Method for promoting efficient decarboxamidation and reducing sensitization of wheat protein

A deamidation desensitization and wheat protein technology, which is applied in plant protein processing, texturization, food science, etc., can solve the problems of large differences in deamidation degree thresholds and significant differences in effects, and achieve high-efficiency deamidation desensitization. , reduce the effect of sensitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

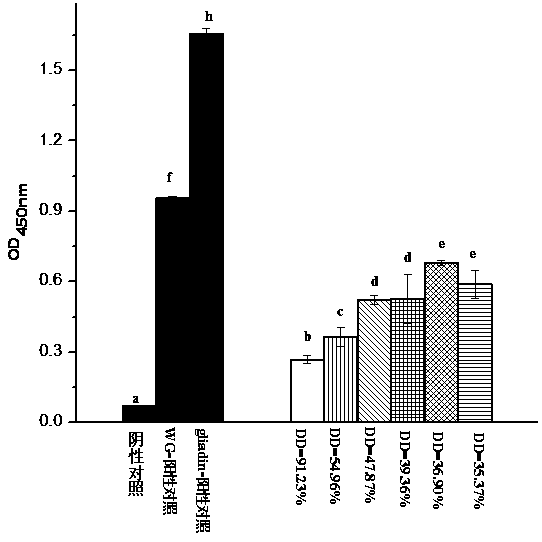

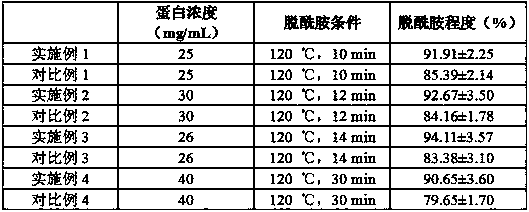

[0017] Add citric acid and glucose solid powder into a round-bottomed flask filled with water at a molar ratio of 1:2, and stir magnetically at 50°C for 30-60 min until a clear and transparent liquid is formed, in which the total concentration of citric acid and glucose is 4.2 mol / L; then the synthetic citric acid-glucose natural deep eutectic solvent was diluted 4 times with water, then wheat protein was added to prepare a protein suspension with a concentration of 25 mg / mL, hydrated at 35 °C for 3 h, and then heated at 120 °C React for 10 min. After the reaction, it was quickly degassed, taken out and cooled, centrifuged at 9500 rpm / min for 10 min, dialyzed at 4 °C for 24 h, and freeze-dried to obtain highly efficient deamidated and desensitized wheat protein.

Embodiment 2

[0019] Add citric acid and glucose solid powder into a round-bottomed flask filled with water at a molar ratio of 1:2, and stir magnetically at 50°C for 30-60 min until a clear and transparent liquid is formed, in which the total concentration of citric acid and glucose is 4.2 mol / L; then the synthetic citric acid-glucose natural deep eutectic solvent was diluted 4 times with water, then added wheat protein to prepare a protein suspension with a concentration of 30 mg / mL, hydrated at 35 °C for 3 h, and then heated at 120 °C React for 12 min. After the reaction, it was quickly degassed, taken out and cooled, centrifuged at 9500 rpm / min for 10 min, dialyzed at 4 °C for 24 h, and freeze-dried to obtain highly efficient deamidated and desensitized wheat protein.

Embodiment 3

[0021] Add citric acid and glucose solid powder into a round-bottomed flask filled with water at a molar ratio of 1:2, and stir magnetically at 50°C for 30-60 min until a clear and transparent liquid is formed, in which the total concentration of citric acid and glucose is 4.2 mol / L; then the synthetic citric acid-glucose natural deep eutectic solvent was diluted 4.6 times with water, and then wheat protein was added to prepare a protein suspension with a concentration of 26 mg / mL. After hydration at 35 °C for 3 h, the reaction was heated at 120 °C 14 min. After the reaction, it was quickly degassed, taken out and cooled, centrifuged at 9500 rpm / min for 10 min, dialyzed at 4 °C for 24 h, and freeze-dried to obtain highly efficient deamidated and desensitized wheat protein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com