Ground limestone-based bismuth and europium co-doped yellow fluorescent powder

A technology of heavy calcium carbonate and yellow phosphor, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of phosphor stability deterioration, limited application range, and lower quality, and achieve short preparation cycle, The effect of clear workflow and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

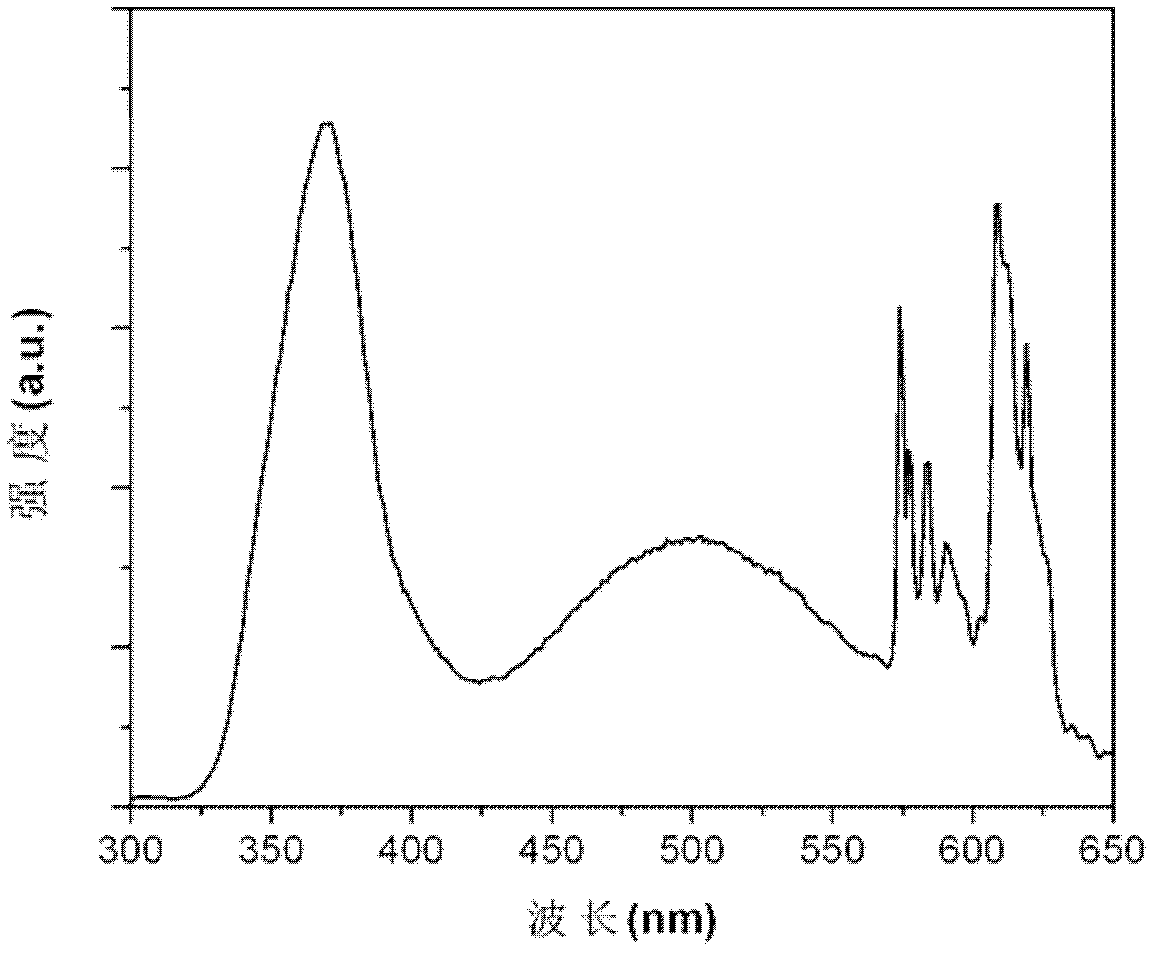

[0030] Weighing raw material: CaCO 3 、Eu 2 o 3 、Bi 2 o 3 , Li 2 CO 3 The molar ratio is weighed according to 100:1.5:3:1.5, and the raw materials are poured into a ball mill tank, fully ball milled for 1 hour, and mixed uniformly to obtain a precursor raw material powder with a particle size of 5-10 μm. Pour into a crucible. Then put it in a furnace at 500°C for pre-calcination for 4 hours, take out the sample, grind it, and emit red light under the excitation of ultraviolet light. CO at standard atmospheric pressure 2 In a protective atmosphere, calcinate in a high-temperature furnace at 900°C for 1 hour, take out the sample, and grind to obtain a white powder with a particle size of 15-25 μm, which emits yellow light when excited by ultraviolet light.

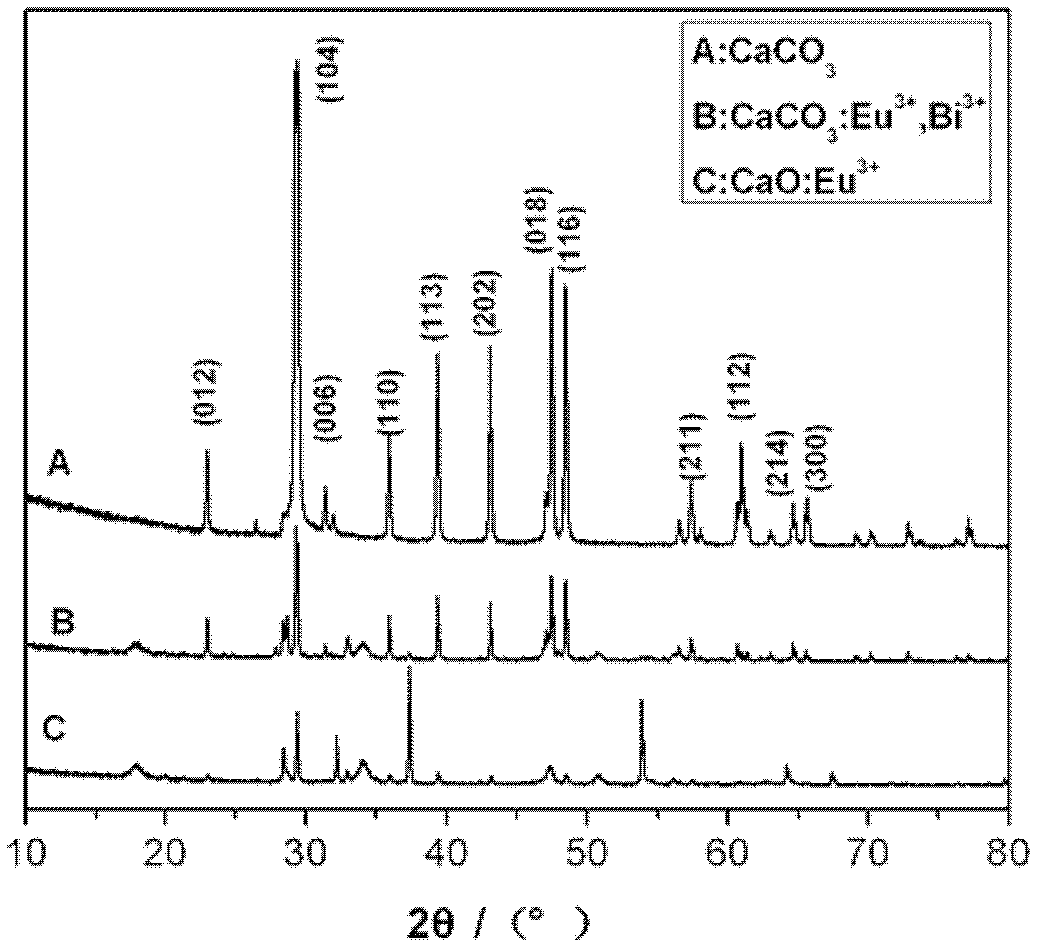

[0031] The specific X-ray diffraction data of the fluorescent powder prepared by the above preparation method are as follows:figure 1 As shown, A in the figure is heavy CaCO 3 The X-ray diffraction pattern, B is sint...

Embodiment 2

[0034] Weighing raw material: CaCO 3 , Eu(NO 3 ) 3 、 Bi 2 o 3 , Li 2 CO 3 、H 3 BO 3 Weigh the molar ratio according to 100:1:2:1:0.4, pour the raw materials into the agate tank of the ball mill, perform full ball milling for 1 hour, and mix evenly to obtain the precursor raw material powder with a particle size of 5-10 μm. Pour into the crucible. Then put it in a furnace at 500°C for calcination and pretreatment for 2h, take out the sample, and grind it. CO at standard atmospheric pressure 2 In a protective atmosphere, calcinate in a high-temperature furnace at 900°C for 2 hours, take out the sample, and grind to obtain a white powder with a particle size of 15-25 μm, which emits yellow light when excited by ultraviolet light.

Embodiment 3

[0036] Weighing raw material: CaCO 3 、Eu 2 o 3 , (BiO) 2 CO 3 、Na 2 CO 3 Weigh the molar ratio according to 100:1.5:4.5:1.5, pour the raw materials into the ball mill tank, perform full ball milling for 1 hour, and mix evenly to obtain the precursor raw material powder with a particle size of 5-10 μm, pour the precursor powder into crucible. Then put it in a furnace at 500°C for pre-calcination for 3 hours, take out the sample, grind it, and emit red light under the excitation of ultraviolet light. CO at standard atmospheric pressure 2 In a protective atmosphere, calcinate in a high-temperature furnace at 860°C for 3 hours, take out a sample, and grind to obtain a white powder with a particle size of 15-25 μm, which emits yellow light when excited by ultraviolet light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com