Patents

Literature

103results about How to "Ensure data reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor memory device and refresh control method thereof

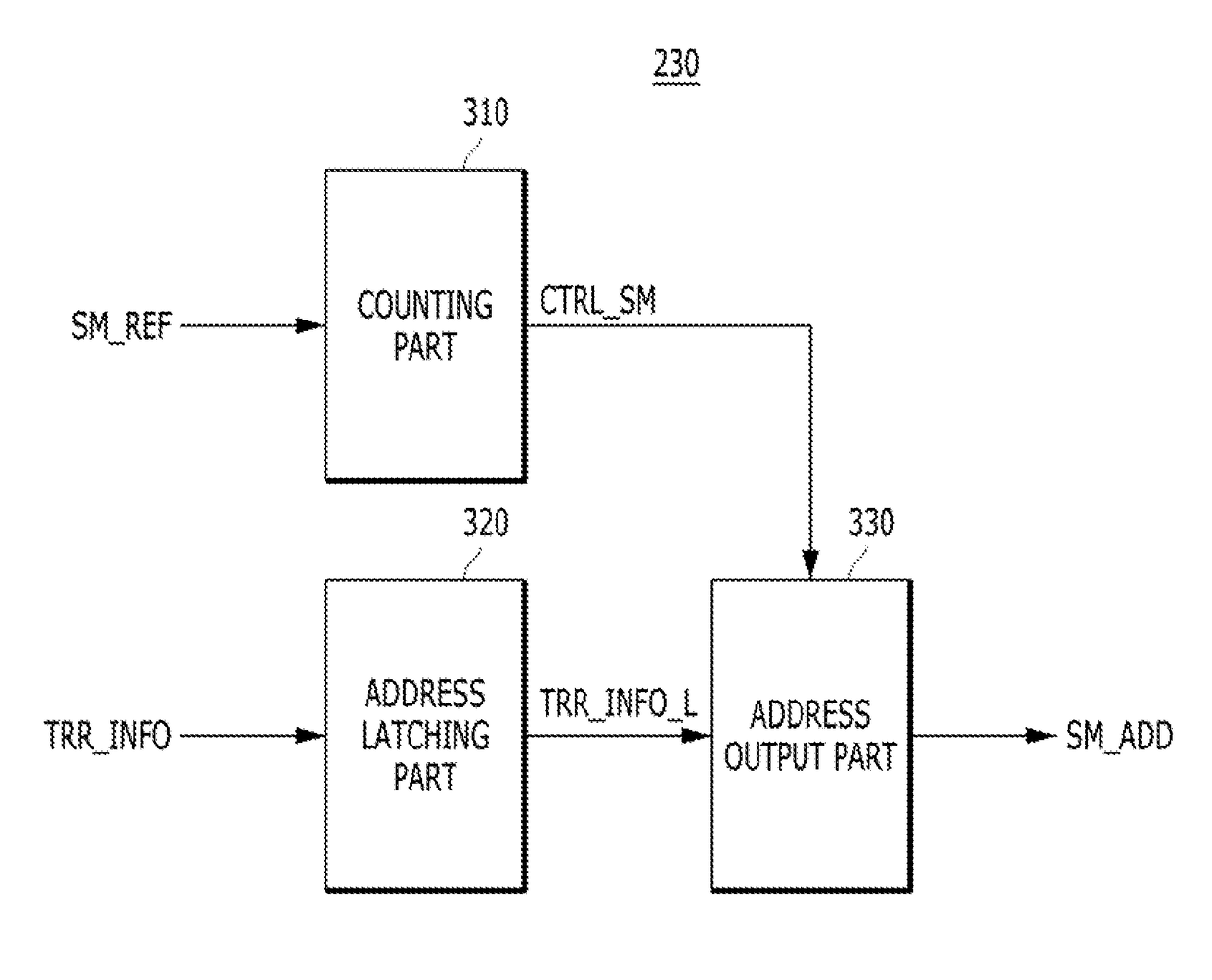

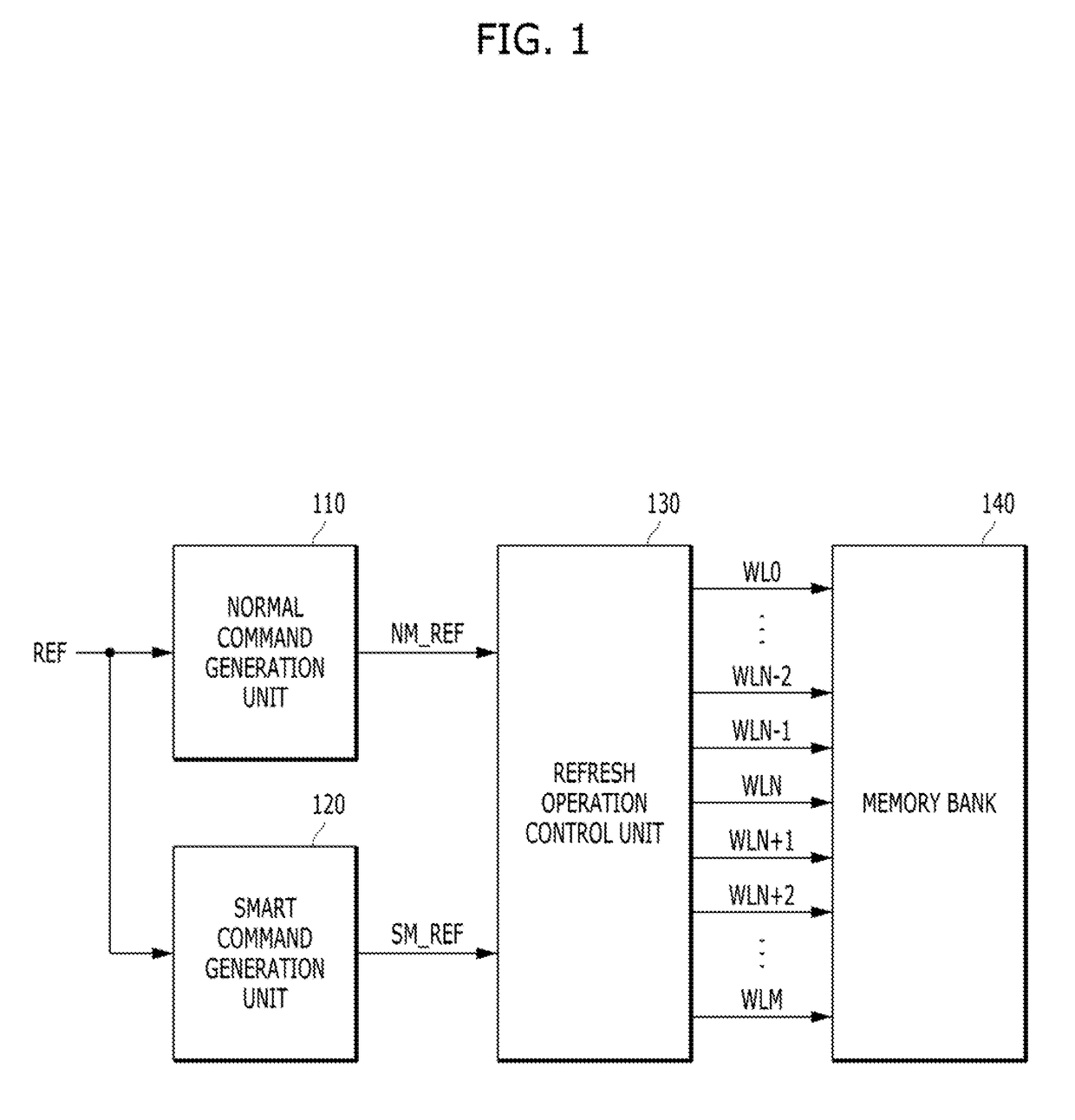

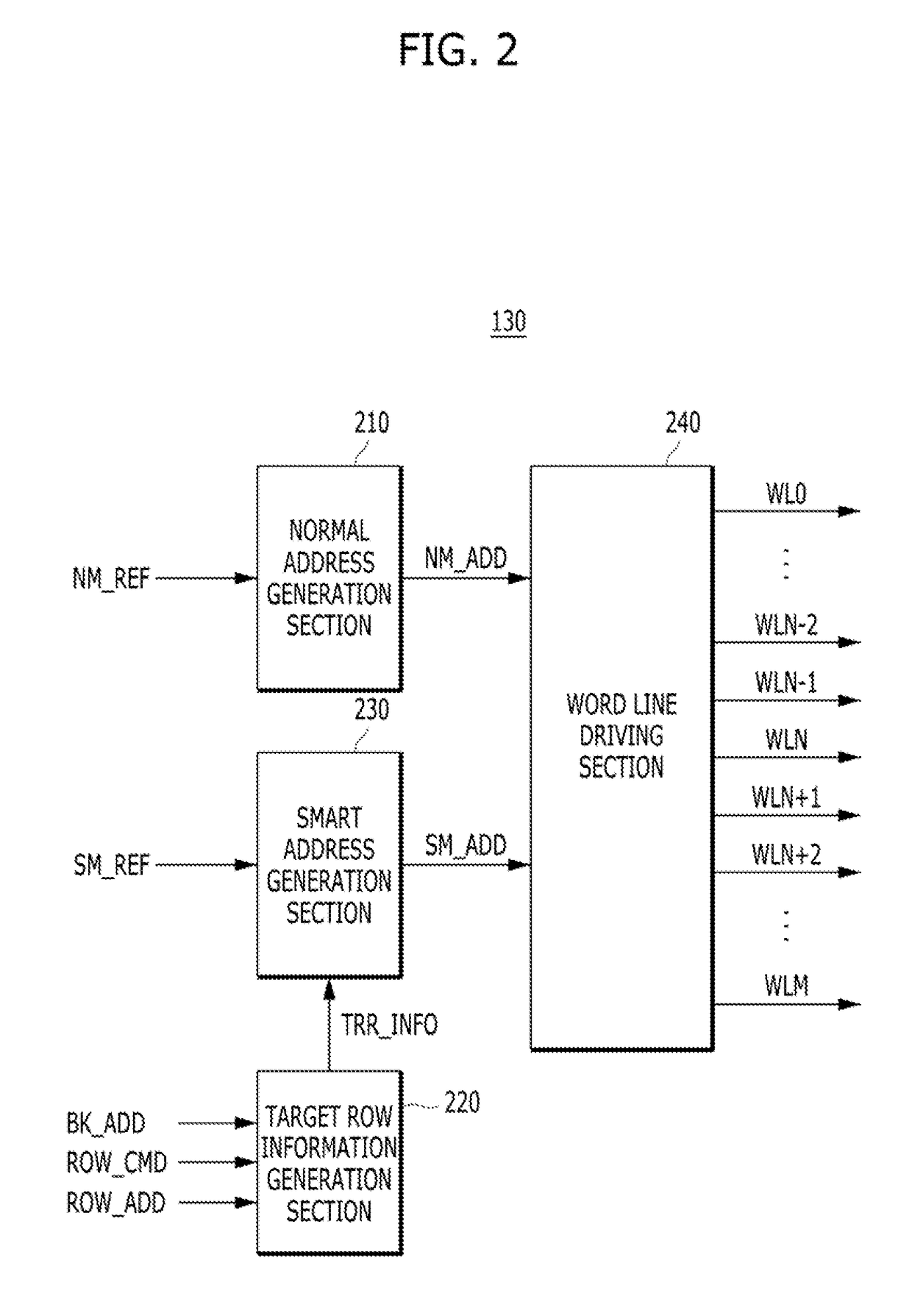

A semiconductor memory device includes a memory bank including a plurality of word lines, and a refresh operation control unit suitable for performing a first refresh operation for a first adjacent word line group of a target word line of the plurality of word lines, and performing a second refresh operation for a second adjacent word line group of the target word line after the first refresh operation, in response to a smart refresh command.

Owner:SK HYNIX INC

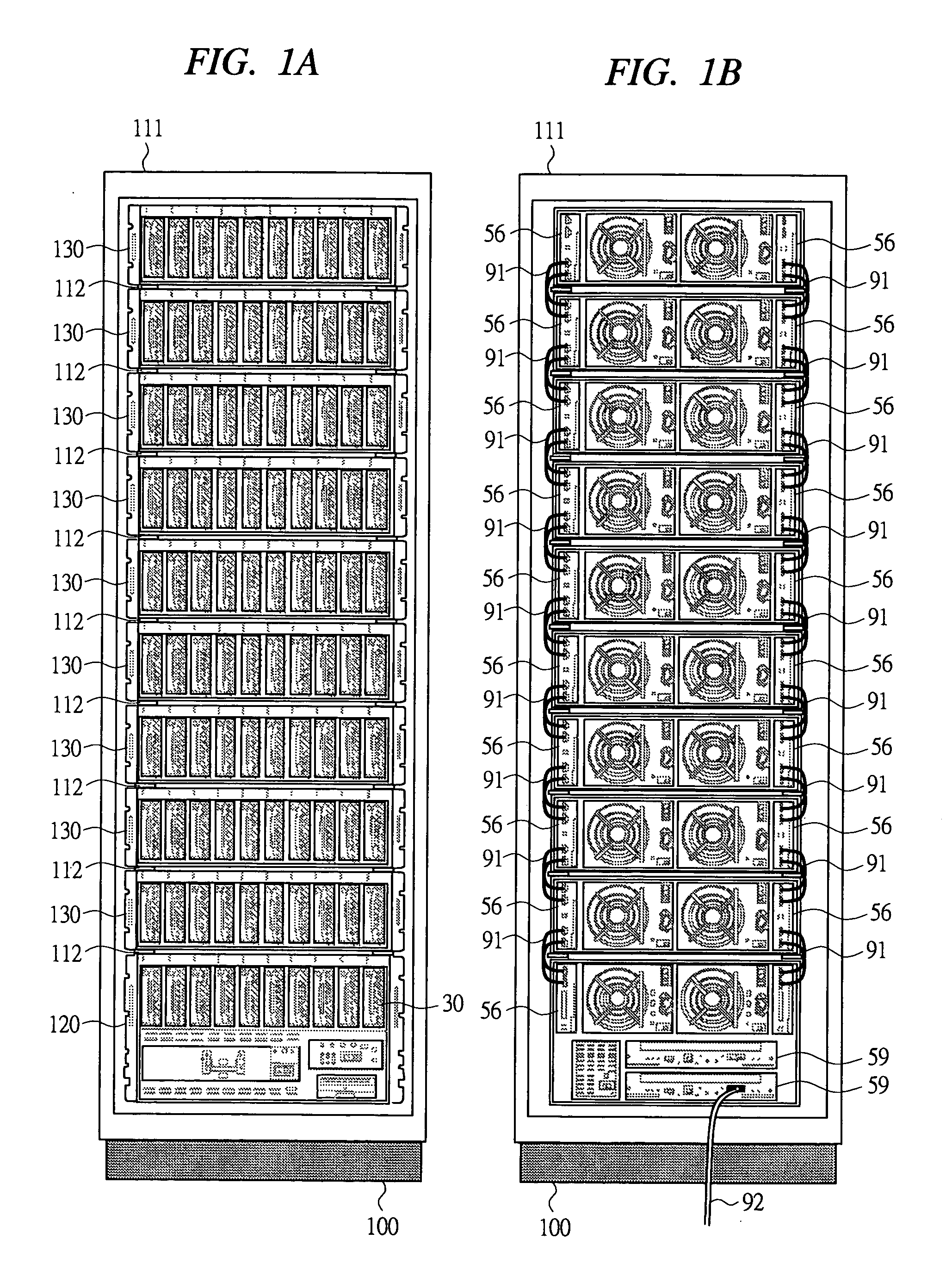

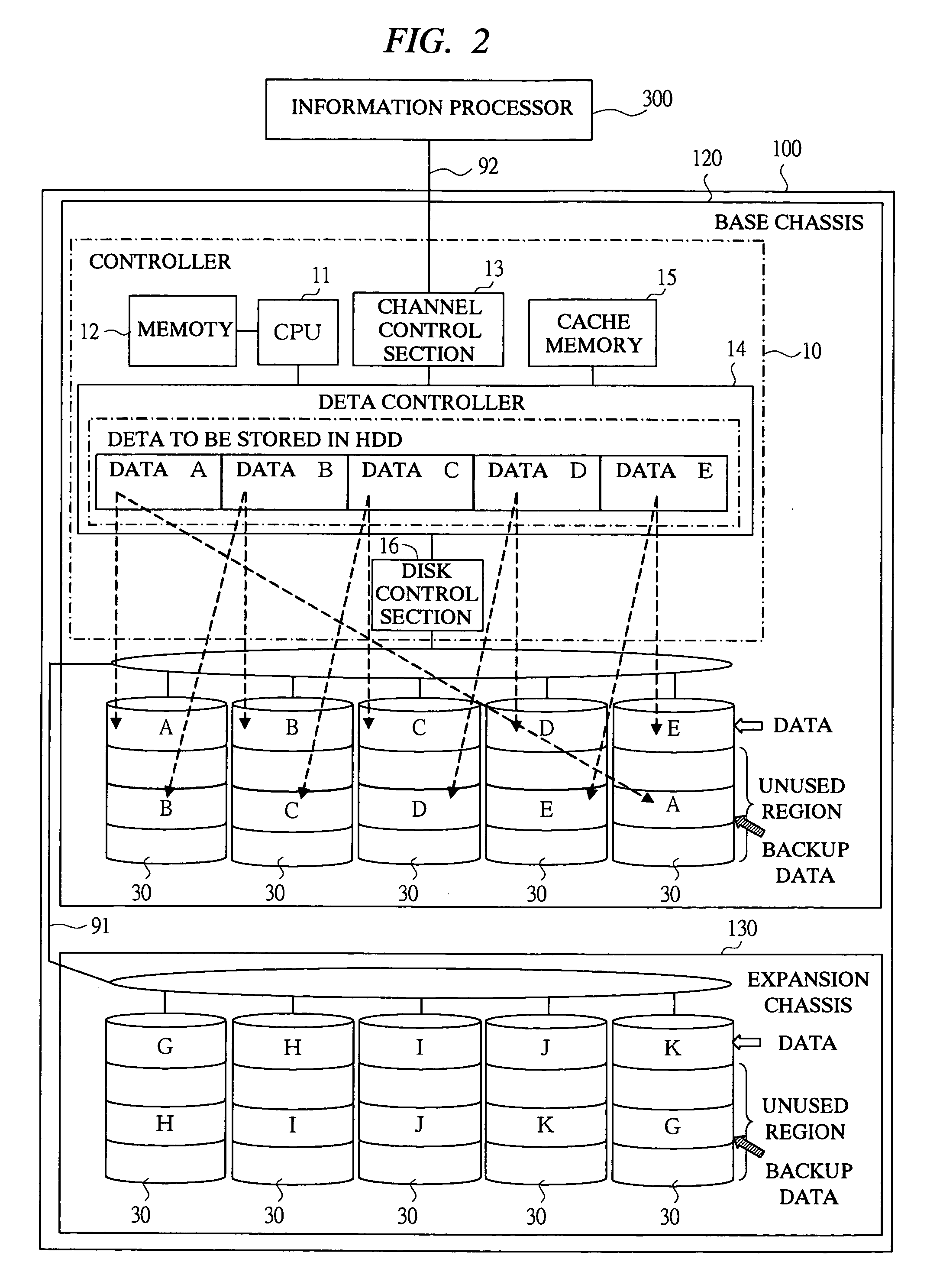

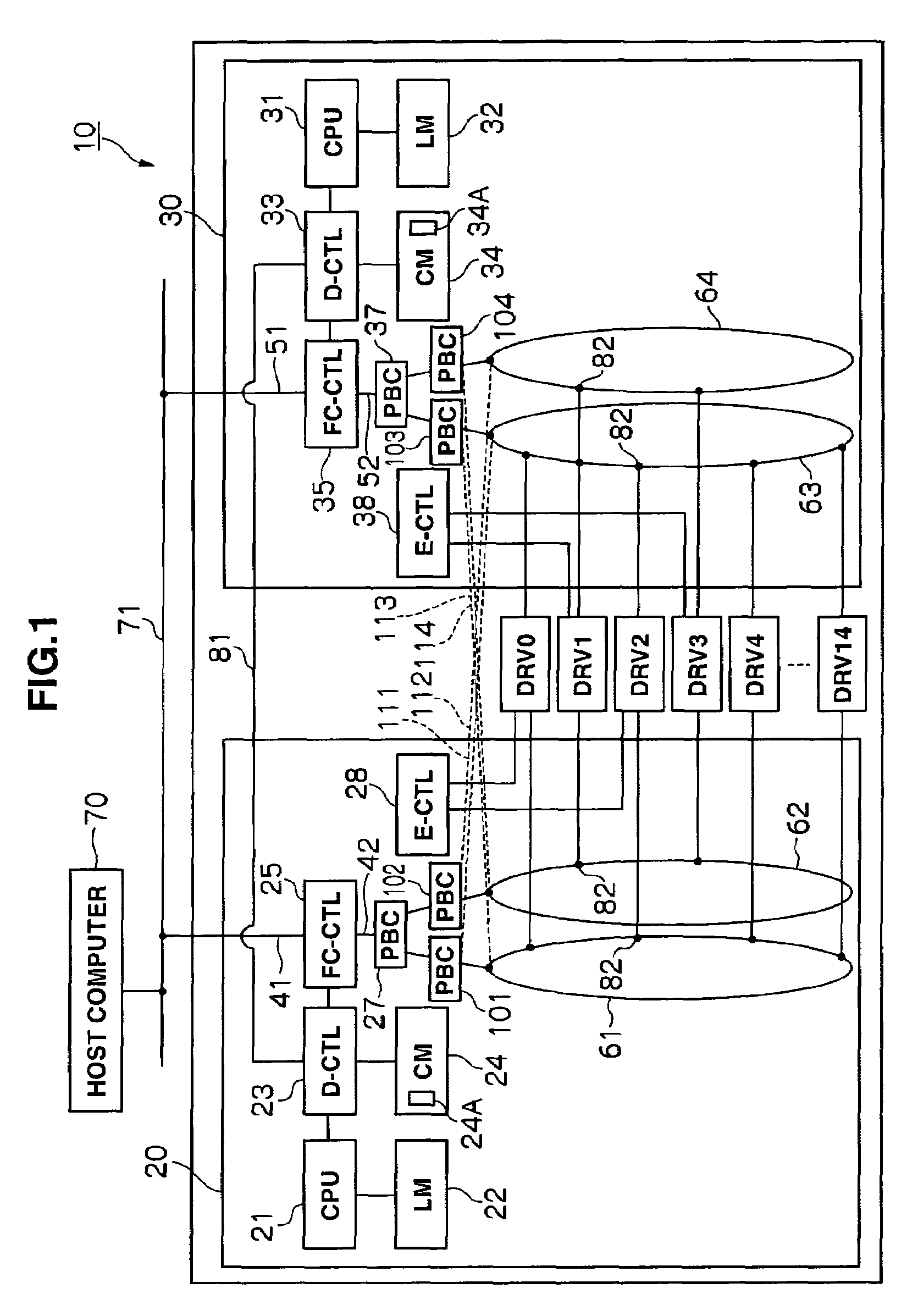

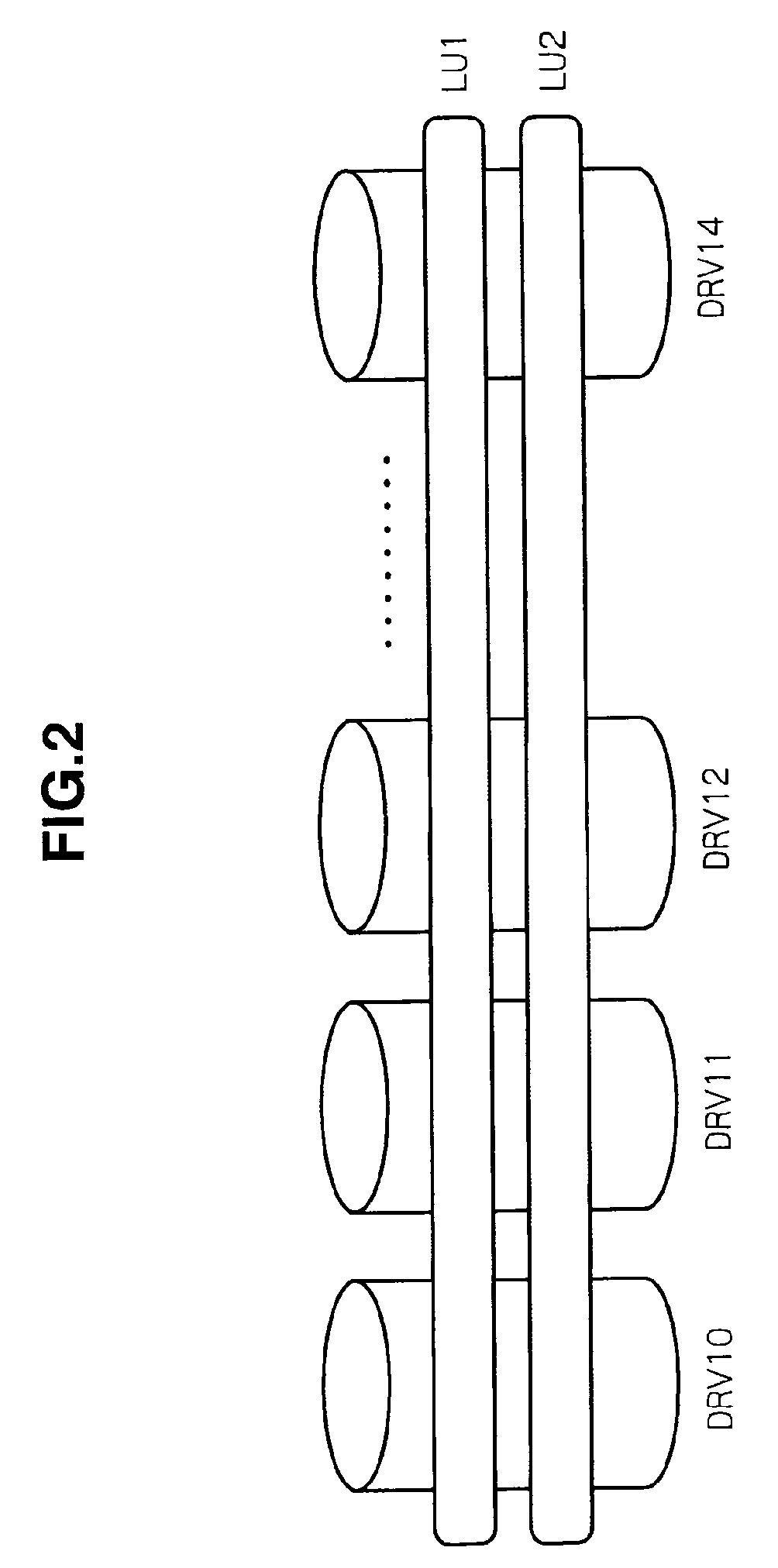

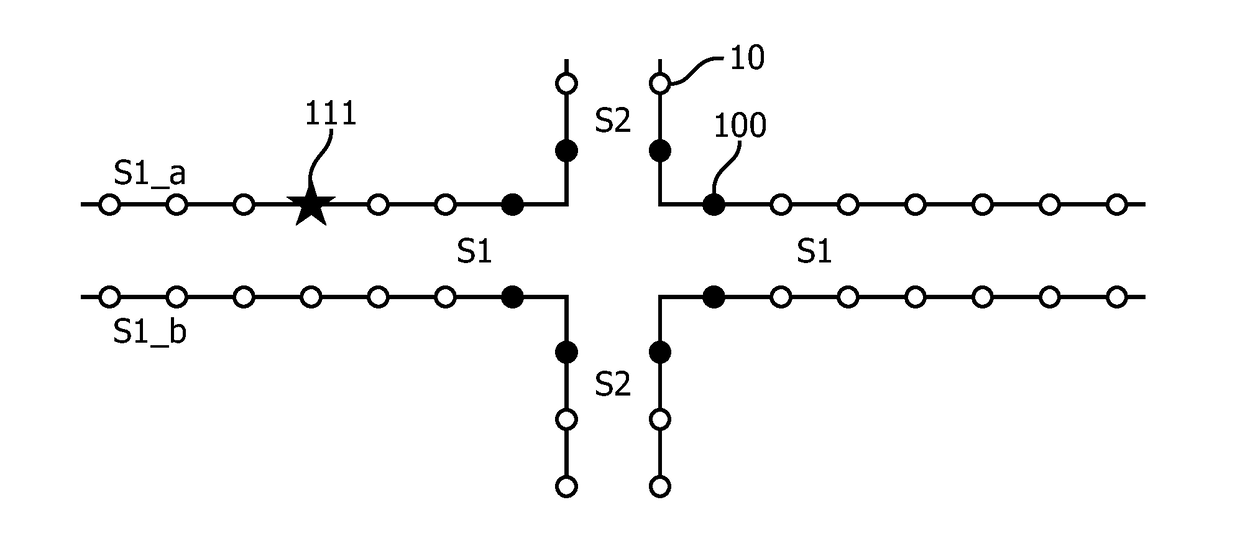

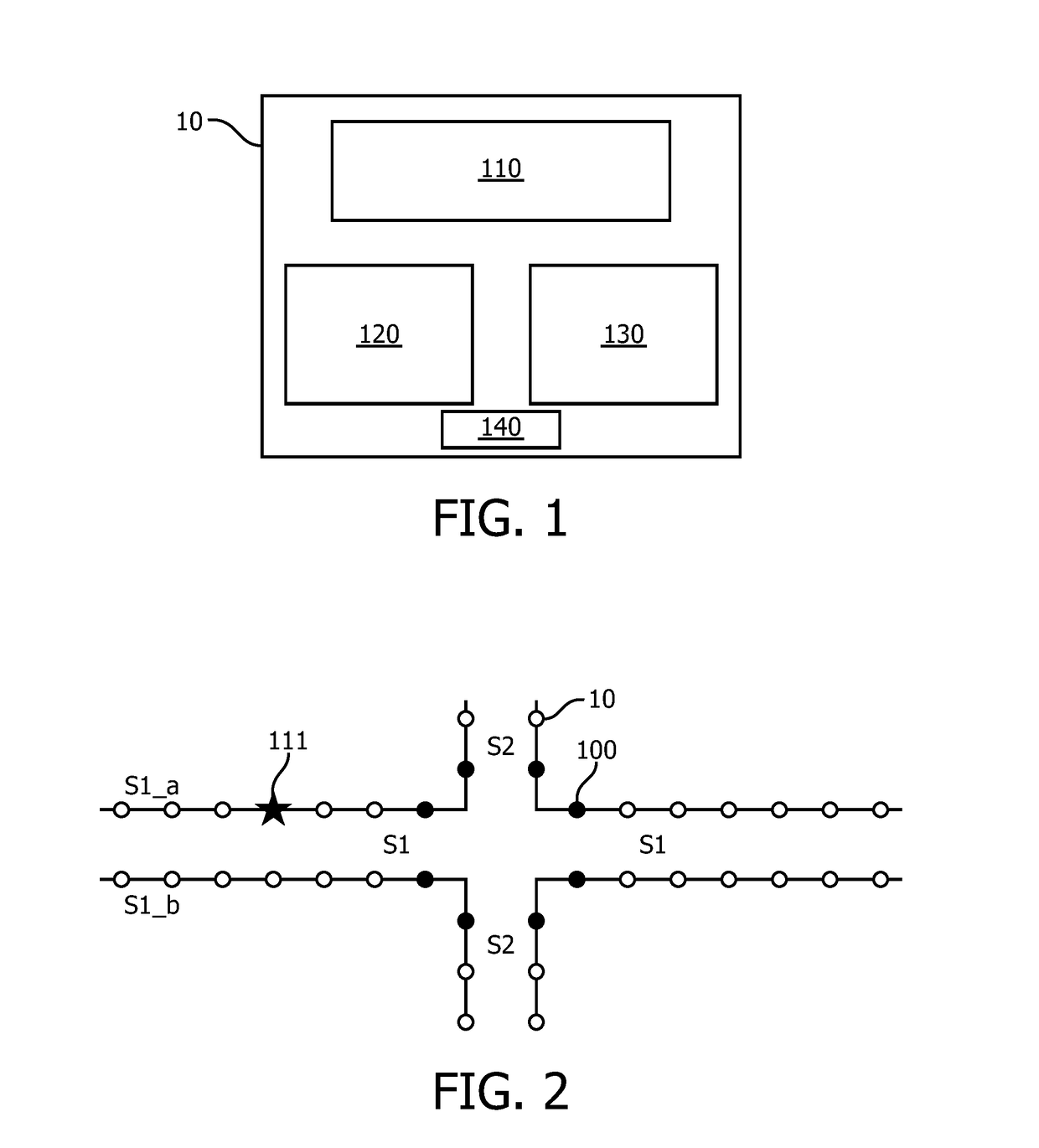

Disk array system

InactiveUS20060077724A1Ensure data reliabilityAvoid data lossRecording carrier detailsError detection/correctionDisk arrayData loss

The present invention enables to secure data reliability by avoiding data loss in an early failure period of an operation of a disk array system to which no particular measures have been taken conventionally. A controller of the disk array system stores first data to be stored in a HDD into a part of the region of one or more HDDs of an overall storage region composed of a plurality of HDDs and stores backup data of the stored first data into a part of the region of one or more HDDs in such a manner that they may be stored in the different HDDs. When there are no enough free space regions to store the first data in the overall storage region, the region in which the backup data is stored is overwritten to be used.

Owner:HITACHI LTD

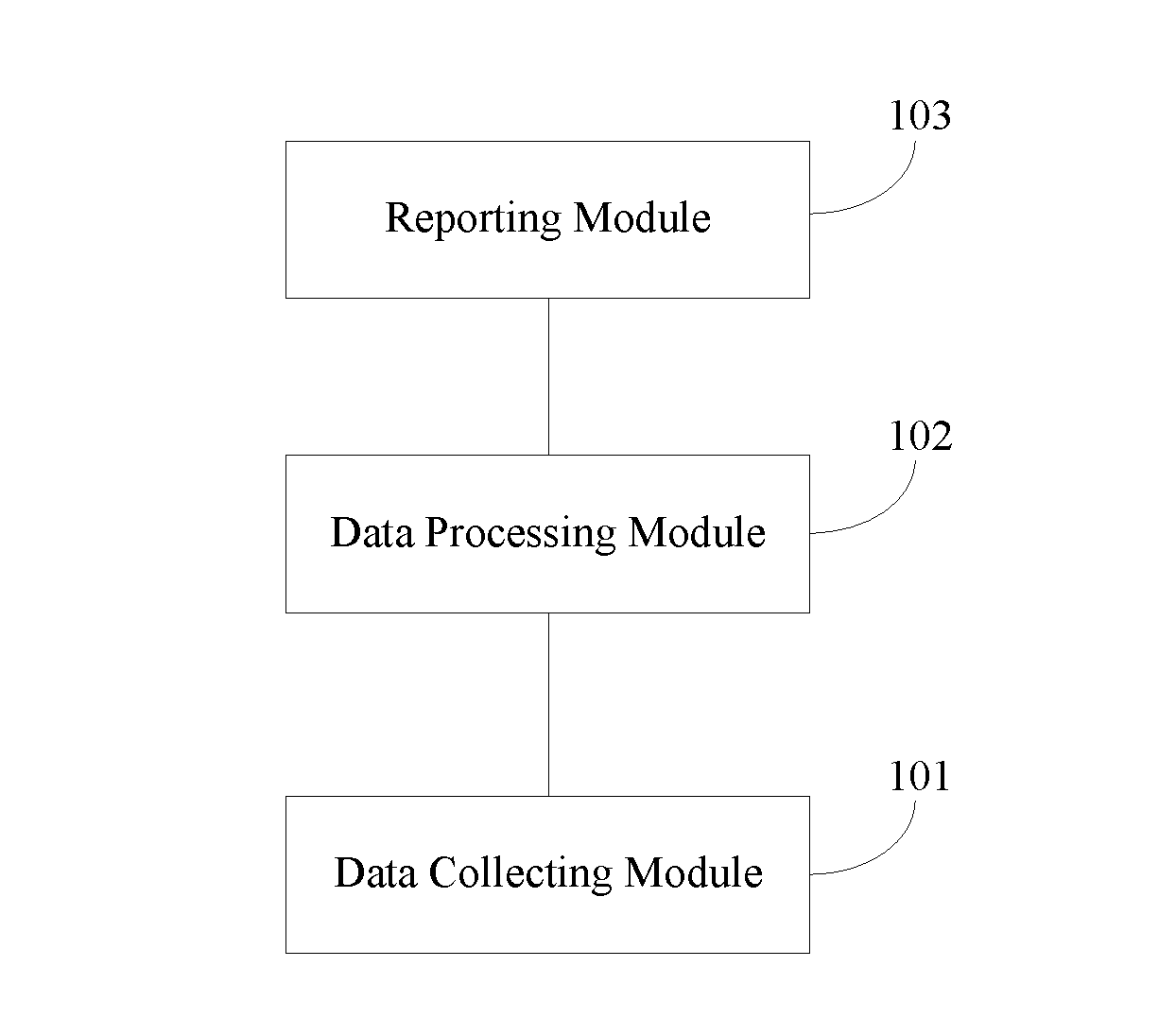

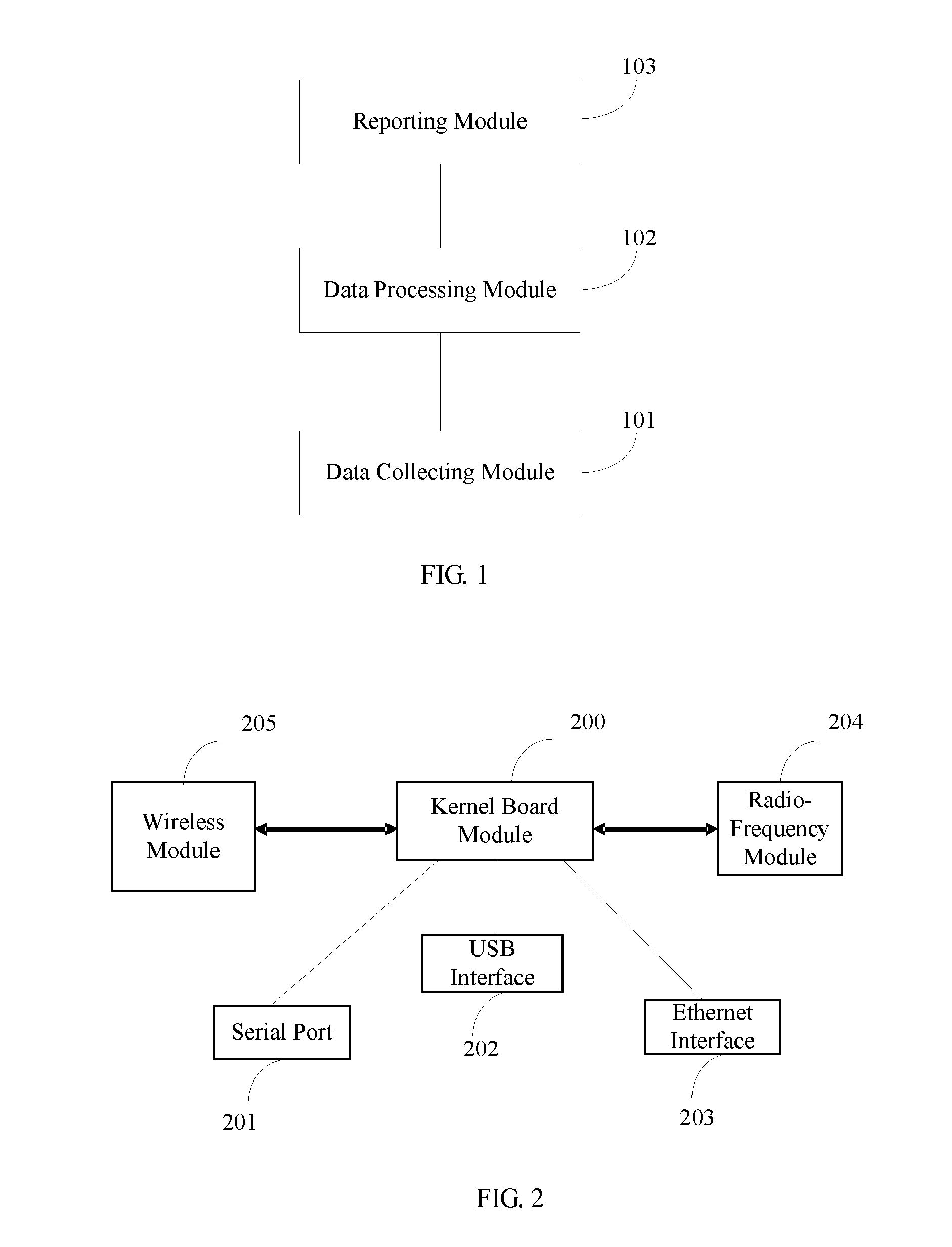

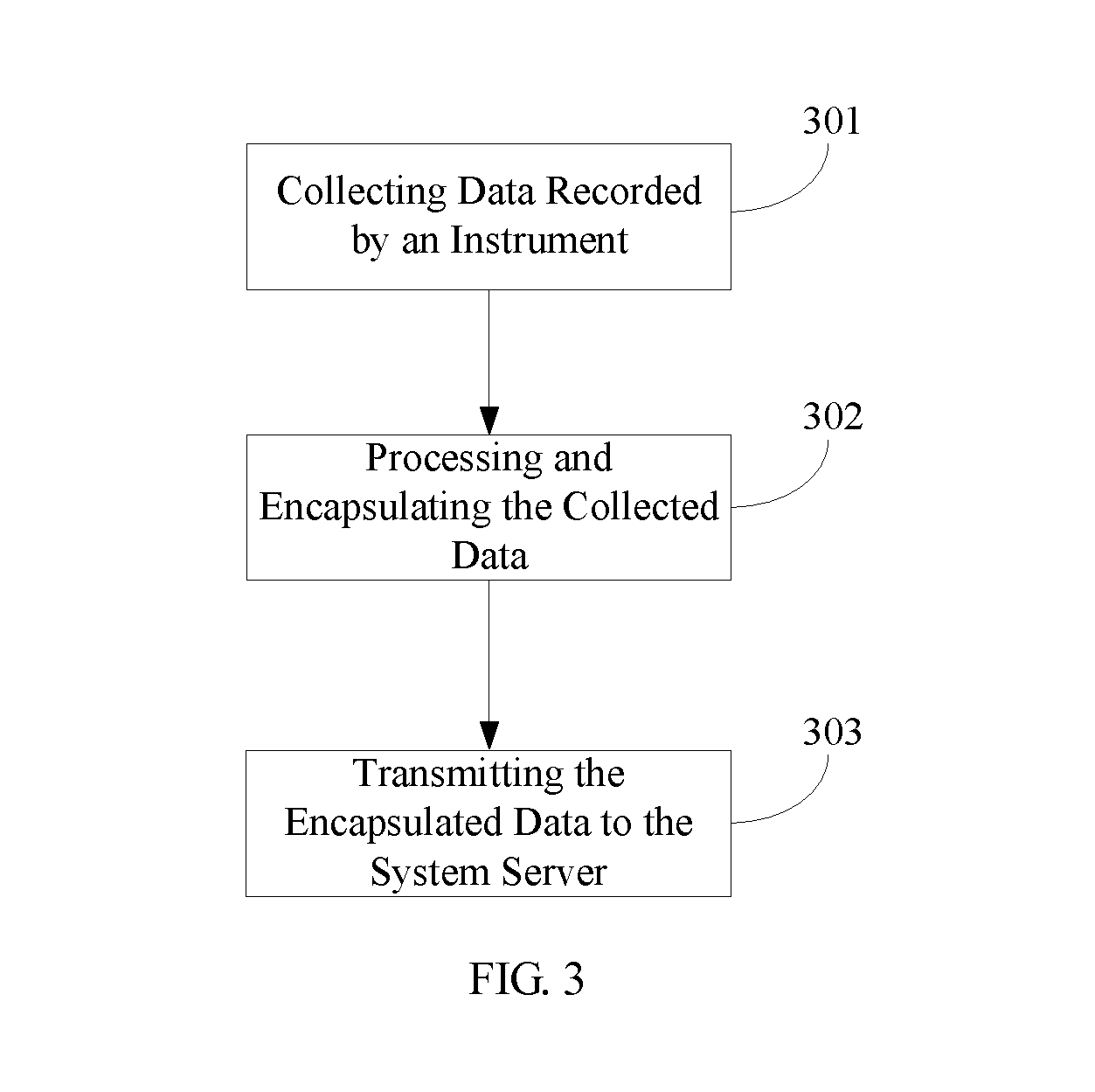

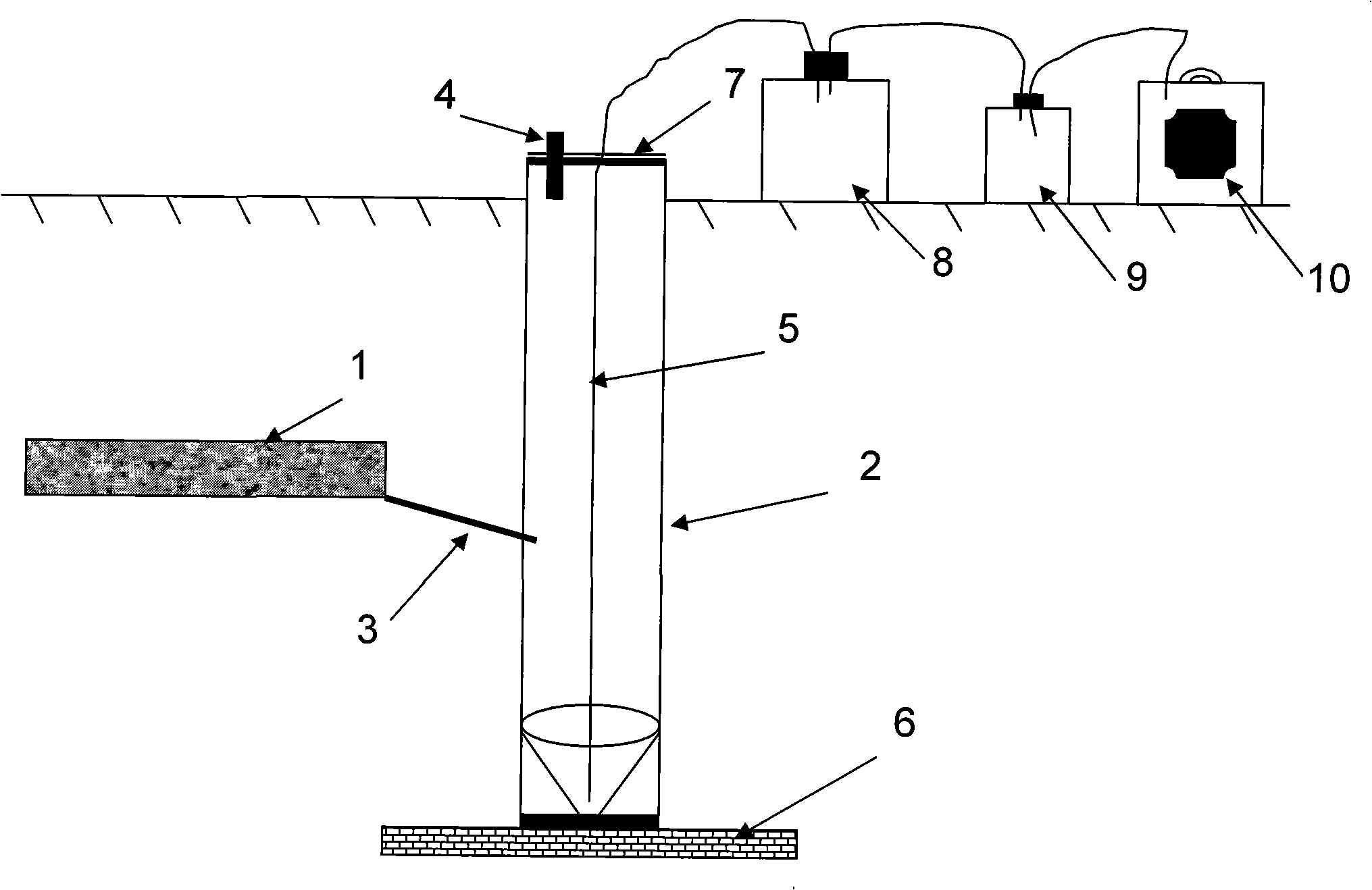

Data collecting concentrator and data collecting method

InactiveUS20130110837A1Easy constructionLow cost installationUtility meters data arrangementsDigital data processing detailsData collectingData acquisition module

A data acquisition concentrator and a data acquisition method are provided. The data acquisition concentrator comprises a data acquisition module (101) for acquiring data recorded by an instrument, a data processing module (102) for processing and encapsulating the data acquired by the data acquisition module (101), and a reporting module (103) for transmitting the data encapsulated by the data processing module (102) to a system server through a universal network. The data acquisition concentrator and the data acquisition method can be applied to meter reading on various occasions such as electric power, water, gas and the like without laying a special circuit.

Owner:GUANGZHOU SUNRISE ELECTRONICS DEV

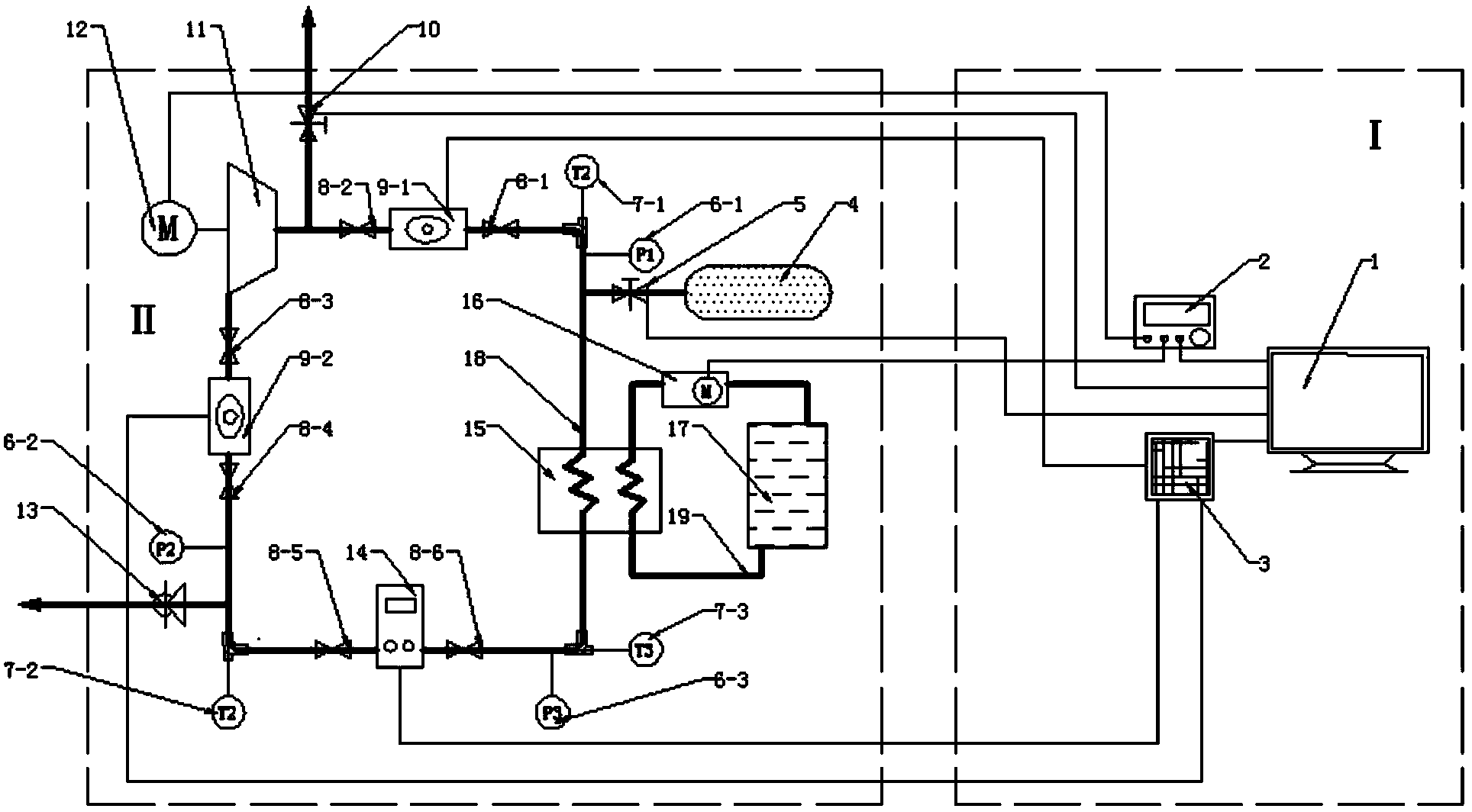

Device and method applied to experiment of supercritical carbon dioxide closed cycle compression characteristic

InactiveCN104297072AComprehensive analysis of compression characteristicsSimple structureMaterial strength using tensile/compressive forcesMeasuring instrumentWater storage tank

The invention discloses a device and a method applied to experiment of supercritical carbon dioxide closed cycle compression characteristic. The experiment device comprises a data acquisition control system and a supercritical carbon dioxide closed cycle system, wherein the supercritical carbon dioxide circulation system is characterized in that carbon dioxide gas is provided by a carbon dioxide gas storage tank, enters a carbon dioxide circulation pipeline by virtue of a carbon dioxide flow control valve, respectively flows through data measuring instruments such as a pressure gauge, a thermometer, and a carbon dioxide texture analyzer, and flows through a reduced pressure control device and a heat exchanger to complete a supercritical carbon dioxide closed cycle. The heat exchanger is connected with a water circulating pump and a cooling water storage tank by virtue of a cooling water circulating pipeline; a blowing valve is arranged on the front of an inlet of a compressor; an overpressure safety valve is arranged on the back of the pressure gauge behind the compressor; the data acquisition control system is capable of intensively controlling the carbon dioxide flow control valve, the blowing valve, a compressor motor, the water circulating pump, the carbon dioxide texture analyzer and the reduced pressure control device. The experiment device is safe and efficient, and is high in operability and reliable in experiment data.

Owner:CHINA UNIV OF MINING & TECH

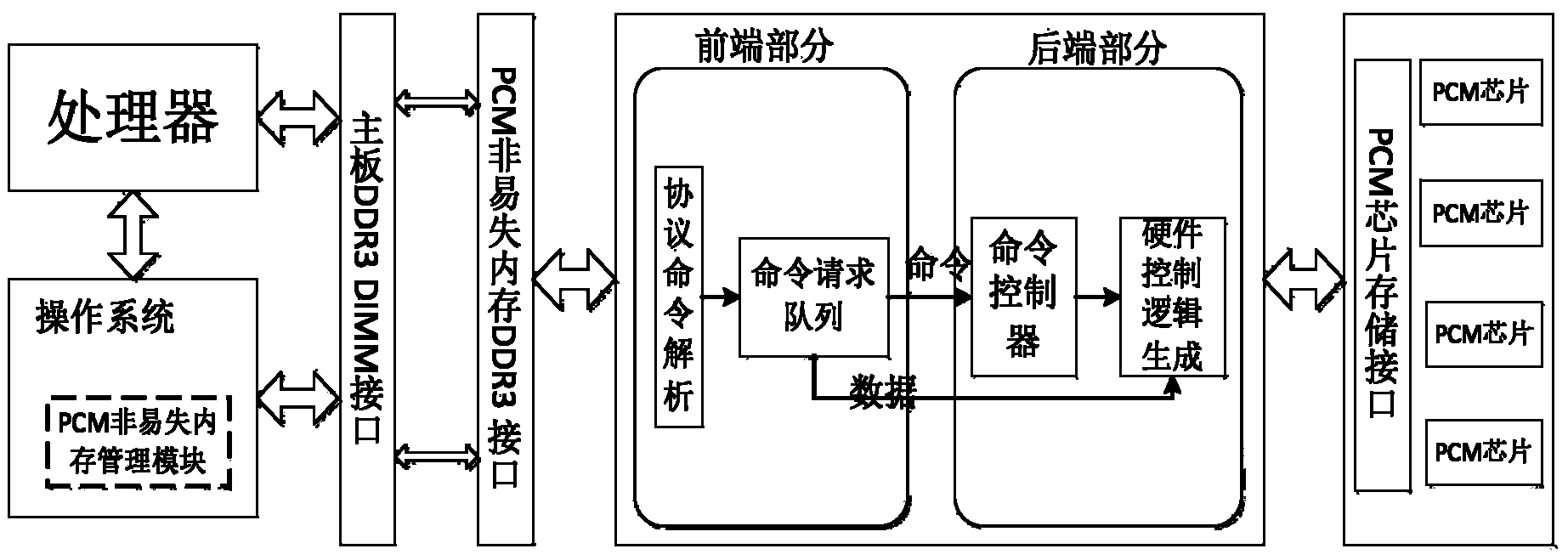

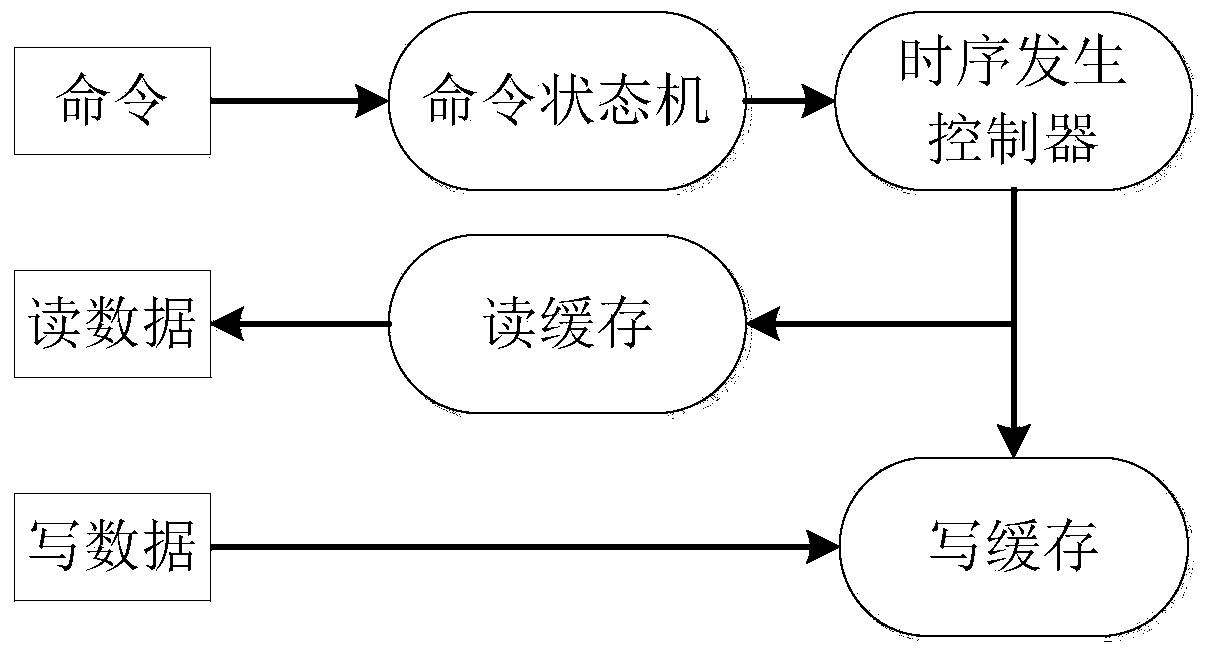

Nonvolatile memory system and management method thereof

ActiveCN103810112ASolve protection problemsPromote recoveryMemory adressing/allocation/relocationEnergy efficient computingDram memoryHost memory

The invention discloses a nonvolatile memory system and a management method of the nonvolatile memory system. A nonvolatile memory is constructed by adopting a nonvolatile PCM storage device, management on the nonvolatile memory is added to a host memory management module, unified management on the nonvolatile memory and a traditional DRAM is achieved, and the nonvolatile memory and the traditional DRAM can be fused to form a unified memory for the access of a host processor. According to the nonvolatile memory system and the management method of the nonvolatile memory system, the problem that power failure data of the traditional DRAM are lost and the problem of data consistency can be solved, and meanwhile energy consumption of the host memory can be lowered.

Owner:HUAZHONG UNIV OF SCI & TECH

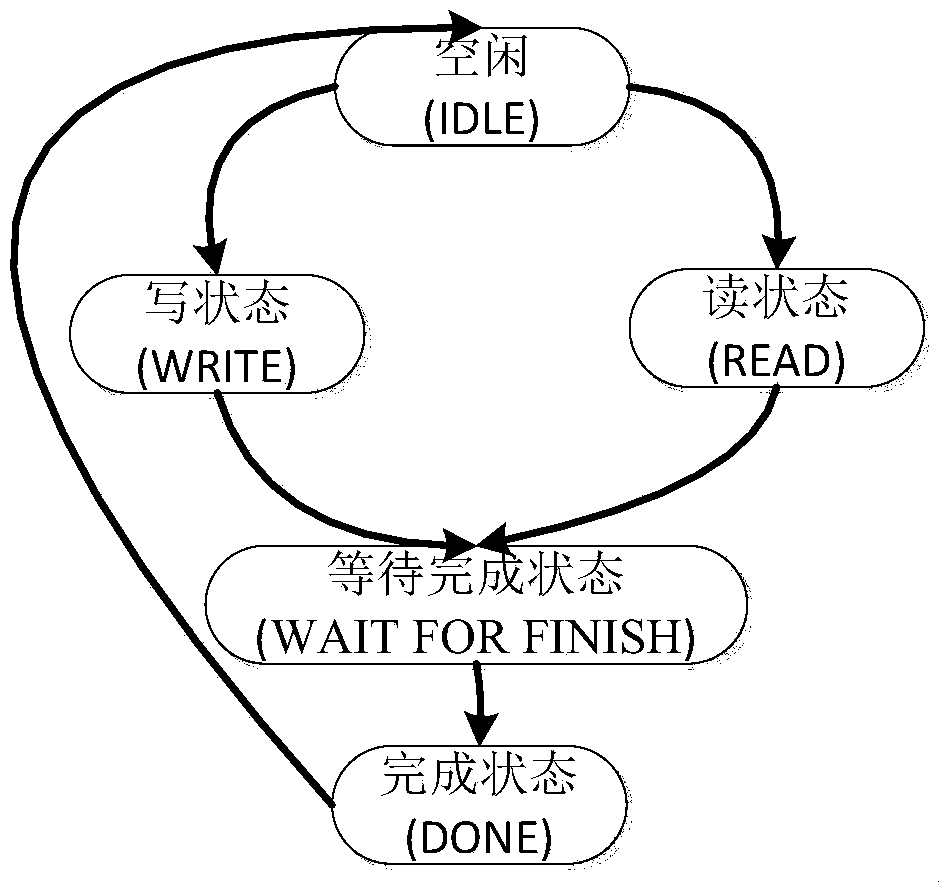

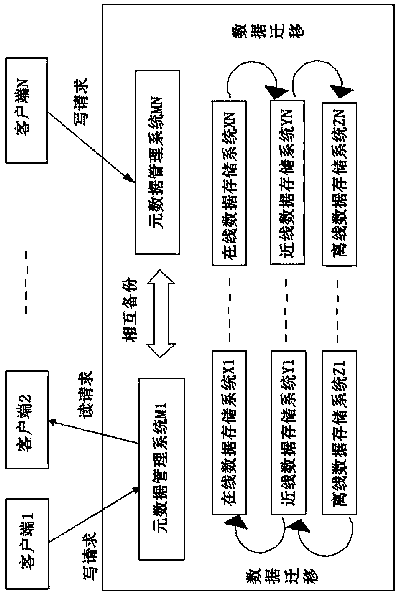

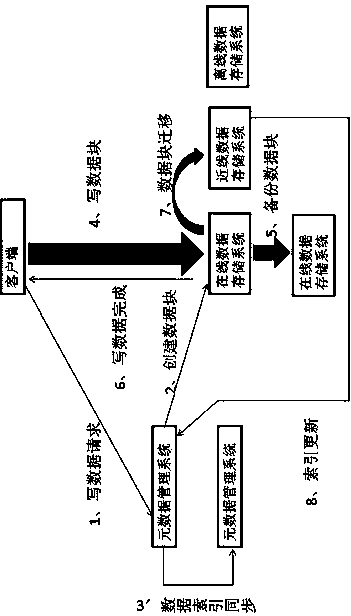

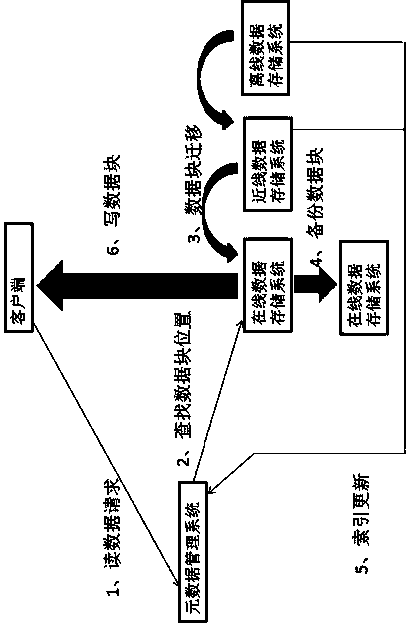

Performance improving data processing method in cloud storage system

InactiveCN103530388AIncrease profitEfficient use ofInput/output to record carriersTransmissionData streamMetadata management

The invention relates to the cloud storage field, and discloses a performance improving data processing method in a cloud storage system. The performance improving data processing method relates to a metadata management system, an online data storage system, a near line data storage system, an off-line data storage system and a client terminal. Only control signal transmission is carried out between the metadata management system and the client terminal, storage data flow transmission is not carried out between the metadata management system and the client terminal, and the storage data flow transmission is carried out between the client terminal and the online data storage system. Data are autonomously transmitted among different devices in the cloud storage system so that the devices with different configurations can be effectively used, and the whole use ratio of the cloud storage system is improved. By means of data segmentation, concurrency of data reading and writing is improved, the IOPS and the bandwidth are improved, the reading and writing time is shortened, and the performance is improved. Improvement is carried out on an existing cloud storage system device, the process is completely implemented through software on the basis that hardware accesses are in good conditions, and the implementation and achieving difficulties are small. The performance improving data processing method can be popularized and used on a large data platform.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Natural state soil leachate collecting method

InactiveCN101261201AReduce disturbanceIrrigation volume controlWithdrawing sample devicesEarth material testingNatural stateSlurry

The invention discloses a soil leaching liquor collection method under natural conditions, which belongs to the research field of environmental science, soil science and plant nutrition. The soil leaching liquor collection method of the invention mainly includes the following steps: a soil profile in the vertical direction is obtained and the dug-out soil is piled up layer by layer according to depth; a horizontal cave is dug based on the target depth of the soil profile and the upper surface of the cave is guaranteed to be level; a leaching plate is inserted into the cave and slurry modulated out of soil of the soil layer of the target depth is placed into the leaching plate; the dug-out soil is backfilled layer by layer and then compacted layer by layer, moreover, in order to recover the raw condition of the backfilled soil as possible, the backfilled soil is irrigated for a plurality of times. The method of the invention can realize collecting and monitoring the soil leaching liquor under natural conditions, in particular is suitable for monitoring the influence caused by the soil leaching liquor of such soil solute as nitrogen, phosphorus and pesticide, etc., on the groundwater.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES +4

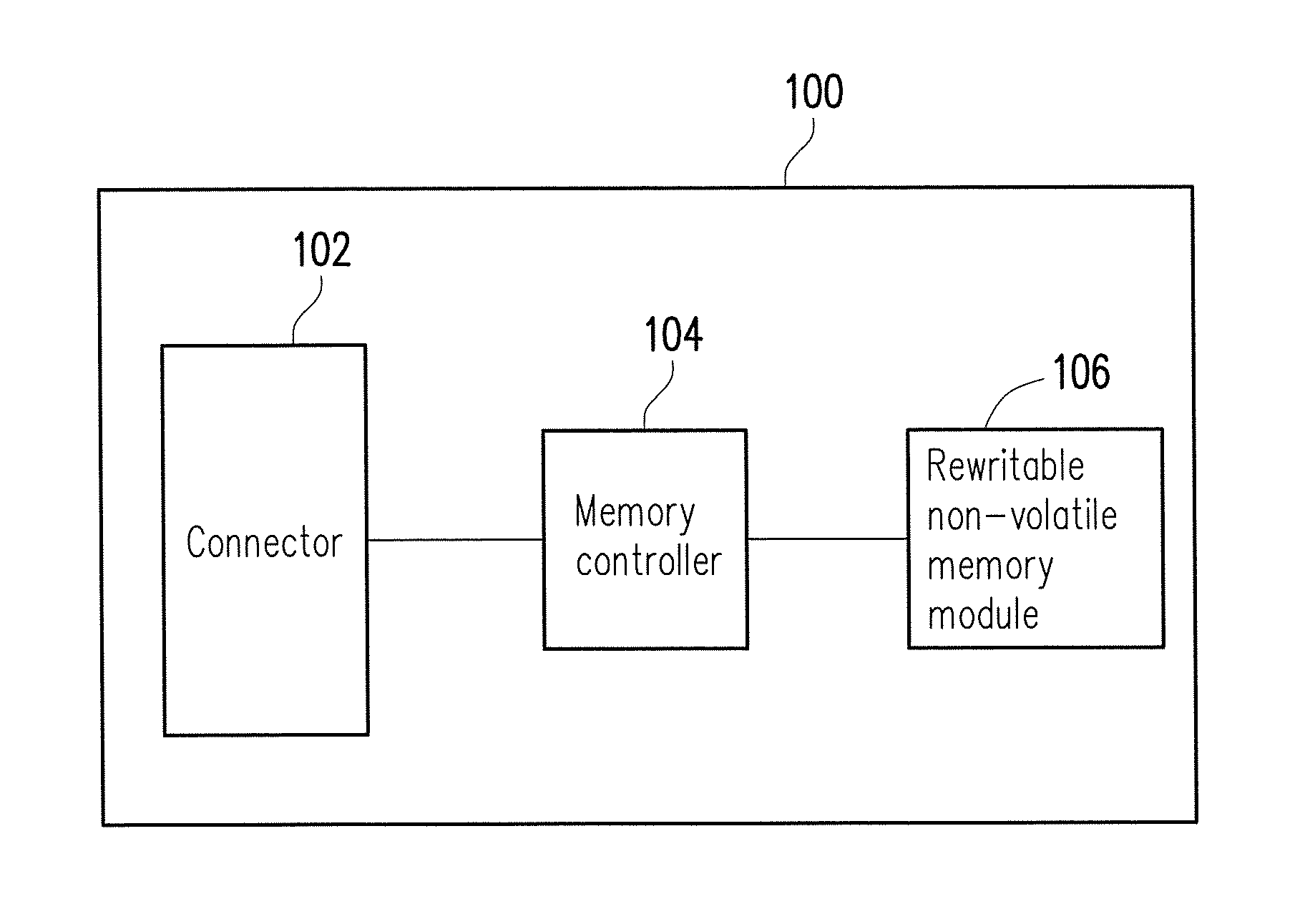

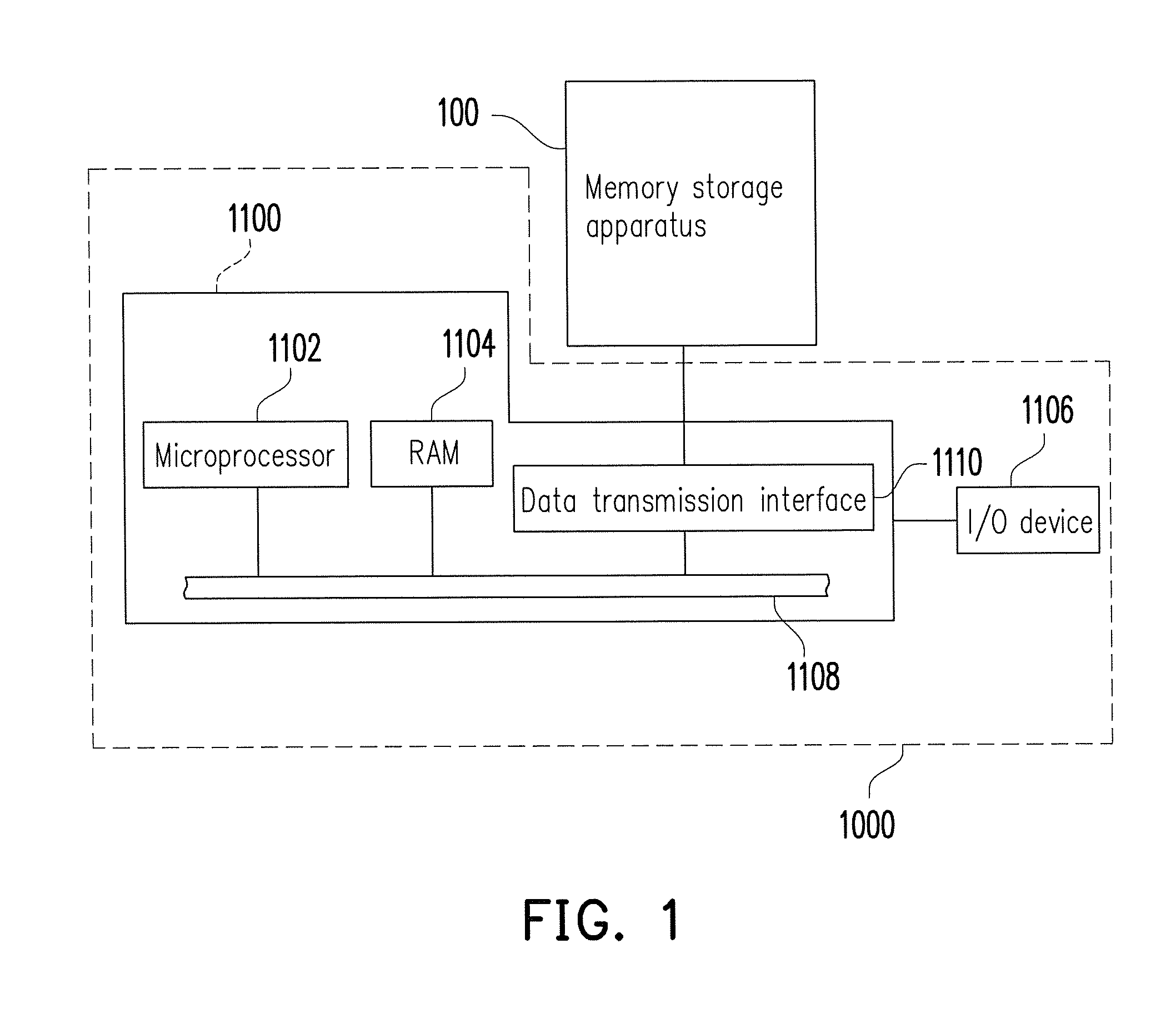

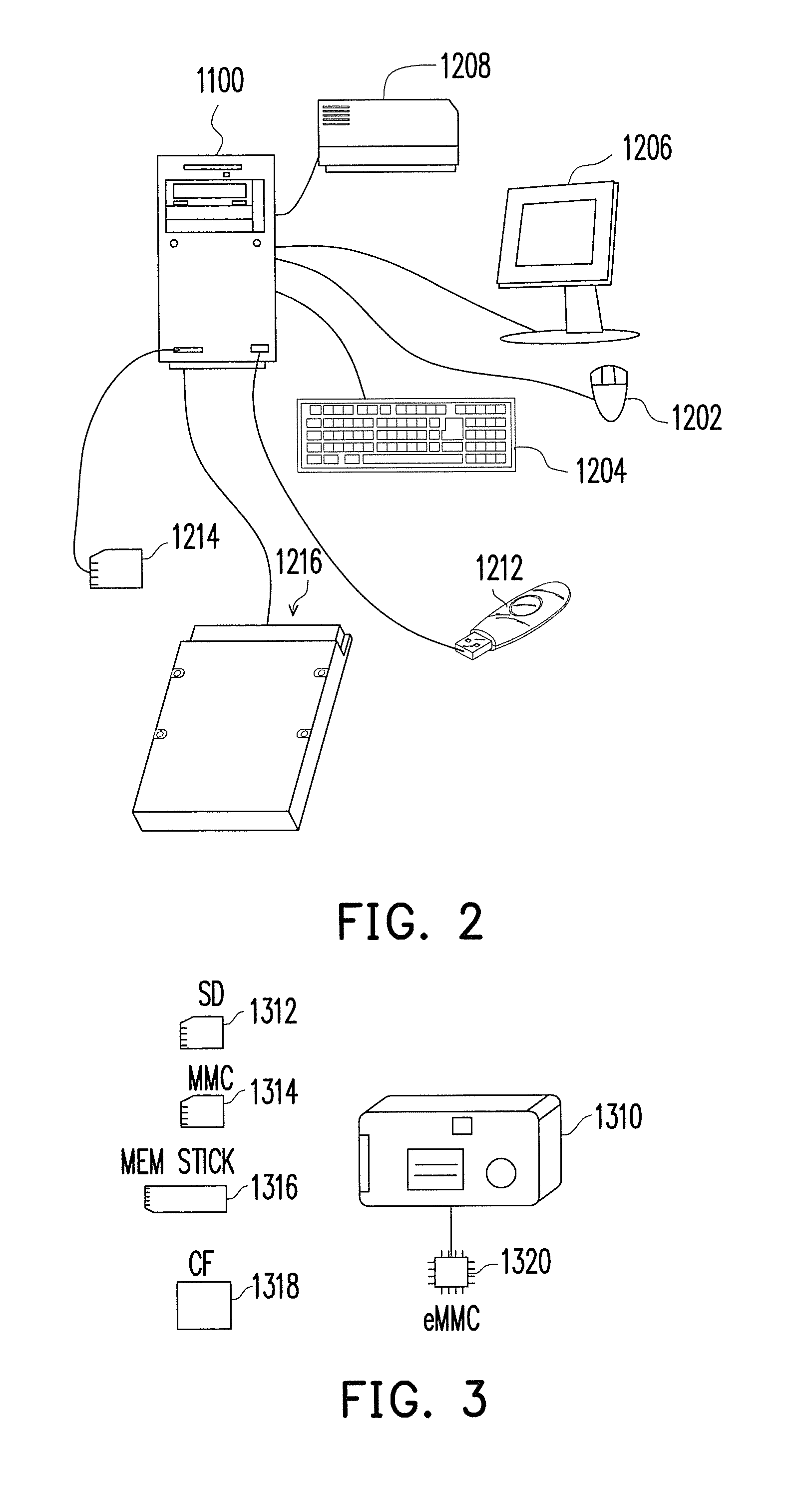

Data writing method, memory controller and memory storage apparatus

ActiveUS20140372667A1Avoid dataReduce spacingMemory architecture accessing/allocationError detection/correctionData streamMemory controller

A data writing method for a rewritable non-volatile memory module is provided. The method includes receiving a write command and data corresponding to the write command from a host system and temporarily storing the data into a buffer memory, and the data includes a plurality of sub-data streams. The method still includes transmitting the sub-data streams into the rewritable non-volatile memory module, thereby writing the sub-data streams into at least one physical erasing unit of the rewritable non-volatile memory module. The method further includes generating parity information based on at least portion of the sub-data streams; storing the parity information into the buffer memory and deleting the data from the buffer memory. Accordingly, the method can effectively utilize the storage space of the buffer memory.

Owner:PHISON ELECTRONICS

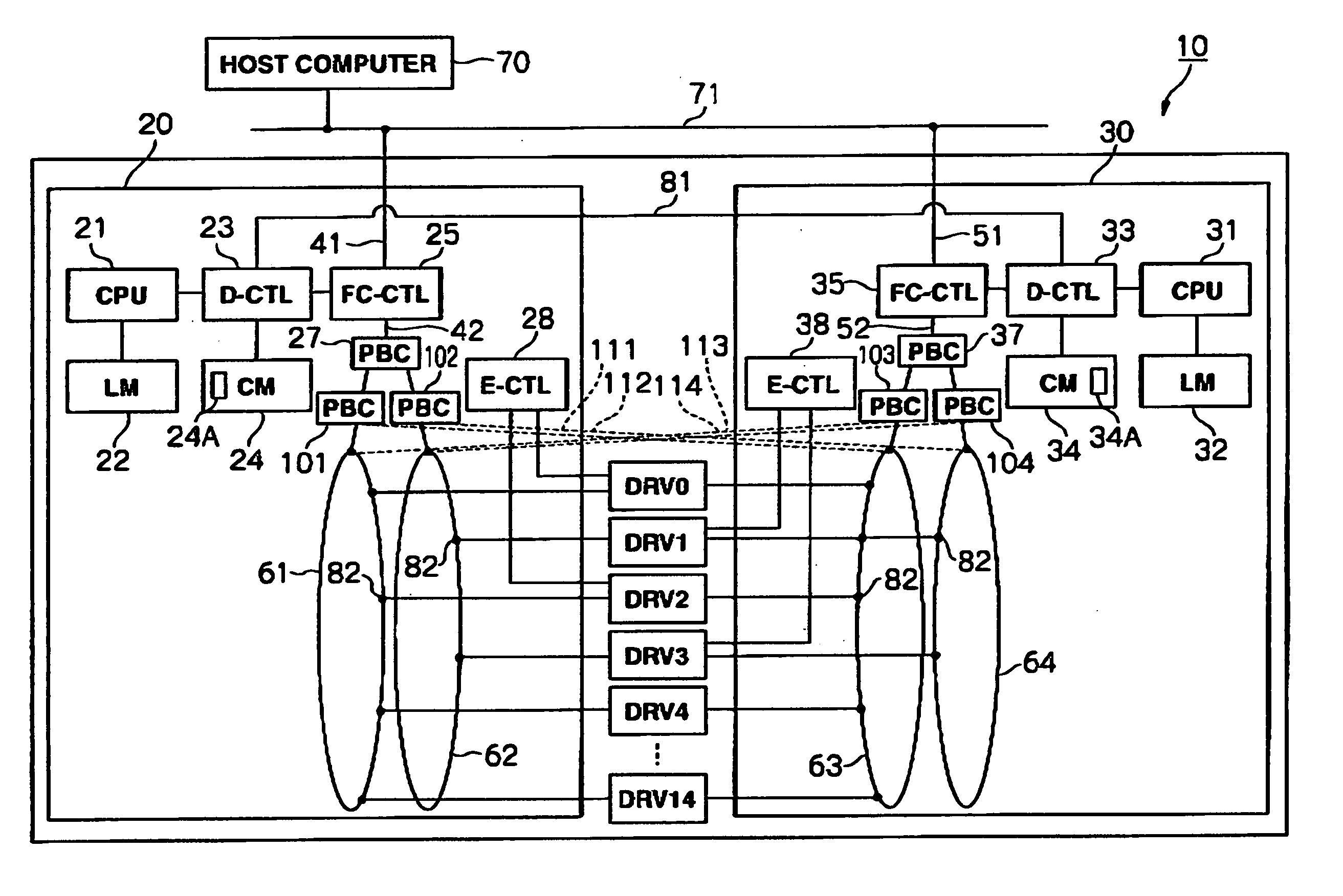

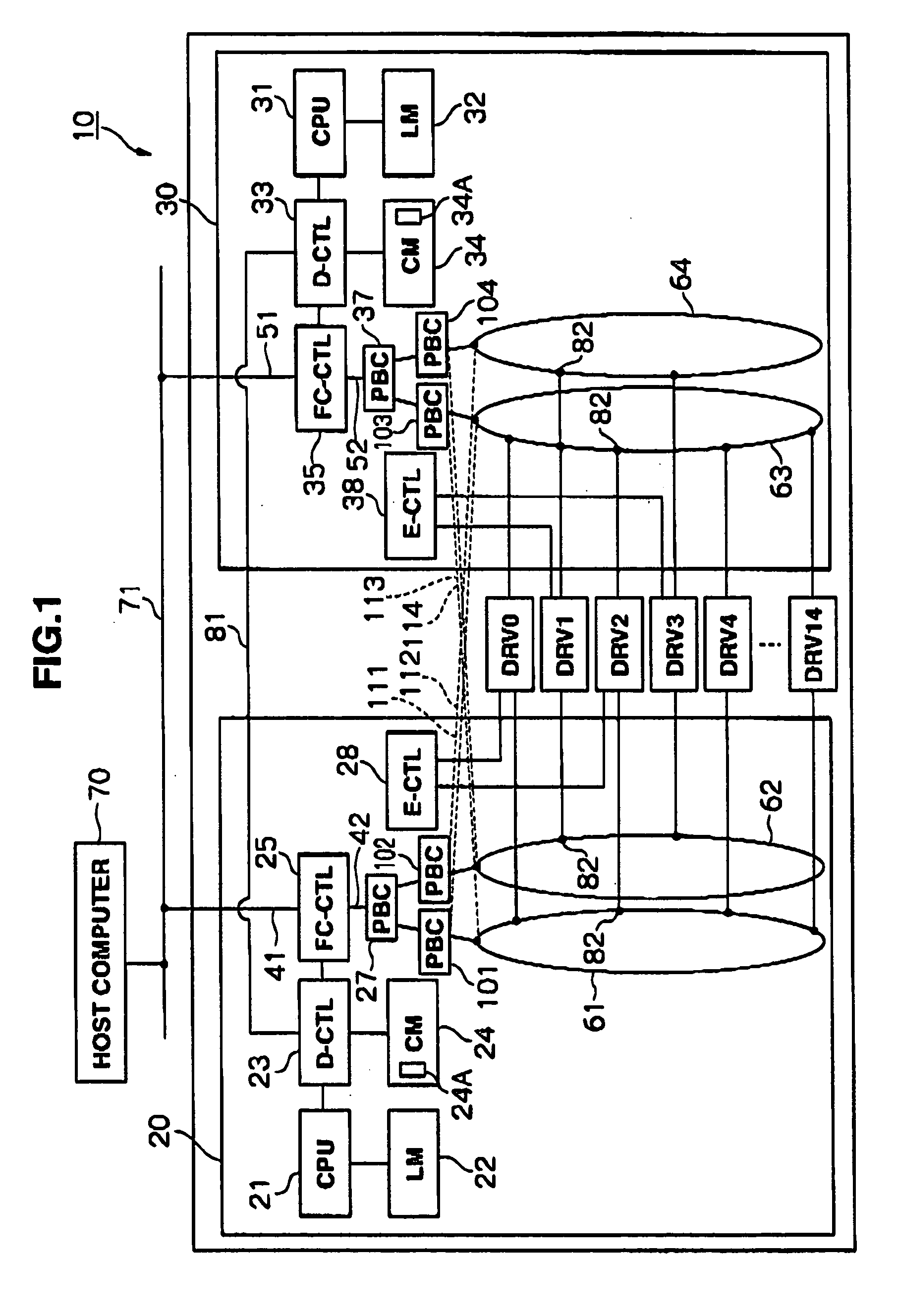

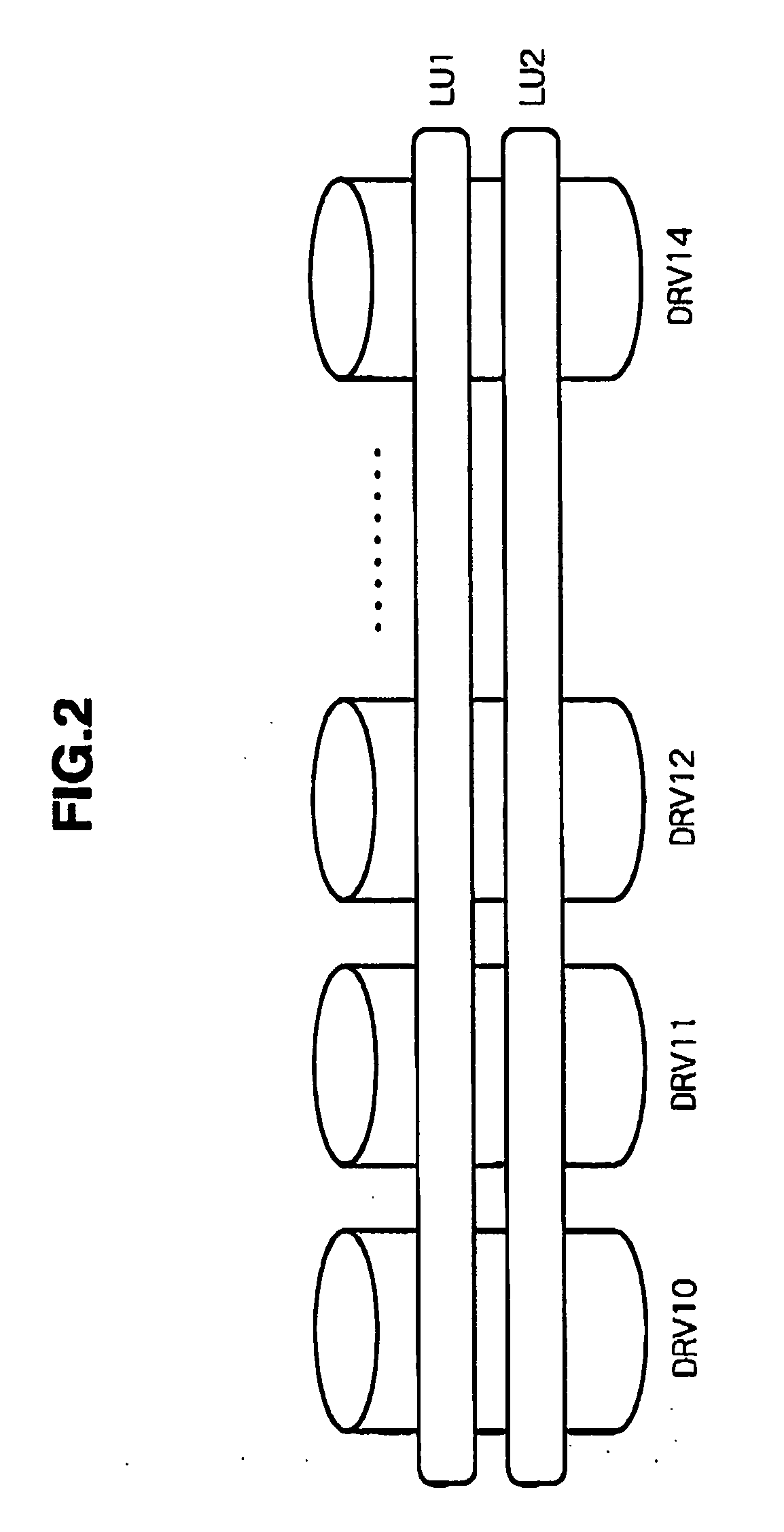

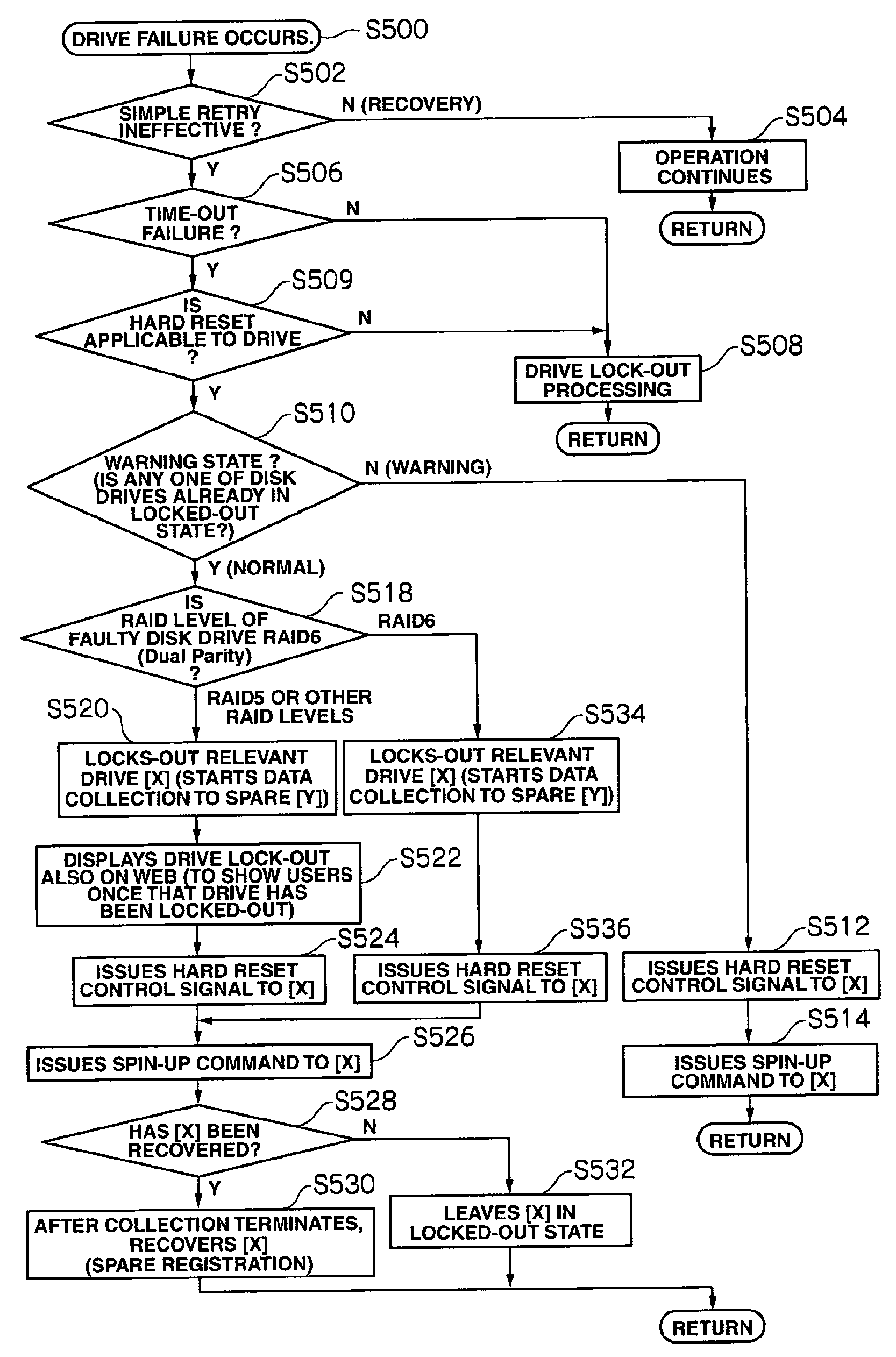

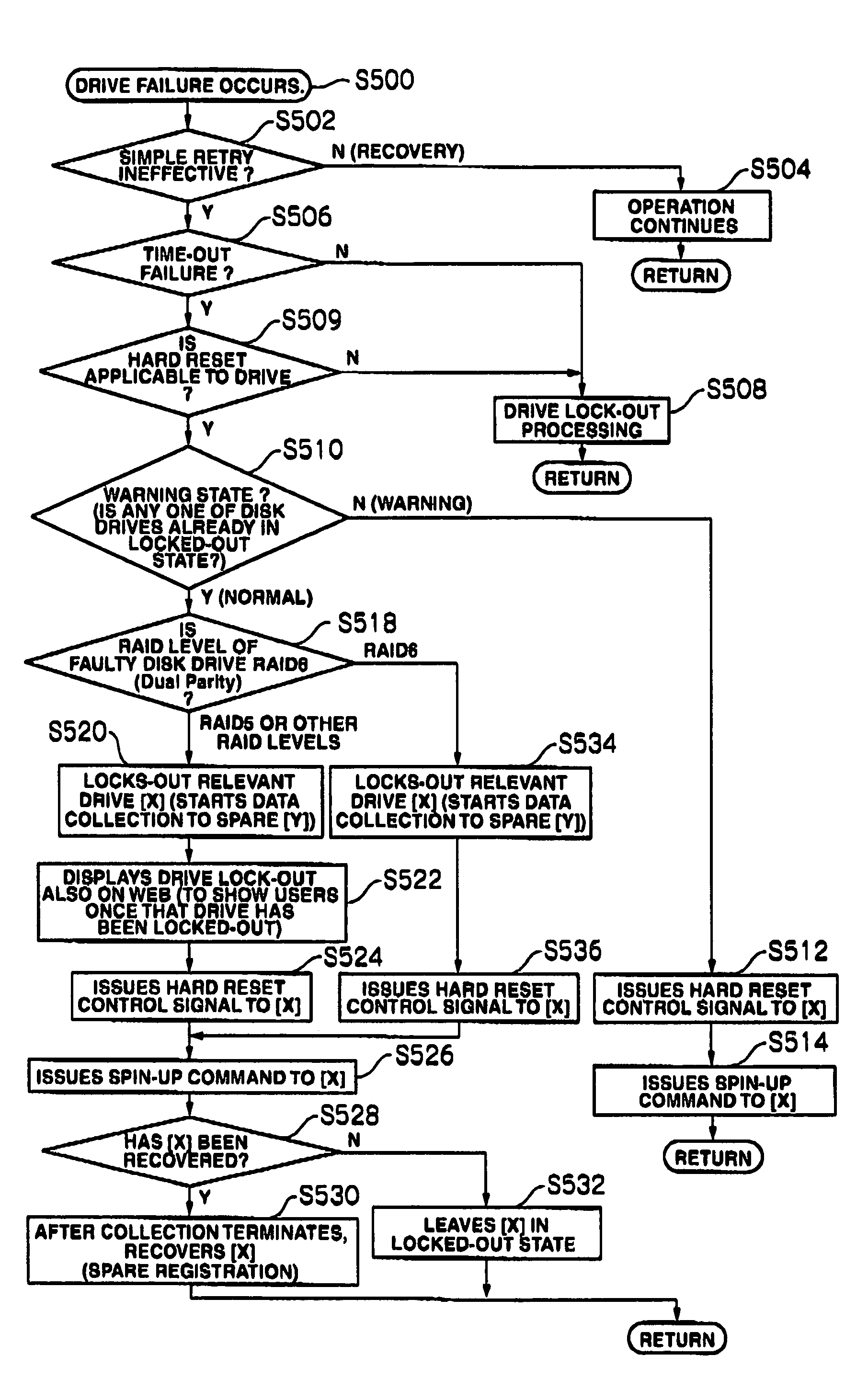

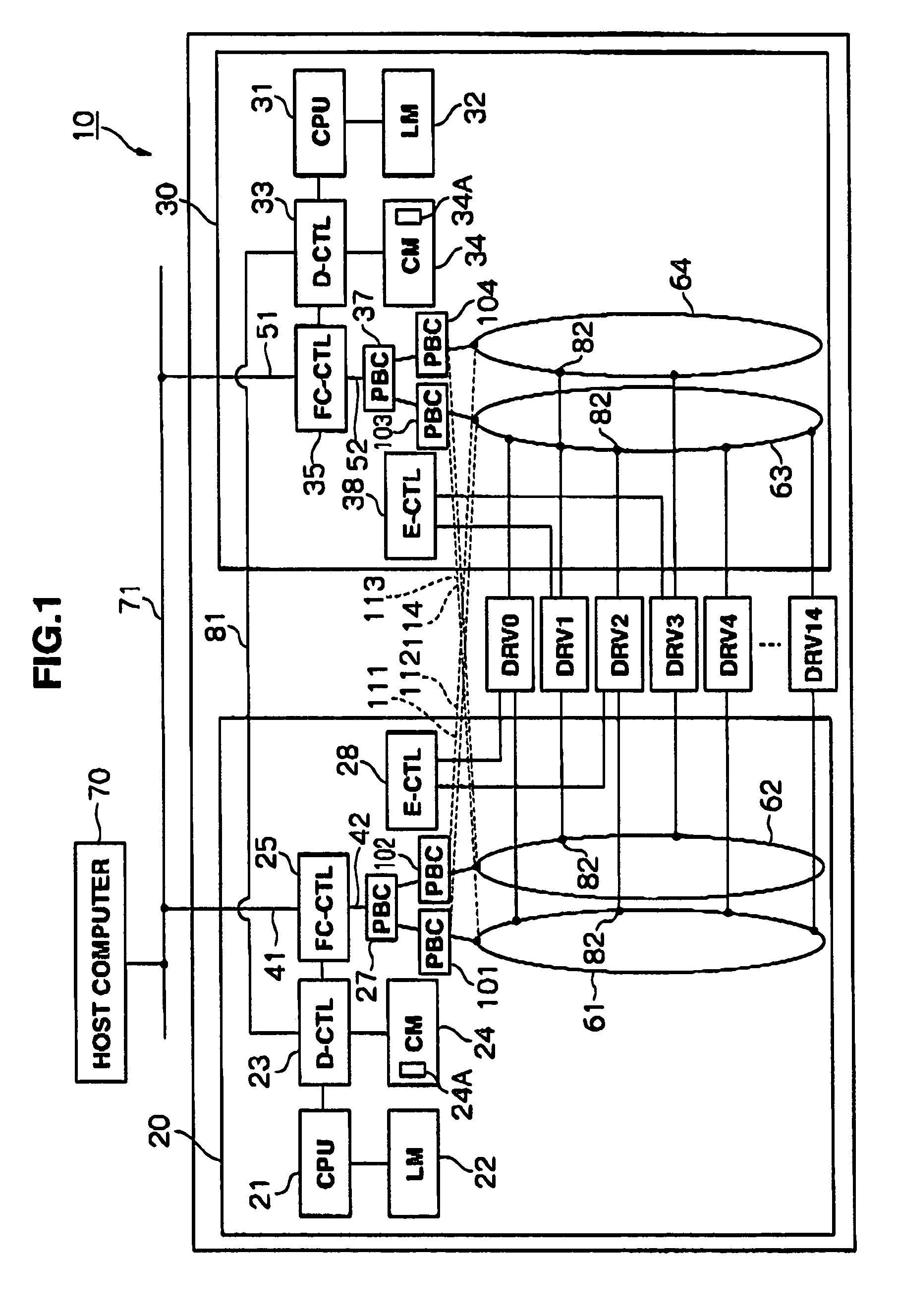

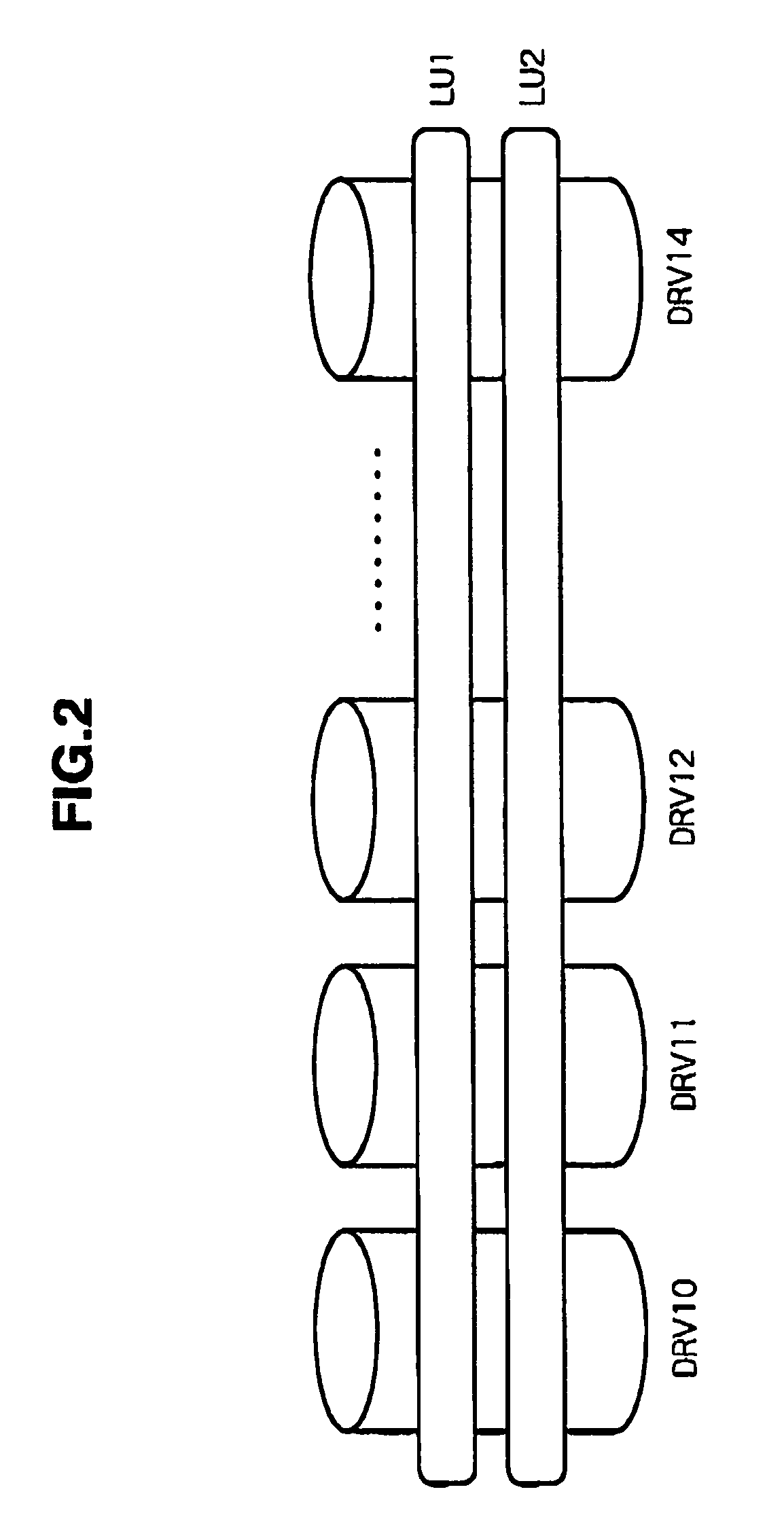

Disk array apparatus and method for controlling the same

InactiveUS20060277445A1Low failure rateEnsure data reliabilityNon-redundant fault processingControl signalDisk array

A disk array apparatus capable of reducing a disk drive fault rate where a time-out failure has occurred is provided. The disk array apparatus includes: a plurality of disk drives; and a control unit for performing data input / output processing of the disk drives in response to a data input / output request from a host system. The control unit includes: a memory for storing control information for specifying a failure of at least one of the disk drives, and failure information of the faulty disk drive; a circuit for specifying, from the failure information, the disk drive in which a time-out failure has occurred, and for issuing an instruction to retry a control command to the disk drive; and a circuit for outputting a control signal to the faulty disk drive in order to hard reset the disk drive if the disk drive does not recover from the failure.

Owner:HITACHI LTD

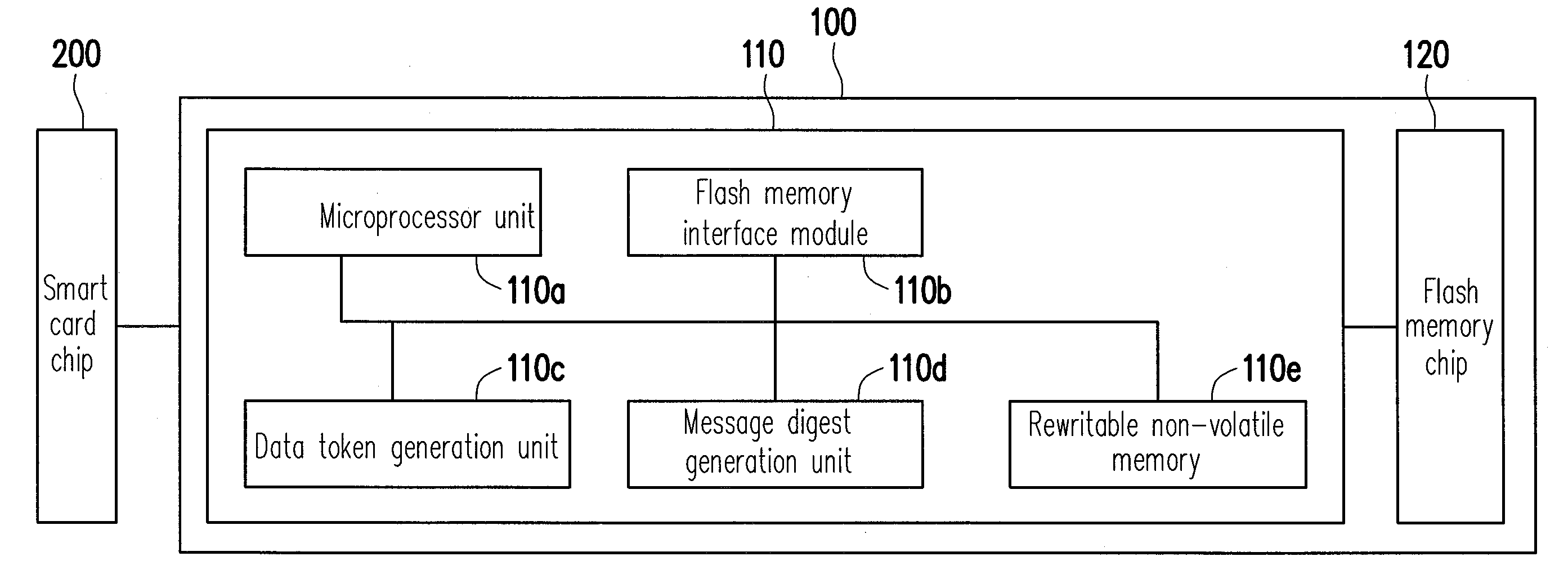

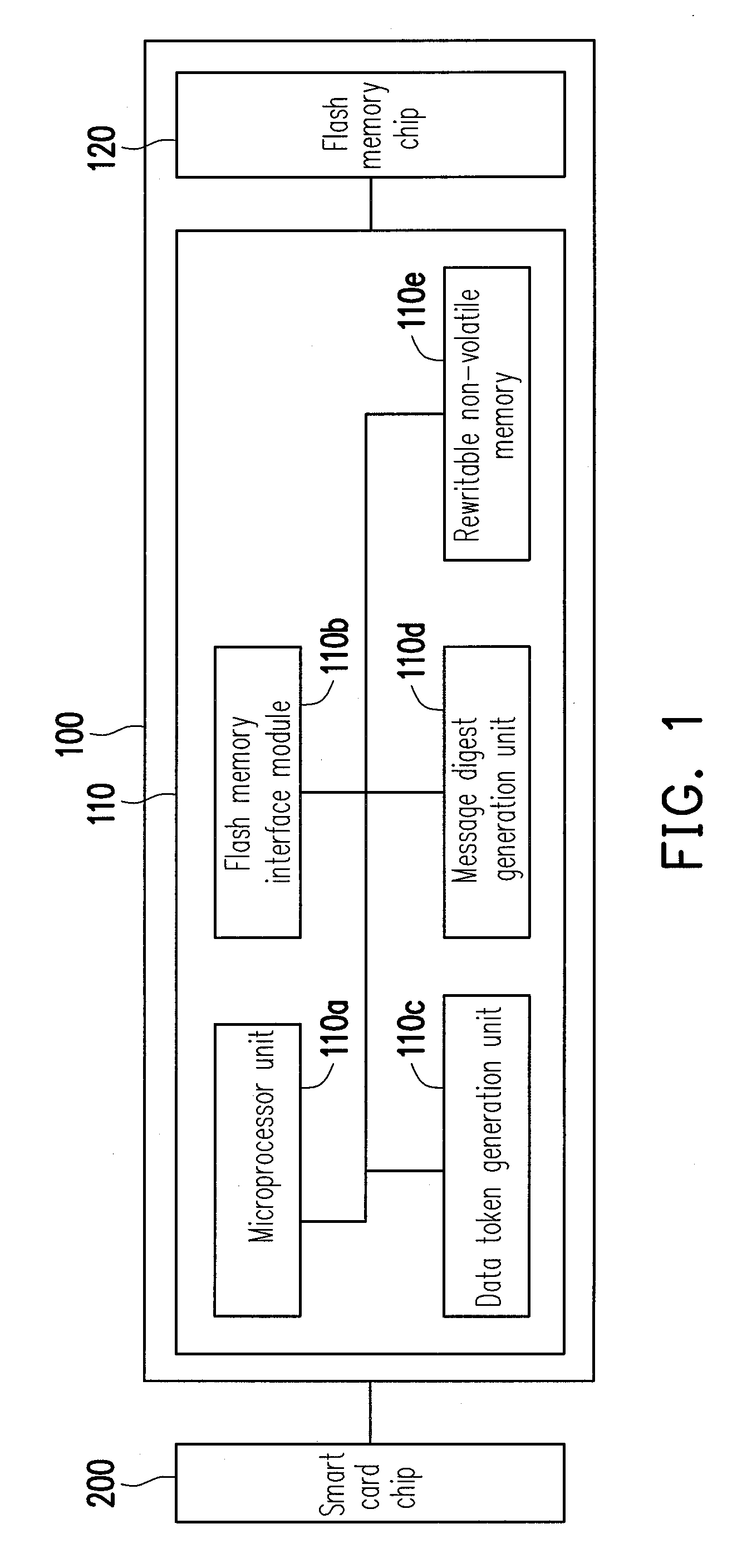

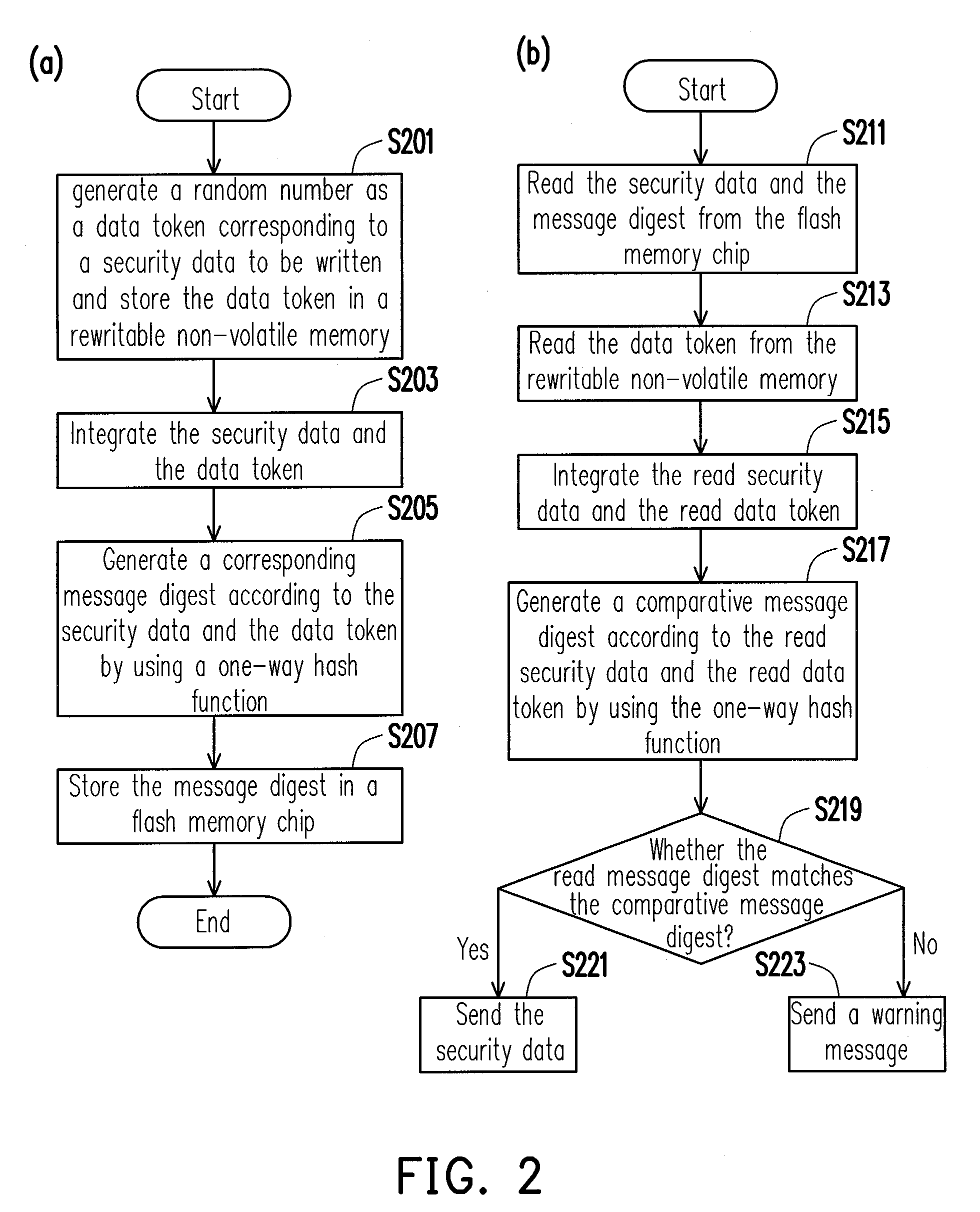

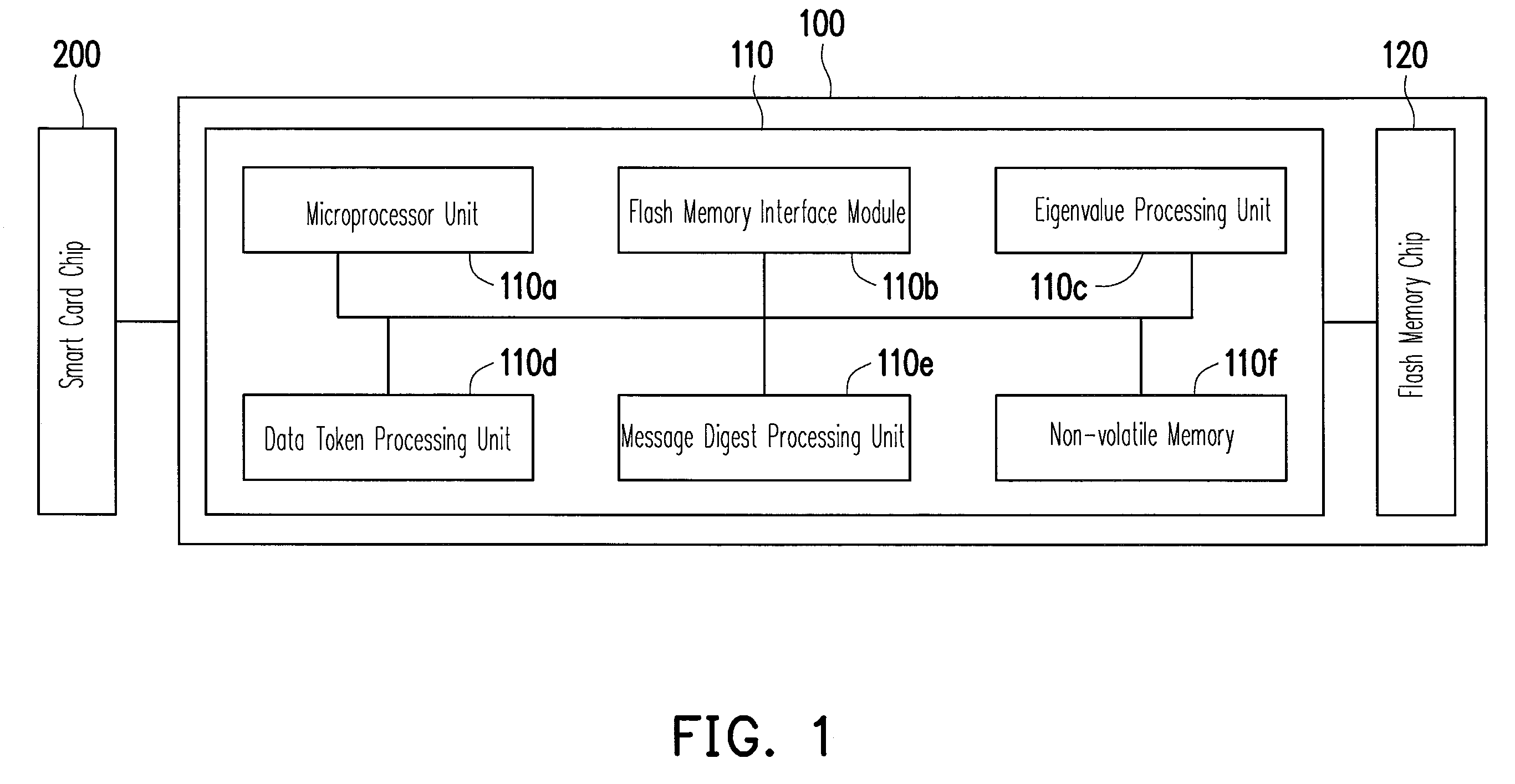

Flash memory storage system and controller and data protection method thereof

ActiveUS20100115184A1Ensure reliabilityEnsure data reliabilityUser identity/authority verificationMemory adressing/allocation/relocationHash functionNon-volatile memory

A flash memory storage system including a controller and a flash memory chip is provided, wherein the controller is disposed with a rewritable non-volatile memory. When the controller writes a security data into the flash memory chip, the controller randomly generates a data token and generates a message digest according to the security data and the data token by using a one-way hash function, wherein the data token and the message digest are respectively stored in the rewritable non-volatile memory and the flash memory chip. Subsequently, when the controller reads the security data from the flash memory chip, the controller determinates whether the security data is falsified according to the data token and the message digest respectively stored in the rewritable non-volatile memory and the flash memory chip. Thereby, the security data in the flash memory chip can be effectively protected.

Owner:SAMSUNG ELECTRONICS CO LTD

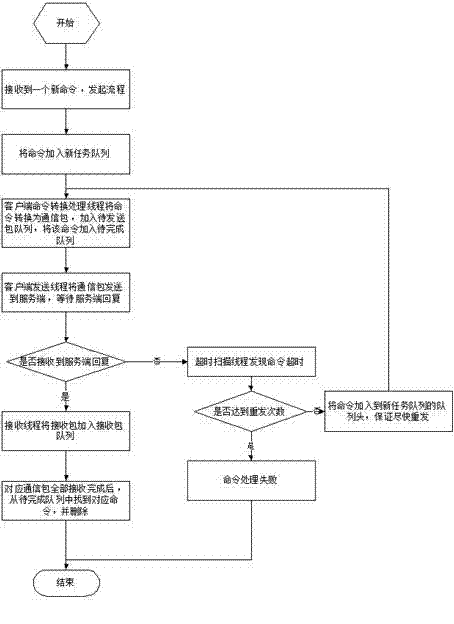

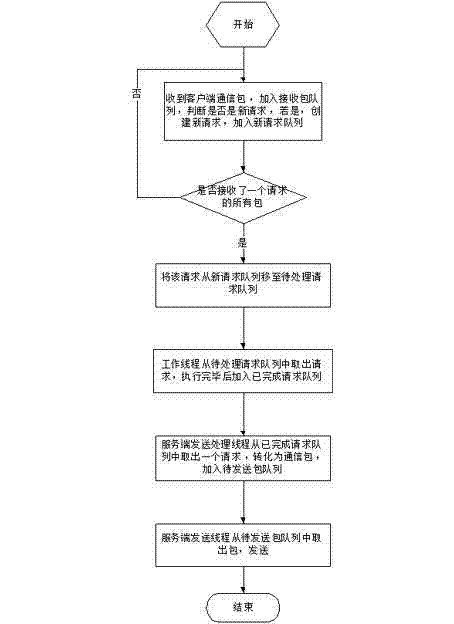

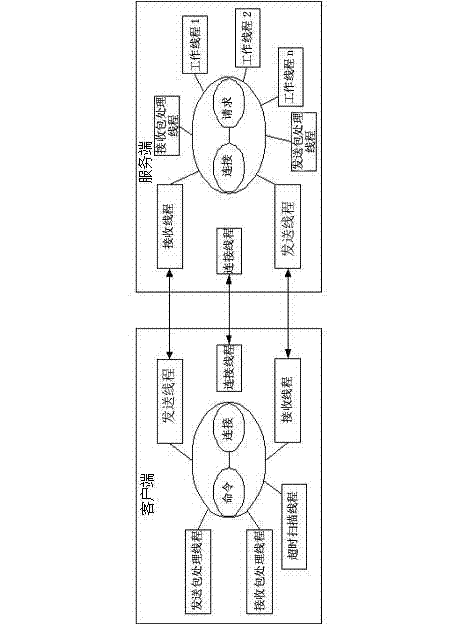

Method for improving data transmission efficiency on basis of TCP (Transmission Control Protocol) long connection

ActiveCN102957627AImprove parallelismEnsure data reliabilityError prevention/detection by using return channelData switching networksConnection poolHeartbeat detection

The invention provides a method for improving data transmission efficiency on the basis of TCP (Transmission Control Protocol) long connection. Data communication is carried out between a client and a server by adopting TCP long connection; the receiving and processing of the client and the server are subjected to parallel processing by adopting an asynchronous mode; a communication data packet adopts a numbering mechanism to ensure the data reliability and the processing consistency; the communication reliability is ensured by a heartbeat detection and failure reconnection mechanism; the parallel transmission efficiency is improved by using a connection pool; and the client and the server process a plurality of queues and a plurality of threads, the parallelism of data processing is improved and the processing efficiency is improved.

Owner:重庆浪潮政务云管理运营有限公司

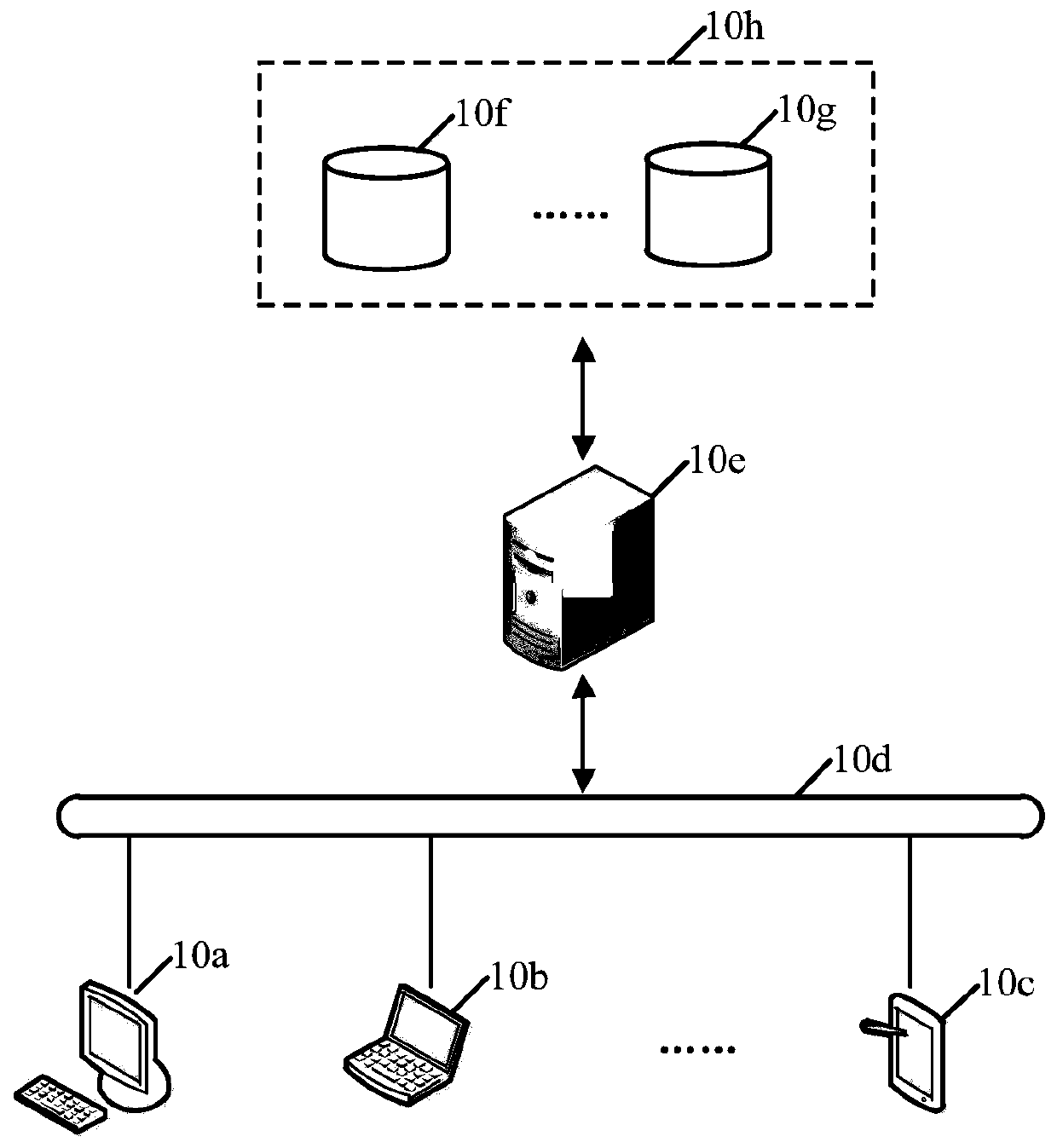

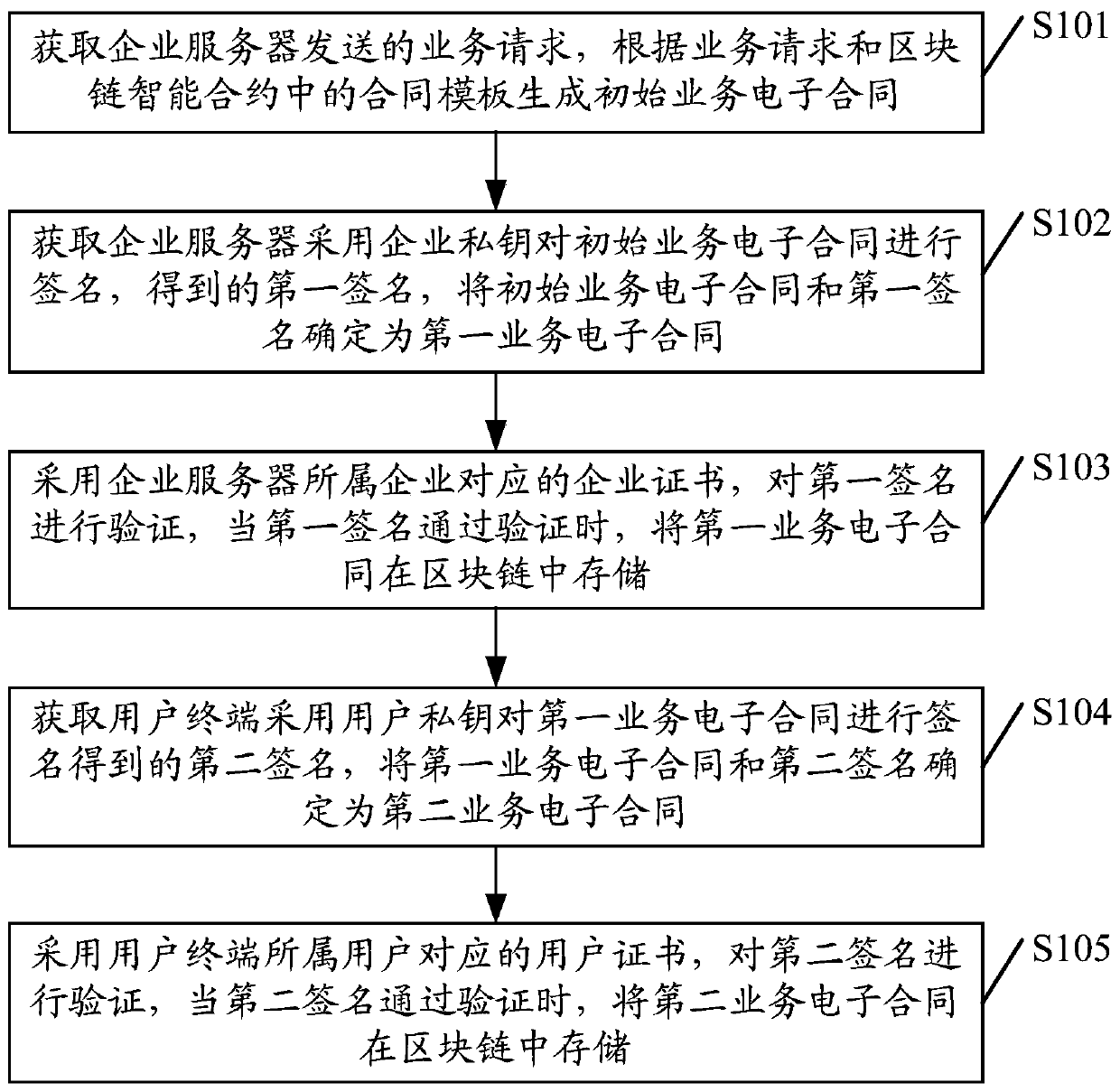

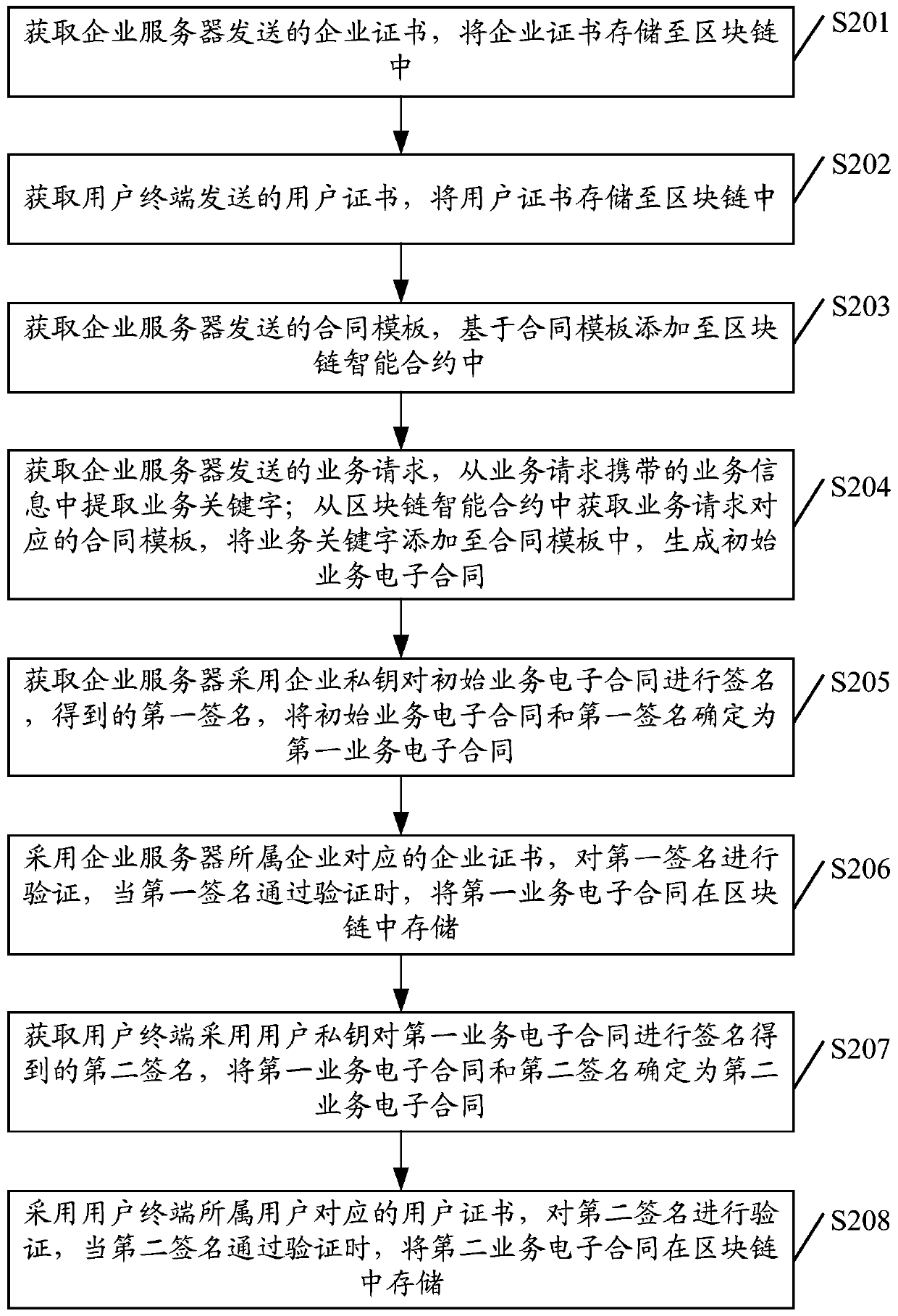

Electronic contract processing method and device based on block chain

PendingCN111080295AAvoidance of loss of interestsEnsure data reliabilityPayment protocolsElectronic contractsBusiness enterprise

The embodiment of the invention discloses an electronic contract processing method and device based on a block chain. The method comprises the steps: obtaining a service request transmitted by an enterprise server, and generating an initial service electronic contract according to the service request and a contract template in an intelligent contract; obtaining a first signature obtained by signing the initial service electronic contract by the enterprise server, and determining the initial service electronic contract and the first signature as a first service electronic contract; verifying the first signature by adopting an enterprise certificate, and when the first signature passes the verification, storing the first service electronic contract in a block chain; obtaining a second signature obtained by signing the first service electronic contract by the user terminal, and determining the first service electronic contract and the second signature as a second service electronic contract; and verifying the second signature by adopting the user certificate, and when the second signature passes the verification, storing the second service electronic contract in the block chain. According to the invention, the data reliability of the network information can be ensured.

Owner:TENCENT TECH (SHENZHEN) CO LTD

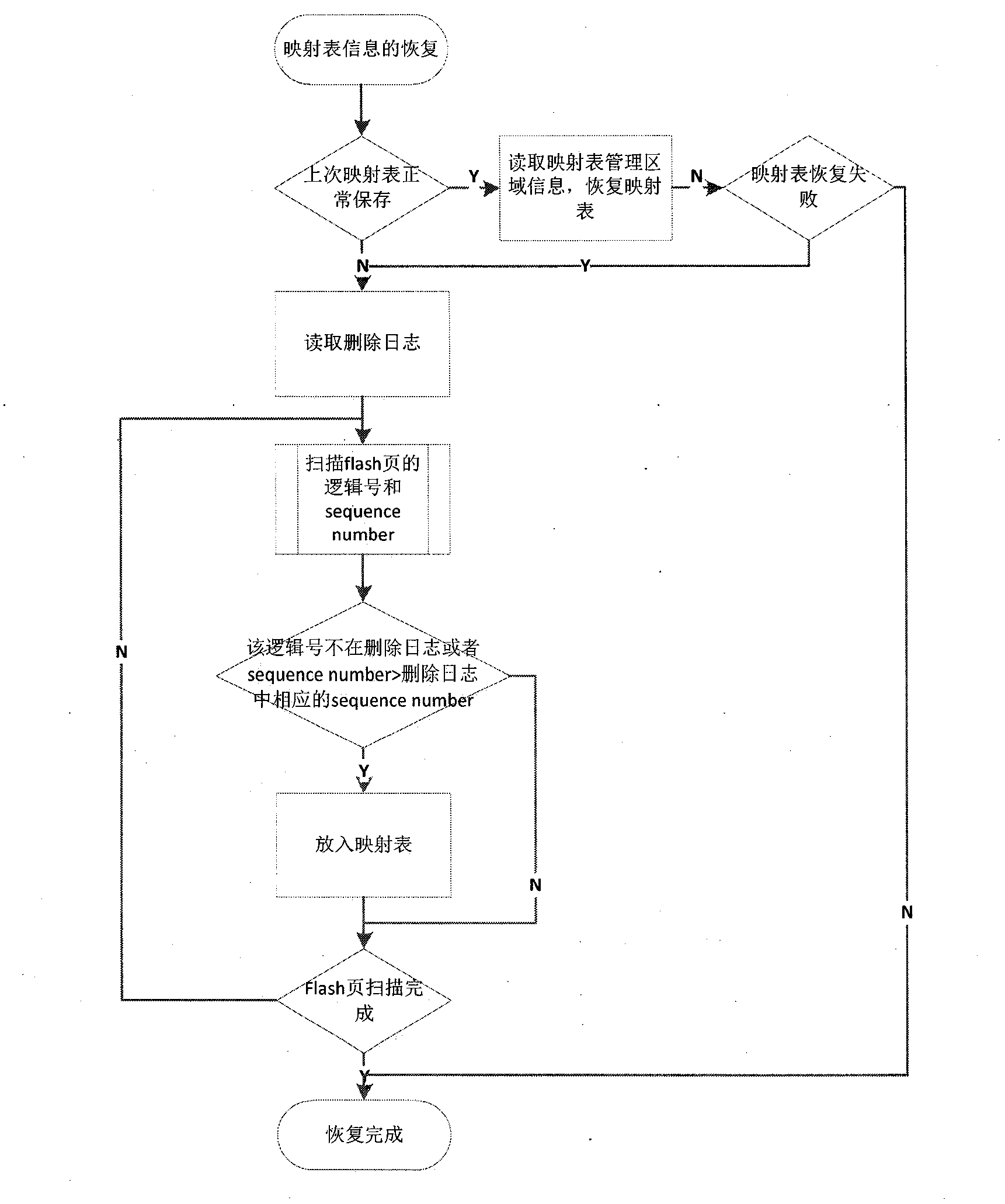

Technology for preserving and recovering mapping table information of high-reliability solid state storage equipment

InactiveCN103902406AEnsure data reliabilityThere will be no unrecoverableHardware monitoringRedundant operation error correctionSolid-state storageDependability

The invention discloses a technology for preserving and recovering mapping table information of high-reliability solid state storage equipment. In order to guarantee that a mapping table can still be reconstructed when a mapping table preservation area is abnormal and then to guarantee reliability of storage equipment based on a flash memory, the technology includes the steps that all change operations, such as writing, erasing and deleting are numbered (Sequence Number), logical block numbers and Sequence Number are preserved in a clear area of a flash memory physical page, deletion operation and Sequence Number are recorded, and high reliability of products can be guaranteed by scanning the clear area of the physical page and scanning deletion operation records to reconstruct the mapping table when the mapping table is abnormal and cannot be recovered. By the implementation of the technology, reliability of the storage equipment based on the flash memory can be guaranteed, and even data can still be effectively recovered when the flash memory locally suffers from mechanical damage.

Owner:FASII INFORMATION TECH SHANGHAI

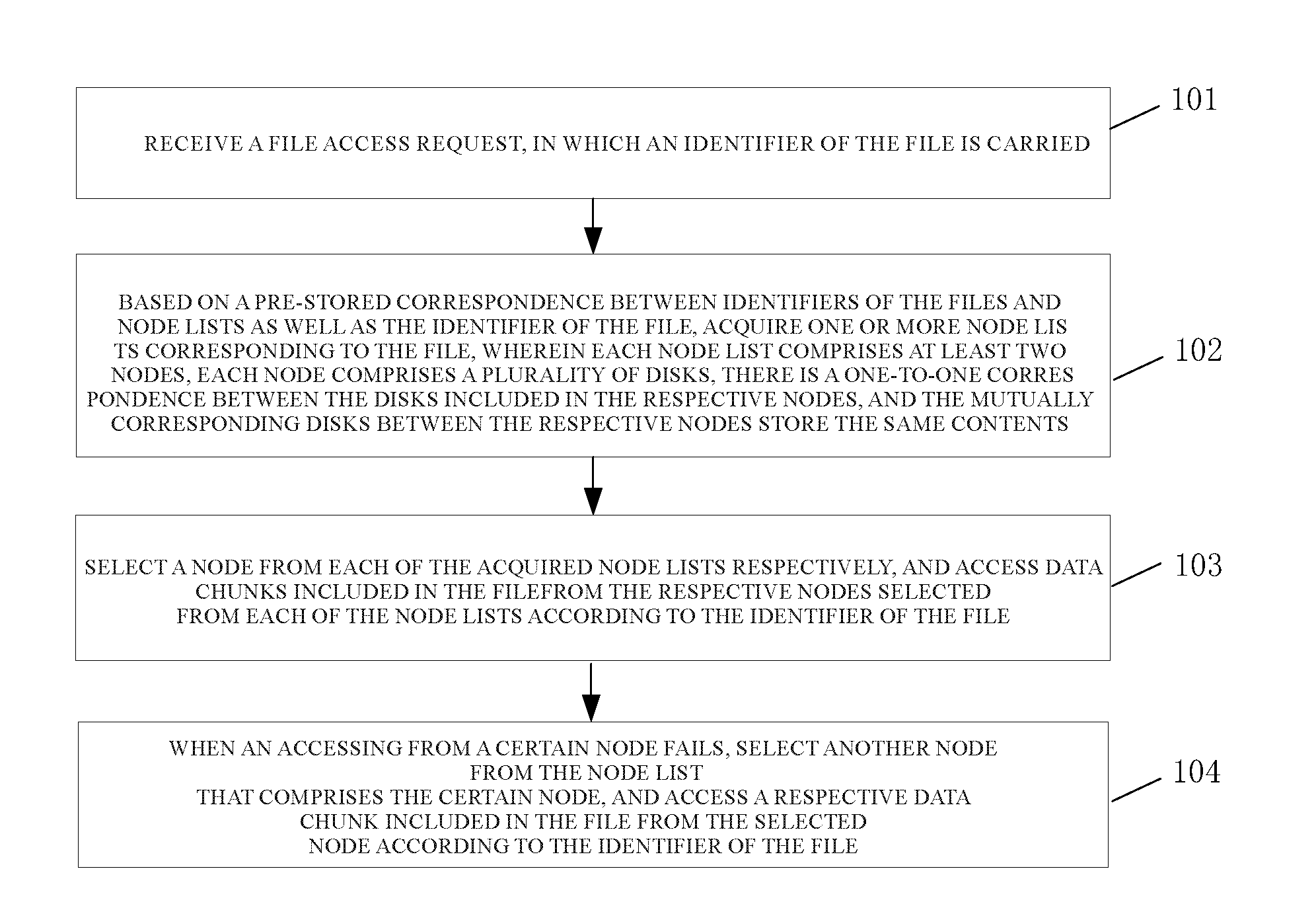

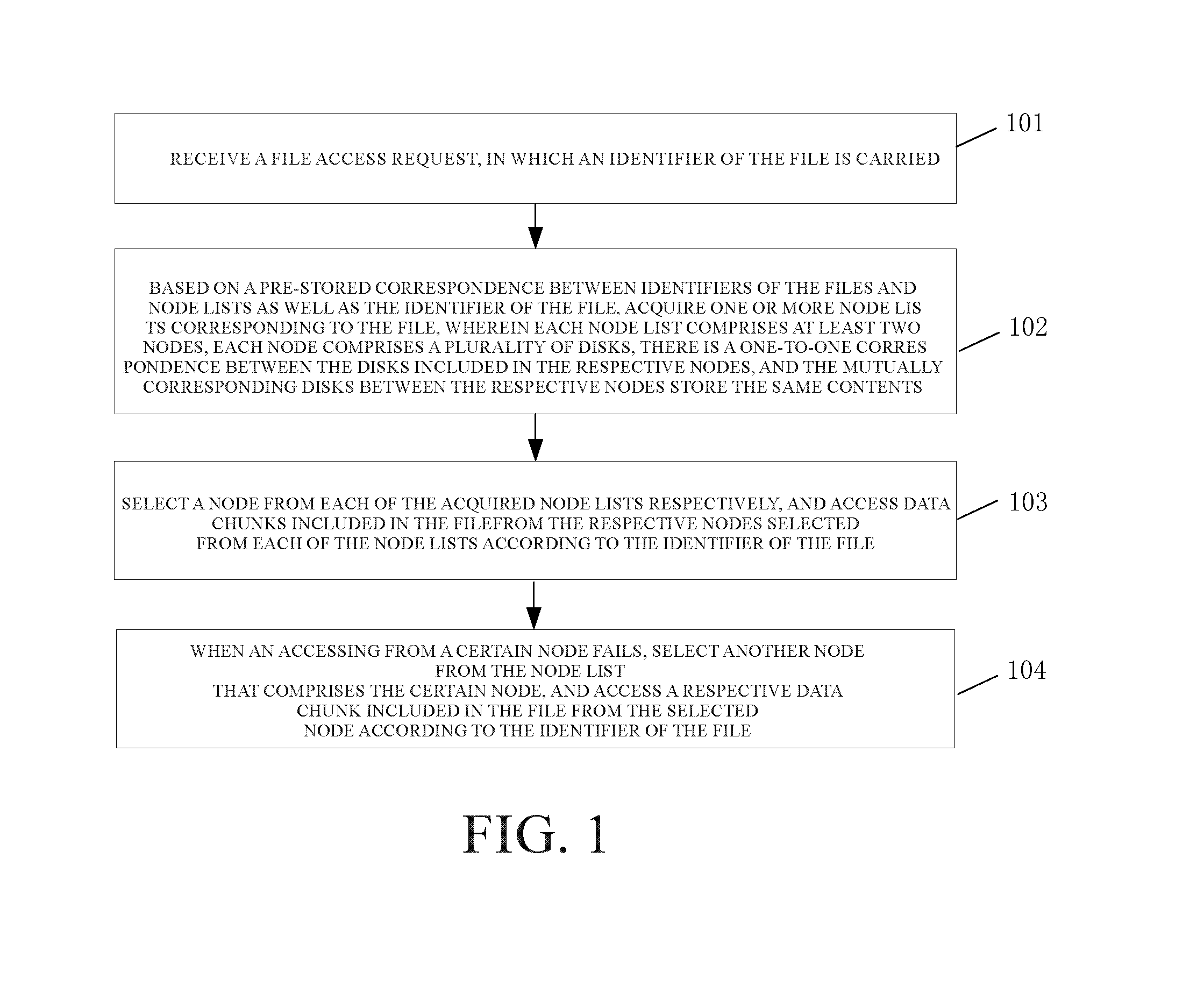

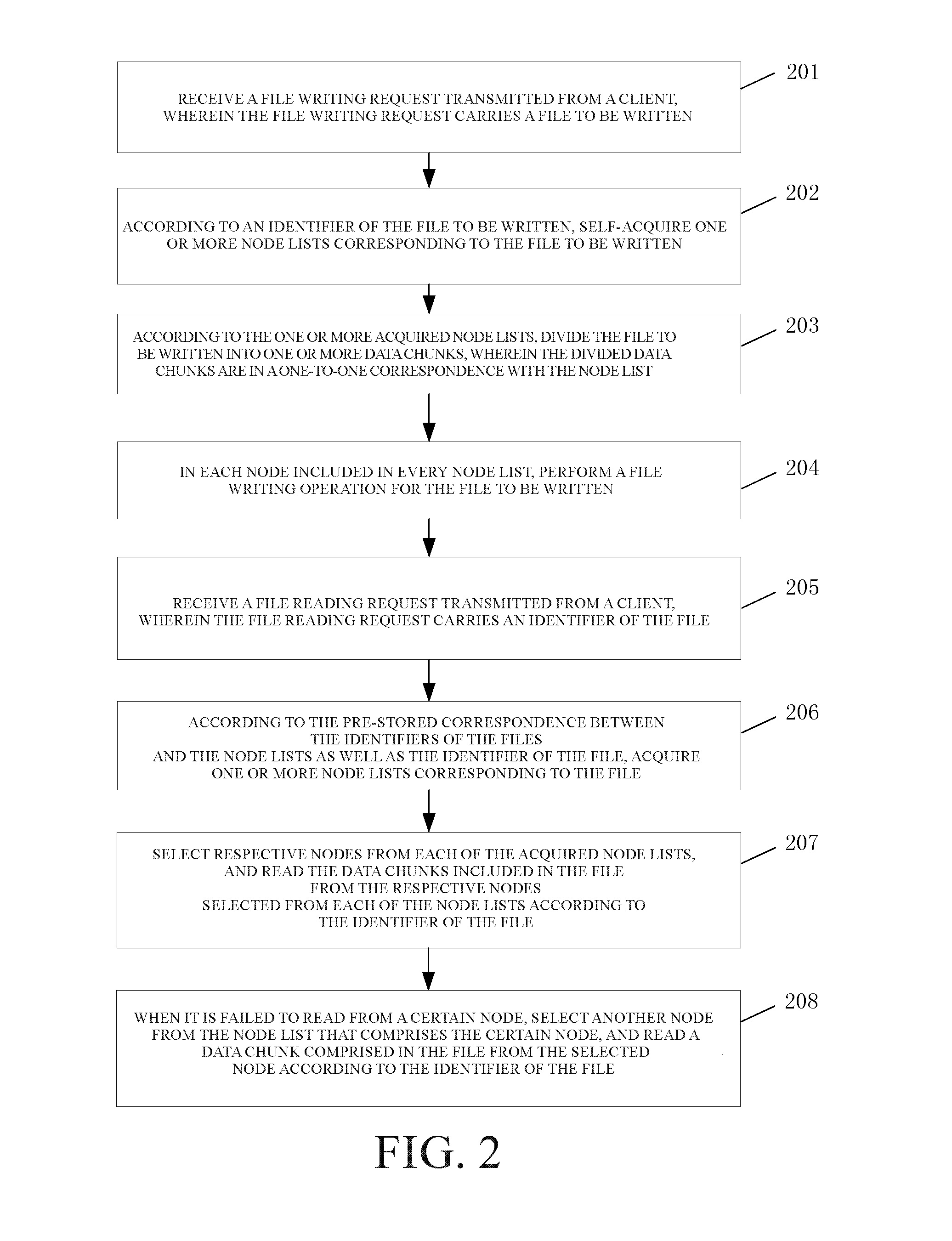

Disk fault tolerance method, device and system

ActiveUS20140229763A1Improve availabilityEnsure data reliabilityRedundant operation error correctionRedundant hardware error correctionFault toleranceData reliability

The present invention relates to disk fault tolerance method, device and system which relates to a field of computer. The method comprises: receiving a file access request; acquiring one or more node lists corresponding to the file, wherein each node list comprises at least two nodes, and the mutually corresponding disks between the respective nodes store the same contents; accessing data chunks included in the file from the respective nodes selected from each of the node lists; and when an accessing from a certain node fails, selecting another node from the node list that comprises the certain node, and accessing a respective data chunk included in the file from the selected node according to the identifier of the file. The present invention proposes a multilevel pairing storage technology in combination with advantages of the dual machine duplexing mechanism, wherein a plurality of completely independent machines are mutually backed up from a node level to a disk level. This solves problems of data read-write fault, a disk fault, single node fault and the like in a large-scale distributed storage system, ensures a data reliability in any scene, and improves a disk availability and read-write performance.

Owner:TENCENT TECH (SHENZHEN) CO LTD

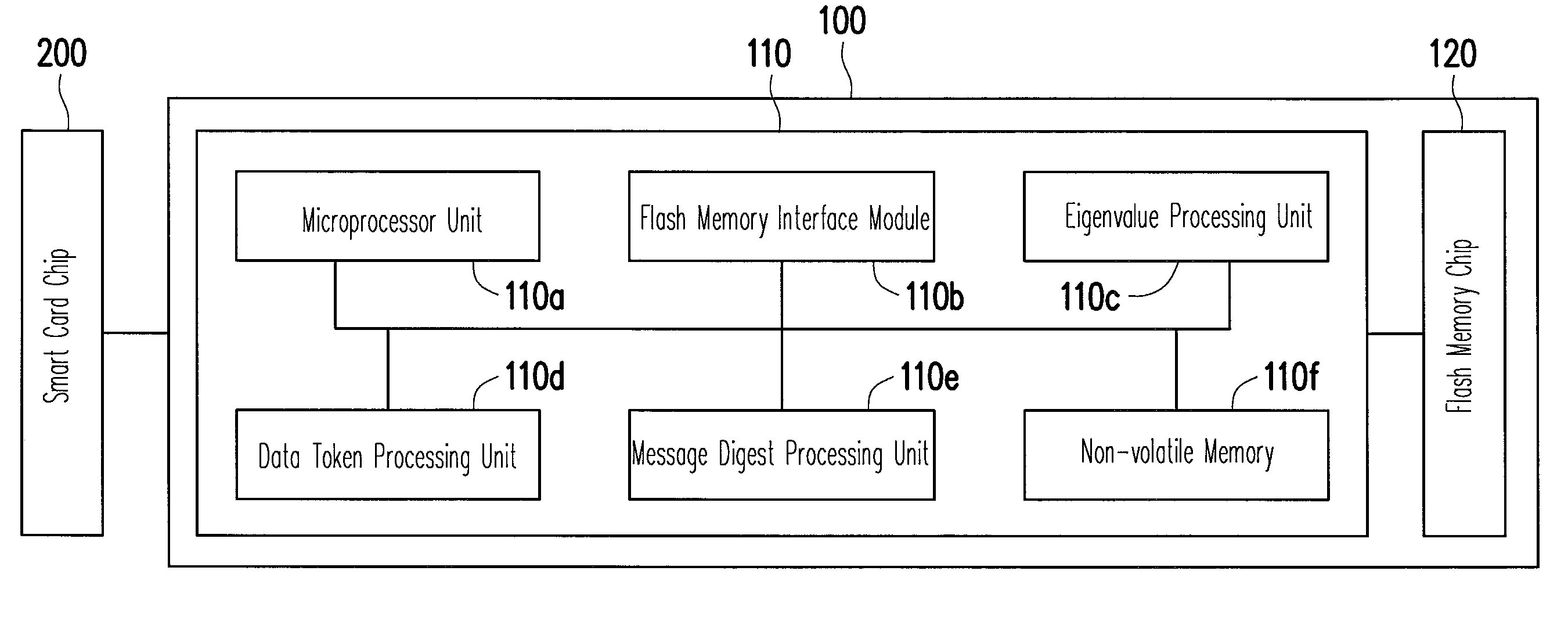

Flash memory storage system, and controller and method for Anti-falsifying data thereof

ActiveUS20100146190A1Ensure reliabilityEnsure data reliabilityUser identity/authority verificationMemory adressing/allocation/relocationHash functionData storing

A flash memory storage system is provided. The flash memory storage system includes a controller having a rewritable non-volatile memory and a flash memory chip. The rewritable non-volatile memory stores a data token and the flash memory chip stores a security data and a message digest. When the security data in the flash memory chip is updated, the controller updates the data token and generates an eigenvalue, and updates the message digest according to the updated data token and the updated eigenvalue by using a one-way hash function, respectively. When the security data in the flash memory chip is processed by the controller, the controller determinates whether the security data is falsified according to the data token, the eigenvalue and the message digest. In such a way, the security data stored in the flash memory storage system can be effectively protected.

Owner:SAMSUNG ELECTRONICS CO LTD

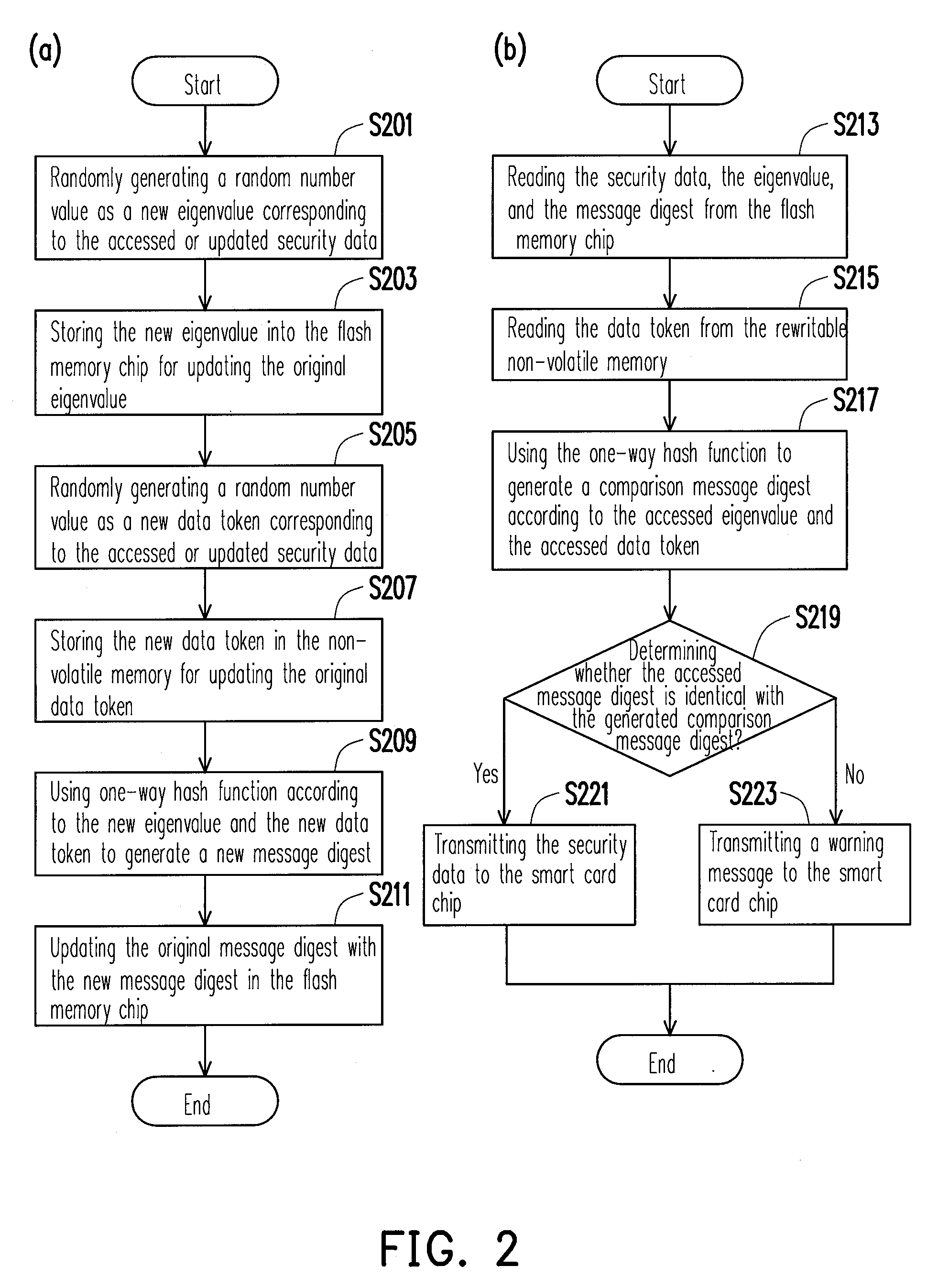

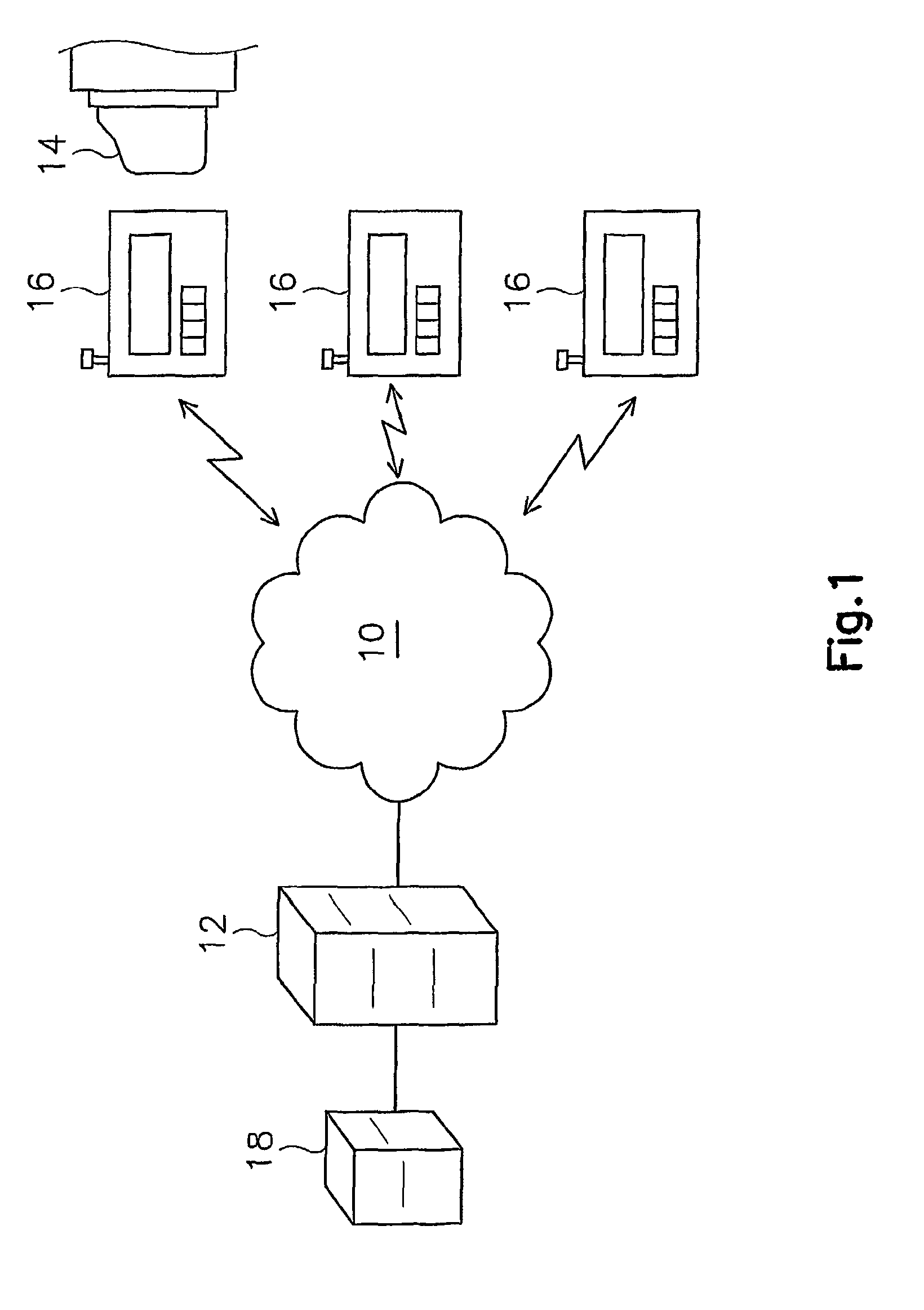

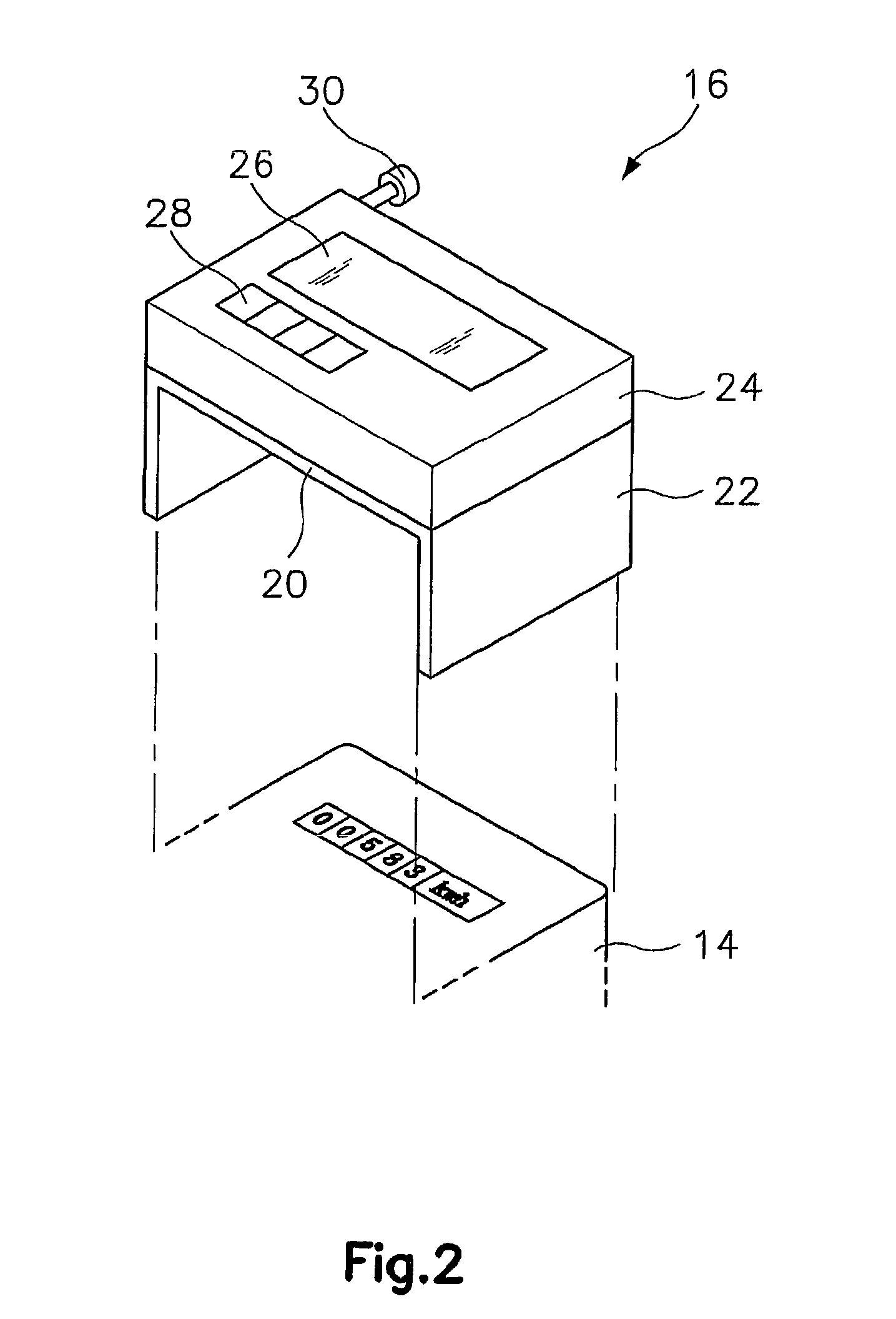

Wireless terminal for checking the amount used of gauge and a gauge management system using a wireless communication network

InactiveUS7064678B2Reducing human resourceEnsure data reliabilityElectric signal transmission systemsTariff metering apparatusTelecommunicationsElectricity

The present invention discloses a wireless terminal for checking the amount used of gauge and a gauge management system using a wireless communication network which checks the amount used of electricity, tap water, and gas by a wireless terminal. A wireless terminal established in a front of gauge, senses image of a figure at gauge, transmit data of the amount used with a wireless communication network. So, management of collecting rates of electricity, tap water, and gas are achieved easily.

Owner:2WG +1

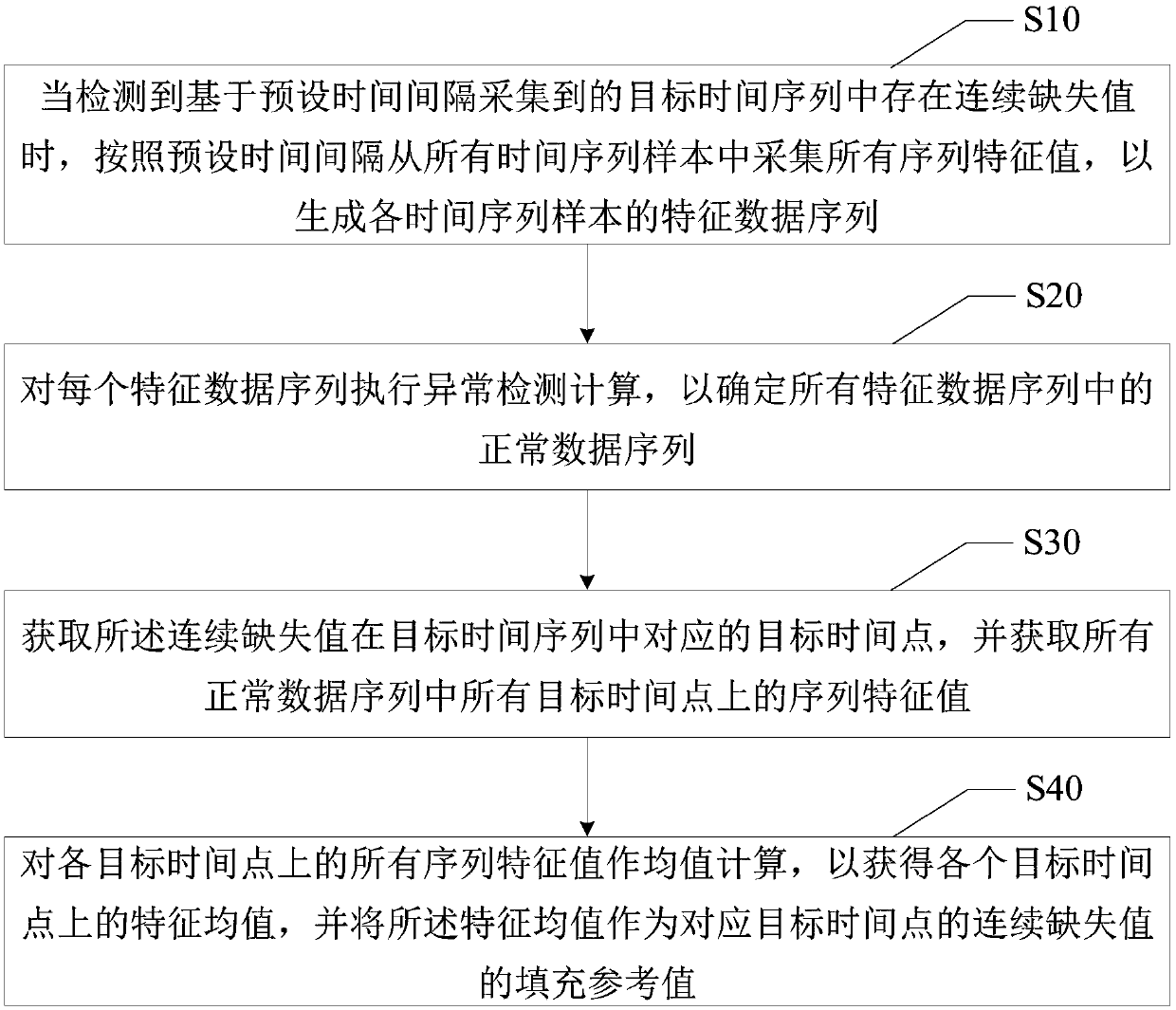

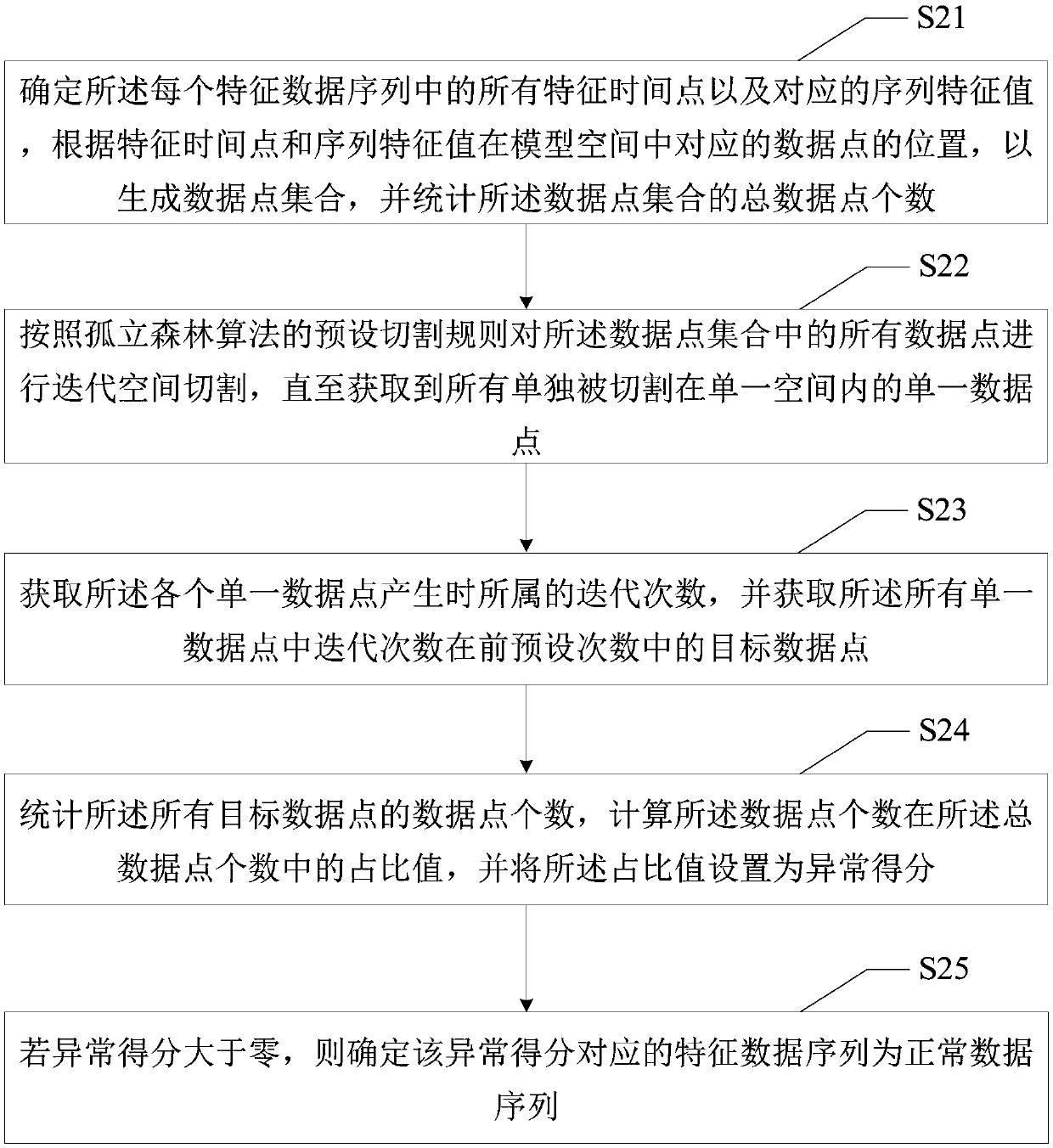

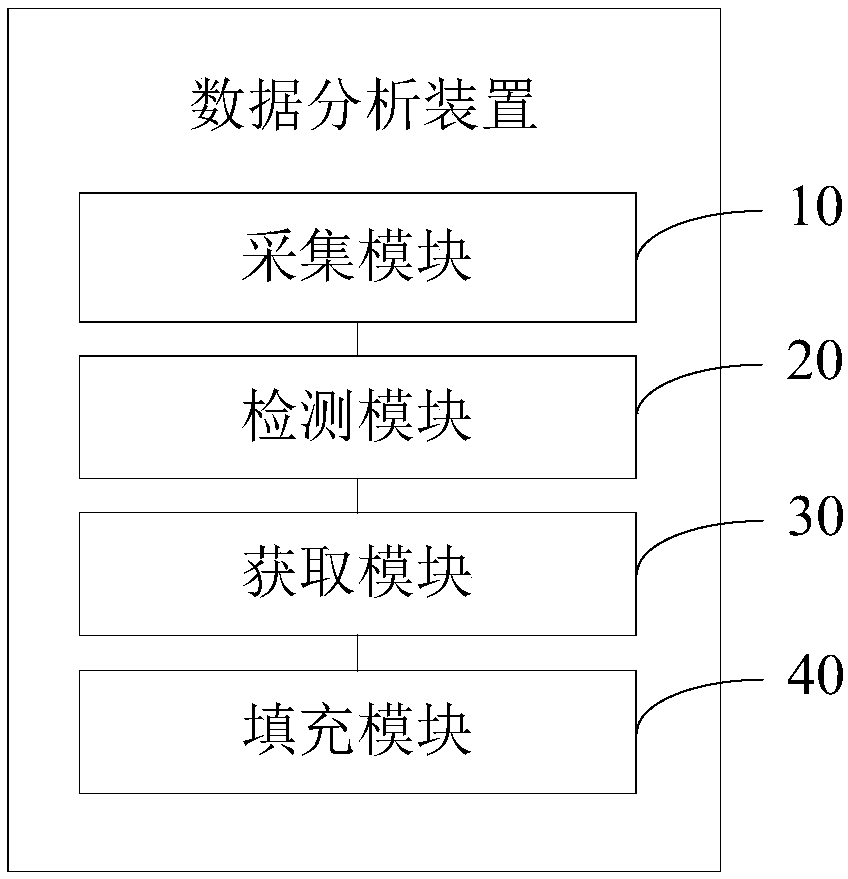

Continuous missing value filling method, data analysis device, terminal and storage medium

PendingCN109947812APreserve distribution propertiesEnsure data reliabilityDigital data information retrievalComplex mathematical operationsAlgorithmAnomaly detection

The invention discloses a continuous missing value filling method, a data analysis device, a data analysis terminal and a computer readable storage medium. The continuous missing value filling methodcomprises the steps that if it is detected that continuous missing values exist in a target time sequence collected on the basis of a preset time interval, collecting all sequence characteristic values from all time sequence samples according to the preset time interval, so that a characteristic data sequence of all the time sequence samples is generated; Performing anomaly detection calculation on each feature data sequence to determine normal data sequences in all the feature data sequences; Obtaining corresponding target time points of the continuous missing value in a target time sequence,and obtaining sequence characteristic values on all the target time points in all the normal data sequences; And carrying out mean value calculation on all sequence characteristic values on each target time point, and taking the characteristic mean value as a filling reference value of the continuous missing value of the corresponding target time point. The data authenticity of the time sequenceis improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

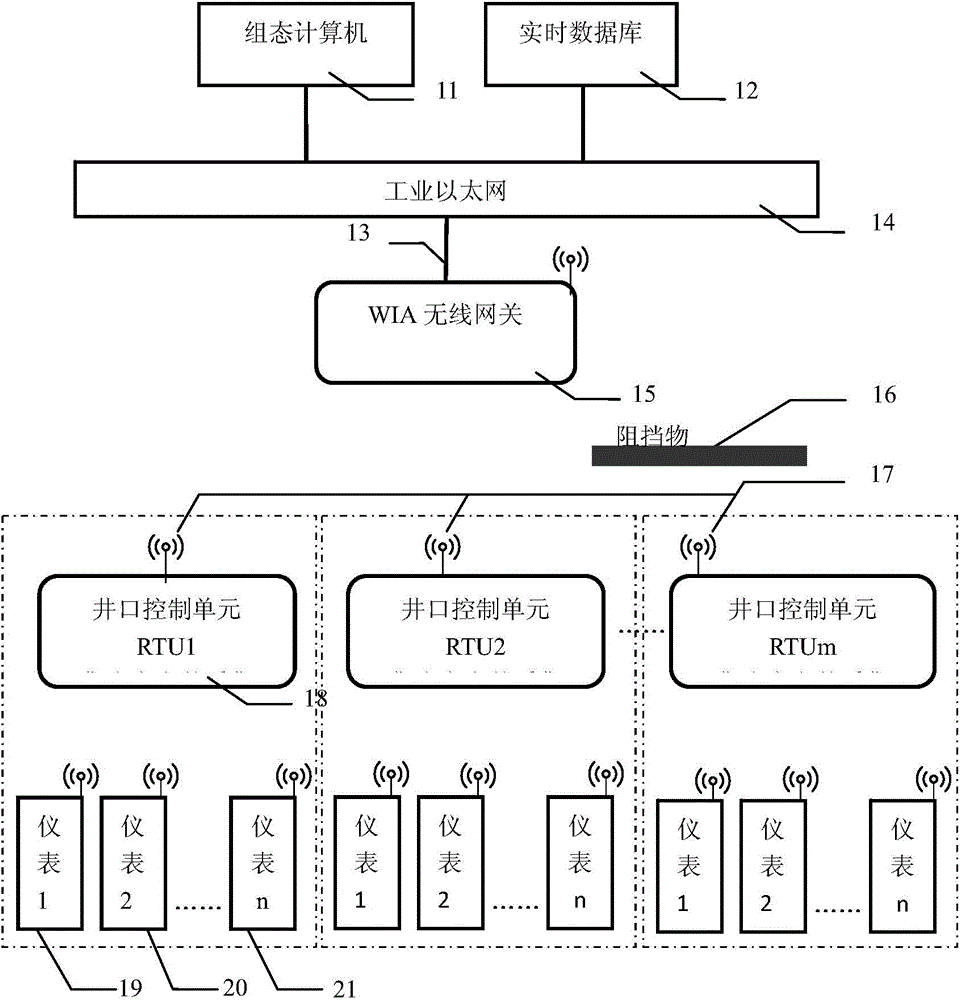

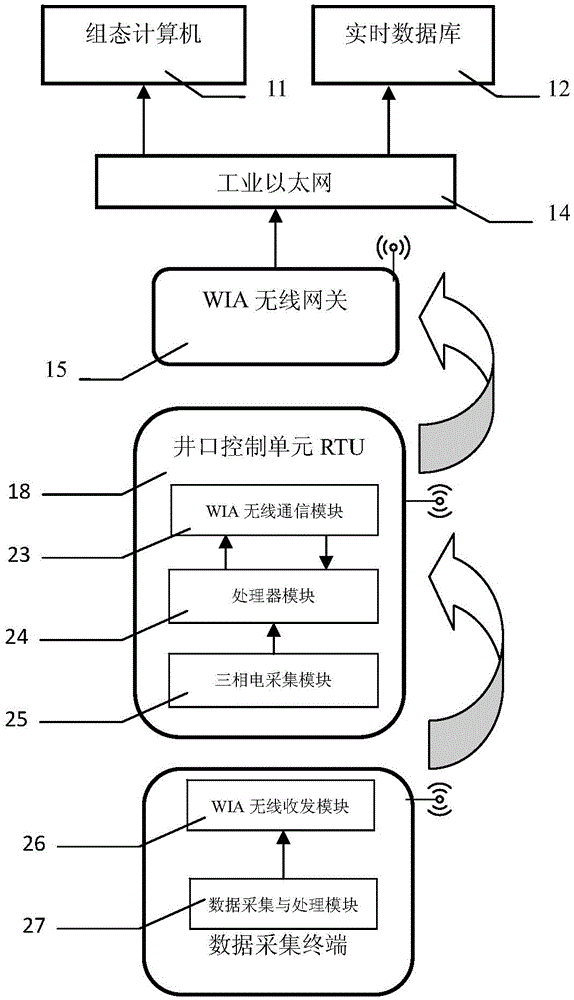

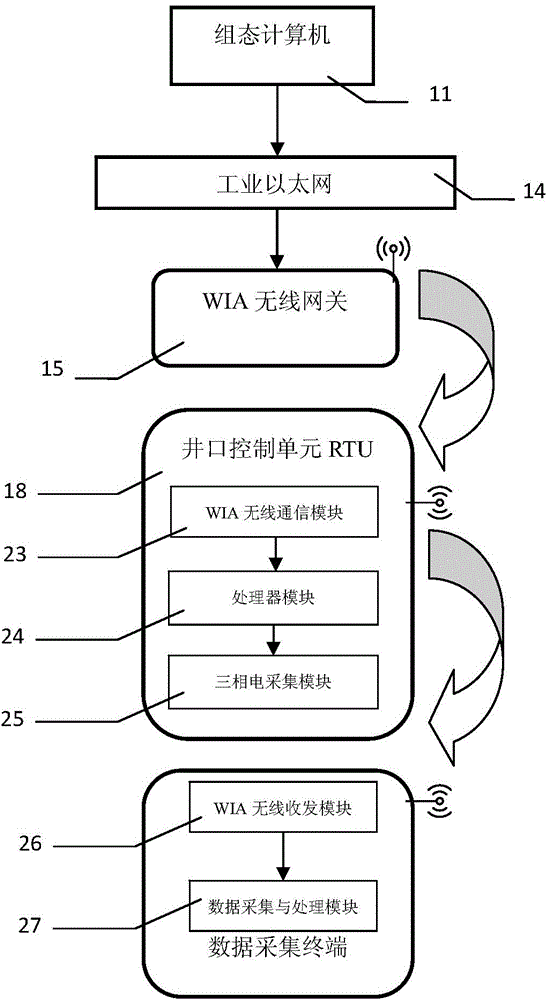

Oil pumping well data acquisition control system and method based on wireless network

ActiveCN104898579ARealize real-time automatic collectionEnsure data reliabilityEnergy industryTotal factory controlIndustrial EthernetWireless mesh network

The invention relates to an oil pumping well data acquisition control system based on a wireless network. The oil pumping well data acquisition control system comprises a configuration computer, an industrial Ethernet, a WIA wireless gateway, well head control units, and a data acquiring terminal. The configuration computer is connected with the WIA wireless gateway through the industrial Ethernet. The well head control units are arranged on oil pumping well heads and wirelessly communicates with the data acquiring terminal and the WIA wireless gateway. An oil pumping well data acquisition control method comprises: meters transmit regularly-acquired oil pumping well data to a well head control unit in the same oil pumping well where the meters are located, wherein the well head control unit transmits the oil pumping well data to the WIA wireless gateway in real time; the configuration computer receives, through the industrial Ethernet, network state information and real-time data of each oil pumping unit transmitted from the WIA wireless gateway. The well head control units RTU are all provided with wireless routing functions and achieve data communication by means of a multi-hop network when a barrier blocks a wireless signal or the wireless signal is not very well, thereby guaranteeing data reliability.

Owner:SHENYANG ZHONGKE AOWEI SCI & TECH CO LTD

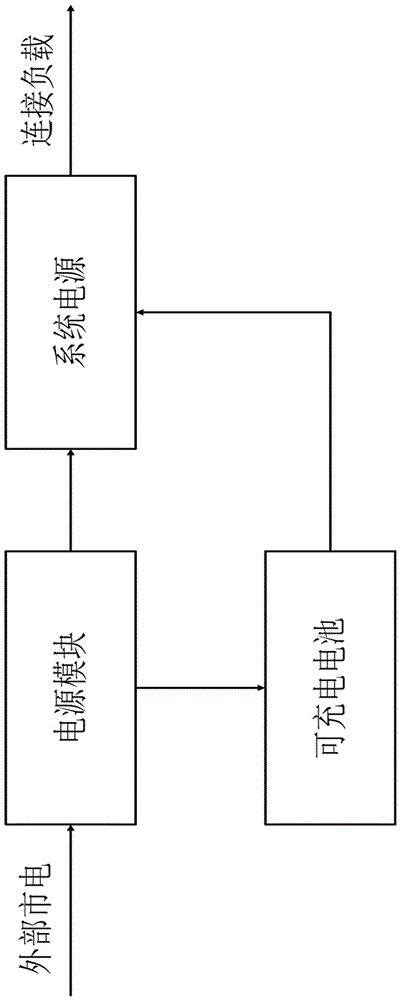

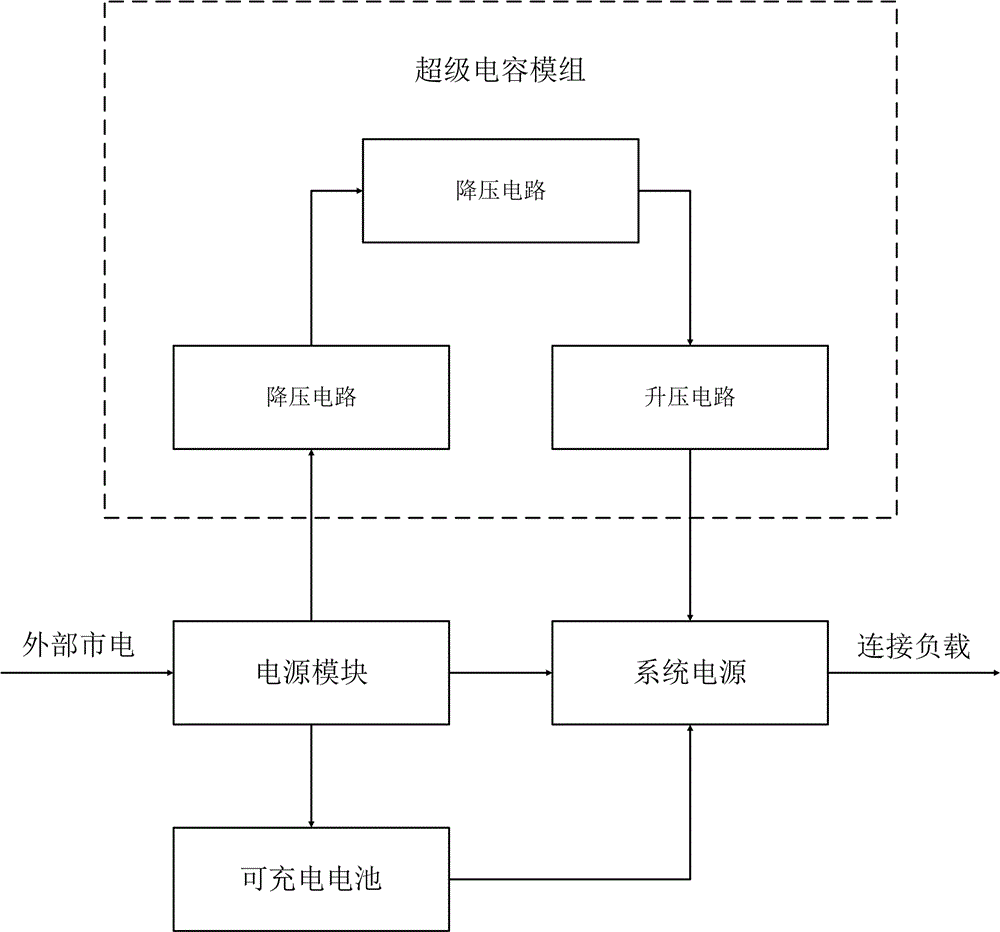

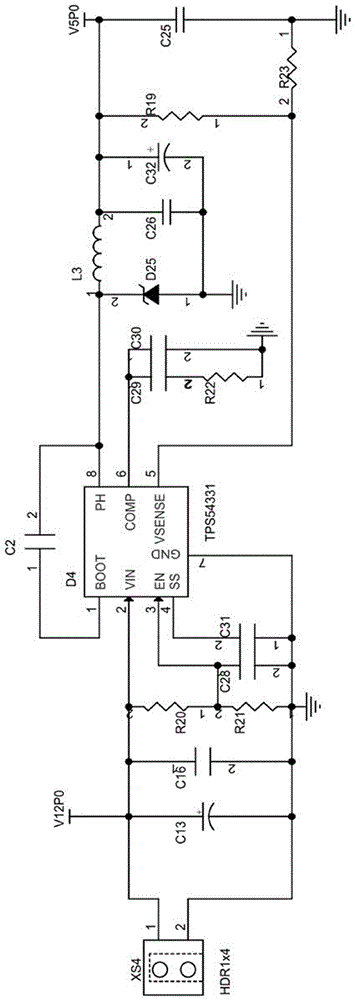

Power supply circuit, power supply method and power-consumption information acquisition terminal manufactured thereby

InactiveCN106410960AGuaranteed and extended service lifeExtended service lifeBatteries circuit arrangementsElectric powerCapacitanceRechargeable cell

The present invention discloses a power supply circuit, comprising a power supply module, a chargeable battery, a system power supply, a step-down circuit, a super capacitor and a booster circuit. The power supply module is connected to the super capacitor via the step-down circuit and is charged. The super capacitor is boosted through the booster circuit and then supplies power to the outside via a system circuit. The present invention also discloses a power supply method of the power supply circuit, comprising a charging step and a discharging step. The present invention also provides a power-consumption information acquisition terminal which is manufactured by the power supply circuit and supplies power by the power supply method. By the invention, the data reliability of a power-consuming load is ensured, and long service lifetime, high reliability, simple circuit and wide application range are achieved.

Owner:WILLFAR INFORMATION TECH CO LTD

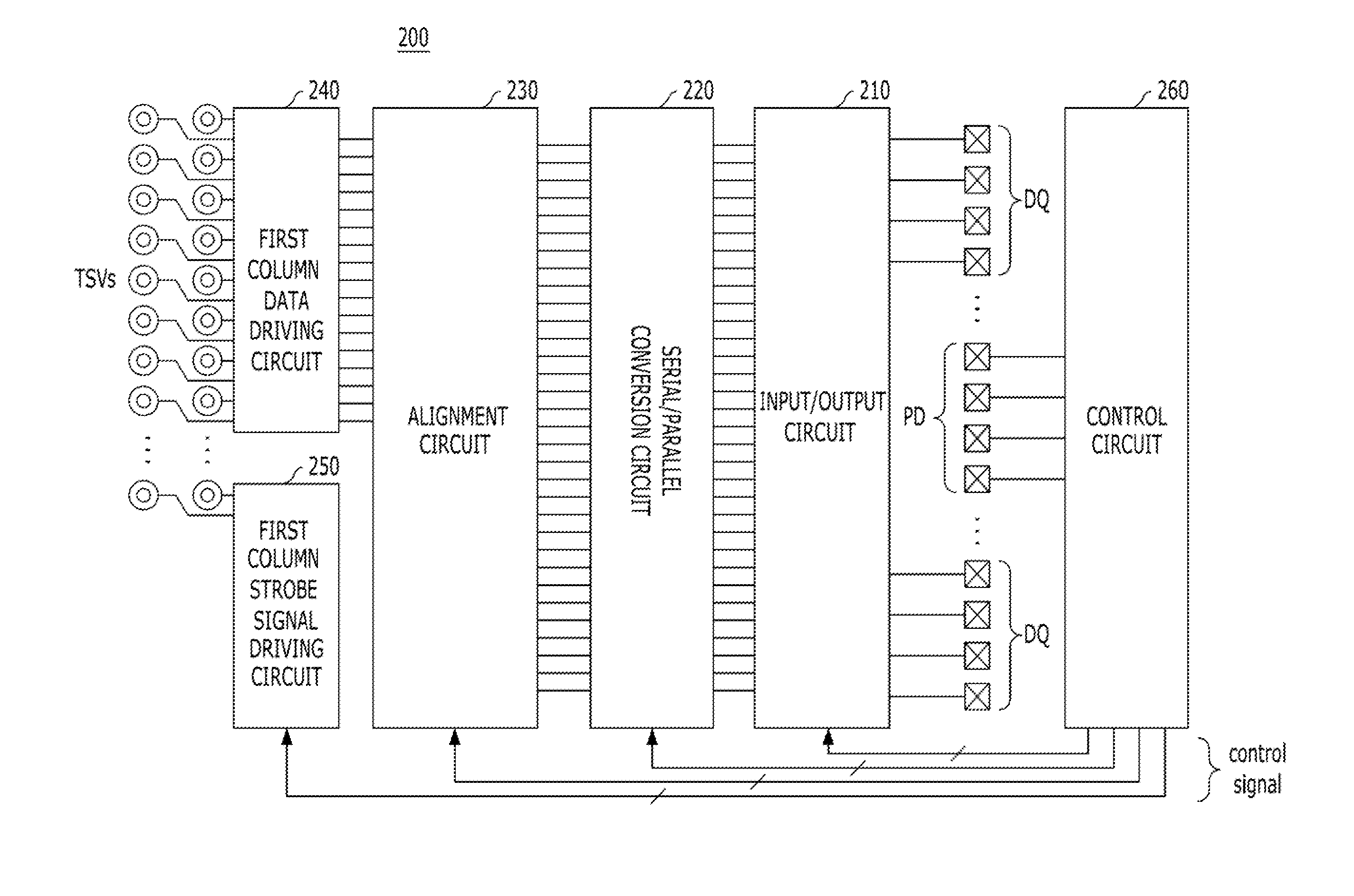

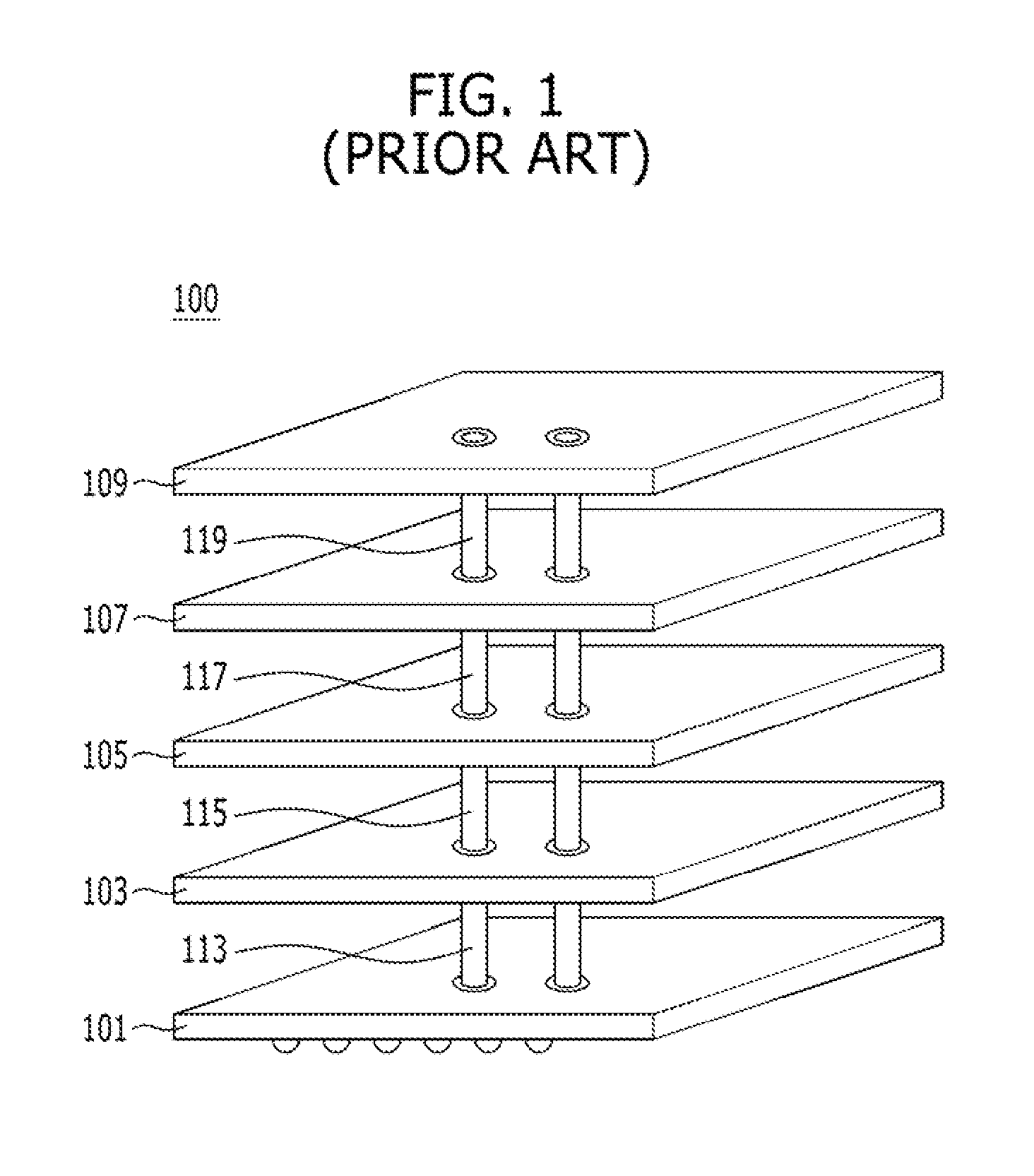

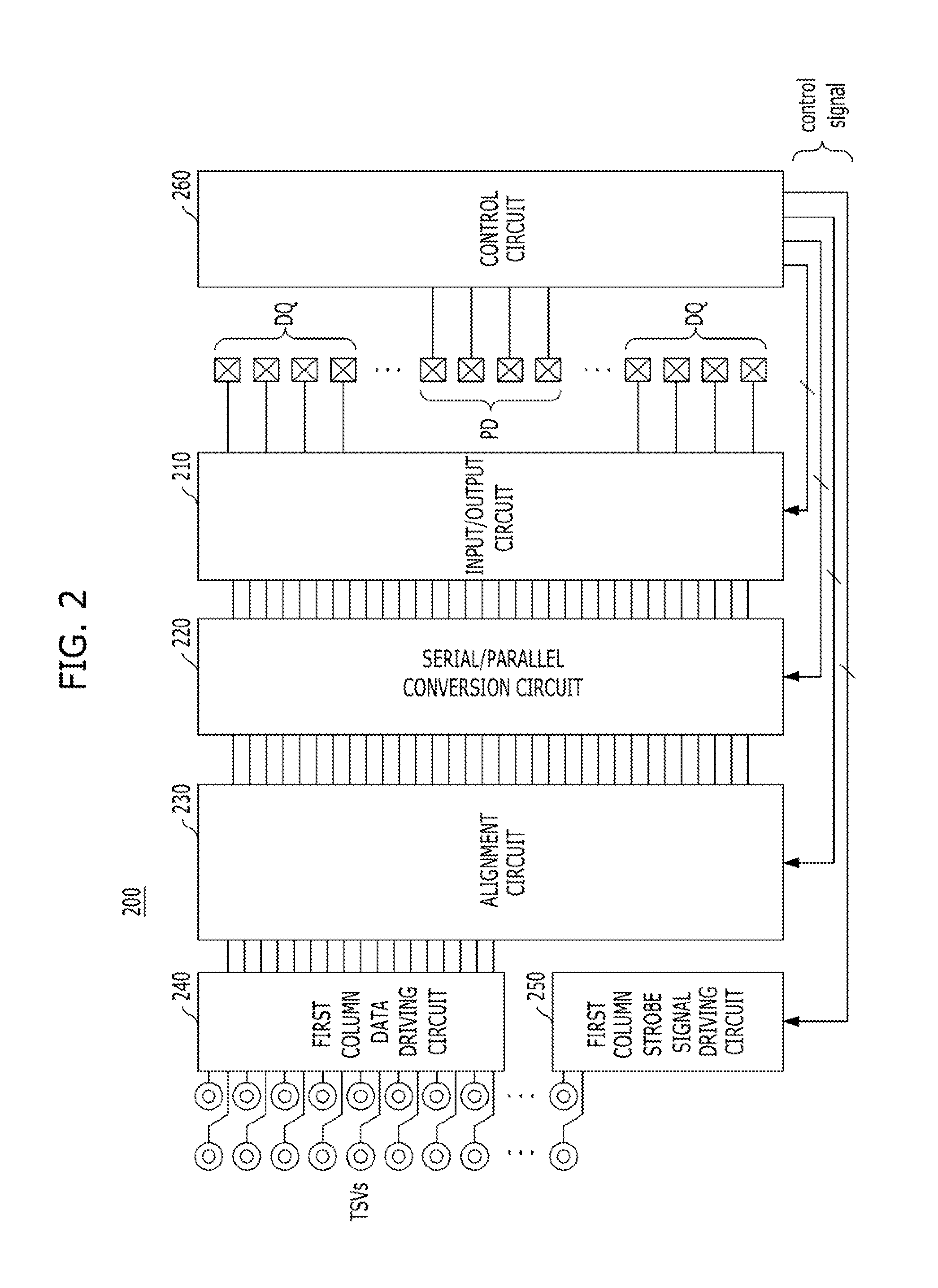

Semiconductor integrated circuit

A semiconductor integrated circuit including first semiconductor chip and second semiconductor chip that are vertically stacked, wherein the first semiconductor chip includes a first column data driving circuit configured to transmit internal data to the second semiconductor chip in a DDR (double data rate) scheme based on an internal strobe signal, and a first column strobe signal driving circuit configured to generate first column strobe signals that are source-synchronized with first column data transmitted to the second semiconductor chip by the first column data driving circuit, based on the internal strobe signal, and transmit the first column strobe signals to the second semiconductor chip.

Owner:SK HYNIX INC

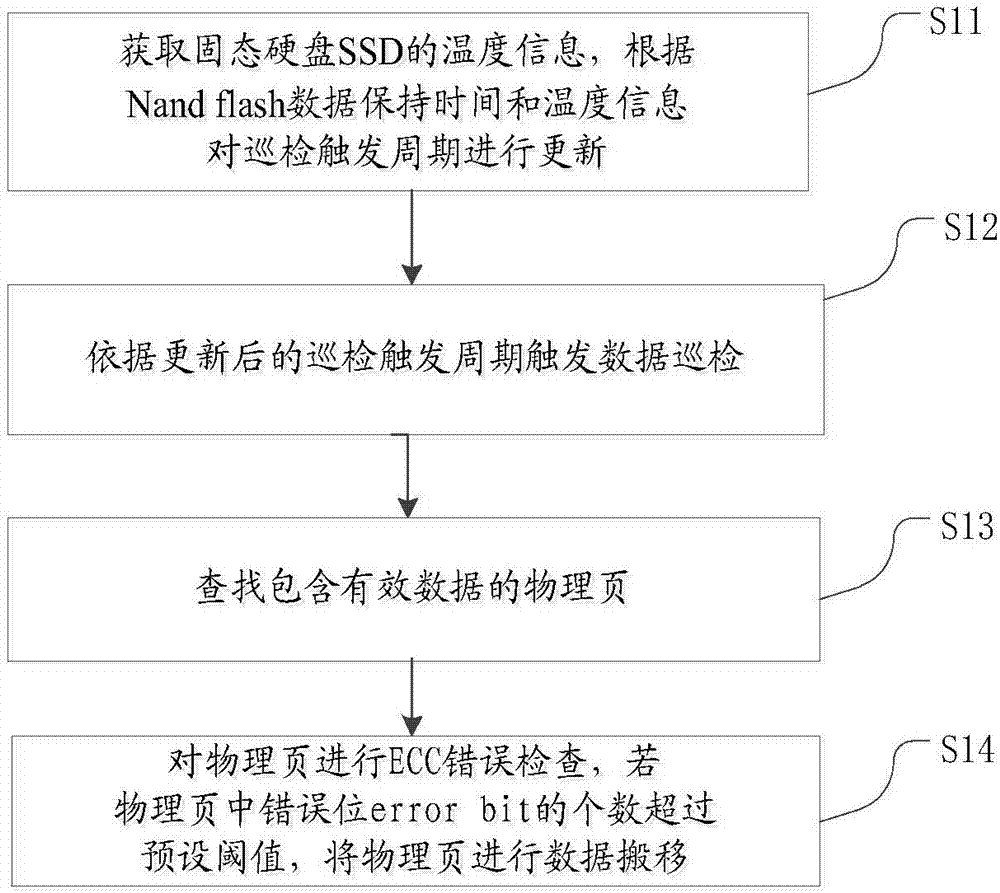

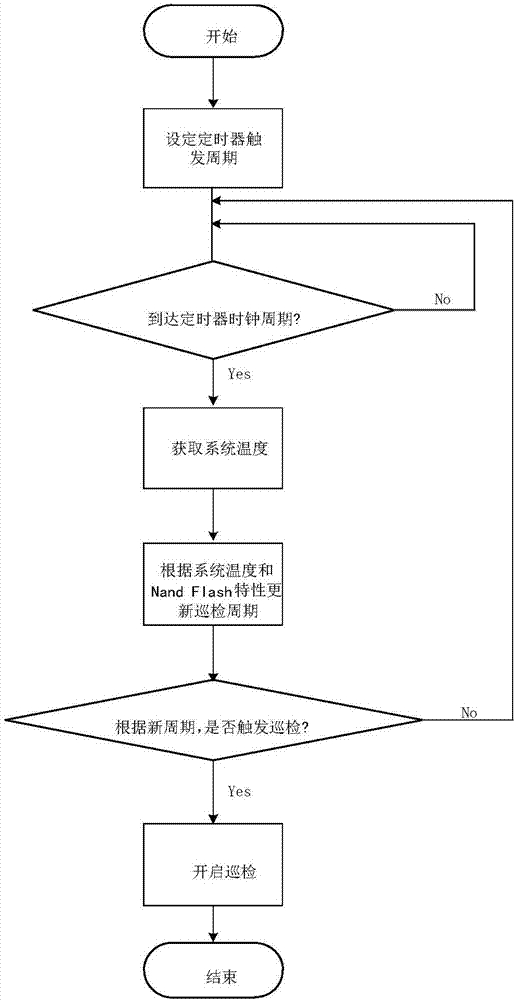

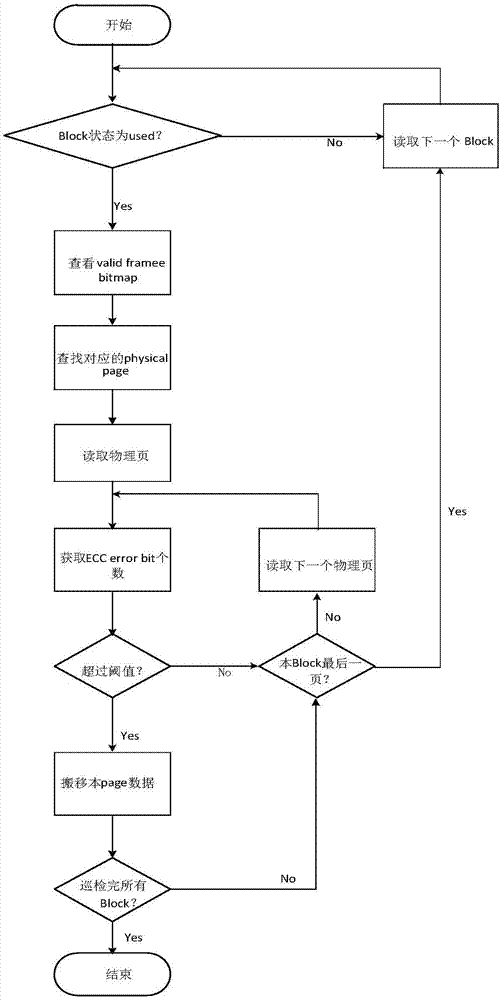

Optimization method and device of SSD (solid state disk) data inspection

ActiveCN106910528AHigh data reliabilityEnsure data reliabilityStatic storageError checkingData migration

The invention discloses an optimization method and device of SSD (solid state disk)data inspection. The method comprises steps as follows: temperature information of an SSD is acquired, and an inspection triggering cycle is updated according to Nand flash data retention time and the temperature information; data inspection is performed according to the updated inspection triggering cycle; a physical page containing valid data is looked up; ECC (error correcting code) error checking is performed on the physical page; if the number of error bits in the physical page exceeds a preset threshold value, the physical page is subjected to data migration. By means of the method, the data reliability is improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Disk array apparatus and method for controlling the same

InactiveUS20090292945A1Low failure rateEnsure data reliabilityNon-redundant fault processingRedundant operation error correctionControl signalDisk array

A disk array apparatus capable of reducing a disk drive fault rate where a time-out failure has occurred. The disk array apparatus includes a plurality of disk drives, and a control unit for performing data input / output processing of the disk drives in response to a data input / output request from a host system. The control unit includes: a memory for storing control information for specifying a failure of at least one of the disk drives, and failure information of the faulty disk drive, a circuit for specifying, from the failure information, the disk drive in which a time-out failure has occurred, and issuing an instruction to retry a control command to the disk drive, and a circuit for outputting a control signal to the faulty disk drive in order to hard reset the disk drive if the disk drive does not recover from the failure.

Owner:HITACHI LTD

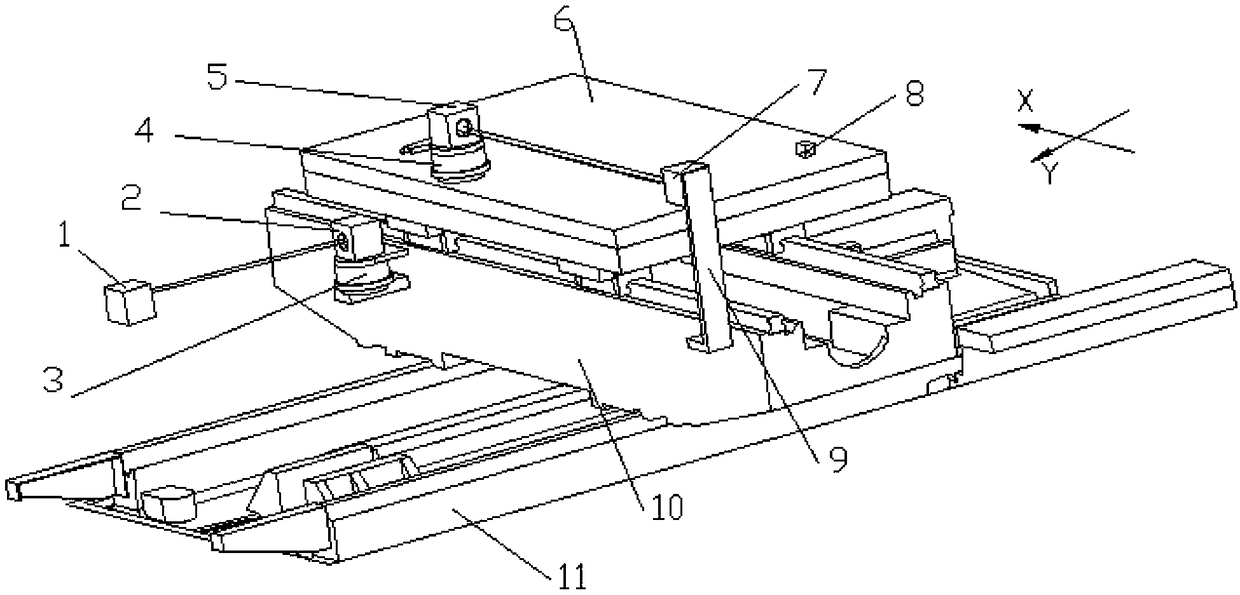

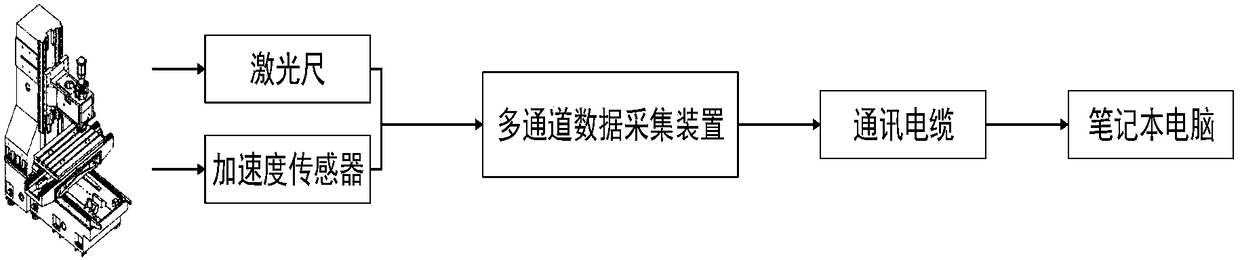

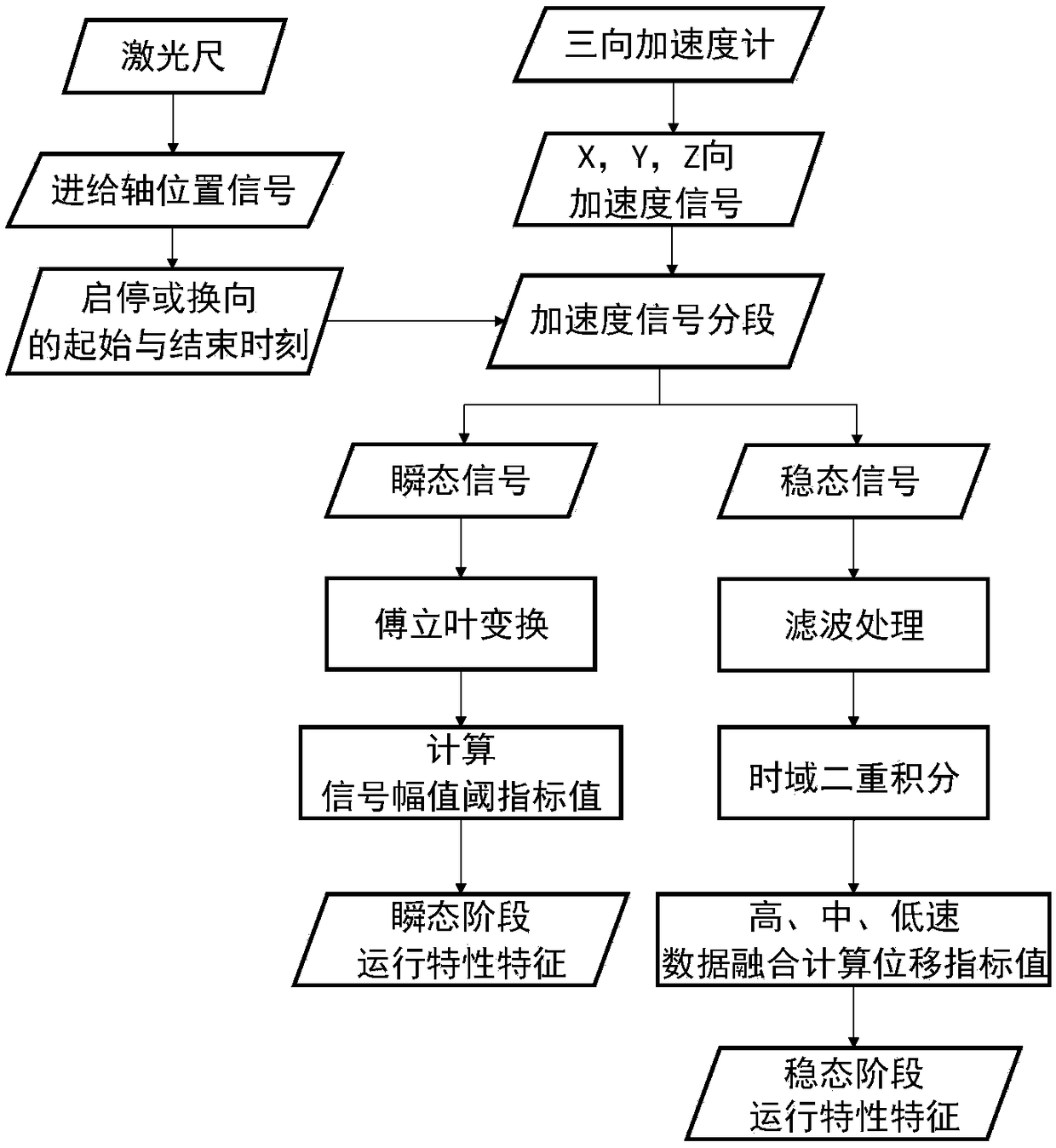

Method for testing and evaluation of operating characteristics of vertical machining center

ActiveCN108145534AAvoid interferenceEasy to disassembleMeasurement/indication equipmentsLow speedEngineering

The invention discloses a method for testing and evaluation of the operating characteristics of a vertical machining center. The method comprises the steps that a laser ruler fixed to a Y-direction machine body emits and receives laser reflected by a reflector fixed to a Y-direction sliding saddle so that the Y-direction movement of a machine tool is detected; a laser ruler RLD fixed to the sliding saddle emits and receives the laser reflected by a reflector fixed to a workbench so that the X-direction movement of the machine tool is detected; an acceleration sensor fixed to the workbench is used for detecting the acceleration signals of the workbench in the running process along a path in the X, Y and Z directions, so that the detection of the operating characteristics of the vertical machining center is achieved; in the detection process, the no-load constant-speed whole stroke acceleration signals of the vertical machining center are decomposed into instantaneous impact signals andsteady state signals, and meanwhile the operating speed of the vertical machining center includes high speed, intermediate speed and low speed; the transient and steady state motion characteristic indexes of the vertical machining center are extracted separately, and the quantitative evaluation of the operating characteristics of the vertical machining center is achieved.

Owner:XI AN JIAOTONG UNIV

Disk array apparatus and method for controlling the same

InactiveUS7607035B2Low failure rateEnsure data reliabilityNon-redundant fault processingControl signalDisk array

A disk array apparatus capable of reducing a disk drive fault rate where a time-out failure has occurred. The disk array apparatus includes a plurality of disk drives, and a control unit for performing data input / output processing of the disk drives in response to a data input / output request from a host system. The control unit includes: a memory for storing control information for specifying a failure of at least one of the disk drives, and failure information of the faulty disk drive, a circuit for specifying, from the failure information, the disk drive in which a time-out failure has occurred, and issuing an instruction to retry a control command to the disk drive, and a circuit for outputting a control signal to the faulty disk drive in order to hard reset the disk drive if the disk drive does not recover from the failure.

Owner:HITACHI LTD

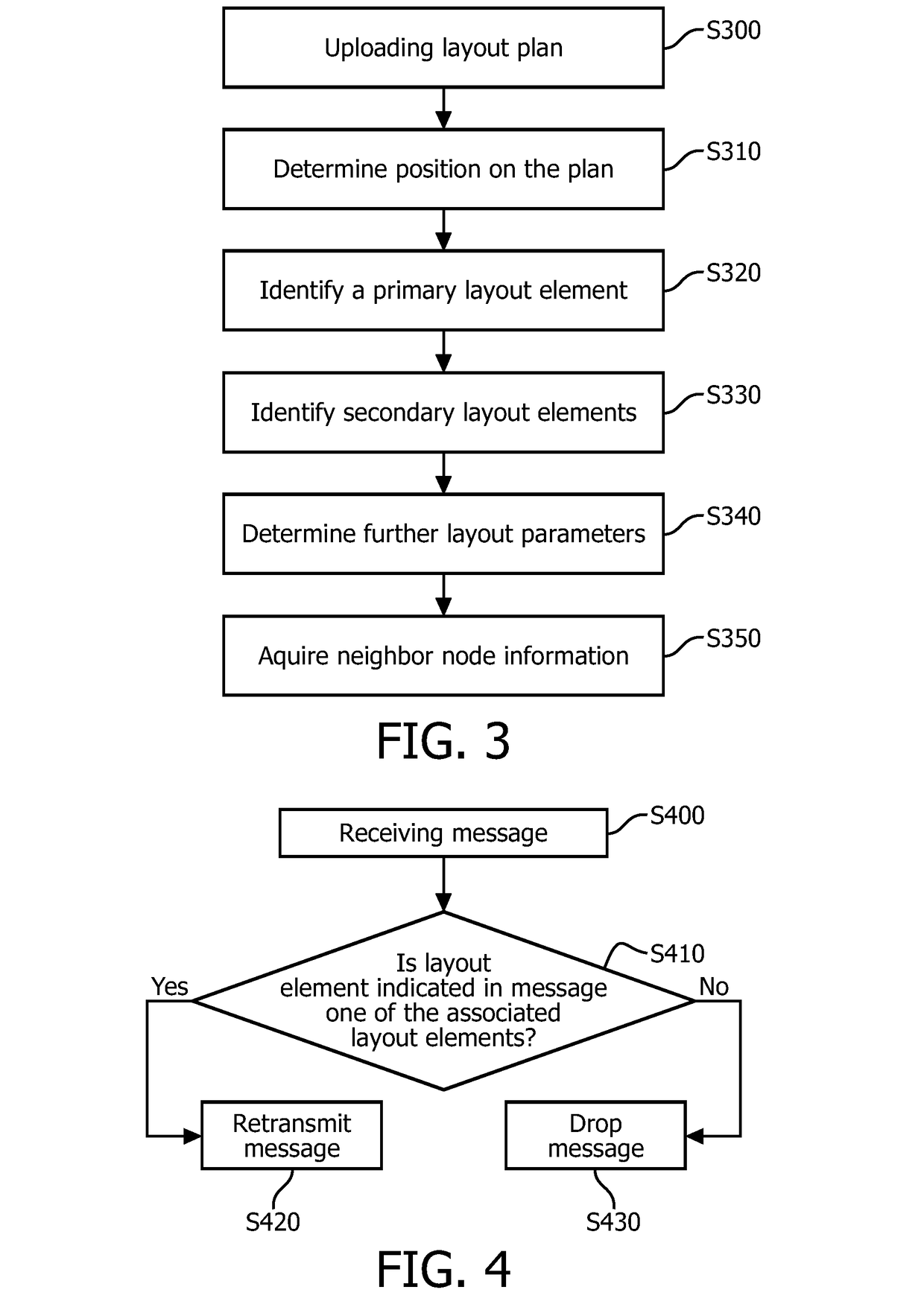

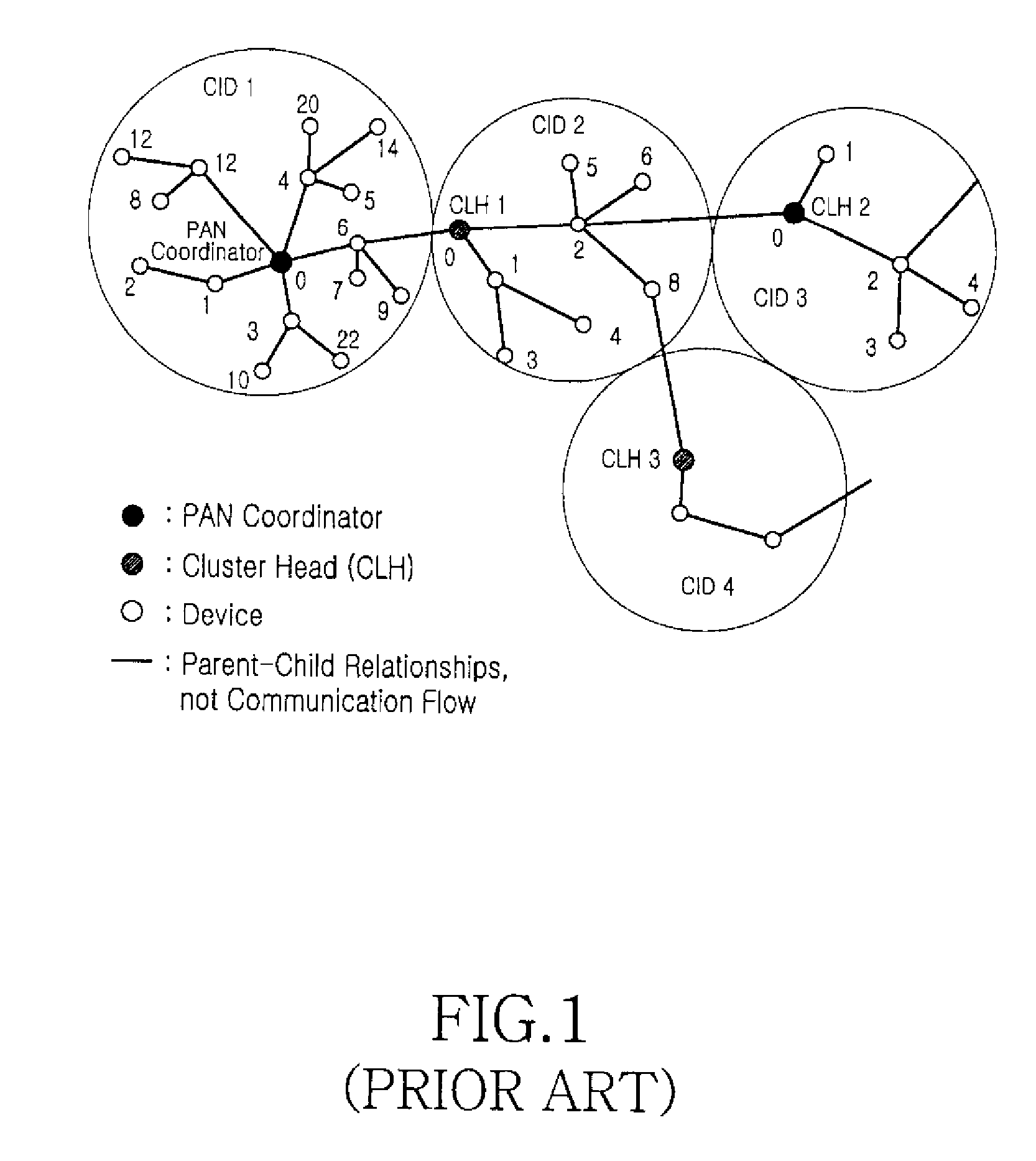

Optimizing message forwarding in a wireless mesh network

ActiveUS20170181053A1Ensure data reliabilityReduce data overheadNetwork traffic/resource managementNetwork topologiesData transmissionMesh networking

For ensuring reliability of data transmission in a wireless mesh network, while reducing the data overhead of the transmissions, a node for a wireless mesh network and a method of controlling the same are provided, wherein the node is configured to decide about retransmission of a message received from a transmitting node, based on whether the transmitting node has at least one layout element of a layout plan in common with the node, at least one of the layout elements of the layout plan being associated with the node.

Owner:SIGNIFY HLDG BV

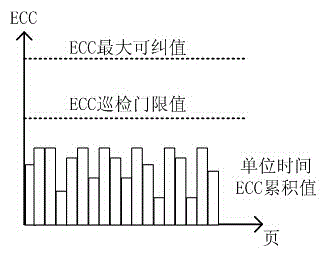

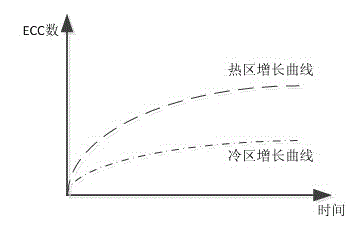

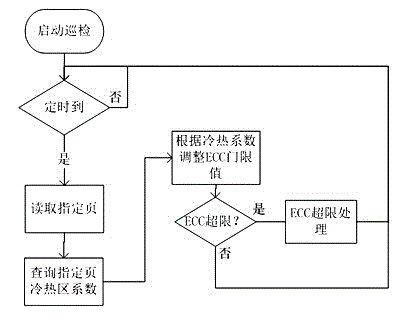

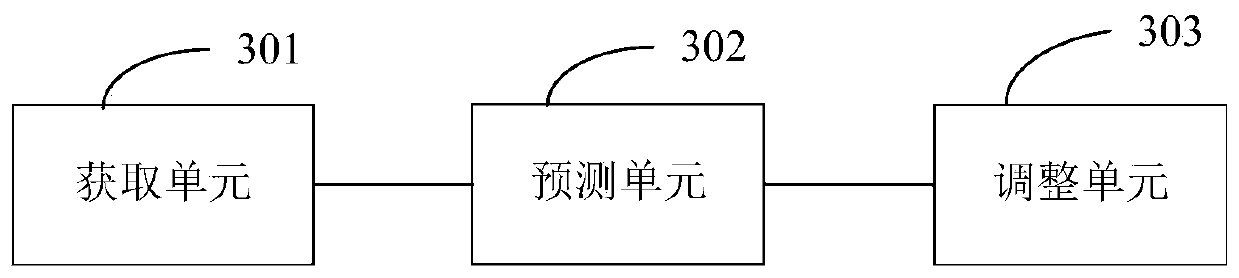

Dynamic adjustment Nand flash error detection method and dynamic adjustment Nand flash error detection device

ActiveCN104658610AIn line with the actual situationEnsure data reliabilityStatic storageDependabilityData reliability

The invention provides a dynamic adjustment Nand flash error detection method and a device. The method comprises the steps that according to differences of physical properties of positions, at which various pages are located, in the Nand flash, and the pages in a block are divided into different groups according to the differences of ECC (Error Correction Code) growth rates; in the practical patrol operation, different ECC patrol threshold values are distributed according to the differences of the ECC growth rates in different pages and groups; the page with faster ECC growth has lower ECC patrol threshold value, otherwise reversed; in the process of performing the patrol, a cold and hot subarea of the physical location of the page is enquired; data volume written in the area in unit time acting as the basis, the more the data is written in, the hotter the area is; a coefficient of the cold and hot subarea is obtained; and the patrol threshold value is adjusted. By adopting dynamic adjustment, actual conditions of particles can be met better, and on the premise of guaranteeing the data reliability, the product life is guaranteed to the greatest extent.

Owner:广东华晟数据固态存储有限公司

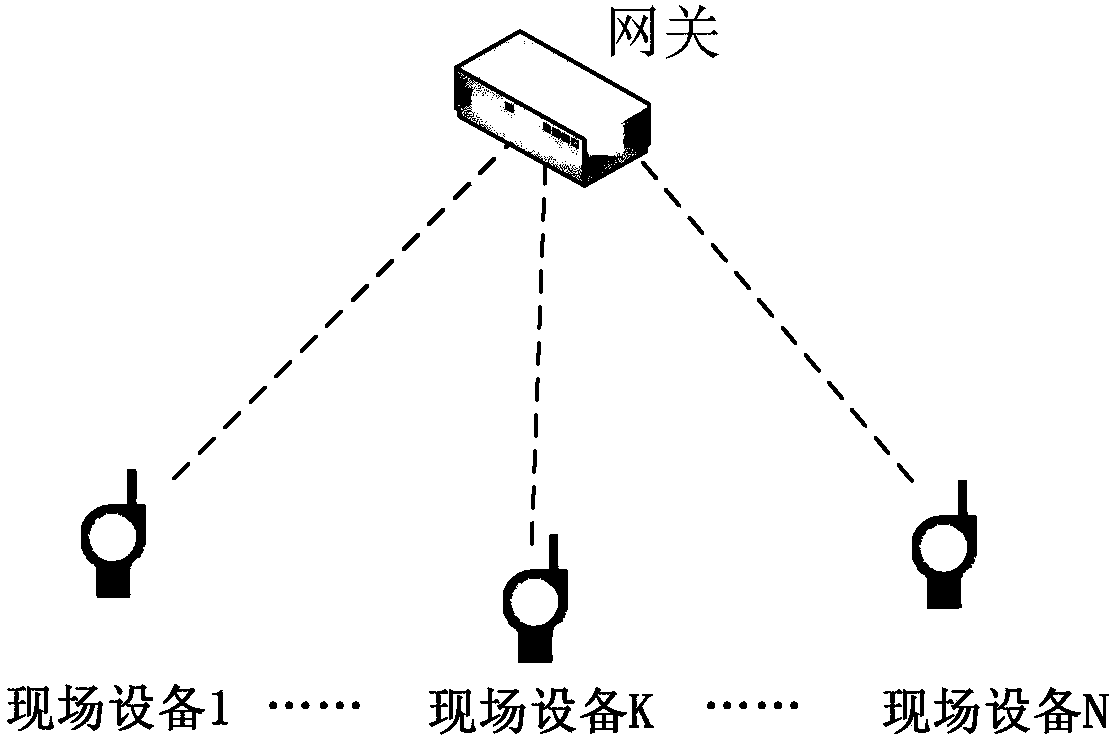

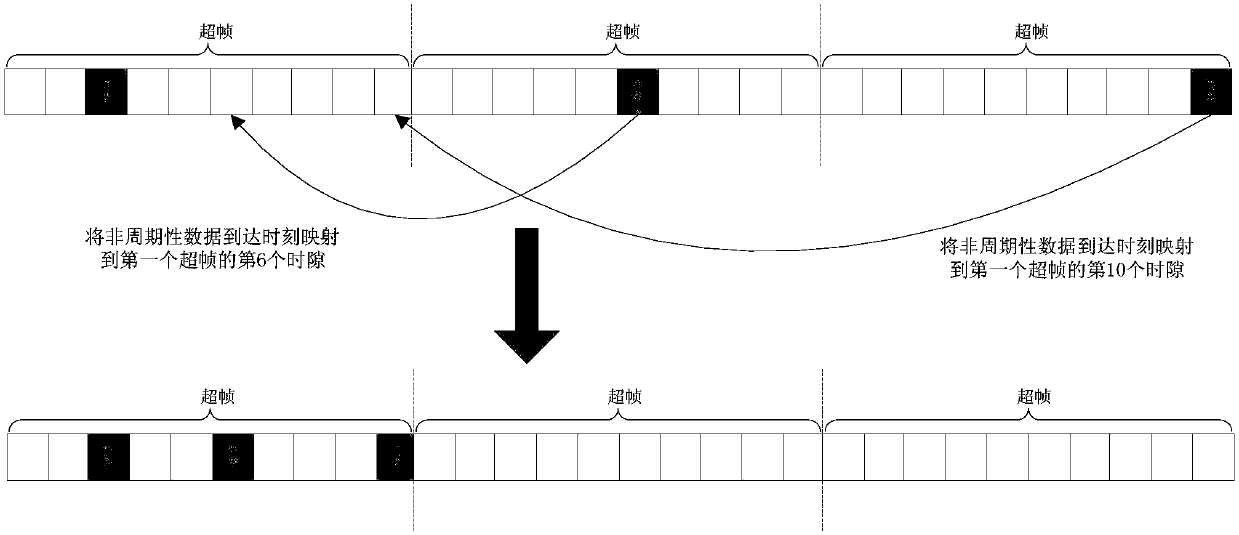

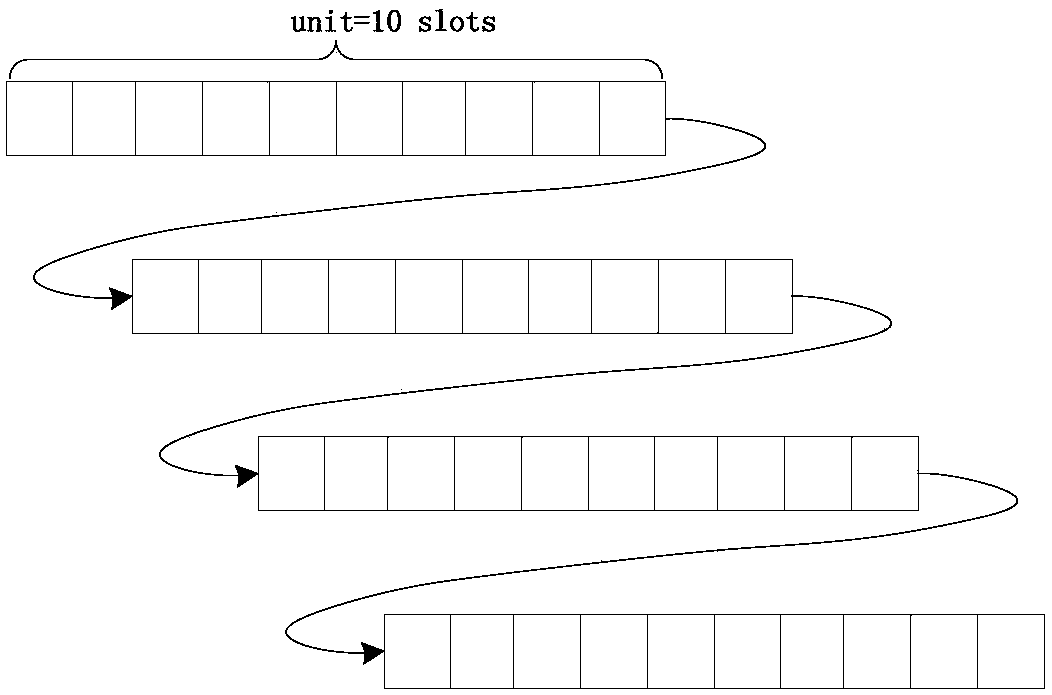

Scheduling method of reliable transmission of mixed data streams in industrial wireless sensor network

ActiveCN108093486AGuaranteed reliabilityEnsure fairnessNetwork topologiesComplete dataReliable transmission

The invention relates to a scheduling method of reliable transmission of mixed data streams in an industrial wireless sensor network, a gateway allocates time slots for periodic data and non-periodicdata sent by each field device, and the time slots are used for each field device to complete data transmission according to the time slot allocation, allocation comprises the following steps: modelling for the periodic data and the non-periodic data; reserving the time slots for the non-periodic data through a cyclic statistics method; and allocating the time slots for the periodic data. The method provided by the invention takes data transmission reliability and fairness as indexes for measuring performance of the scheduling method, reserves the time slots for the non-periodic data through the cyclic statistics method, allocates the time slots for the periodic data through an even allocation method, comprehensively considers a waiting mechanism and a seizing / discarding mechanism and provides an effectively scheduling scheme for transmission of the mixed data streams.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

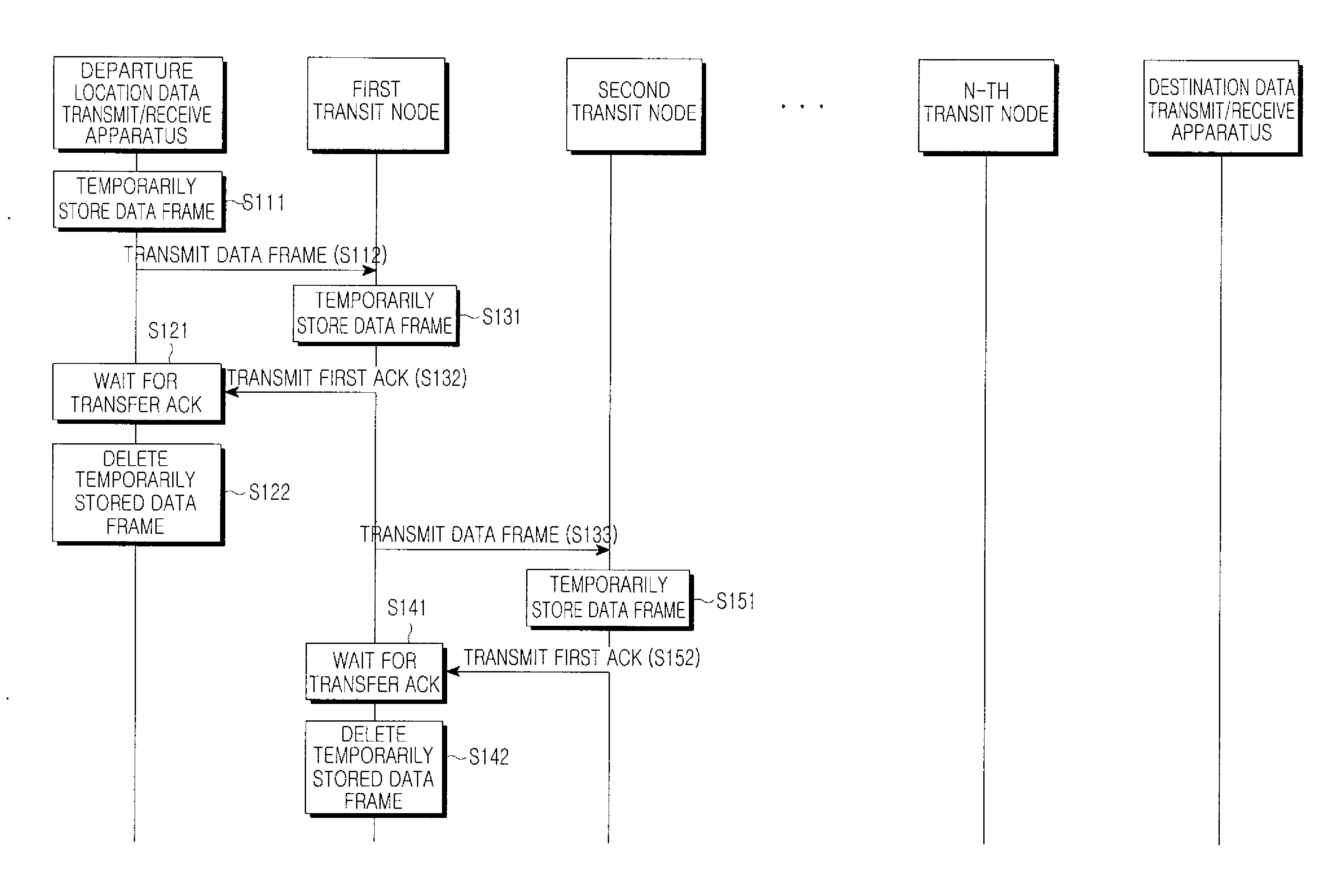

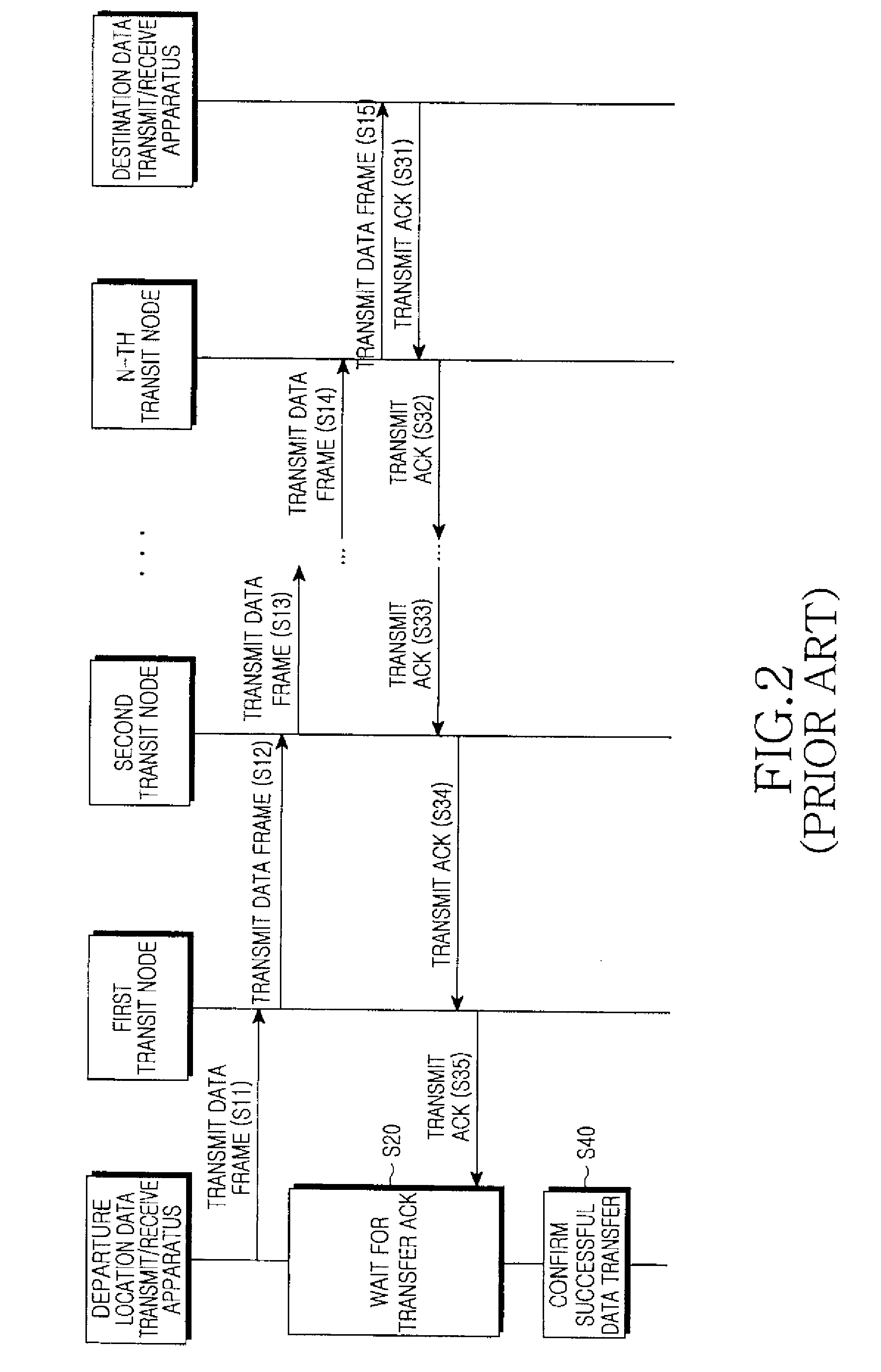

Method for transmitting/receiving data with transfer obligation delegated in wsn

InactiveUS20090028093A1Ensure data reliabilityGuaranteed reliabilityPower managementEnergy efficient ICTWireless sensor networkingData shipping

A method for transmitting / receiving data with transfer obligation delegated in a Wireless Sensor Network (WSN) reduces the time and power spent by a transmitting apparatus to wait for acknowledgment that a data transfer was successful. The method for transmitting data from a transmitting end to a receiving end through a set transfer route by multiple data transmit / receive apparatuses provided in a Wireless Sensor Network (WSN), typically includes the steps of: performing temporary storage of data to be transmitted on receiving a request to transmit data; requesting a data transmit / receive apparatus, existing on a next route, to transmit data while transmitting data to a data transmit / receive apparatus which is set as a transfer route; and confirming the delivery of the data to the data transmit / receive apparatus set as the transfer route, and then deleting the temporarily stored data frame.

Owner:SAMSUNG ELECTRONICS CO LTD

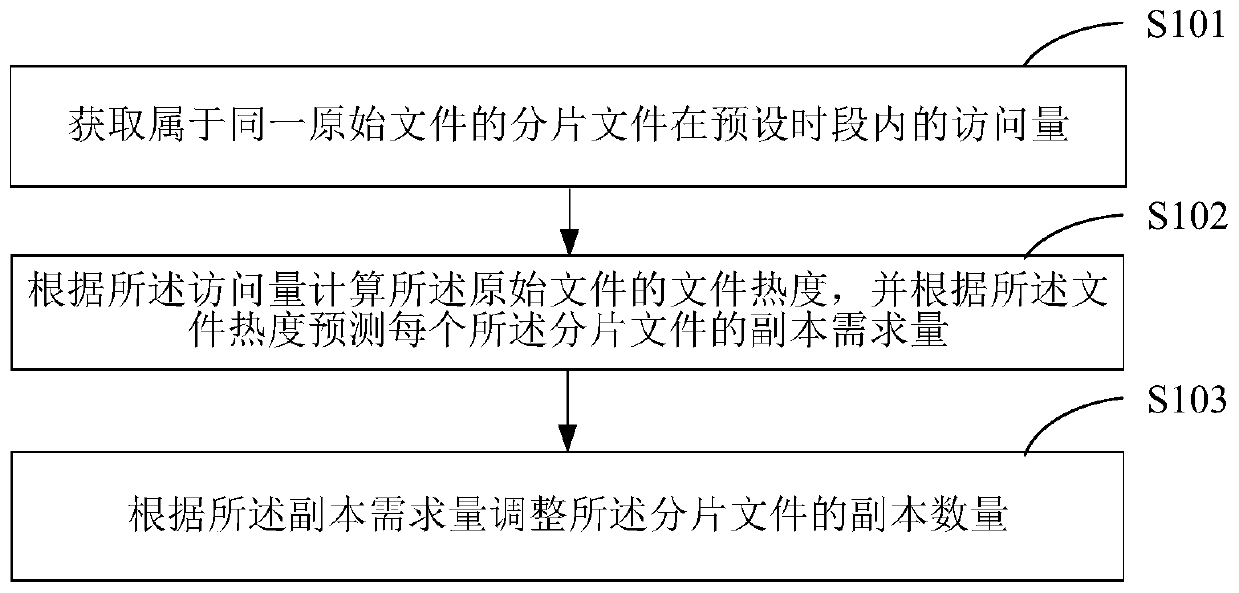

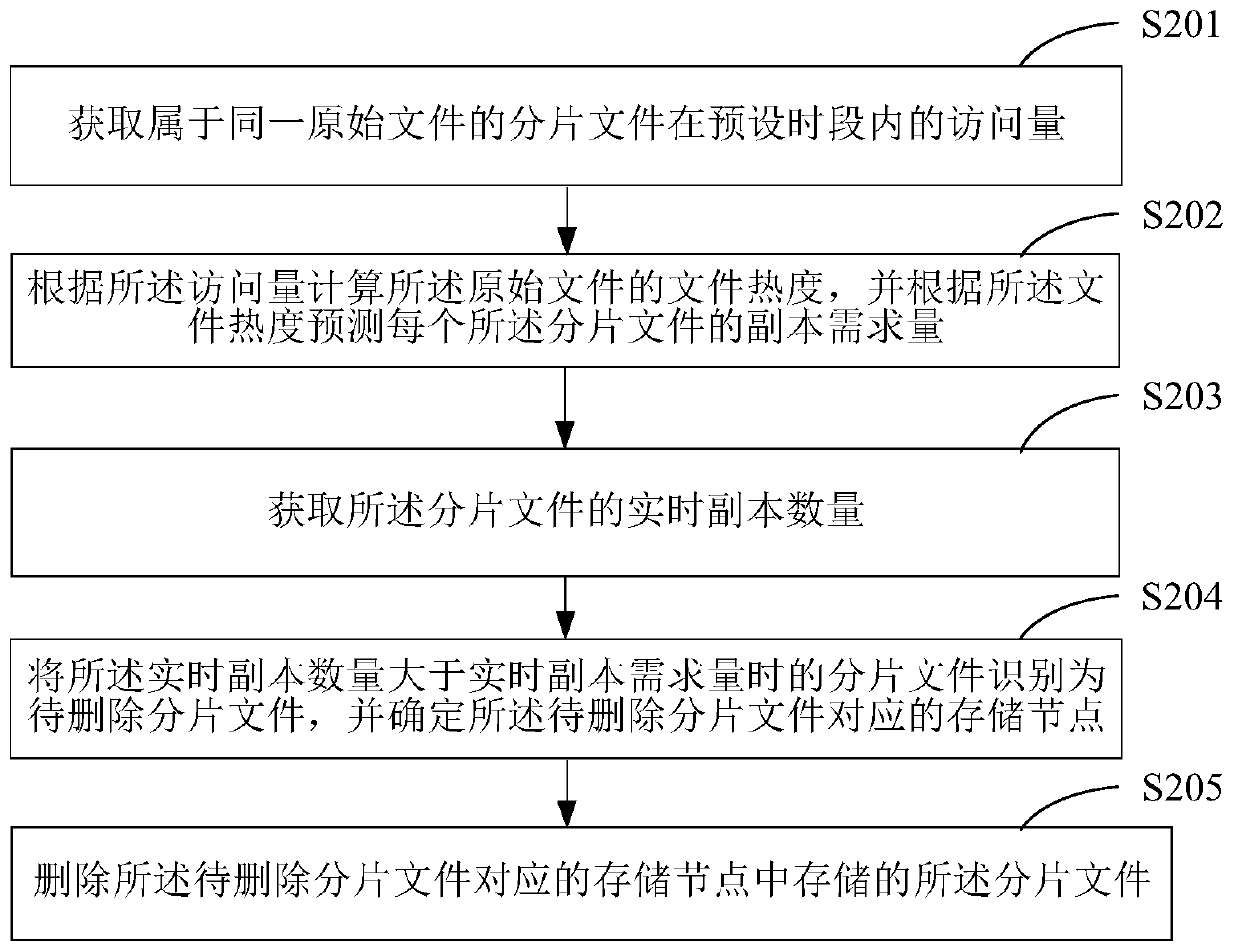

Distributed storage method, computer equipment and computer readable storage medium

PendingCN111475108AReduce loadLoad balancingInput/output to record carriersEngineeringData reliability

The invention is suitable for the technical field of computer application, and provides a distributed storage method, computer equipment and a computer readable storage medium, and the method comprises the steps: obtaining the page view of fragmented files belonging to the same original file in a preset time period, wherein the fragmented file is obtained by fragmenting an original file; calculating the file popularity of the original file according to the page view, and predicting the copy demand of each fragmented file according to the file popularity; and adjusting the number of copies of the fragmented file according to the copy demand. The file popularity of an original file is calculated according to the page view of all fragmented files of the original file; the predicted copy number of each fragmented file is predicted according to the file popularity, and finally the copy number of each fragmented file is adjusted according to the predicted copy number and the real-time numberof each fragmented file, so that the load of a storage node is reduced on the premise of ensuring the data reliability, and the purpose of load balancing is achieved.

Owner:深圳赛安特技术服务有限公司

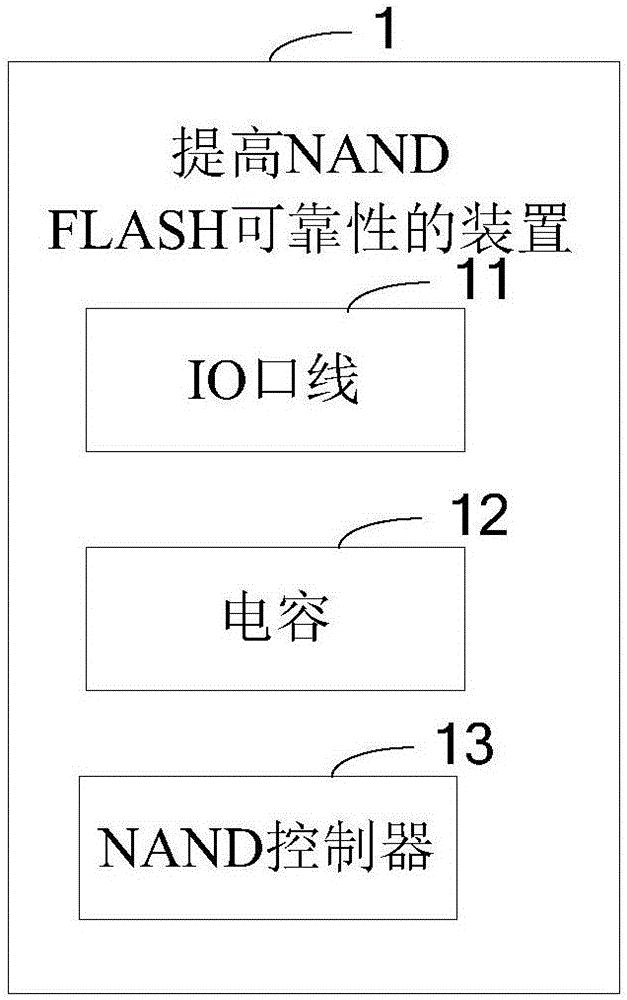

Method and device for improving reliability of NAND FLASH

InactiveCN106409321AAvoid damageEnsure data reliabilityRead-only memoriesCapacitanceComputer terminal

The invention relates to the technical field of flash memories, in particular to a method and device for improving the reliability of an NAND FLASH. The method comprises the following steps of judging the type of a current operation of the NAND FLASH after an NAND controller receives an interrupt signal; if the current operation is a programming operation, completing the programming operation by using a capacitor, resetting the NAND FLASH through an NAND FLASH controller and finishing the current ongoing operation; and if the current operation is not the programming operation, resetting the NAND FLASH through the NAND FLASH controller and finishing the current ongoing operation. The method and the device have the beneficial effects that a key operation-programming operation which needs to be protected after a power failure is caught; the damage of the power failure to NAND FLASH data is effectively avoided through ensuring that the whole programming operation is completed in the power failure; and the data reliability of using an NAND FLASH terminal is ensured.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com