Silencer test device based on airflow temperature and flow matching

A flow matching and testing device technology, applied in measurement devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of increasing the production cycle cost of mufflers, lack of rigorous measurement methods for muffler insertion loss, etc., to achieve the best Effects of Noise Reduction Performance, Guaranteed Accuracy and Data Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

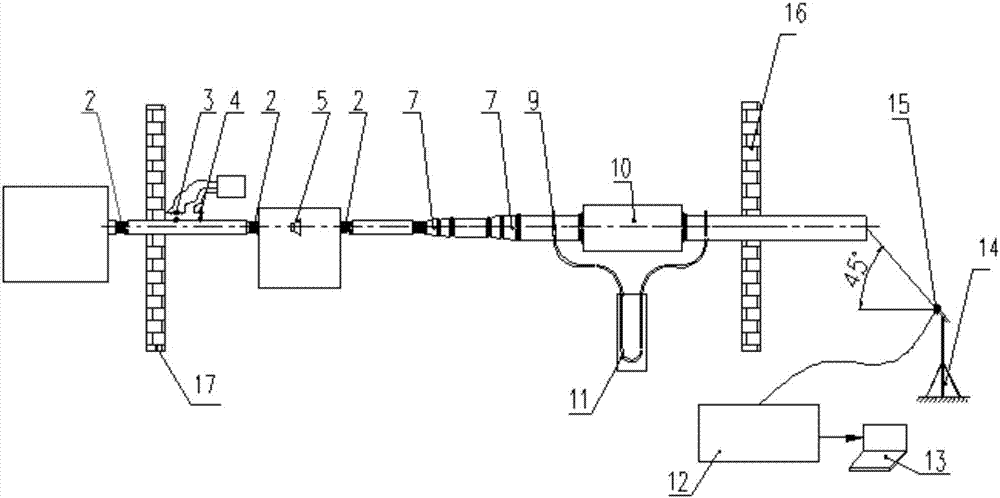

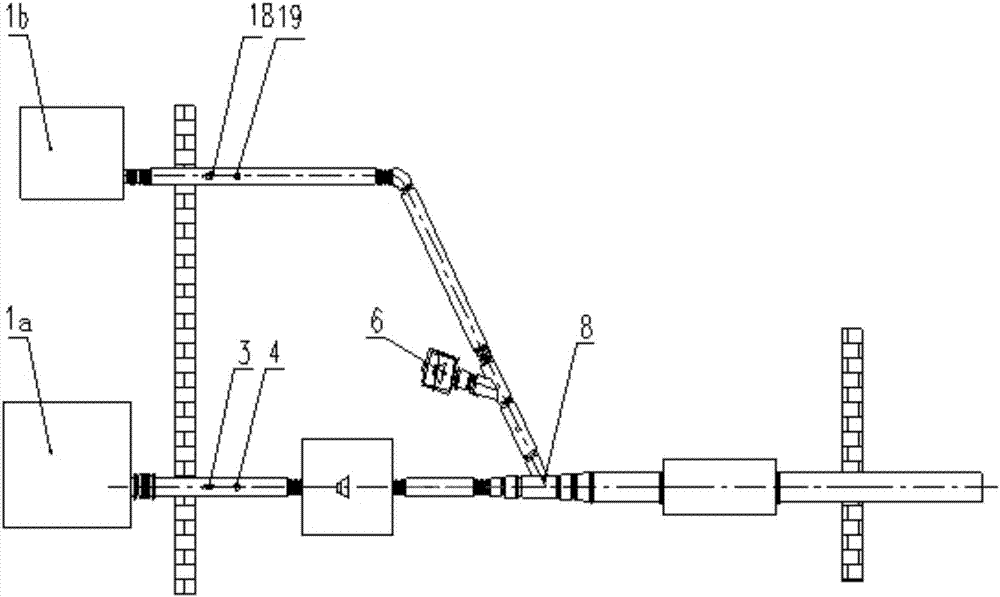

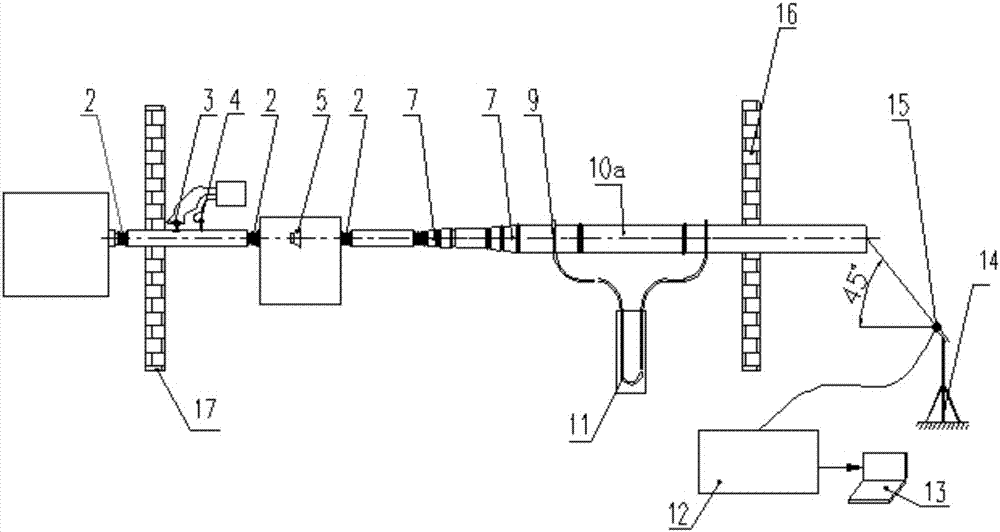

[0024] The present invention is described in more detail below in conjunction with accompanying drawing:

[0025] Such as figure 1 with figure 2 As shown, the outlet of the kerosene test bench 1b is connected to the bellows 2, and the bellows 2 is connected to the second flow sensor 18 and the second temperature sensor 19 through the pipeline through the first sound insulation wall 17, and the second temperature sensor 19 is connected to the second temperature sensor 19 through the pipeline. The electroacoustic sources 6 are connected to form a first pipeline. The outlet of the diesel test bench 1a is connected to the bellows 2, and the bellows 2 is connected to the first flow sensor 3 and the first temperature sensor 4 through the pipeline through the first sound insulation wall 17, and the first temperature sensor 4 is connected to the mechanical sound source 5, Form the second pipeline. The diesel test bench 1a and the kerosene test bench 1b generate airflow with a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com