Hydraulic combination system for dumper

A combined system and dump truck technology, applied in fluid pressure actuating devices, vehicles with tilt bearing motion, servo motors, etc., can solve the problems of high starting pressure of the working system, poor system stability, heavy cylinder weight, etc., to reduce steel The effect of usage, life extension, and cylinder weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

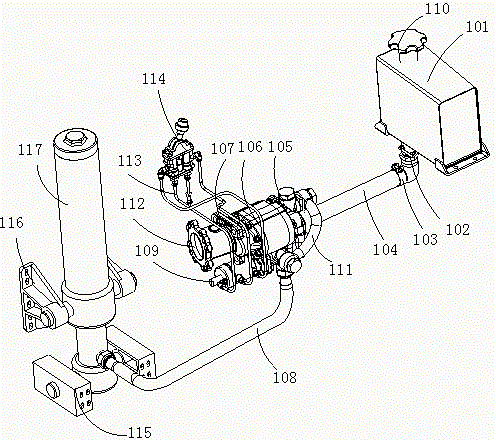

[0043] see figure 1 As shown, it is a structural schematic diagram of a dump truck hydraulic combination system according to an embodiment of the present invention. The hydraulic combination system in the present invention includes a fuel tank 101, a pump valve combination assembly 105, and an oil cylinder combination 117. The pump valve combination assembly 105 connects the fuel tank 101 The low-pressure hydraulic oil in the pump is converted into high-pressure hydraulic oil and transmitted to the oil cylinder assembly 117 through the high-pressure oil pipe 108. In the present invention, the hydraulic assembly system is installed on the dump truck, and the oil cylinder assembly 117 is combined with the tipping bucket of the dump truck to lift Raise or lower the bucket. In this embodiment, the pump-valve assembly 105 is used to convert the low-pressure hydraulic oil. Ordinary hydraulic oil pumps can also be used, and connected to the oil tank and hydraulic cylinder through the...

Embodiment 2

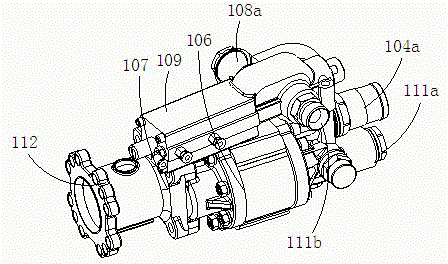

[0075] see Figure 8 As shown in FIG. 2 , it is a structural schematic diagram of the dump truck hydraulic combination system in Embodiment 2 of the present invention. The difference from the above-mentioned embodiments is that the working pressure of the pump-valve combination assembly is high, and two inlet and outlet oil pipes 104a are arranged on the pump-valve assembly. A low-pressure oil pipe 104 is connected to the oil inlet and outlet 101a, and a valve oil outlet pipe is provided on the valve 109, which is connected with the oil outlet pipe 108 to provide hydraulic oil to the actuator; correspondingly, a valve return valve is also provided inside the valve body. Oil pipe, the oil return pipe communicates with the inlet and outlet oil pipe 104a of the valve and the pump. When the valve body returns oil, the hydraulic oil flows into the oil inlet and outlet pipe 104a through the valve oil return pipe.

[0076] The valve 109 is provided with a valve oil outlet pipe 108a,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com