Exhaust and noise elimination structure of pressure release valve of automobile

A technology for pressure relief valves and automobiles, which is applied in the direction of intake mufflers, combustion air/combustion-air treatment, internal combustion piston engines, etc., and can solve problems such as the inability to solve the pressure relief valve leakage sound, and the lack of improvement in the pressure relief valve leakage sound. , to achieve the effect of simple structure, convenient installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

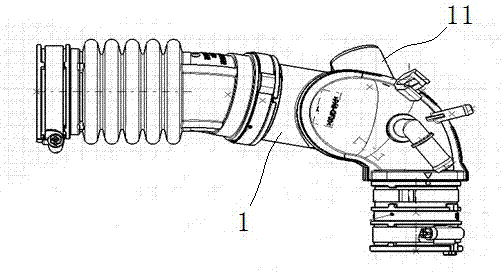

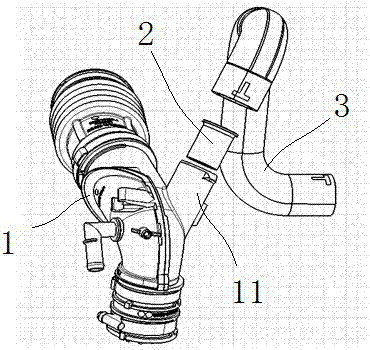

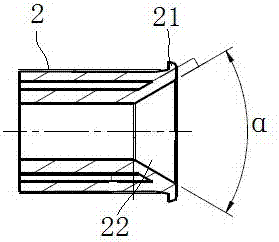

[0022] see Figure 1 to Figure 3 , the exhaust muffler structure of the automobile pressure relief valve shown includes pressure relief valve exhaust pipe 3 and air filter outlet pipe 1. The interface 11, the other end of the exhaust pipe 3 of the pressure relief valve is used for fixed connection with the pressure relief valve, which is not shown in the figure. It also includes a muffler pipe 2 arranged in the exhaust pipe 3 of the pressure relief valve. The material of the muffler pipe 2 is die steel, which is low in cost and has a certain rigidity, which satisfies the operating conditions of the vehicle. The outer diameter of the muffler pipe 2 matches the inner diameter of the exhaust pipe 3 of the pressure relief valve. One end of the muffler pipe 2 facing the interface 11 is inserted into the interface 11, and the inner hole at the other end is a tapered hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com