Low-load system increasing denitration flue gas temperature

A low-load, gunpowder technology, applied in lighting and heating equipment, etc., can solve the problems of substandard flue gas emission and low inlet flue gas temperature, and achieve the effect of increasing temperature and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

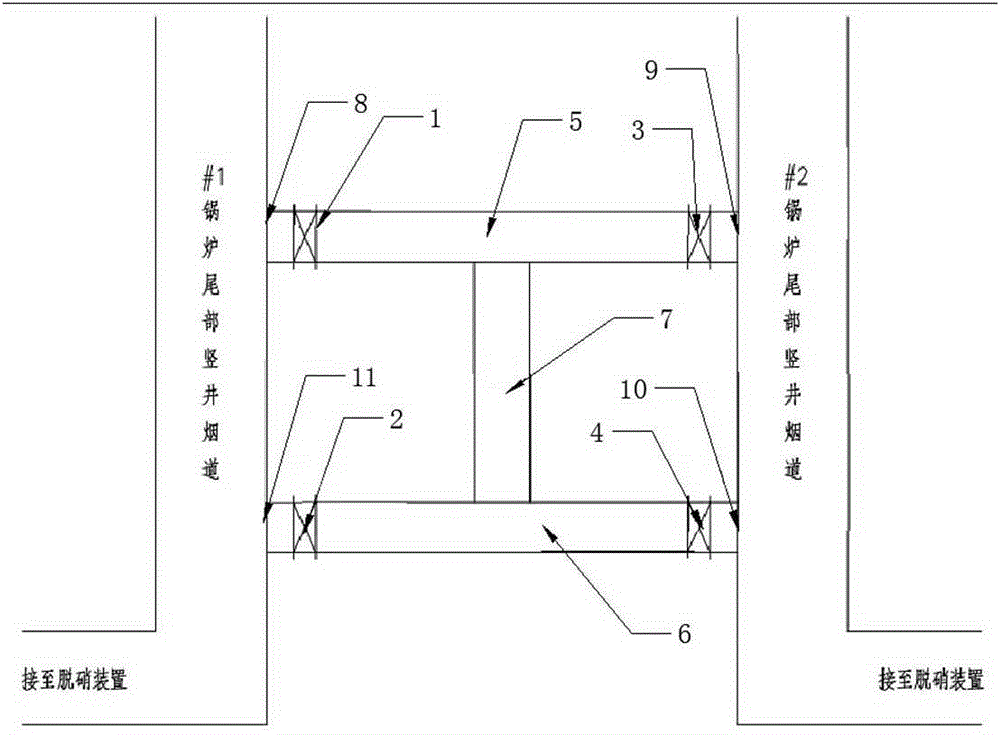

[0011] Such as figure 1 As shown, the system includes #1 low temperature superheater flue baffle 1, #1 denitrification inlet flue baffle 2, #2 low temperature superheater flue baffle 3, #2 denitrification inlet flue baffle 4, low temperature superheating The device is connected to the flue 5, the denitrification inlet is connected to the flue 6, and the vertical flue 7. The low-temperature superheater is connected to the flue 5, the denitrification inlet is connected to the flue 6, and the vertical flue 7 forms a bypass flue.

[0012] The flue gas discharged from the vertical flues at the tail of the two boilers all enters the denitrification device, and the denitrification inlet connecting flue 6 connected between the vertical flues at the tail of the two boilers is close to the connection between the vertical flue at the tail of the boiler and the denitrification device.

[0013] Because the vertical flue at the bottom of the boiler is equipped with a heating surface to abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com