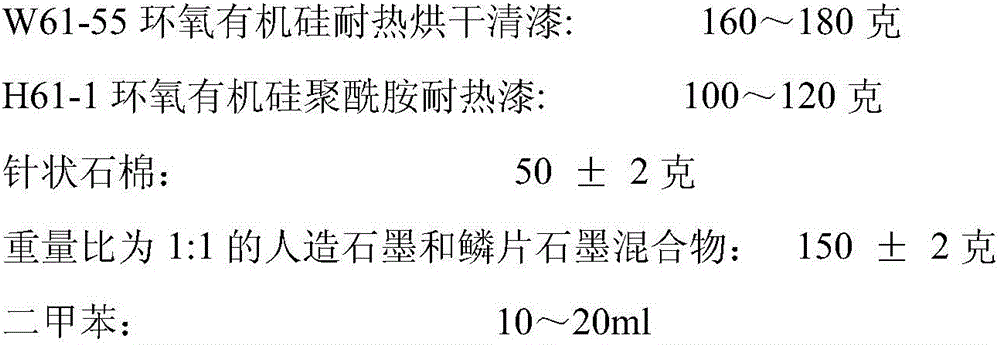

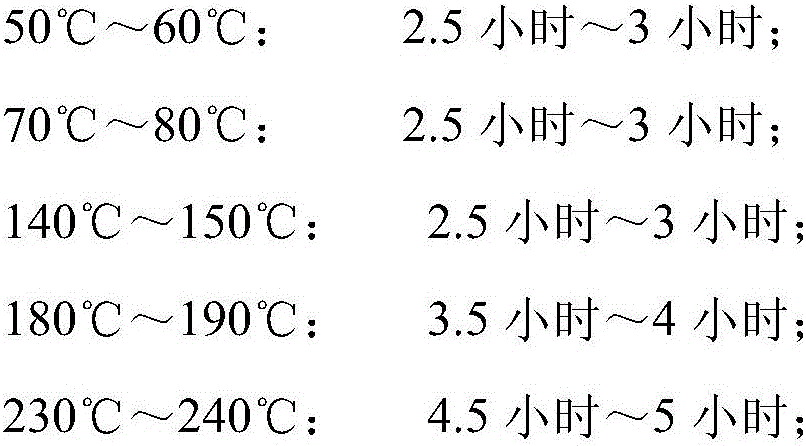

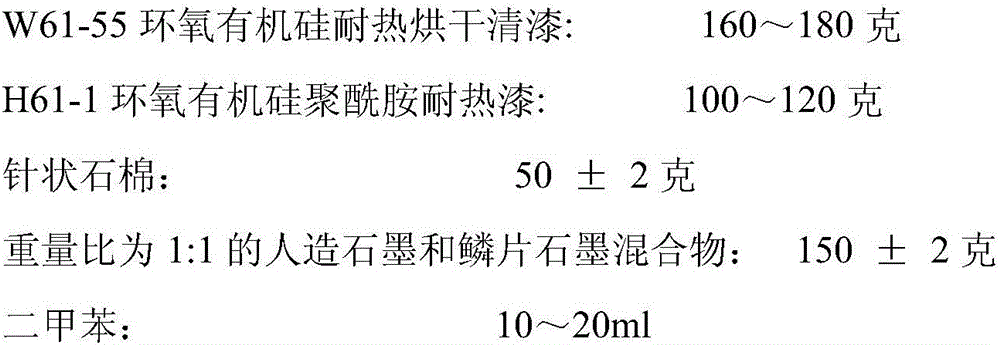

[0053] (1) Coating formula

[0054]

[0055]

[0056] (2) preparation

[0057] Put the graphite mixture and acicular asbestos into a clean container and mix well; put W61-55 epoxy silicone heat-resistant drying varnish, H61-1 epoxy silicone polyamide heat-resistant paint and xylene into another In a container, stir evenly, then slowly pour into the dry mixture of graphite mixture and acicular asbestos, mix thoroughly with a scraper to make a coating, add xylene during the mixing process to dilute to a suitable consistency, then mechanically stir for 15 minutes and then , in a closed container, park for more than 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com