Two-stage hydraulic cylinder with multi-layer core tube and crane

A technology of hydraulic cylinders and core tubes, which is applied in mechanical equipment, fluid pressure actuation devices, etc., can solve the problems that the levels cannot be controlled individually, and the mass and volume of multi-stage oil cylinders are large, so as to improve the performance of the boom and the stability of the whole machine , easy to place and optimize, and the effect of reducing the weight of the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

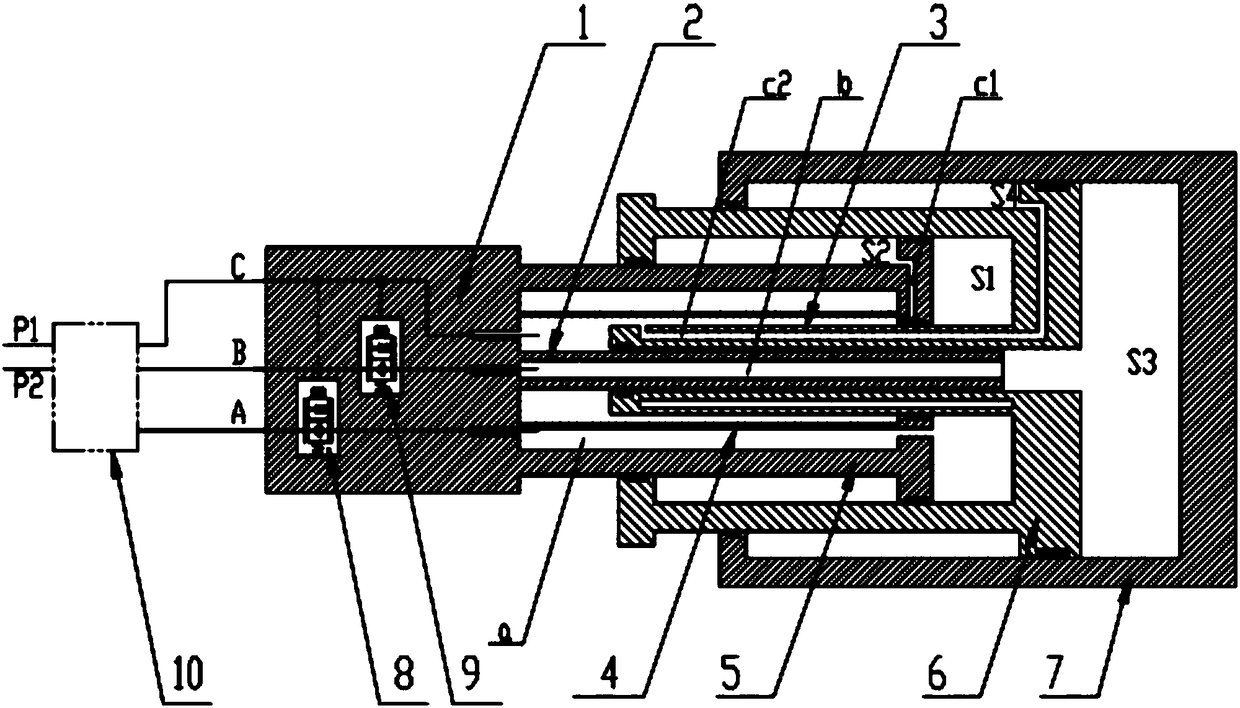

[0022] Such as figure 1 Shown: a two-stage hydraulic cylinder with a multi-layer core tube, including a piston rod head (1), an inner telescopic core tube (2), a casing (4), a piston rod assembly (5), a first-stage cylinder barrel (6 ) and the second-stage cylinder (7), the piston rod head 1 has three working oil ports A, B, and C, and the first balance valve 8 and the second balance valve 9 are arranged inside, and the two balance valves include Two work ports and one control port. The piston rod head 1 is connected to the piston rod assembly 5, the sleeve 4 and the inner telescopic core tube 2, the first-stage cylinder 6 is built into the second-stage cylinder 7, and the first-stage cylinder 6 is connected (built-in) to the piston rod The outer cavity of the assembly 5 and the inner cavity connected to the inner telescopic core tube 2, the first stage cylinder 6 is also provided with the outer telescopic core tube 3, and the second stage cylinder 7 is in the outermost layer...

Embodiment 2

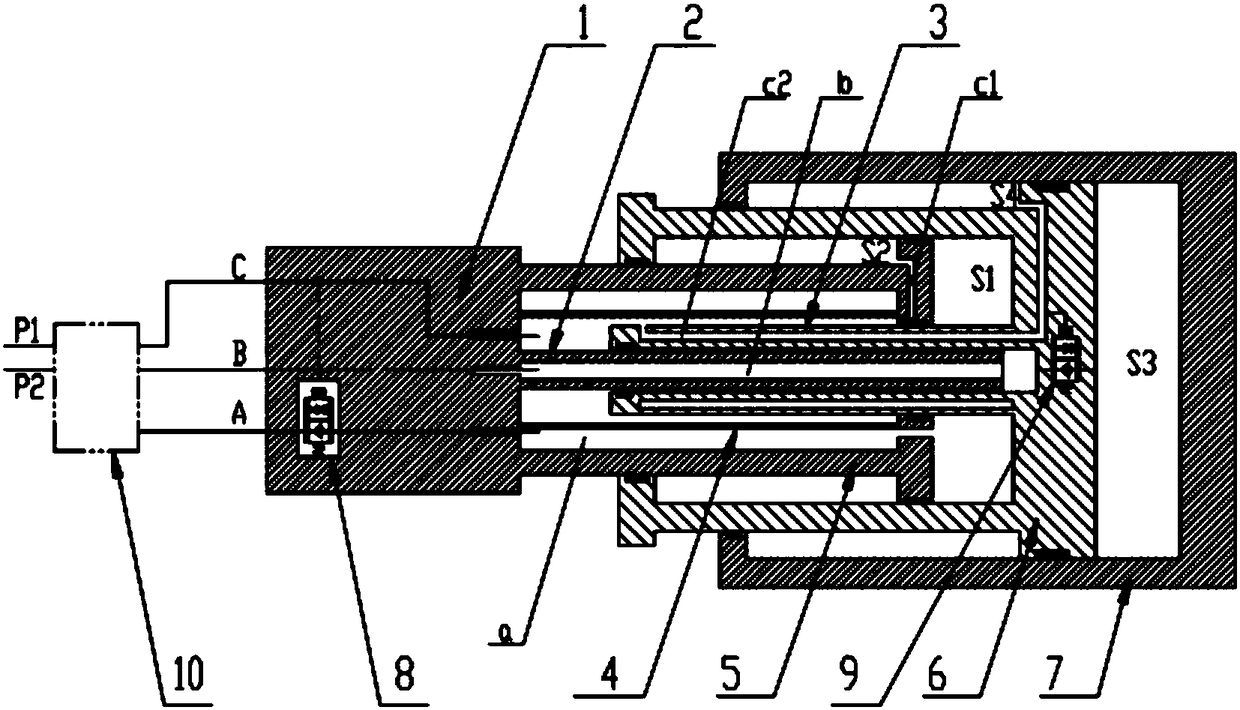

[0045] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the second balance valve 9 is built inside the first-stage cylinder 6, and the two working oil ports are connected to the inner cavity of the first-stage cylinder 6 and the second-stage cylinder respectively. The rodless chamber S3 of the second-stage cylinder, the control oil port connection channel 4 C2 (when there is no pressure at the control oil port, the inner cavity of the first-stage cylinder 6 is unidirectionally connected to the rodless chamber S3 of the second-stage cylinder), specifically The process is basically the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com