Heat-reduction metallization copper plating process for carbon fiber surface

A carbon fiber and metallization technology, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of high cost and complex control of reducing atmosphere in the pretreatment step, so as to reduce the experimental cost and achieve good copper plating effect, the effect of simplifying the preprocessing step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

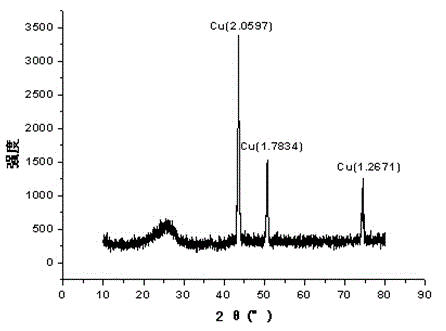

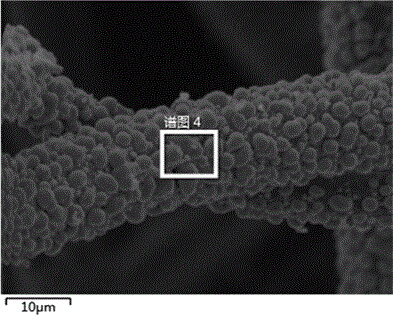

[0031] The present invention and its beneficial effects will be further described below in conjunction with the accompanying drawings.

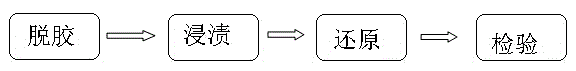

[0032] A thermal reduction metallization copper plating process on the surface of carbon fibers, which utilizes the property of copper salts to be reduced by reducing gases to plate copper on the surface of carbon fibers in a micro-oxygen and carbon-containing atmosphere. The carbon fibers are bundled before copper plating, and each bundle contains 1.2k monofilaments, the main component of the surface is epoxy resin coating, which includes the following steps:

[0033] Step 1. Carbon fiber pretreatment: use the air burning-oxidizing acid composite treatment method to degumming the carbon fiber surface, first heat the to-be-treated carbon fiber sample in a resistance furnace at 400°C for 40 minutes, and then ultrasonically soak it in a concentrated nitric acid solution Coarse treatment for 30 minutes, take it out, wash it with distilled water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com