Method for testing and evaluation of operating characteristics of vertical machining center

A technology of vertical machining centers and operating characteristics, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve problems such as not considering semi-closed-loop machining centers, large environmental factors, and difficulty in obtaining motor torque signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

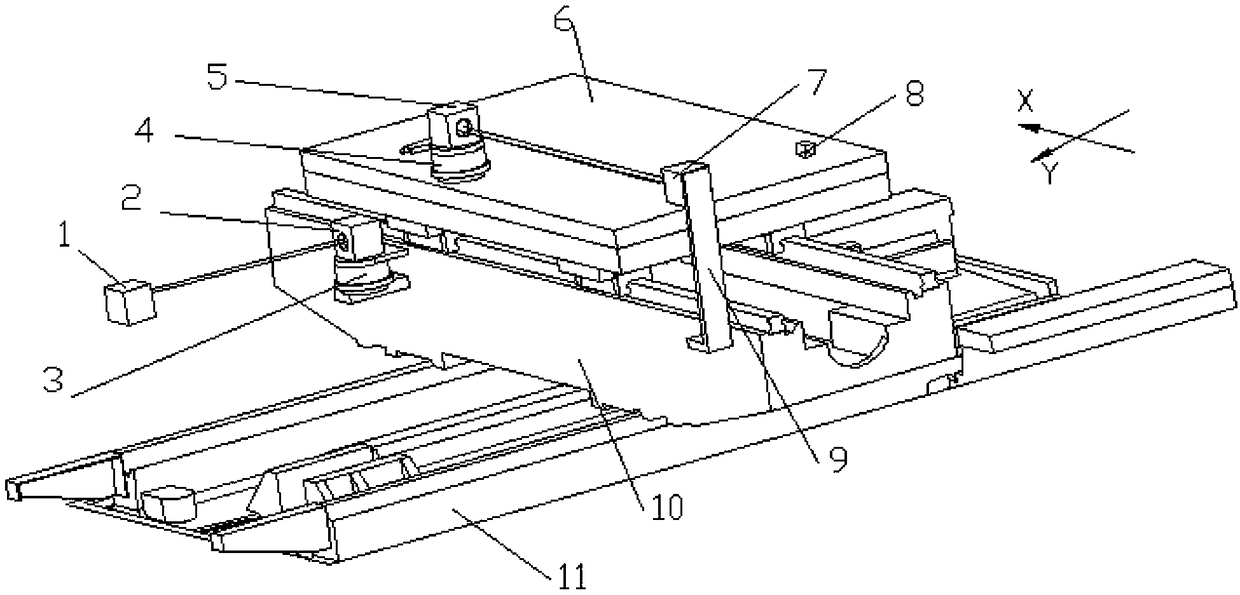

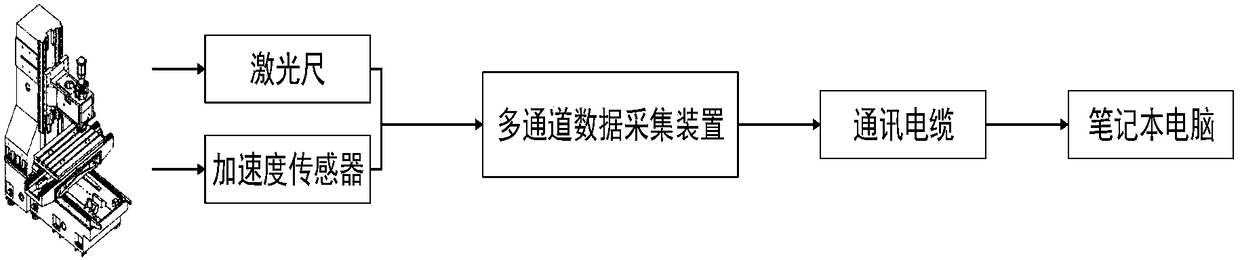

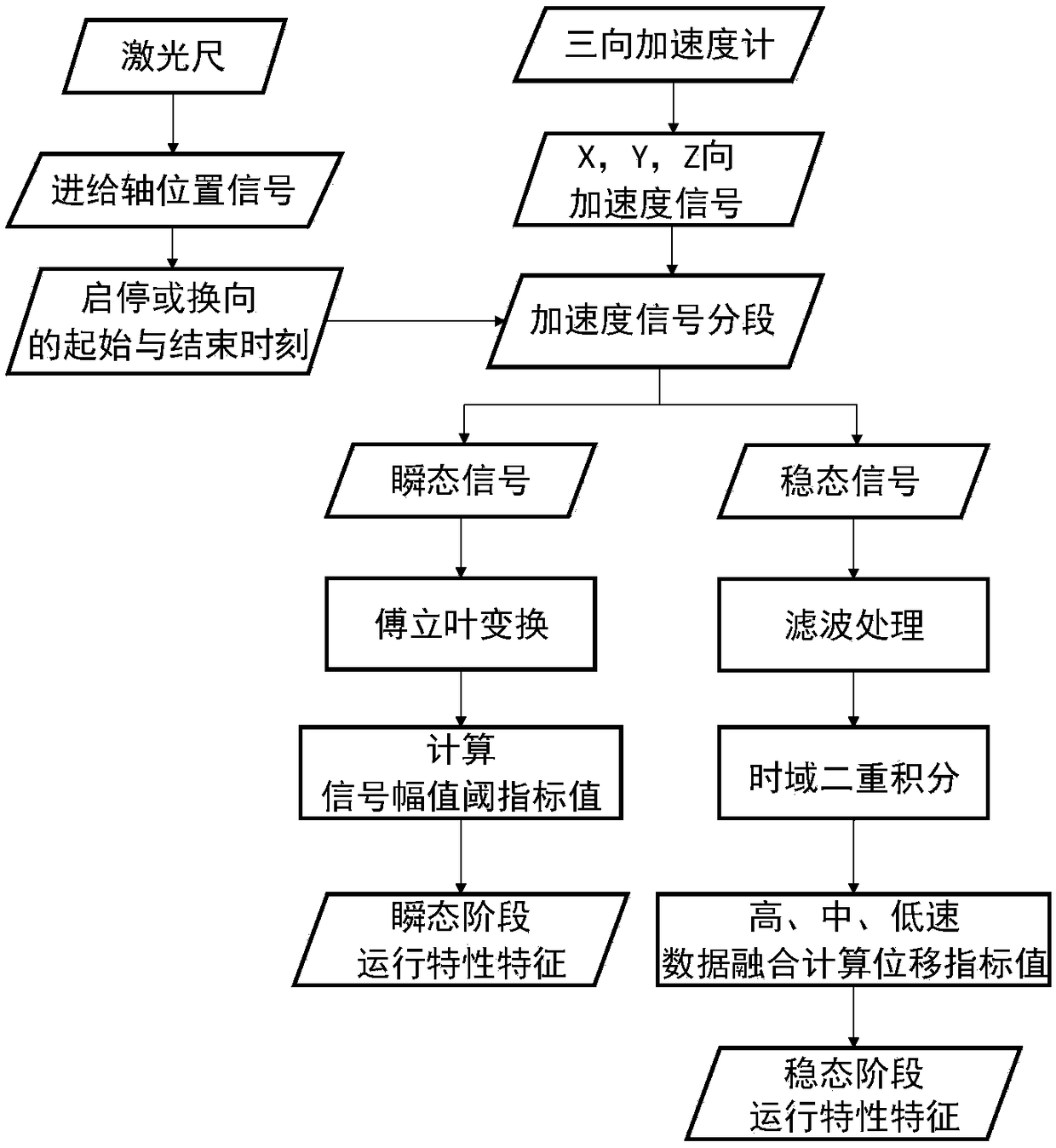

[0063] refer to figure 1 , this embodiment provides a schematic diagram of the installation structure of the vertical machining center operating characteristic detection device, a saddle 10 is installed on the bed 11, a workbench 6 is installed on the saddle 10, and a mirror mounting seat I3 is fixed in the Y direction On the saddle 10, fix a mirror I2 on the mirror mounting base I3; fix a laser ruler RLD-I1 on the bed 11 in the Y direction; fix the other mirror II5 on the mirror mounting base II4 , Fix the mirror mount II4 on the workbench 6, fix the other laser ruler RLD-II7 on the laser ruler base 9, and fix the laser ruler base 9 on the saddle 10. An acceleration sensor 8 is also installed on the workbench 6 for detecting vibration signals in X, Y and Z directions when the workben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com