Patents

Literature

63results about How to "Reduce sensitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hardfacing electrode

ActiveUS20060165552A1Prolong lifeTrend downMolten spray coatingWelding/cutting media/materialsMetalMaterials science

An electrode to form a hardfacing alloy for use as a surfacing on metal that is subjected to high thermal and mechanical stresses. The electrode includes chromium, a metal sensitization inhibitor, and iron to form a hardfacing alloy.

Owner:LINCOLN GLOBAL INC

Hardfacing electrode

ActiveUS7491910B2Improved arc stabilityModification to compositionMolten spray coatingWelding/cutting media/materialsMetalChromium

An electrode to form a hardfacing alloy for use as a surfacing on metal that is subjected to high thermal and mechanical stresses. The electrode includes chromium, a metal sensitization inhibitor, and iron to form a hardfacing alloy.

Owner:LINCOLN GLOBAL INC

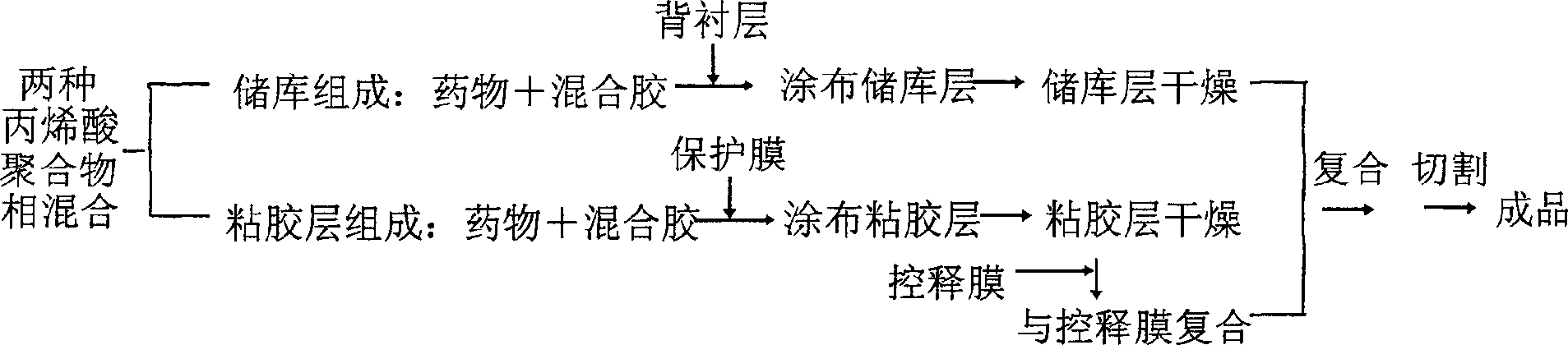

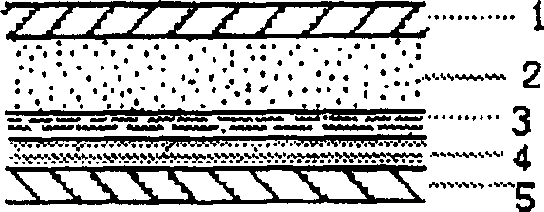

Acrylic acid base adhesive composition, and its medicinal composition and transdermal treating system

ActiveCN1640500APressure sensitive or notIncrease varietySurgical adhesivesMedical devicesMedicineAdhesive

The present invention relates to an acrylic-based adhesive composition, containing component (A) and component (B). Said component (A) contains (methyl) acrylamide or its N,N-substituted monomer (methyl) acrylate copolymer, and the component (B) contains tertiary amine or quaternary ammonium based (methyl) acrylate copolymer. Said invention also relates to application of said adhesive composition in transdermal therapeutic system, medicine composition containing said adhesive composition and transdermal therapeutic system and its preparation method.

Owner:JIANGSU KANGBEIDE PHARMA

Dental adhesive compositions with desensitizing agents

InactiveUS20020082317A1Reduce incidenceReduce severityImpression capsDentistry preparationsPotassiumDentistry

Dental cements containing desensitizing agents, preferably potassium-containing desensitizing agents, are described. The cements favorably provide decreased post-application sensitivity upon application compared to prior art formulations. Methods for preparing these cements are also described, as are methods for decreasing the incidence and the severity of post-application sensitivity using the desensitizing cements of the invention.

Owner:SULTAN CHEMISTS

Absorbent products with a linked enzyme treatment

InactiveUS7928282B2Improve abilitiesReduce sensitizationSynthetic resin layered productsBaby linensProtein structurePhotochemistry

The present invention provides a substrate treated with an linked enzyme. It has been discovered that a substrate treated with a linked enzyme can be effective in improving the ability of the substrate to absorb viscoelastic materials, such as menses, by cleaving a protein structure present in some viscoelastic materials. In addition, the linked enzyme is less likely to migrate from the treated material onto the user, as compare to an enzyme being placed directly on the substrate, thereby reducing the risk of sensitization to the user of the absorbent product. Also provided by the present invention are absorbent articles which contain at least one surface or layer containing the linked enzyme.

Owner:KIMBERLY-CLARK WORLDWIDE INC

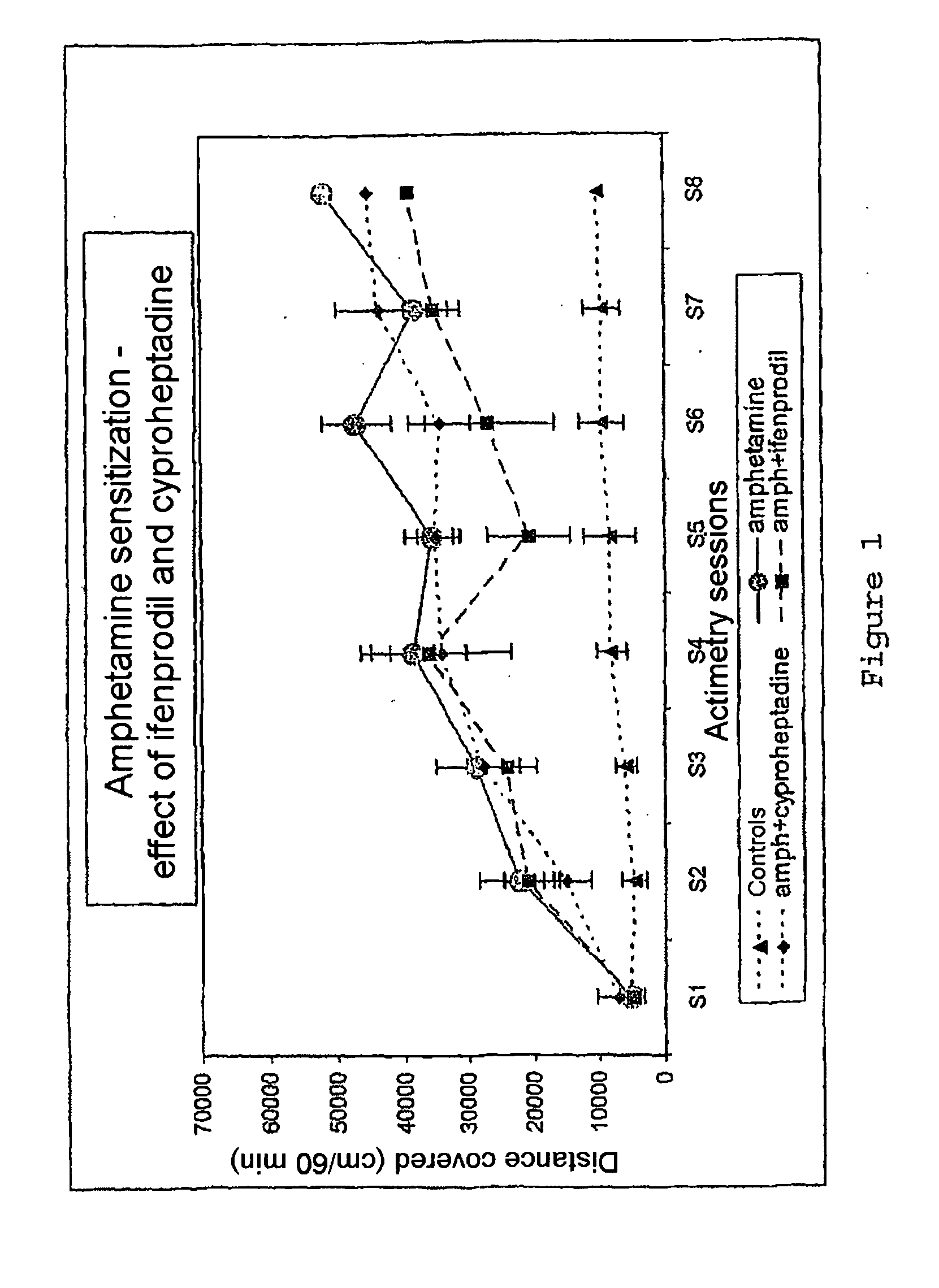

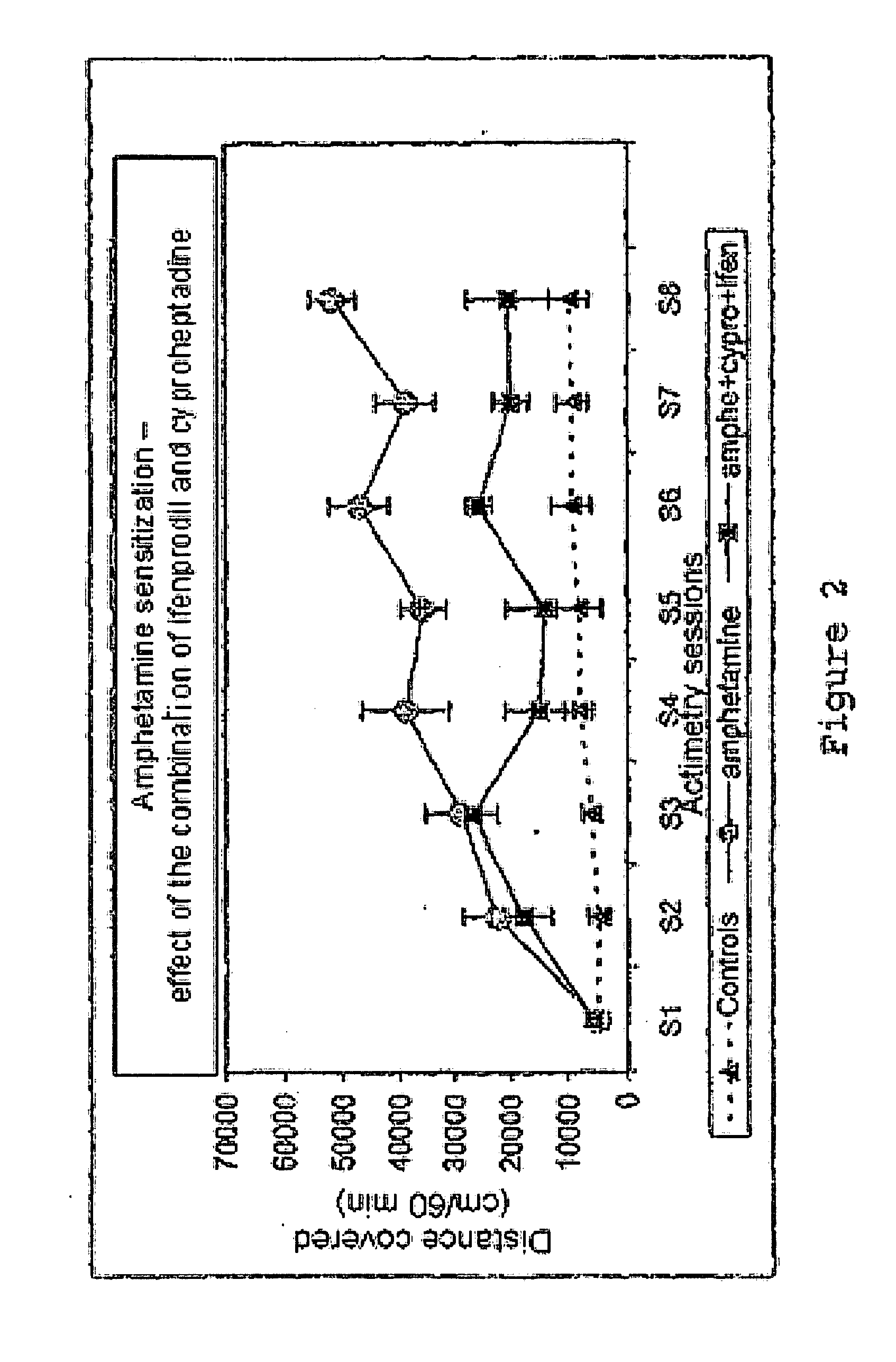

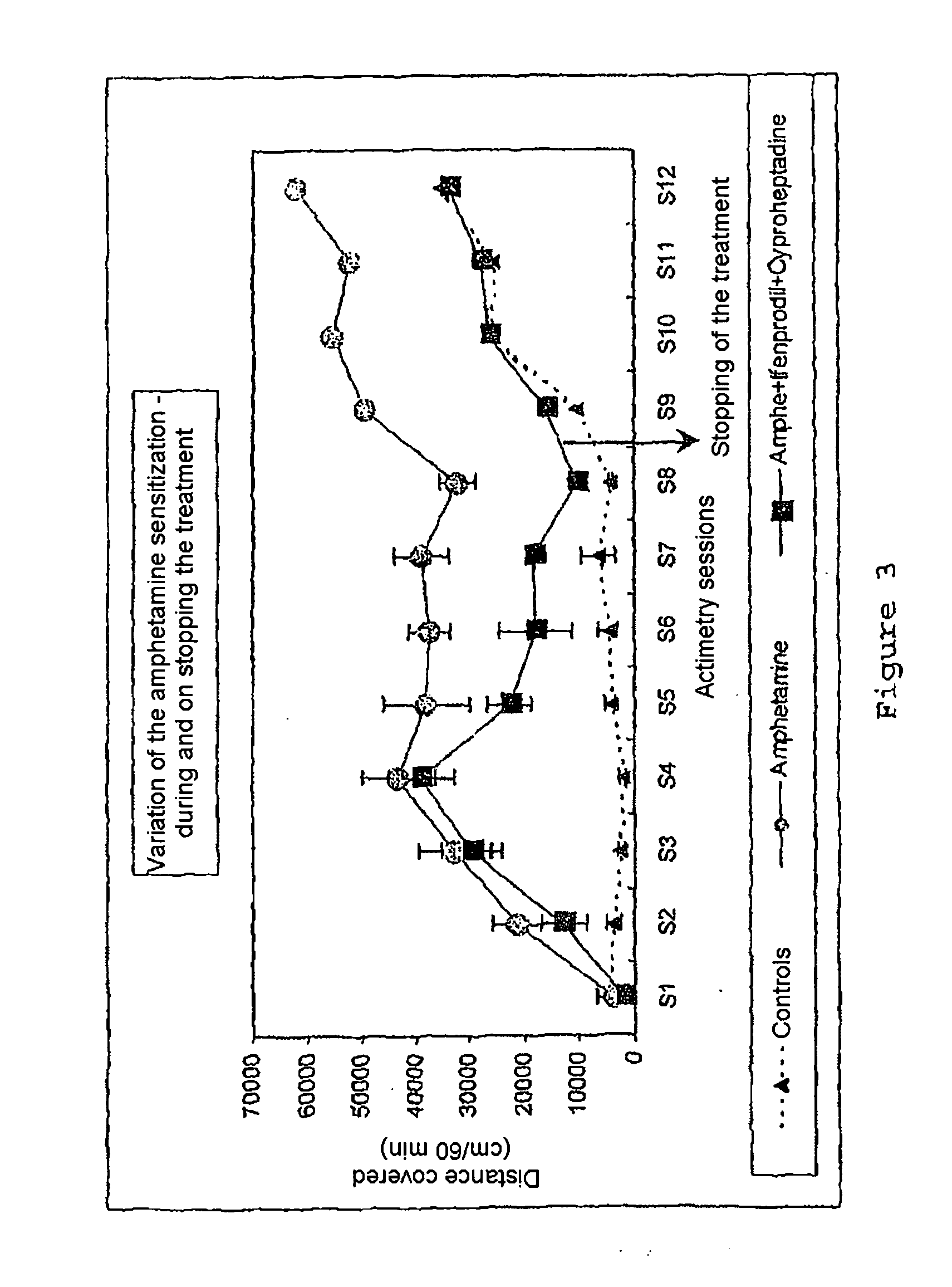

Medicament For the Treatment of Central Nervous System Disorders

The invention relates to the use of a molecule, alone or in combination, chosen from the group of molecules having a simultaneous antagonist action on the alpha1-noradrenergic, glutamatergic NMDA and serotoninergic 5HT2 receptors, for the preparation of a medicament intended for treating pathologies of the central nervous system.

Owner:KEY OBS +1

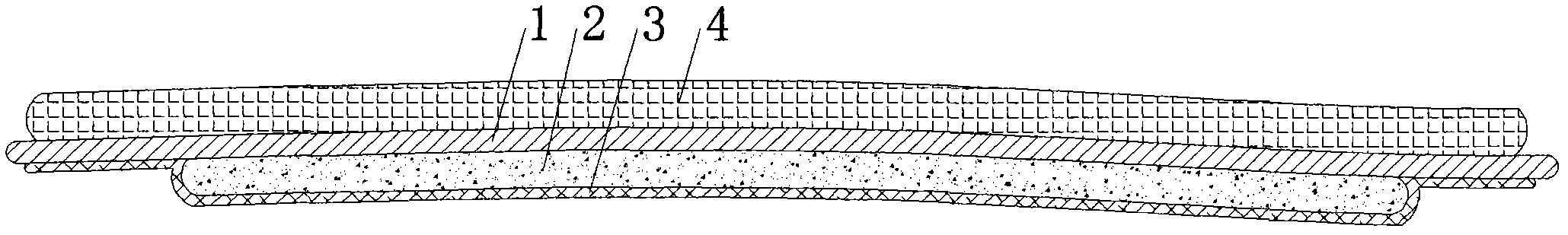

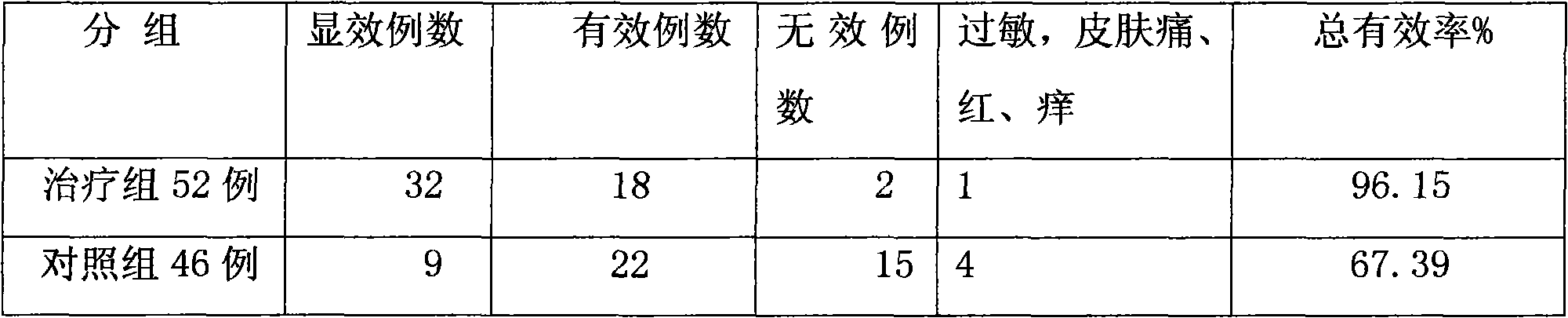

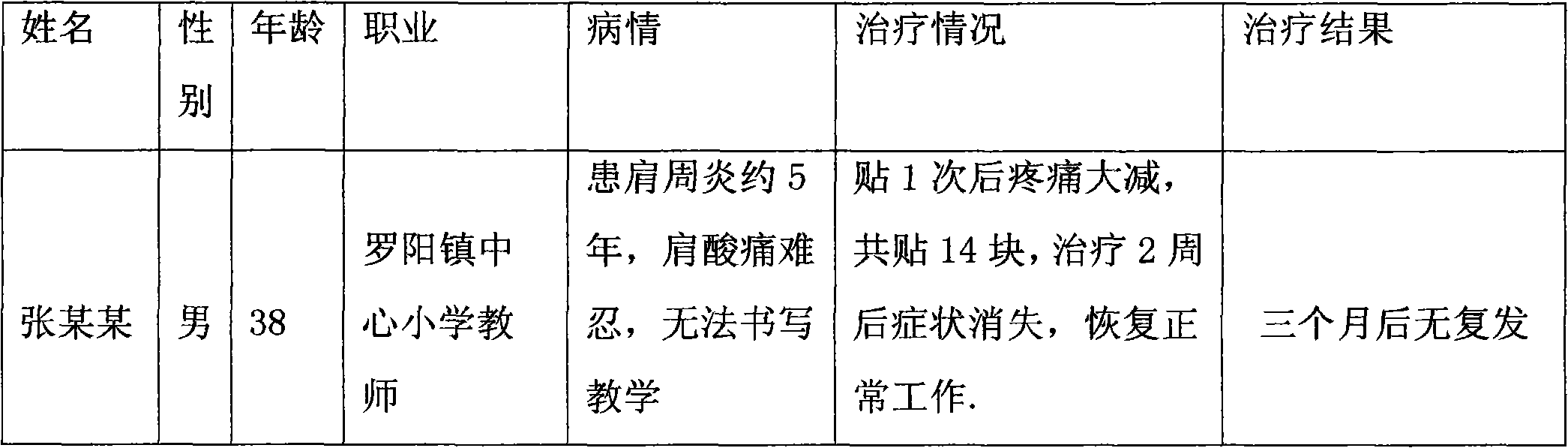

Novel mud and wax therapy application

The invention relates to a novel mud therapy application, which comprises nonwoven fabric, a plaster and a plaster protective film. A self-heating bag is arranged on the upper side of the nonwoven fabric. The plaster comprises components: 1-70% of nano-level mineral powder, 0.1-40% of plant extracts or traditional Chinese medicine, 0.1-20% of transdermal enhancer and 1-70% of pressure-sensitive adhesive or water base cement. The invention further relates to a novel wax therapy application, which comprises nonwoven fabric, a plaster and a plaster protective film. A self-heating bag is arranged on the upper side of the nonwoven fabric. The plaster comprises components: 1-70% of nano-level mineral powder, 0.1-40% of plant extracts or traditional Chinese medicine, 0.1-20% of transdermal enhancer and 1-70% of pressure-sensitive adhesive or water base cement. Different parts of the novel mud and wax therapy application coordinate with each other to realize comprehensive treatment effect.

Owner:葛纪宏

Hardfacing alloy

A hardfacing alloy for use as a surfacing on metal that are subjected to high thermal and mechanical stresses. The hardfacing alloy includes at least about 7 weight percent chromium, at least about 0.02 weight percent nitrogen, metal sensitization inhibitor, and a majority weight percent iron. The hardfacing alloy includes a low percentage of ferrite.

Owner:LINCOLN GLOBAL INC

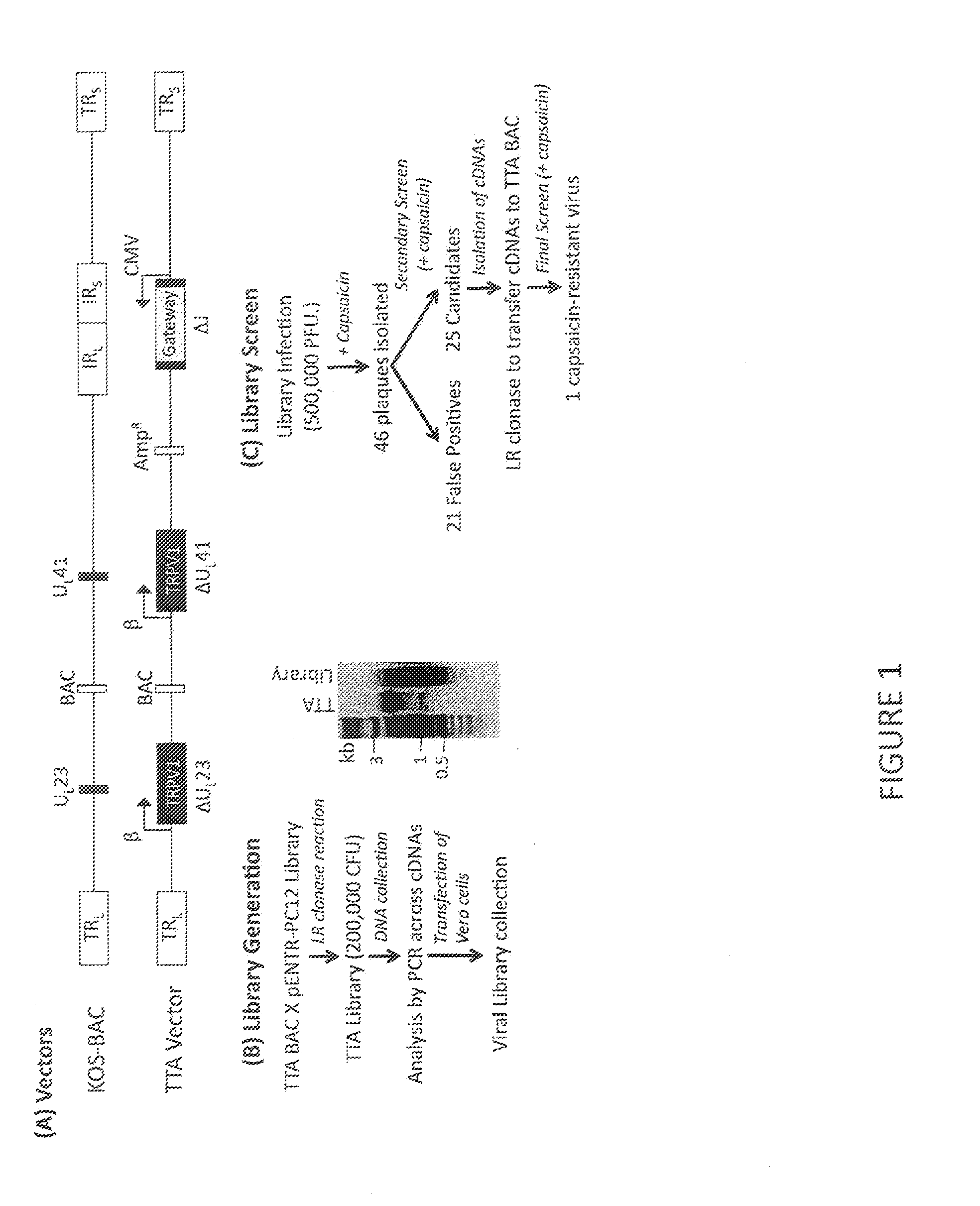

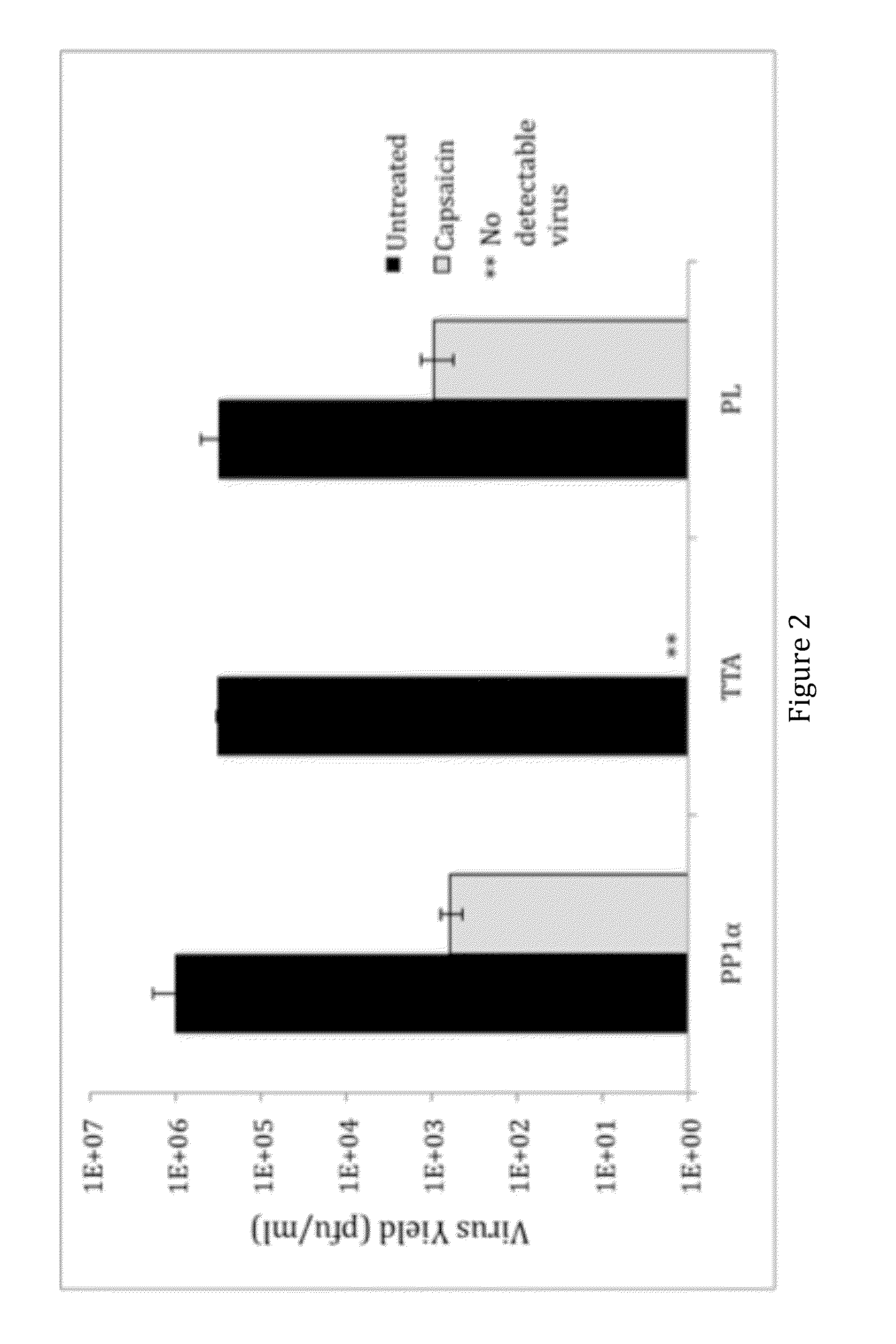

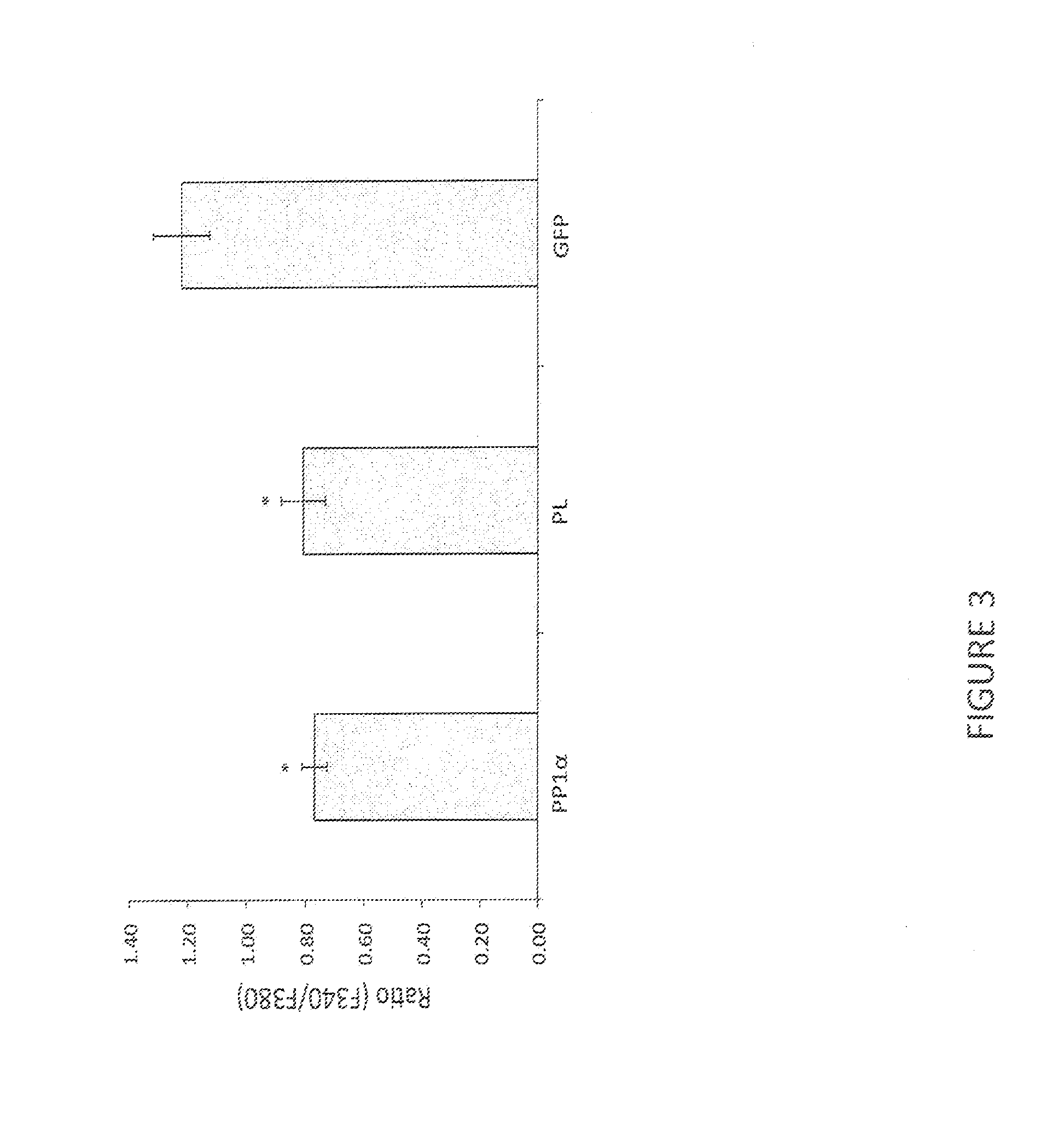

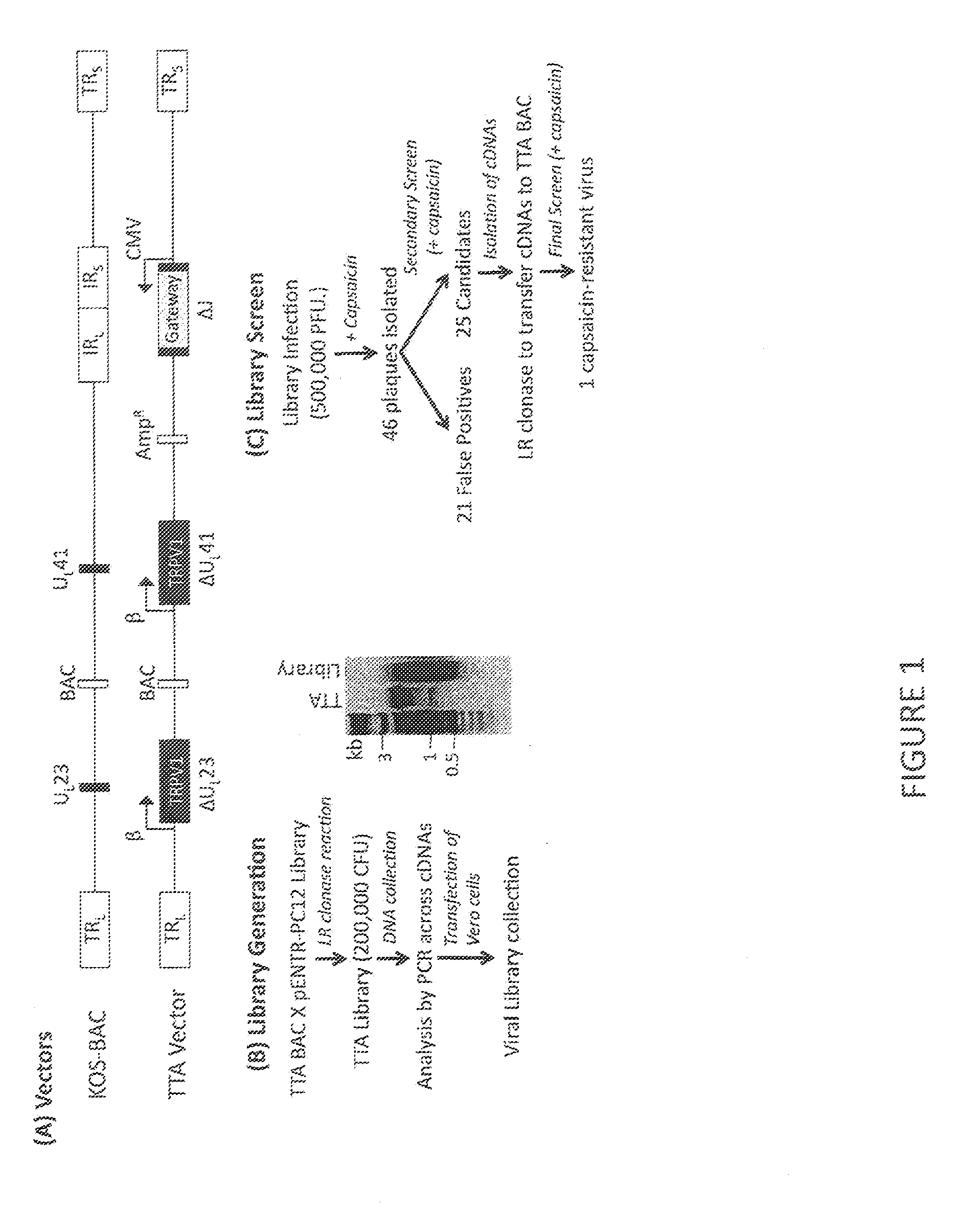

TRPV1 MODULATORY GENE PRODUCT THAT AFFECTS TRPV1-SPECIFIC PAIN BEHAVIORAL RESPONSES IDENTIFIED IN A FUNCTIONAL SCREEN OF AN HSV-BASED cDNA LIBRARY

ActiveUS20150297649A1Eliminate side effectsReduce sensitizationBiocideHydrolasesCDNA libraryTRPV Cation Channels

Owner:UNIVERSITY OF PITTSBURGH

Dental adhesive compositions with desensitizing agents

InactiveUS20040054027A1Reduce incidenceReduce severityImpression capsDentistry preparationsPotassiumDentistry

Dental cements containing desensitizing agents, preferably potassium-containing desensitizing agents, are described. The cements favorably provide decreased post-application sensitivity upon application compared to prior art formulations. Methods for preparing these cements are also described, as are methods for decreasing the incidence and the severity of post-application sensitivity using the desensitizing cements of the invention.

Owner:MILTON HODOSH

Absorbent products with a linked enzyme treatment

InactiveUS20050256471A1Promote absorptionImprove abilitiesSynthetic resin layered productsBaby linensProtein structureEnzyme

The present invention provides a substrate treated with an linked enzyme. It has been discovered that a substrate treated with a linked enzyme can be effective in improving the ability of the substrate to absorb viscoelastic materials, such as menses, by cleaving a protein structure present in some viscoelastic materials. In addition, the linked enzyme is less likely to migrate from the treated material onto the user, as compare to an enzyme being placed directly on the substrate, thereby reducing the risk of sensitization to the user of the absorbent product. Also provided by the present invention are absorbent articles which contain at least one surface or layer containing the linked enzyme.

Owner:KIMBERLY-CLARK WORLDWIDE INC

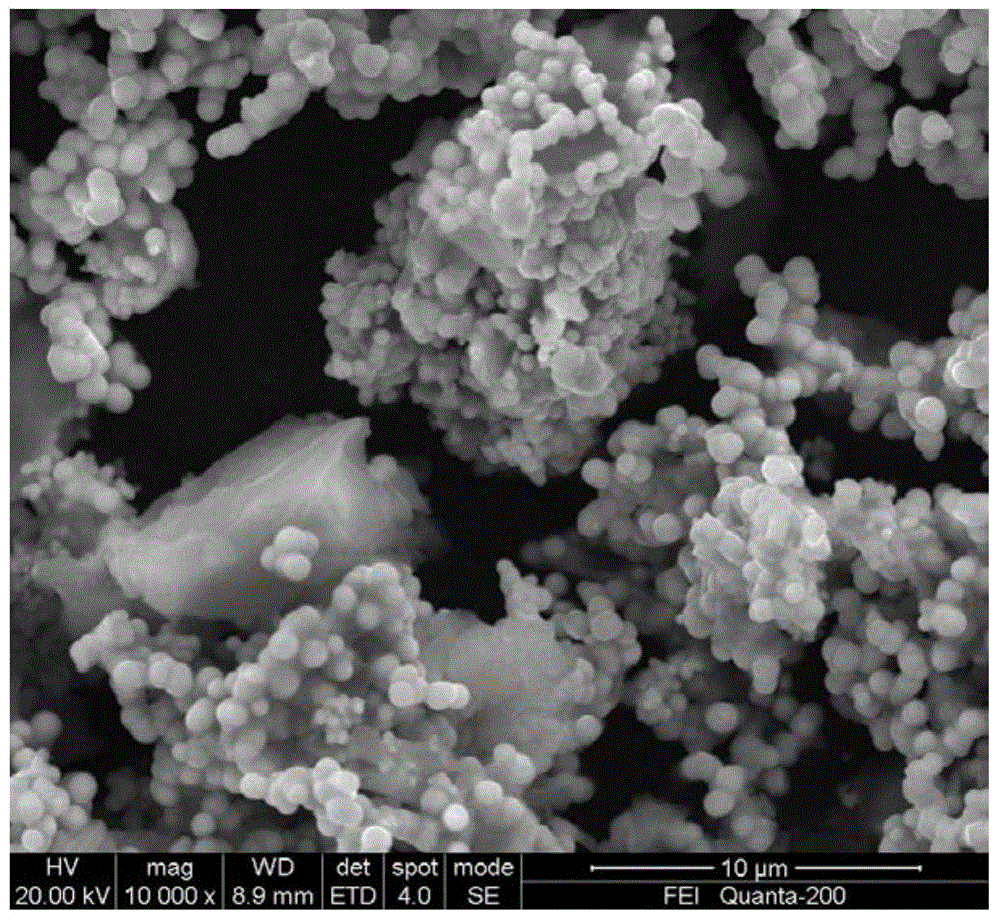

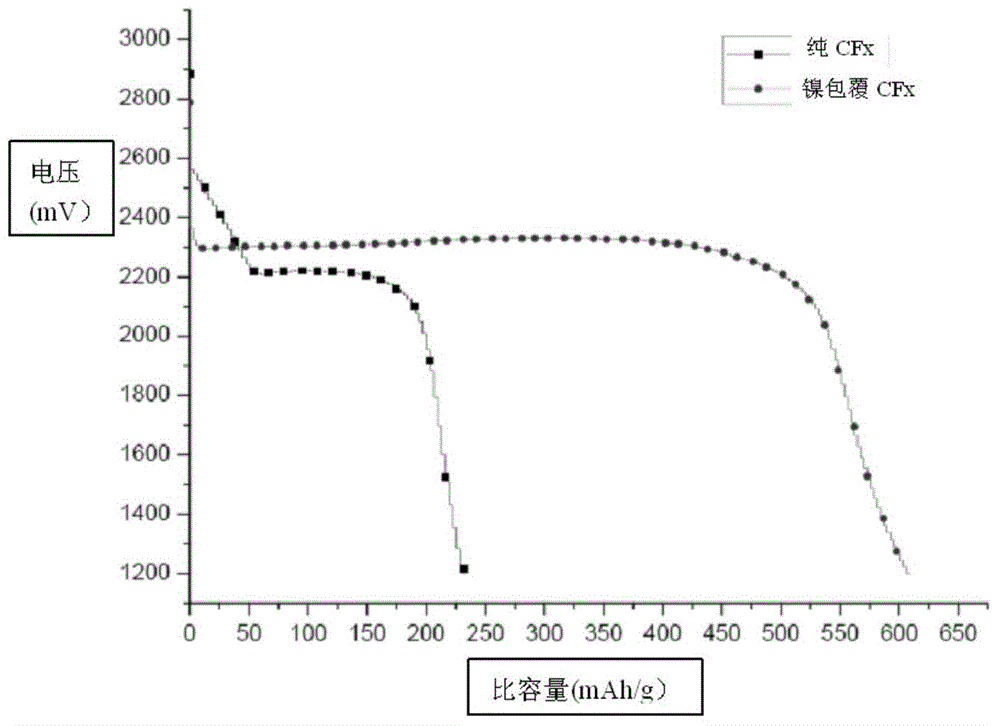

Nickel coated carbon fluoride positive electrode material and preparation method thereof

The invention discloses a nickel coated carbon fluoride positive electrode material and a preparation method of the nickel coated carbon fluoride positive electrode material. The positive electrode material is prepared by coating the surface of carbon fluoride particles with a nickel-plating layer. The preparation method comprises the steps that the carbon fluoride particles are sequentially sensitized, activated and reduced under a function of dispersing agents and the nickel-plating layer is plated; the carbon fluoride particles coated with the nickel-plating layer are subjected to thermal treatment to obtain the nickel coated carbon fluoride positive electrode material. The preparation method is easy to operate, mild in process conditions and low in cost; the prepared nickel coated carbon fluoride positive electrode material is uniform in coating of nickel-plating layer, stable in structure, and can be used for preparing a lithium carbon fluoride battery with high conductivity, high specific capacity and high power density.

Owner:XIANGTAN UNIV

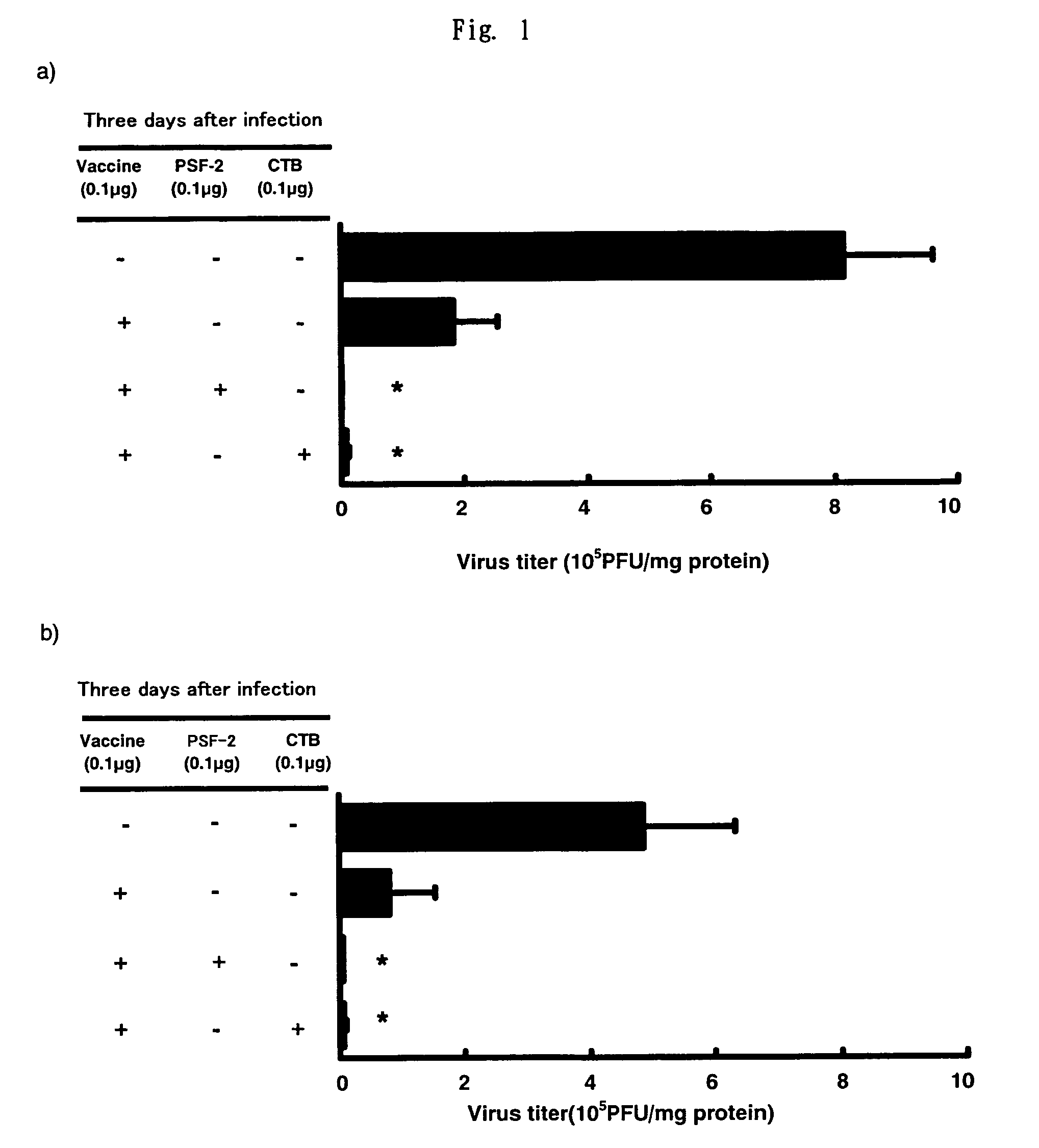

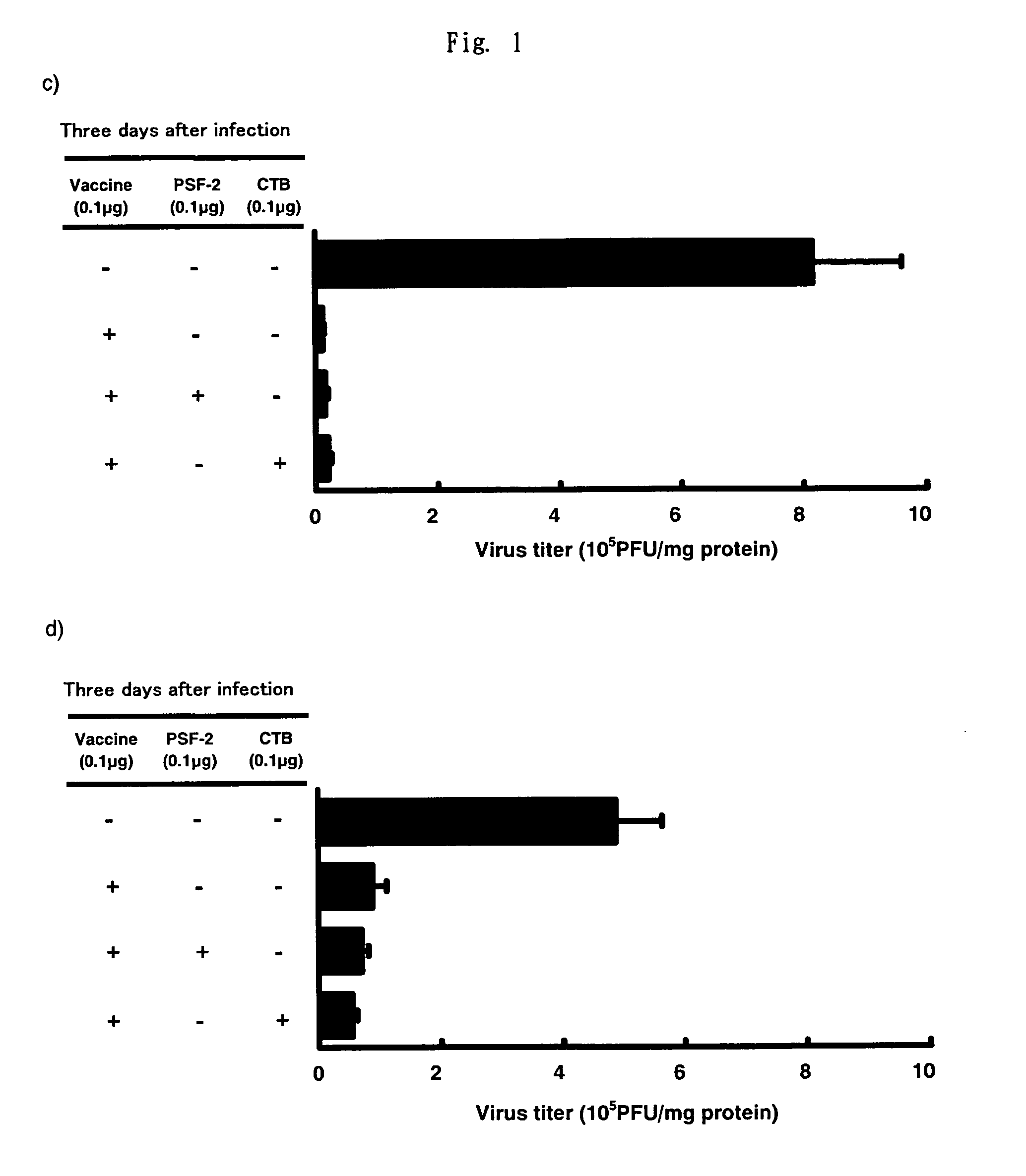

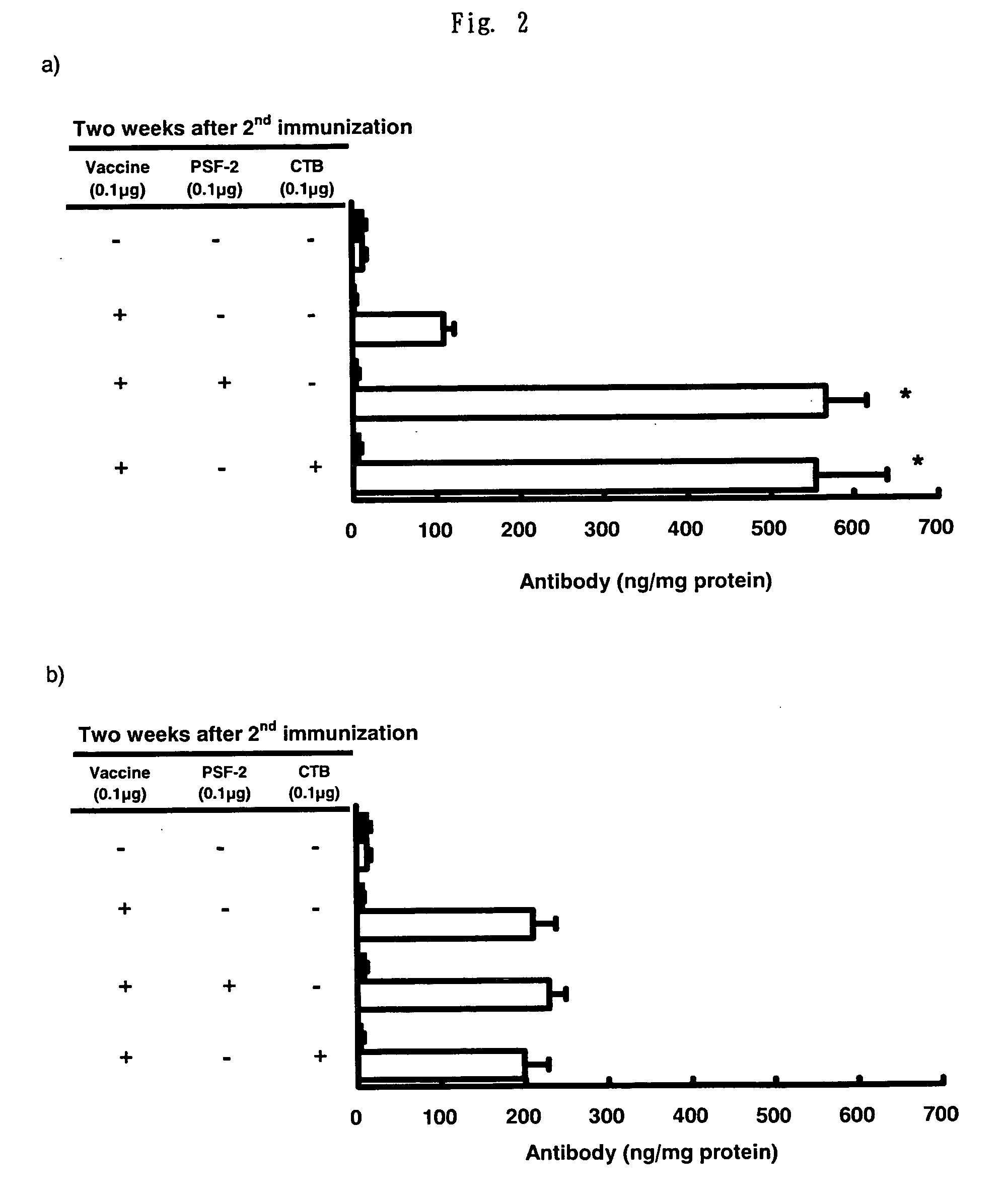

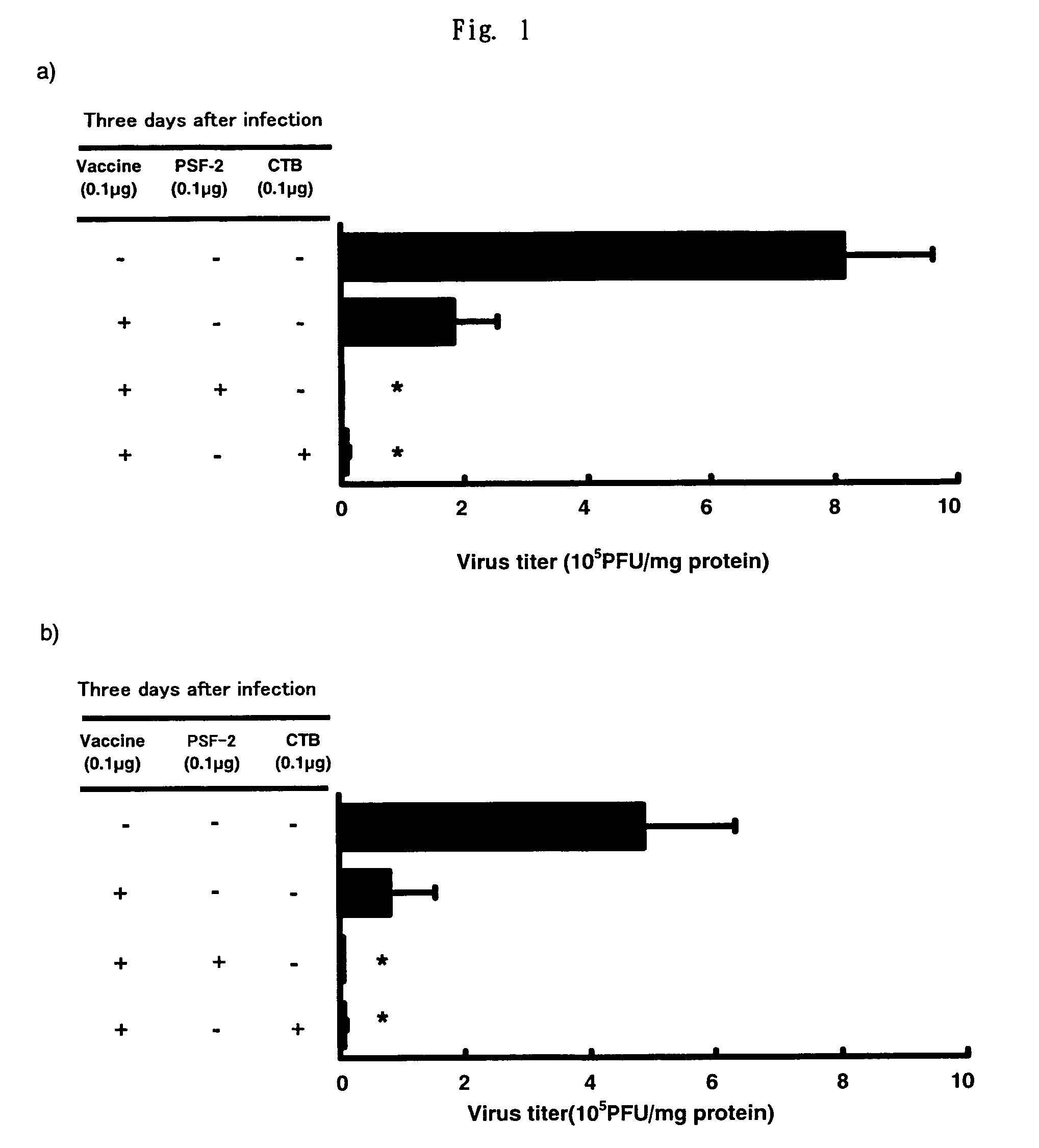

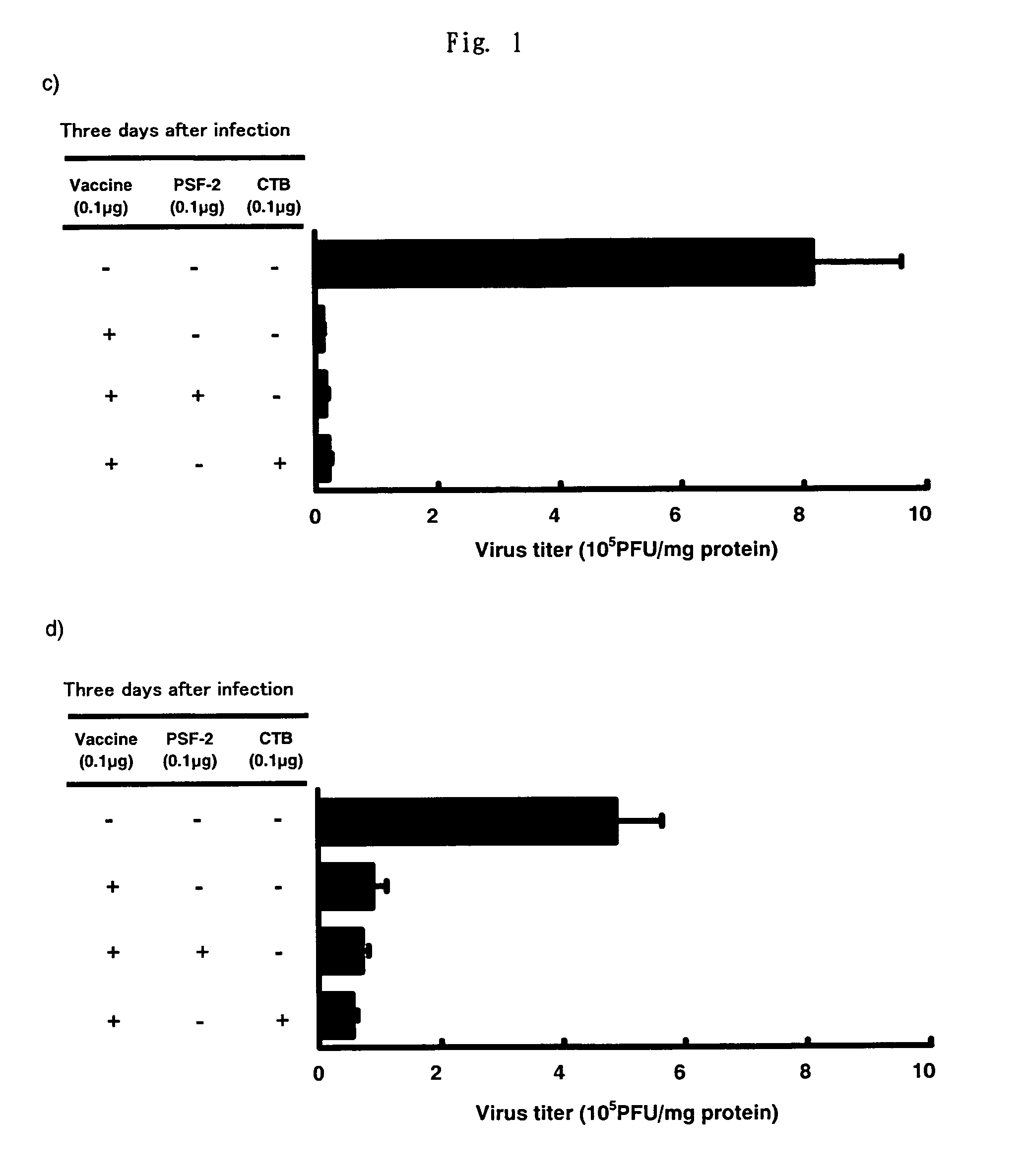

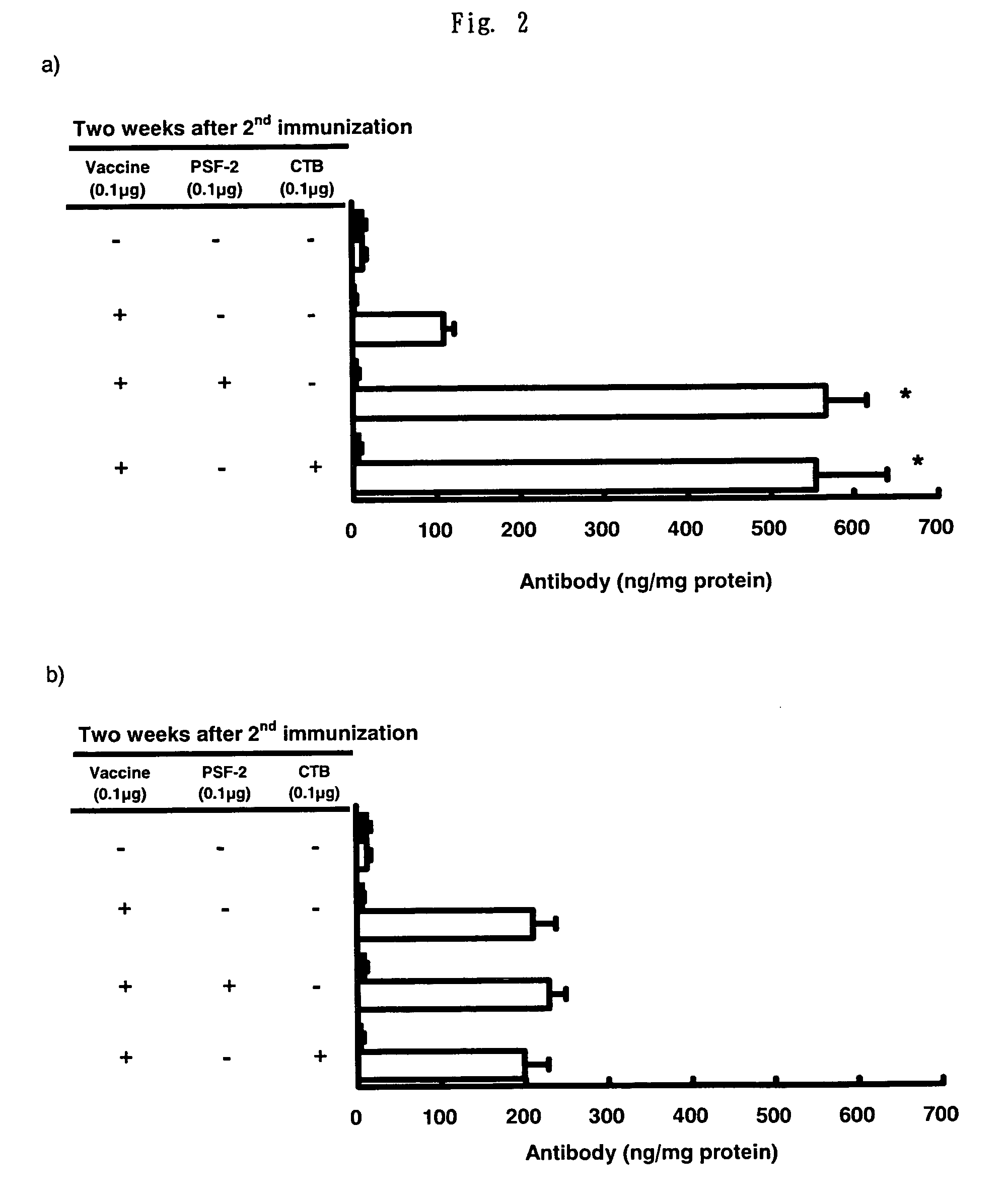

Antigen-drug vehicle enabling transmucosal and transdermal administration, and method of inducing mucosal immunity and mucosal vaccine and dds using the same

ActiveUS20070141073A1Excellent infection defense effectReduce sensitizationPeptide/protein ingredientsViral antigen ingredientsMucosal immunityAntigen specific

Disclosed are an antigen-drug vehicle (AD vehicle) exerting a function of inducing the preferential and selective production of an antigen-specific secretory IgA antibody, local immunity or mucosal immunity; a method of inducing mucosal immunity, a mucosal vaccine and a preventive or a remedy for allergy using the above AD vehicle; and a transmucosal or transdermal DDS using the above vehicle.

Owner:UNIVERSITY OF TOKUSHIMA

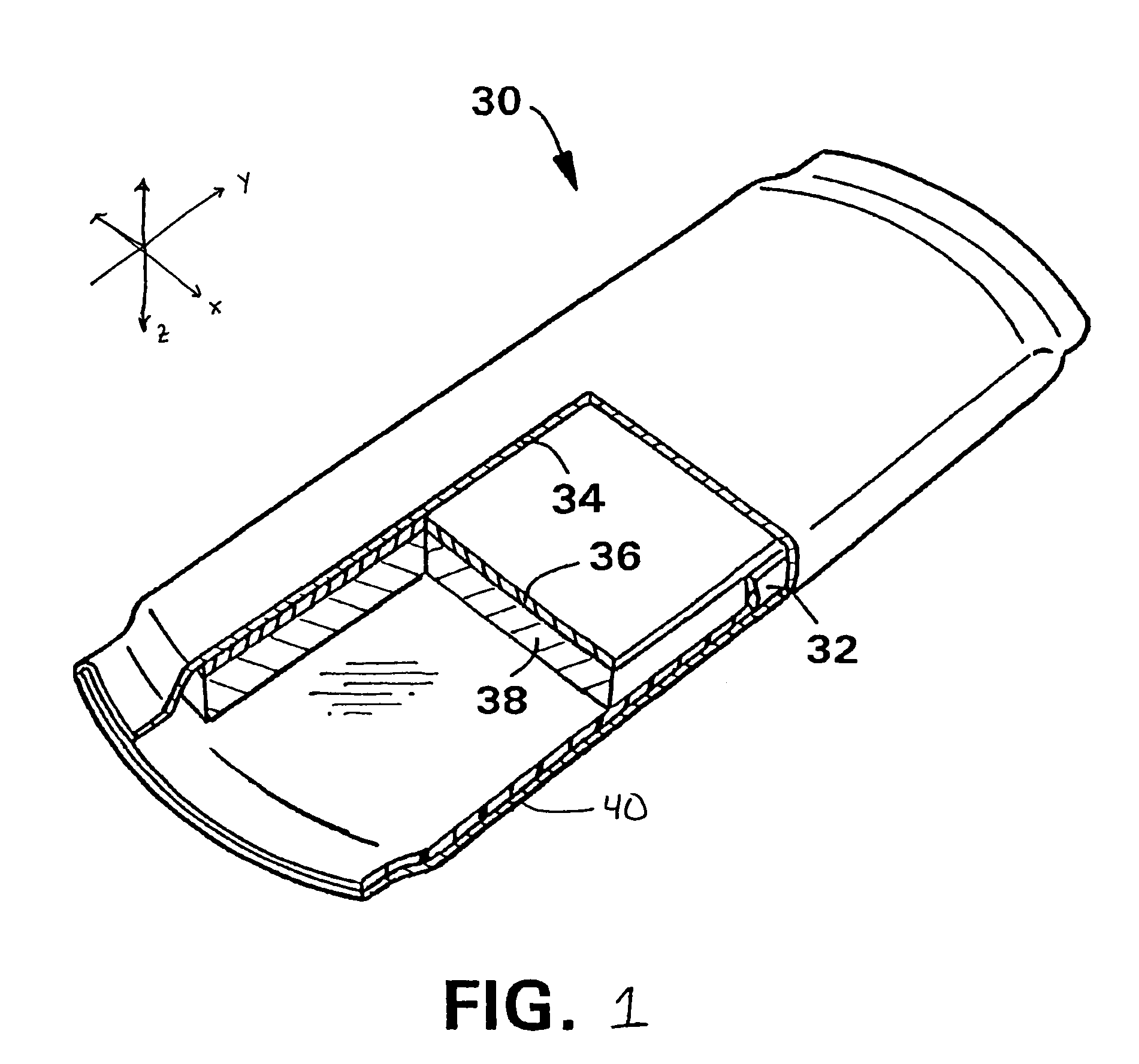

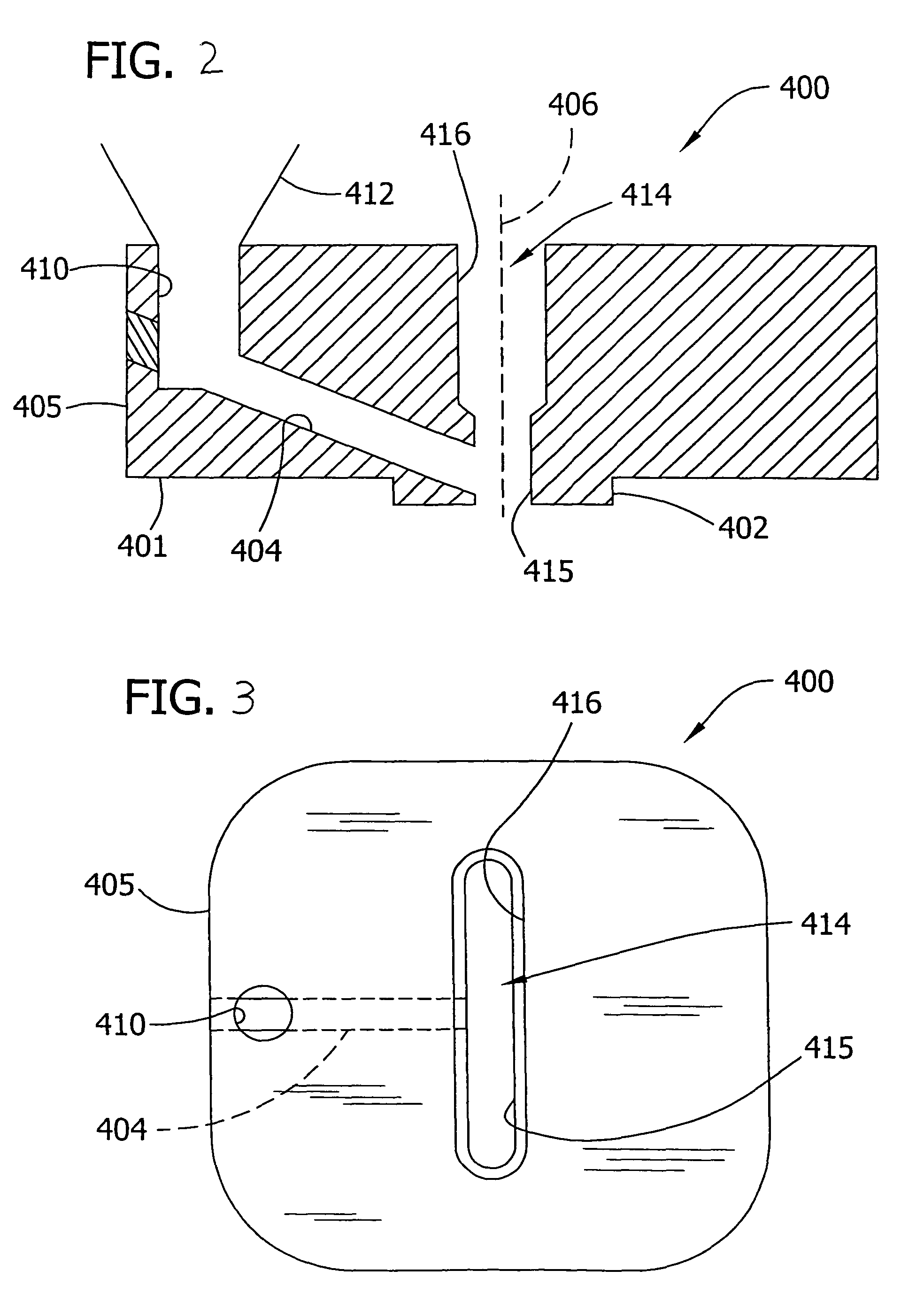

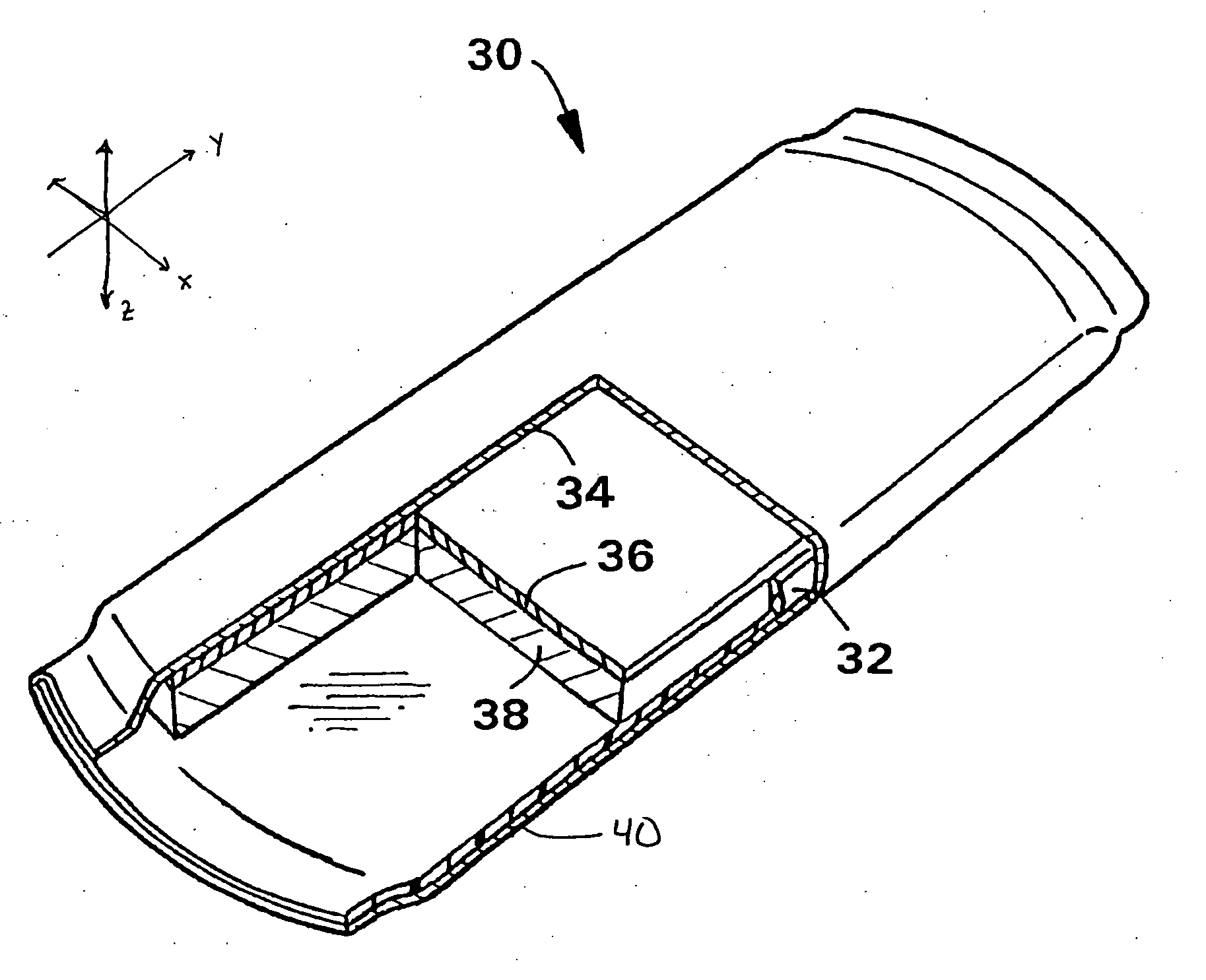

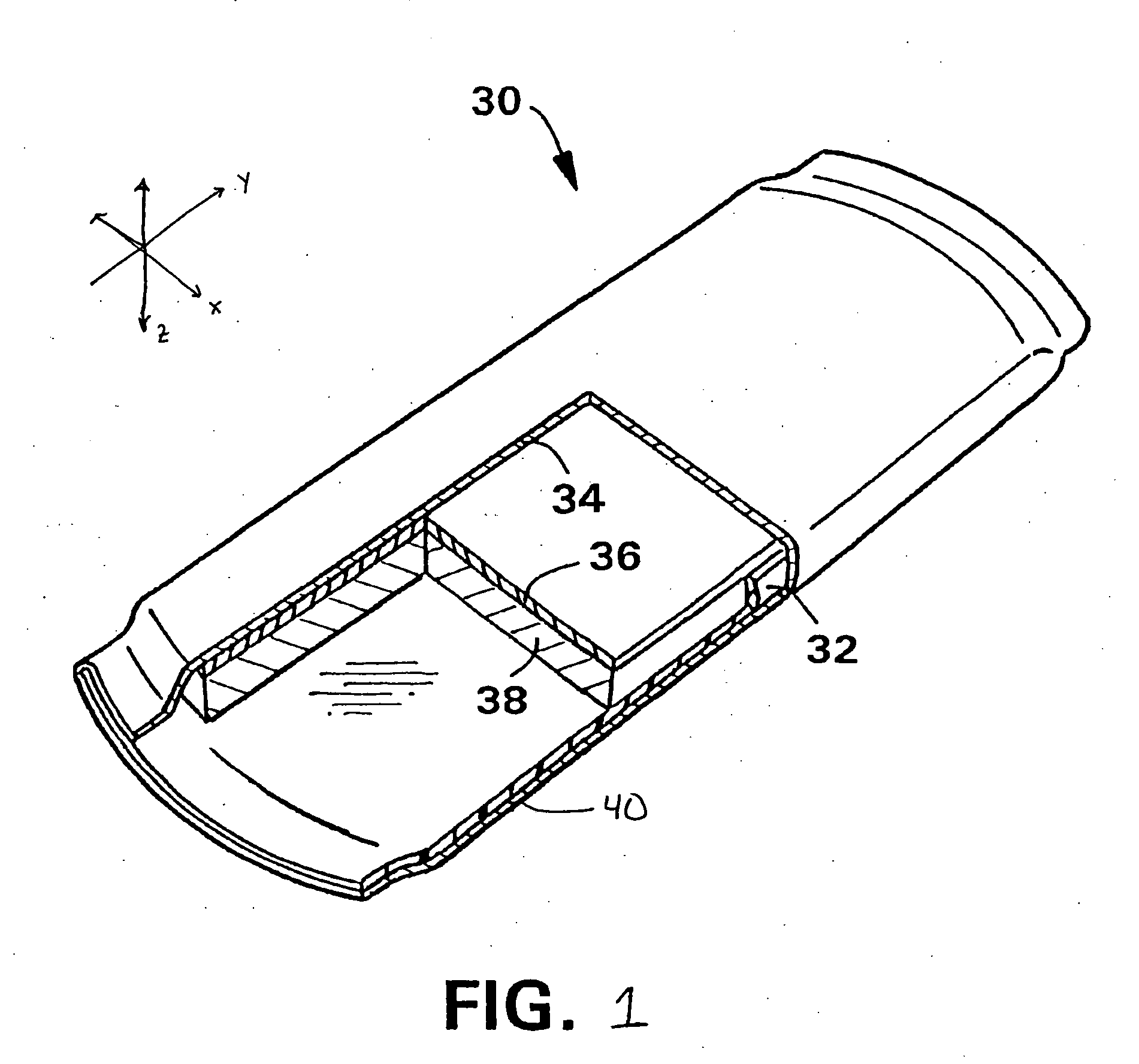

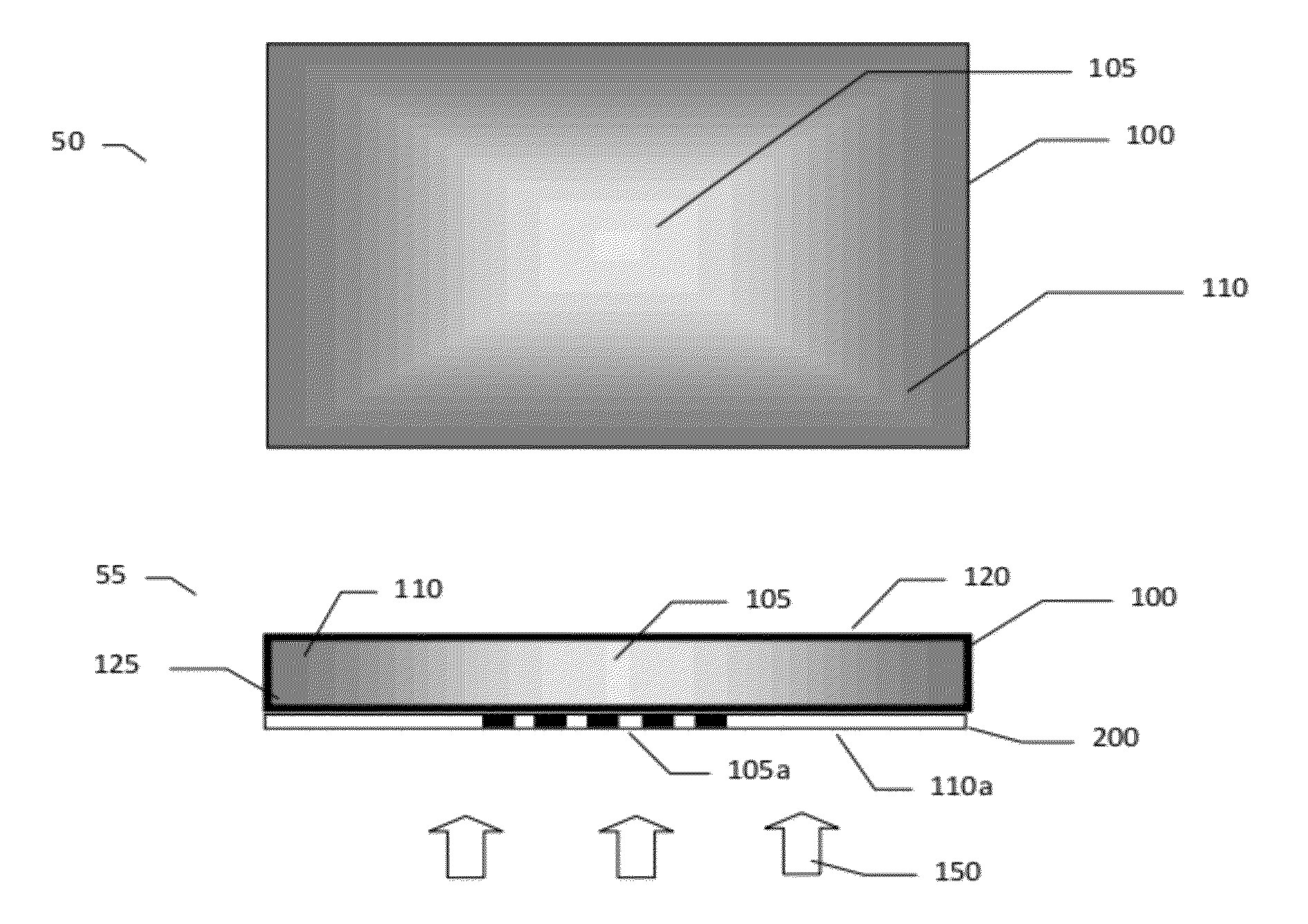

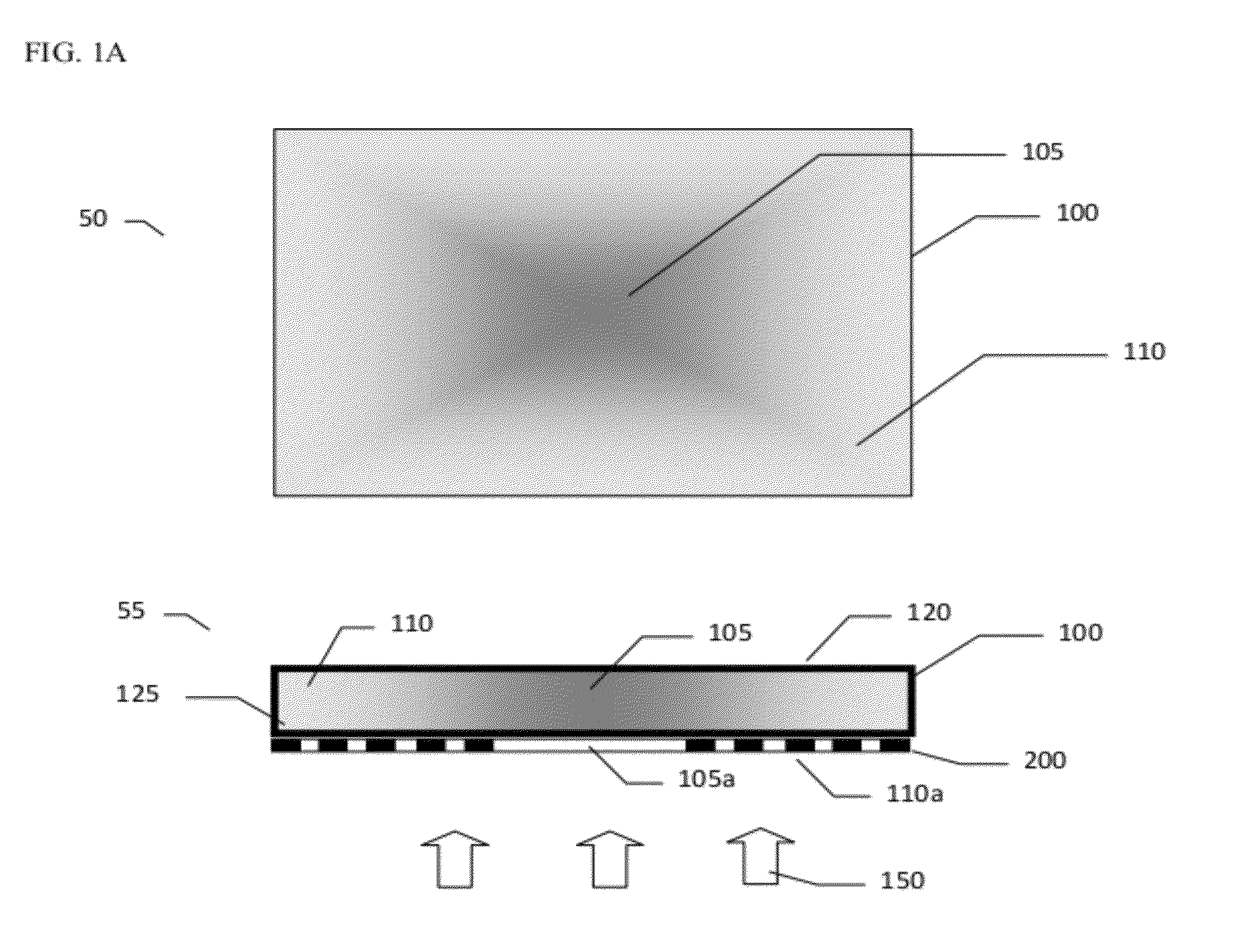

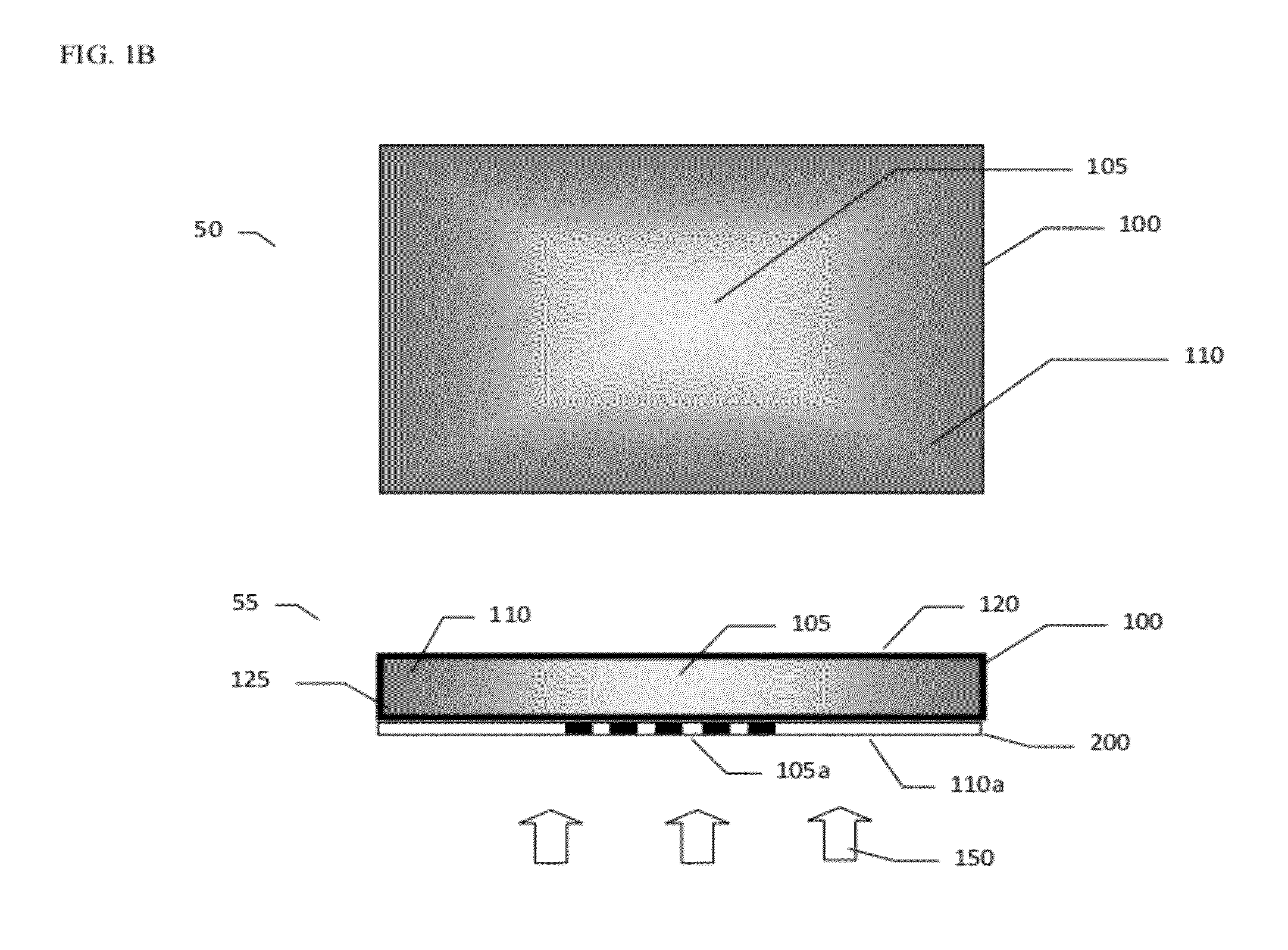

Thermal treatment device with variable heat distribution

InactiveUS20120232621A1Heating evenlyAddress bad outcomesTherapeutic coolingTherapeutic heatingEngineeringThermal treatment

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

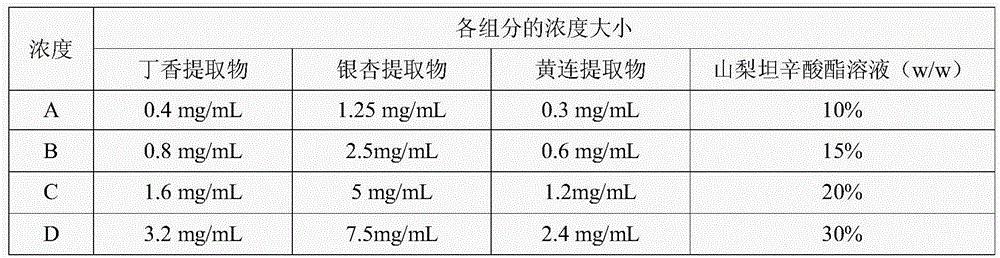

Corrosion-proof composition and application of corrosion-proof composition in cosmetics

ActiveCN104856906ALow risk to human healthReduce health risksBiocideCosmetic preparationsGalega officinalis extractBiology

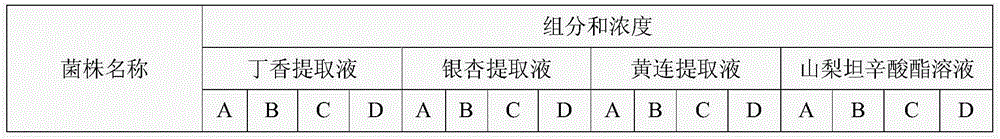

The invention discloses a corrosion-proof composition which comprises a combination of two or more of a clove extract, a gingko extract, a coptis root extract and sorbitan octoate. The composition has an inhibiting and killing effect on various bacteria and fungi. The composition cannot cause the problems such as skin allergy or pigment sediment, and skin yellowing, so that the composition is applicable to cosmetics. The invention discloses a cosmetic comprising the corrosion-proof composition at the same time.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

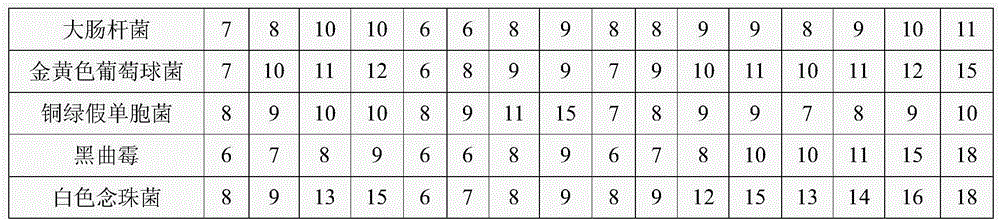

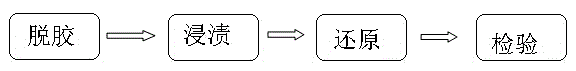

Heat-reduction metallization copper plating process for carbon fiber surface

ActiveCN104975278AReduce usageReduce sensitizationLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a heat-reduction metallization copper plating process for a carbon fiber surface, which belongs to the technical field of modification methods for the carbon fiber surface. The process comprises the following steps: pretreatment of a carbon fiber; preparation of a pre-plating liquid; dipping; heat-reduction copper plating; etc.; wherein the process is carried out in a micro-aerobic carbon environment, N2 is used as protection and dilution gas, reduction temperature is 650 to 700 DEG C, reduction time is 40 to 50 min, and the pH value of the pre-plating liquid is 11 to 12. Compared with chemical copper plating and electrical copper plating of the carbon fiber, the copper plating process provided by the invention has the following advantages: since a micro-aerobic carbon atmosphere is employed for reduction of a copper salt, the two major steps of sensitization and activation before copper plating are omitted, usage of precious metals like AgNO3 and PdCl2 is reduced, experiment cost is reduced, and a pretreatment step is simplified. According to XRD and EDS analysis, a great amount of copper is attached onto the carbon fiber surface after copper plating, reaching a certain coverage ratio; and according to SEM observation results, the copper on the carbon fiber surface is distributed on the carbon fiber surface in a superposed island shape.

Owner:GANSU HAOSHI CARBON FIBER

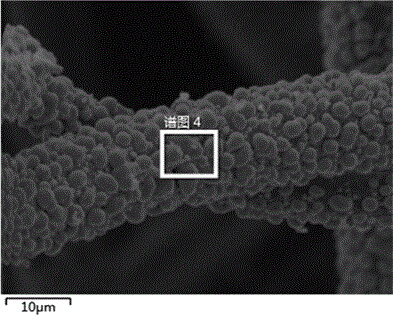

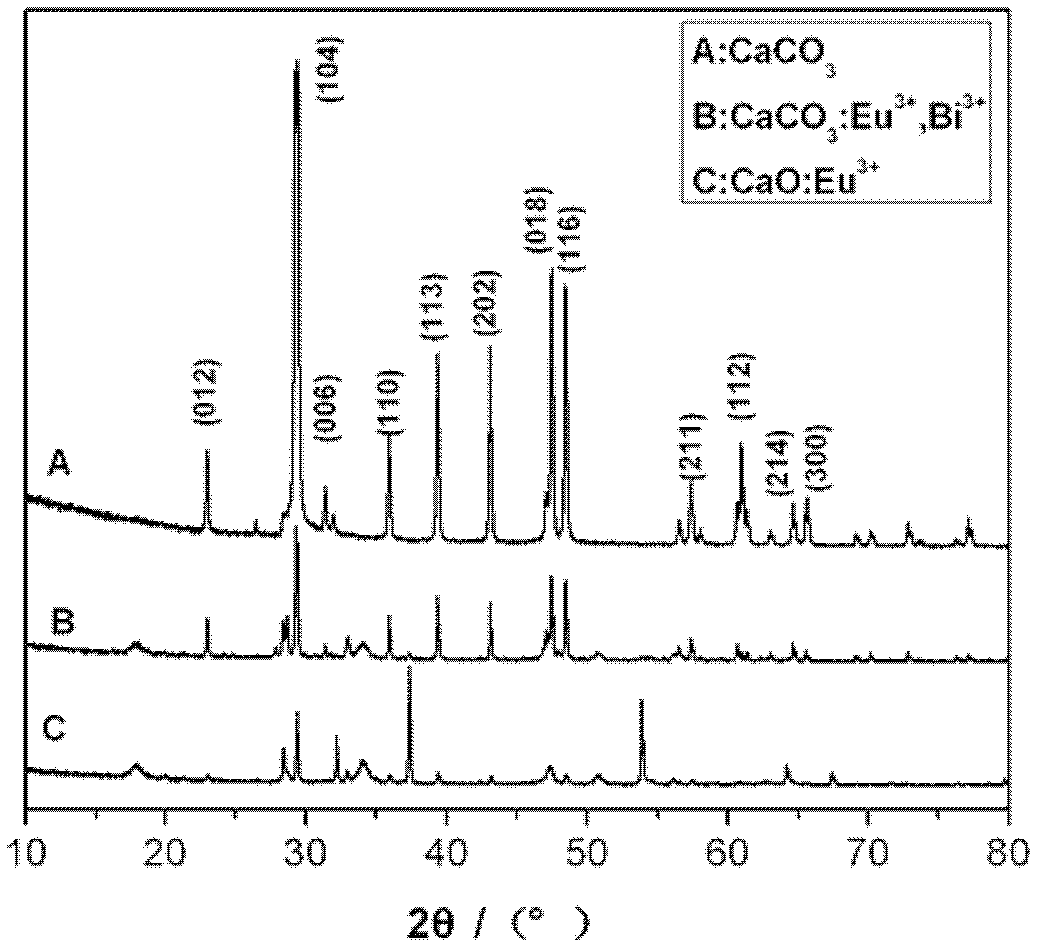

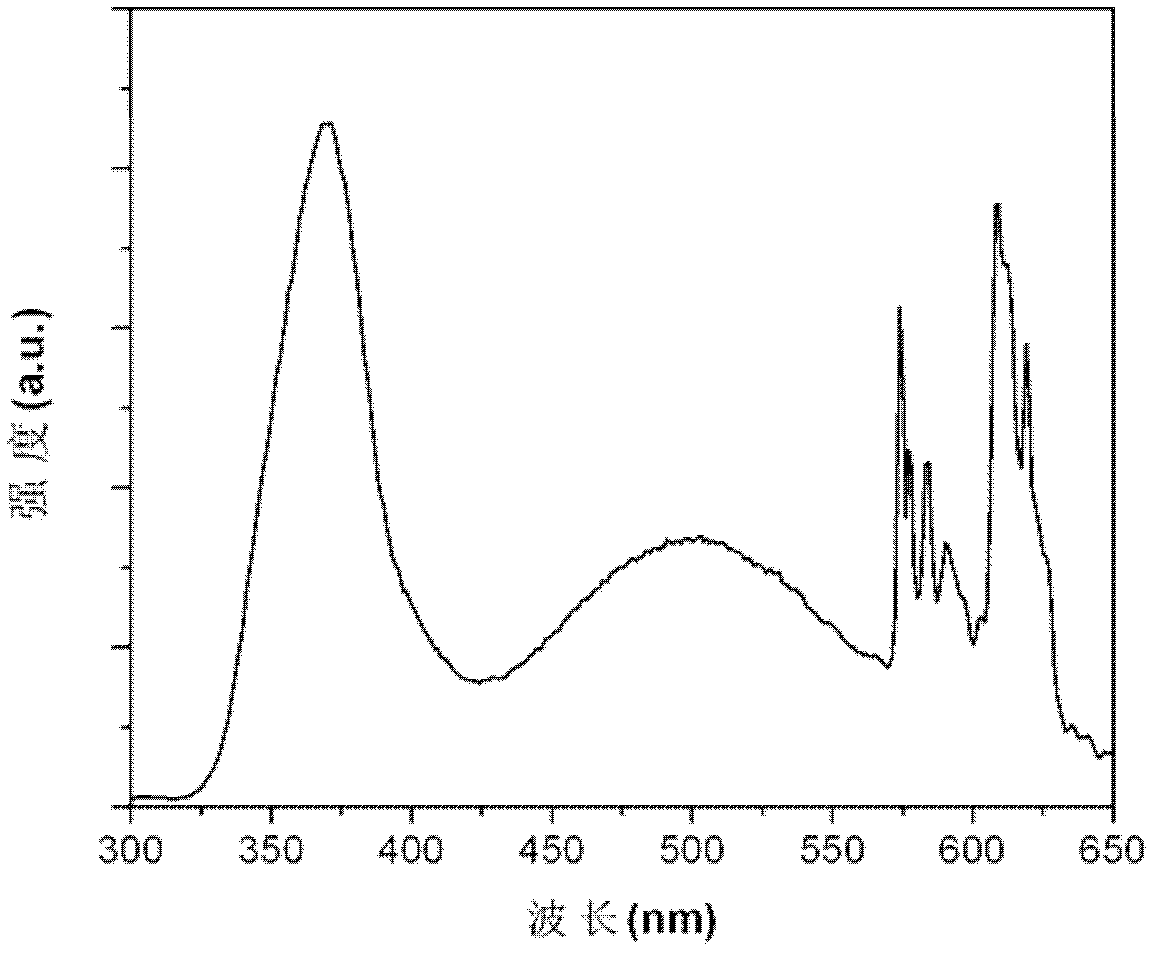

Ground limestone-based bismuth and europium co-doped yellow fluorescent powder

InactiveCN102585816ALow priceLow reaction temperatureLuminescent compositionsLuminous intensityBall mill

The invention discloses ground limestone-based bismuth and europium co-doped yellow fluorescent powder. According to the fluorescent powder, ground limestone is used as matrix, EU<3+> is used as an activating agent, Bi<3+> ions are used as a sensitizing agent, and alkali carbonate is used as a fluxing agent and a charge compensation agent; and the molar ratio of ground limestone to EU<3+> to Bi<3+> to M2CO3 is 100:(1-5):(1-15):(0.5-2.5), wherein M is one or more of Li<+>, Na<+> or K<+>. The invention also discloses a preparation method for the ground limestone-based bismuth and europium co-doped yellow fluorescent powder; and the preparation method comprises the following steps of: accurately weighing raw materials, fully grinding the raw materials in a ball grinding mill, mixing uniformly to form powder and thus obtaining precursor, pre-treating in a high-temperature furnace, grinding, calcining the precursor at CO2 atmosphere of standard atmospheric pressure, and grinding to obtain a sample. The provided preparation method for the fluorescent powder is simple, and the fluorescent powder is stable in performance, and high in luminous intensity and has important application value.

Owner:ZHEJIANG UNIV OF TECH

Antigen-drug vehicle enabling transmucosal and transdermal administration, and method of inducing mucosal immunity and mucosal vaccine and DDS using the same

ActiveUS8268321B2Excellent infection defense effectReinforces and promotes preventive and therapeutic effect of drugPeptide/protein ingredientsViral antigen ingredientsSecretory IgA antibodyLocal immunity

Owner:UNIVERSITY OF TOKUSHIMA

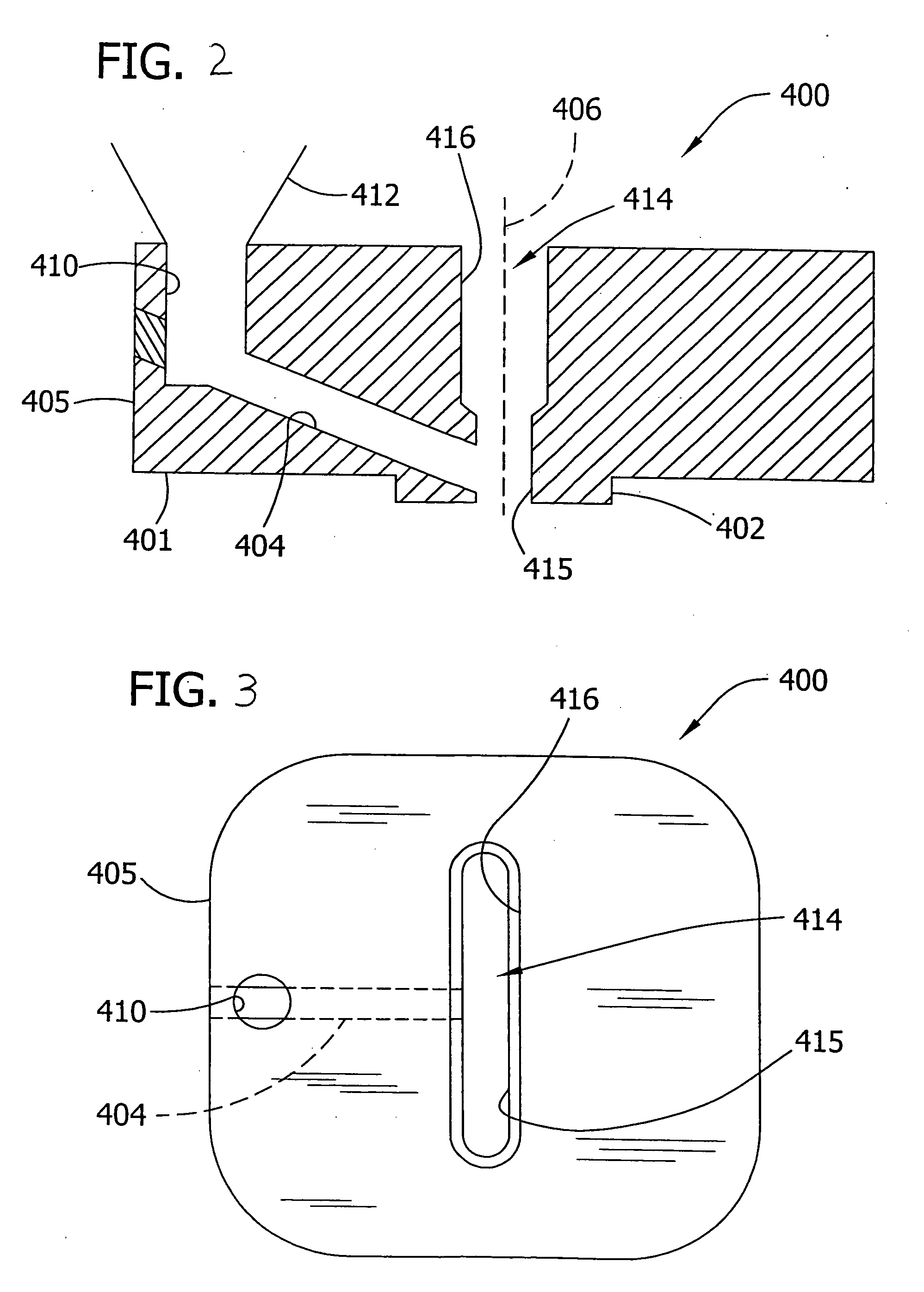

Dressing plaster provided U-shaped notch

InactiveCN103284838ASimple structureReduce sensitizationAdhesive dressingsSacroiliac jointBiocompatibility Testing

The invention relates to the technical field of medical nursing materials, in particular to a waterproof dressing plaster which can promote wound healing and is suitable for large-area wound. The dressing plaster provided with a U-shaped notch comprises a piece of base cloth, wherein the inner surface of the base cloth is coated with thermosensitive glue; a wound protecting layer sticks to the middle of the base cloth and is covered with a piece of isolating paper; the outer edge of the isolating paper is fixed at an exposed part corresponding to the periphery of the base cloth; and the U-shaped notch is formed in one side of the outer edge of the wound protecting layer (2). The dressing plaster provided with the U-shaped notch is simple in structure, the U-shaped notch is formed in one side of the dressing plaster, so that the dressing plaster is suitable for the wound in joints, has low sensitization, good biocompatibility and no stimulation or damage to skin, and is sterile; and further, the breathability is good, and the natural functions of the skin are not influenced.

Owner:朱建华

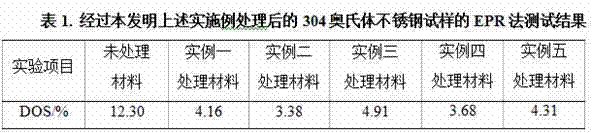

Heat treatment process for reducing sensitization degree of austenitic stainless steel

The present invention discloses a heat treatment process for reducing the sensitization degree of an austenitic stainless steel, wherein an austenitic stainless steel is subjected to segmented annealing treatment under a reduced protection atmosphere, and then water cooling is performed to achieve a room temperature. According to the present invention, with the heat treatment process, the residence time of the austenitic stainless steel in the sensitization temperature zone during the austenitic stainless steel heat treatment process can be reduced, the formation of the partial chromium carbide can be effectively inhibited, the carbide formed at the grain boundary position can be re-dissolved into the austenite to form the appropriate amount of the delta-ferrite, the sensitization degree of the austenitic stainless steel can be reduced, and the intergranular corrosion resistance can be improved; and the heat treatment process has advantages of simple process, remarkable effect and strong operability, and can be used for large-scale industrial production.

Owner:SHANGHAI UNIV

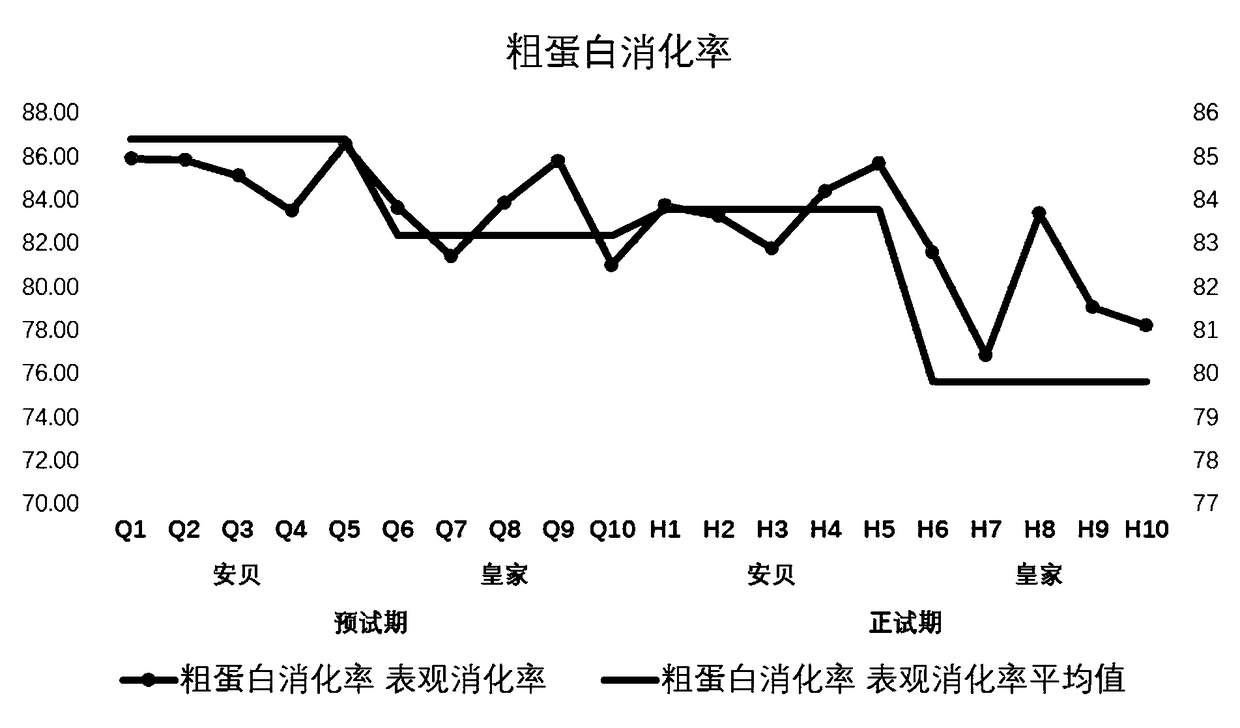

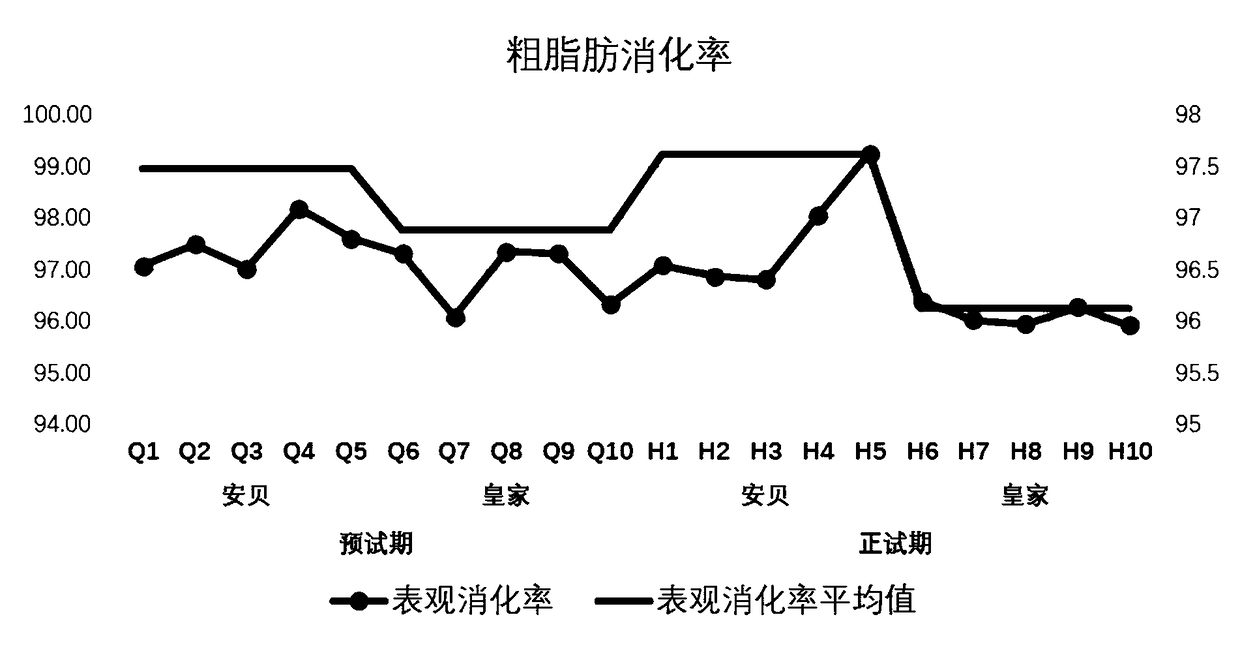

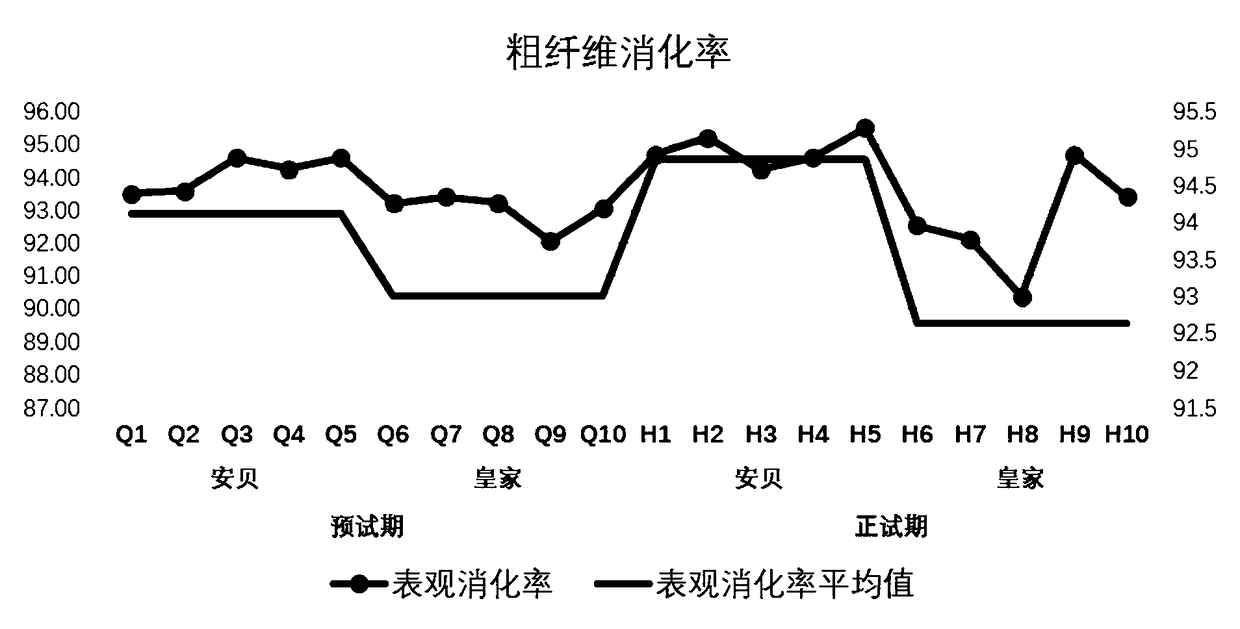

Animal feed composition and preparation method thereof

InactiveCN109007285AEasy to absorbReduce sensitizationLactobacillusAnimal feeding stuffSunflower seedPoultry meat

The present invention relates to the field of feeds, in particular to an animal feed composition and a preparation method thereof. The animal feed composition comprises the following components in parts by weight: 5-25 parts of poultry meat powder; 5-15 parts of poultry liver powder; 5-15 parts of goat milk powder; 0.5-3.5 parts of milk calcium; 25-65 parts of grain and vegetable protein; 5-20 parts of poultry oil; and 1-10 parts of sunflower seed oil. This product is suitable for dogs and cats in weaning period, in puppy period, in adult dog period, in pregnancy and lactation period, in old age and in disease period, and is also suitable for pets during the disease treatment and recovery period.

Owner:怀来安贝宠物食品有限公司

Plant protein powder and production method thereof

ActiveCN102342510AReduce volumeReduce sensitizationFood processingAnimal feeding stuffPROTEIN S HEERLENNutrition

The invention relates to the field of plant proteins, in particular to plant protein powder and a production method thereof. The plant protein powder comprises lysine, methionine, tryptophan, threonine and isoleucine in the ratio 1:(0.25-0.3):(0.14-0.16):(0.5-0.6):(0.5-0.6), and preferably comprises the following raw materials in parts by weight: 280 parts of bean pulp, 250 parts of rapeseed dregs, 220 parts of cottonseed meal, 140 parts of corn protein powder and 11 parts of beer yeast. The method comprises the following production steps of: determining a formula and production dosage; initially smashing; weighing; mixing; and performing micron smashing, and the like. The plant protein powder is natural, has reasonable nutrition, and contributes to absorbing; the production method is easy to operate; and the protein digestion rate is increased by 10 percent, and the metabolic utilization efficiency is increased by or over 20 percent.

Owner:SICHUAN JINRUIKE ANIMAL PHARMA

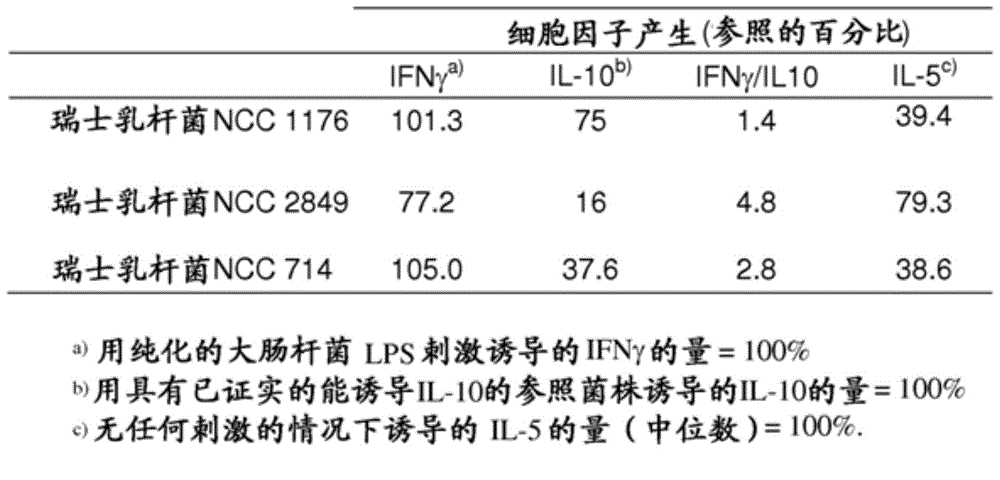

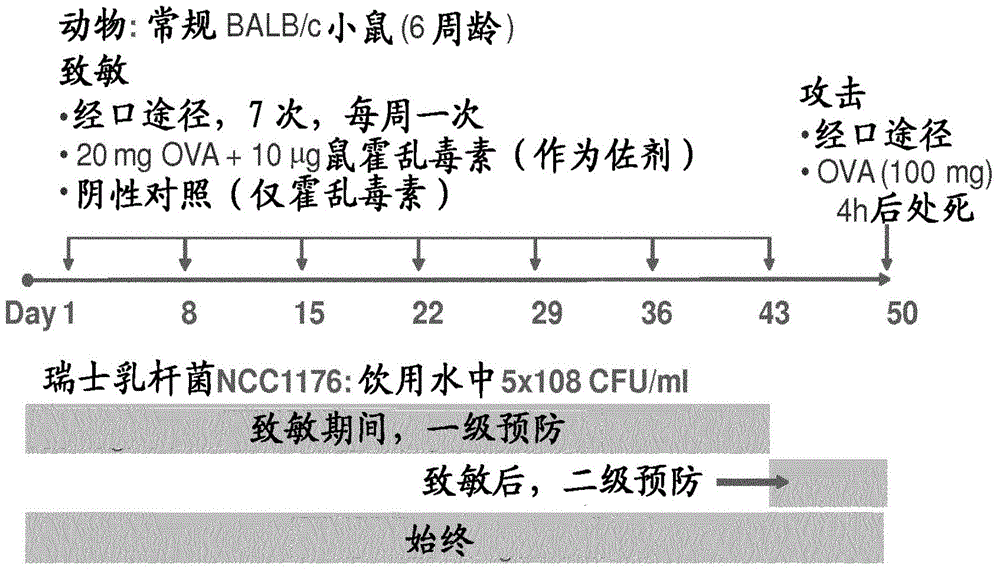

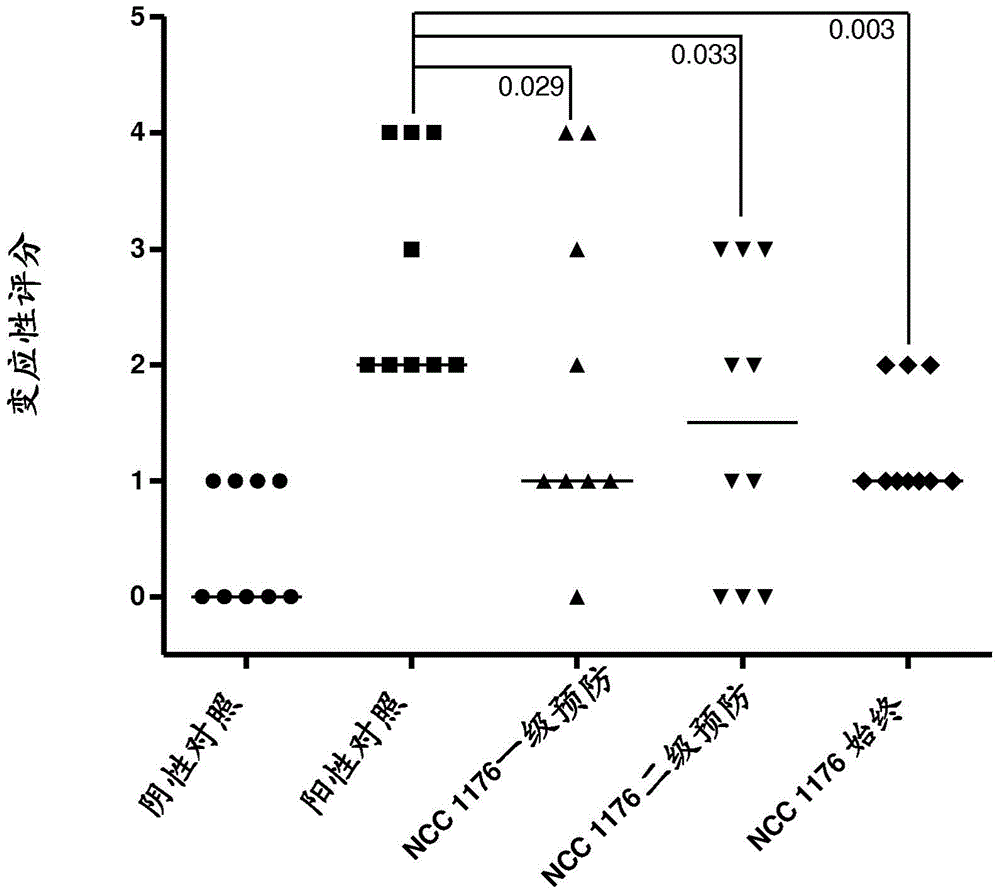

A composition comprising specific lactobacillus helveticus strains and reducing food and/or respiratory allergy symptoms

ActiveCN104039171AReduce sensitizationOrganic active ingredientsPeptide/protein ingredientsContact allergensEnvironmental health

A composition comprising specific Lactobacillus helveticus strains is provided for reducing the symptoms of allergies originating from food, respiratory or contact allergens. Preferably the composition reduces symptoms of allergies (secondary prevention)while also able to reduce sensitization (primary prevention).

Owner:SOC DES PROD NESTLE SA

Leak repairing method of phase connection lines of stator winding in turbonator

ActiveCN105033422AImprove sealingAvoid missing solderArc welding apparatusWelding/cutting media/materialsWorkloadRepair method

The invention discloses a leak repairing method of phase connection lines of a stator winding in a turbonator. The leak repairing method includes the steps that leak points are heated through two welding guns with the 180-degree inclined angle, meanwhile, the temperature is detected through a silver solder, when the silver solder is melting, the leak points are evenly coated with the silver welding powder, the silver solder is placed on the silver welding powder, welding-all-around is conducted on the leak points on the phase connection lines, and the surfaces of the welded parts are coated with the silver welding powder again 1-2 minutes after welding is completed, then the portions where plated silver is exfoliated are grinded through abrasive cloth to be smooth, the two welding guns with the 180-degree inclined angle heat the tin-enameled portions while the temperature is detected through tin bars, when the tin bars are melting, the tin-enameled portions are evenly coated with soldering paste so that immunities can be removed, and then the tin bars are boned onto the soldering paste. The leak repairing method is simple in operation, the workload of inspectors is lowered, and working efficiency is improved.

Owner:大唐桂冠合山发电有限公司

Mammary gland plaster for far-infrared physiotherapy, and preparation method thereof

InactiveCN109966441APromote generationHas a sedative effectHeavy metal active ingredientsInanimate material medical ingredientsSide effectMastitis

The invention discloses a mammary gland plaster for far-infrared physiotherapy, and a preparation method thereof. The mammary gland plaster comprises, by weight, 60-80% of sharp and mild type functional drug mixtures, 5-12% of slippery functional drug mixtures, 10-15% of compatible functional drug mixtures and 6-11% of special functional drug mixtures. The mammary gland plaster can effectively treat lobular hyperplasia of mammary glands, breast nodules, fibroid tumors, lumps, mastitis, dysmenorrhea, myomas and coldness of the uteruses, lymphadenectasis and other symptoms of the lymphatic system; by a method for external application of traditional Chinese medicine, the mammary gland plaster is safe, free from side effects, and has low sensitization effect, high penetrating power and quick action; patients have different conditioning feelings, such as feeling cold, hot, sore, itching and pricking, according to different causes.

Owner:平措绕吉

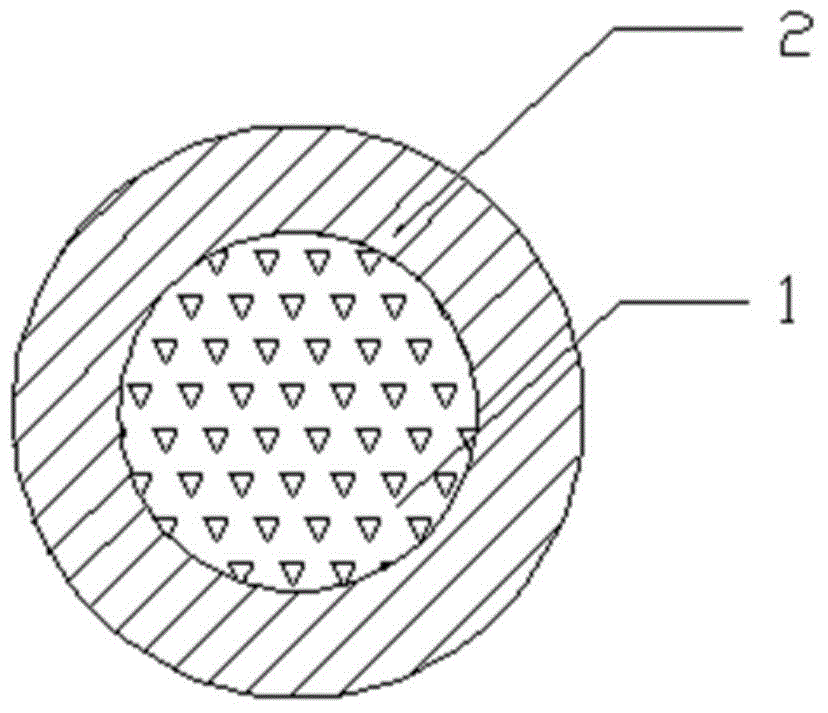

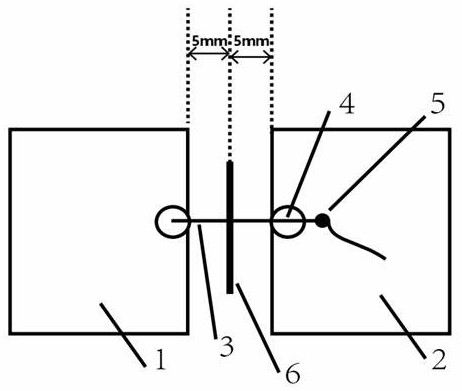

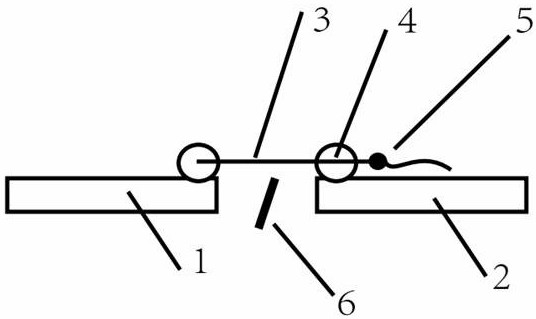

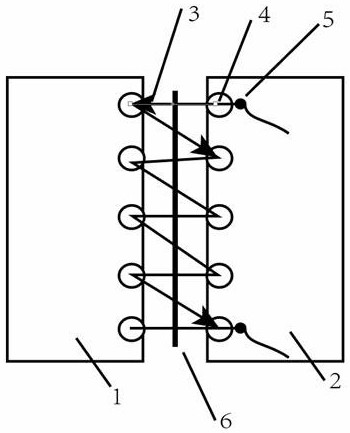

Body surface suturing auxiliary unit

PendingCN112294377AEliminate the pain of stitch removalStable closing forceSuture equipmentsProtection SkinMedical treatment

The invention discloses a body surface suturing auxiliary unit, and belongs to the technical field of medical supplies. The body surface suturing auxiliary unit is characterized by comprising a moduleA (1) and a module B (2) which are separately arranged, adhesives are arranged on the bottom surfaces of the module A (1) and the module B (2), the the module A (1) and the module B (2) are adhered to the skin of a patient through the adhesives, and the module A (1) and the module B (2) are respectively provided with a thread passage (4). The invention provides a novel skin incision suturing method which can be used for noninvasively closing a skin incision while protecting the skin. The novel skin incision suturing method is simple and convenient to operate, the suturing efficiency of doctors is improved, the pain of patients suffering traditional skin suturing is eliminated, the medical cost is saved, multiple advantages are achieved compared with the existing suturing instrument, and the social significance and application value are great. Non-invasive incision suturing is achieved, the requirements of doctors are met, the suturing difficulty is greatly reduced, the operation efficiency is greatly improved, and the wound infection probability is reduced; and the requirements of patients are met, the skin suture pain is eliminated, centipede scars of pinholes are eliminated, theincision healing time is shortened, and the problems of low incision involution accuracy, troublesome suture removal and the like are solved.

Owner:黄丛威

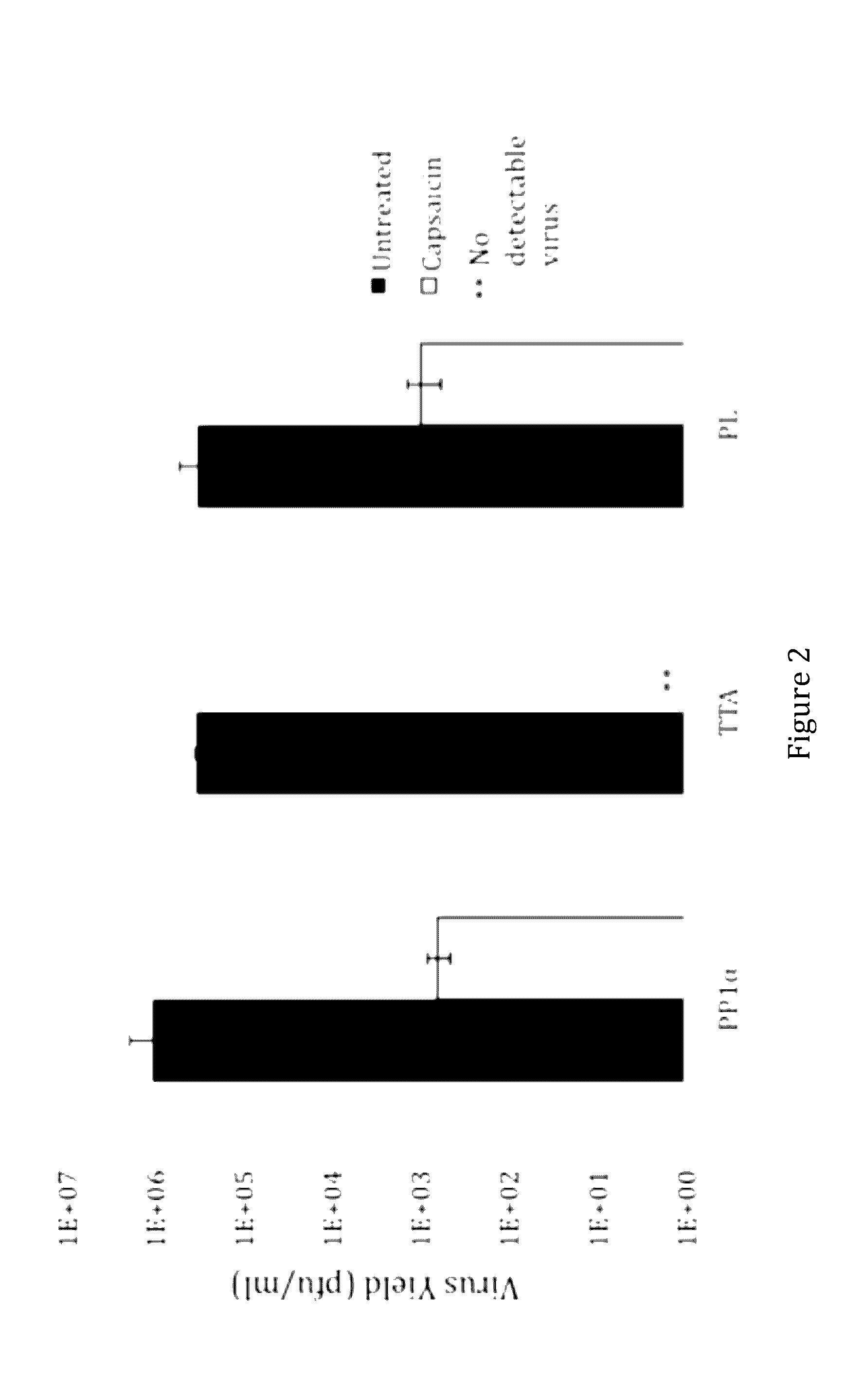

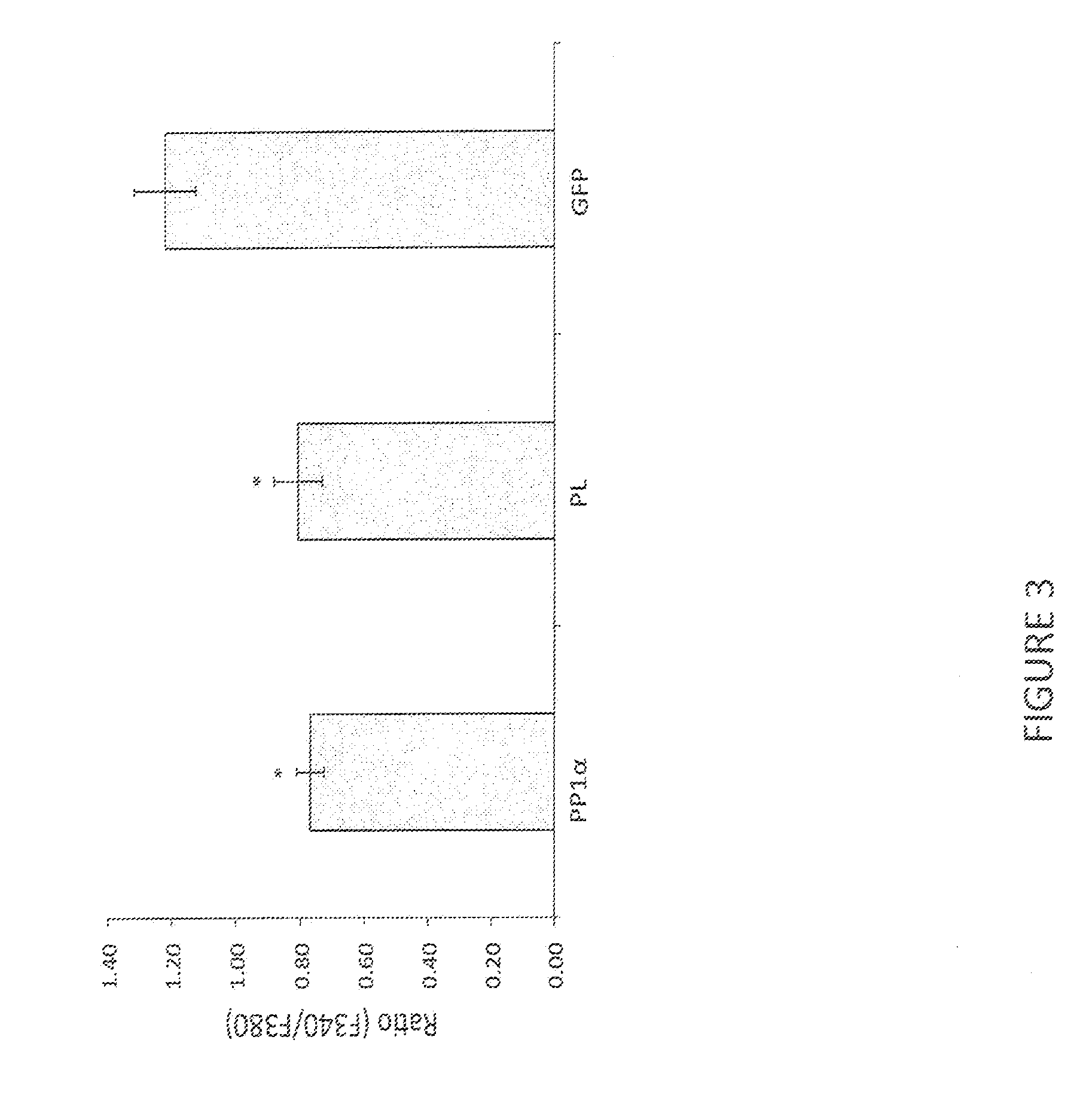

TRPV1 modulatory gene product that affects TRPV1-specific pain behavioral responses identified in a functional screen of an HSV-based cDNA library

ActiveUS9580699B2Eliminate side effectsReduce sensitizationVectorsPeptide/protein ingredientsCDNA libraryNeurophysins

The invention provides a method for ameliorating chronic pain signaling involving transient receptor potential cation channel subfamily V member 1 (TRPV1) by expressing PP1α in neurons. The invention also provides HSV vectors for expressing PP1α within neurons and compositions comprising such vectors.

Owner:UNIVERSITY OF PITTSBURGH

Hardfacing alloy

A hardfacing alloy for use as a surfacing on metal that are subjected to high thermal and mechanical stresses. The hardfacing alloy includes at least about 7 weight percent chromium, at least about 0.02 weight percent nitrogen, metal sensitization inhibitor, and a majority weight percent iron. The hardfacing alloy includes a low percentage of ferrite.

Owner:LINCOLN GLOBAL INC

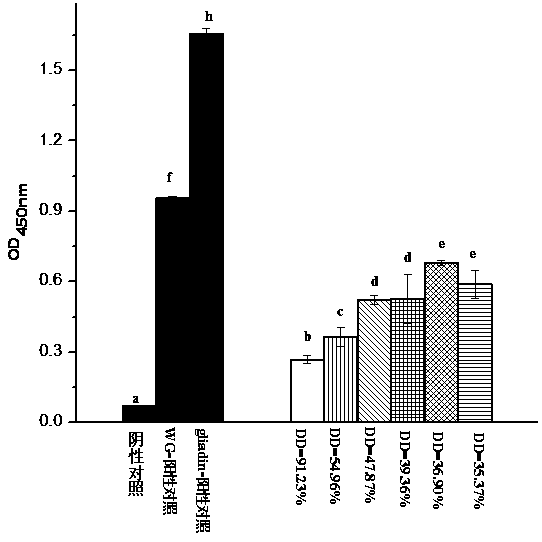

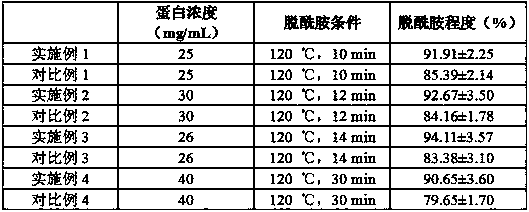

Method for promoting efficient decarboxamidation and reducing sensitization of wheat protein

ActiveCN109463526AEfficient deamidation and desensitizationReduce sensitizationProteins working-up by texturisingFood ingredientsOrganic acidFreeze-drying

Owner:FUZHOU UNIV

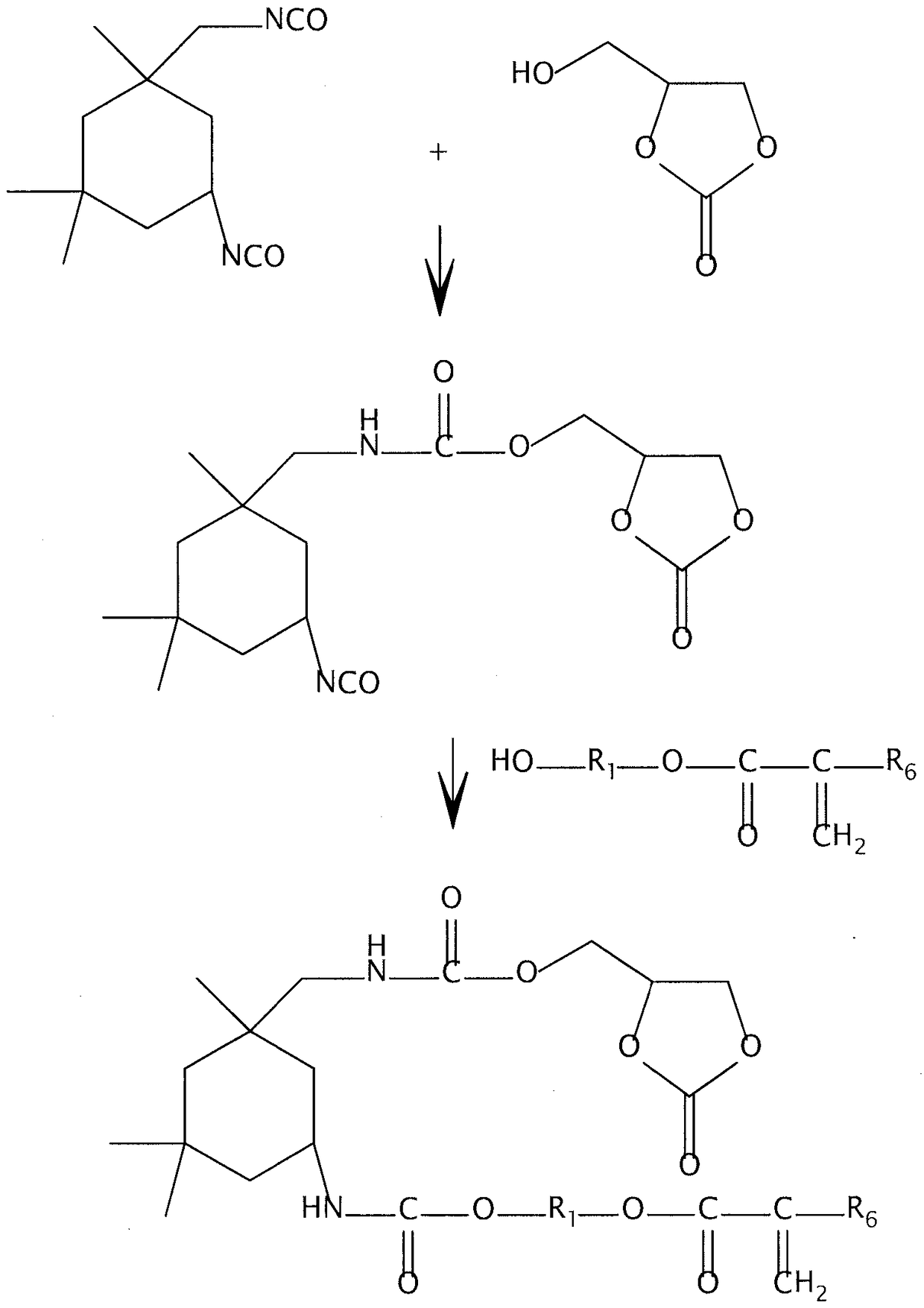

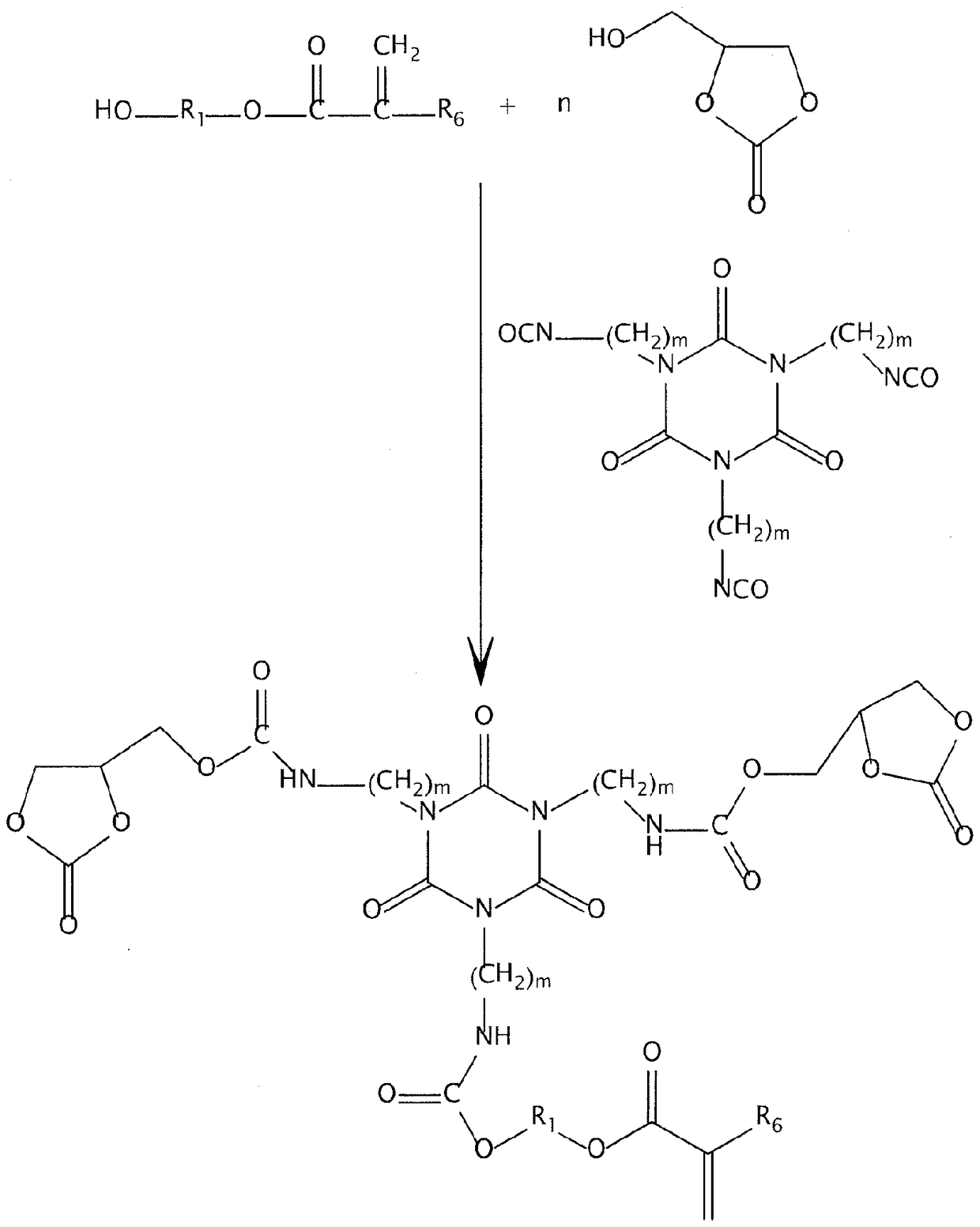

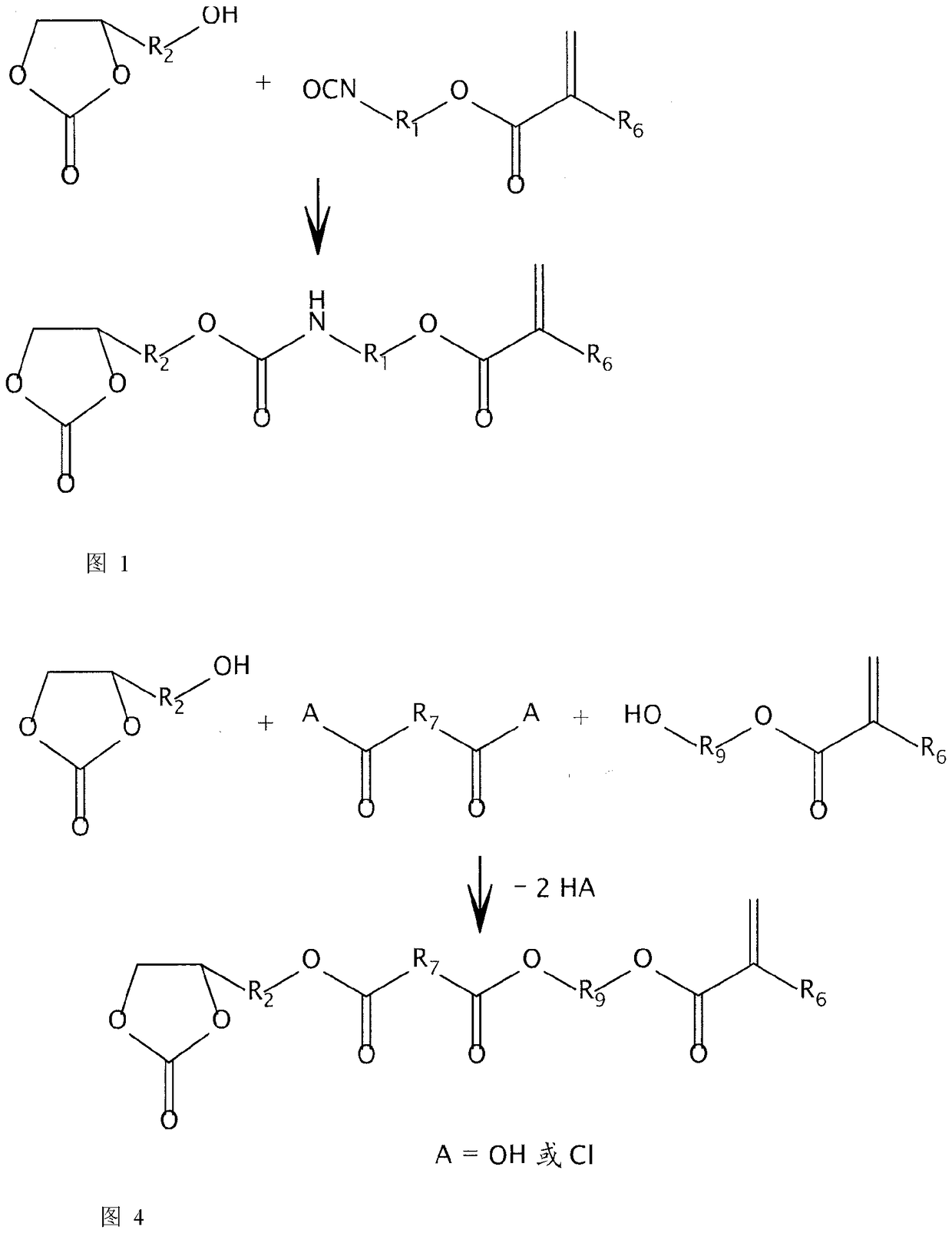

Non-isocyanate polyurethane inks for 3D printing

ActiveCN109071981AHigh printing resolutionImprove toughnessAdditive manufacturing apparatusInksMethacrylatePolymer science

In one aspect, inks for use with a 3D printer are described herein. In some embodiments, an ink described herein comprises a cyclic carbonate monomer and an amine monomer. Further, in some instances,an ink described herein also comprises an ethylenically unsaturated monomer such as a (meth)acrylate. Additionally, an ink described herein, in some cases, further comprises a colorant, such as a molecular dye, a particulate inorganic pigment, or a particulate organic colorant. An ink described herein may also comprise one or more additives selected from the group consisting of inhibitors, stabilizing agents, photoinitiators, and photosensitizers.

Owner:3D SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com